Mold shell and mold core same mill group modular surface taper method and system

A mold core and mold shell technology is applied in the field of mold surface taper method and system of mold shell and mold core grinding group, which can solve the problems of high cost, short service life of mold, low efficiency of cold heading production operation, etc. Effects of increased friction, increased fatigue life value, and increased compressive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples.

[0025] In this embodiment, the nut stroke mold for high-speed nut forming machine used in the method and system for grinding the mold shell and the mold core together to form the taper of the mold surface is mainly suitable for 5-station and 6-station high-speed nut forming machines, and the range of nut specifications is The nuts produced by the cold heading process of M10~M24 in accordance with GB / T6170, GB / T6171, GB / T6172.1, GB / T6173, GB / T6174, GB / T56 and other national standards, due to the mold material and manufacturing process of this series The principles are the same and the parameters are similar. This embodiment mainly uses the M12 mold as an example for illustration.

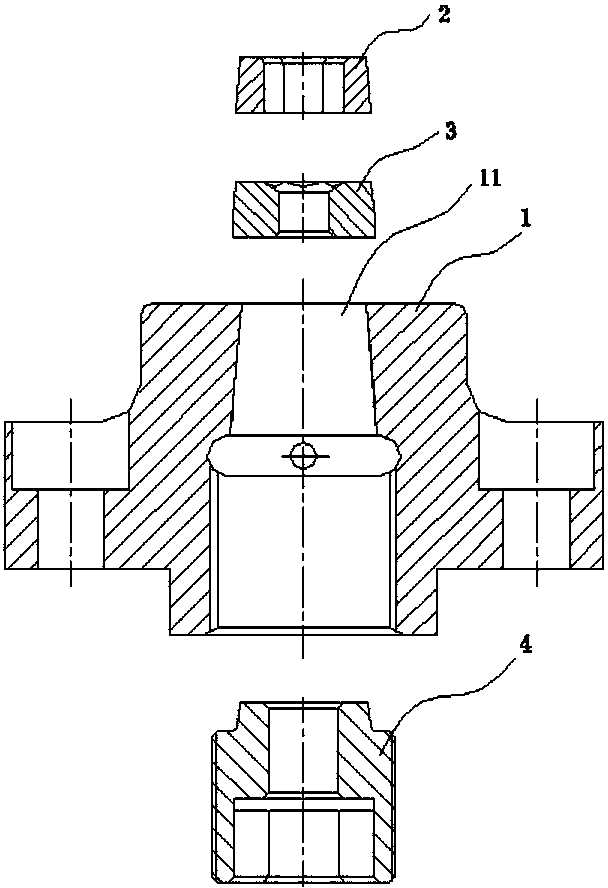

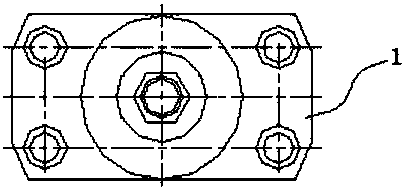

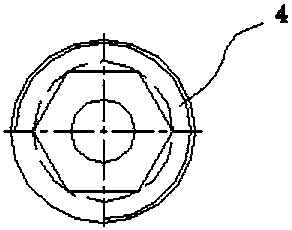

[0026] In this example, if Figures 1 to 5 As shown, the nut stroke mold for a high-speed nut forming machine includes a stroke mold shell 1, an upper mold core 2, a lower mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com