Clamping tool for drilling and reaming thin-wall parts

A thin-walled part and clamping technology, which is applied in drilling/drilling equipment, clamping, positioning devices, etc., can solve the problems of complex clamping methods, low processing yield, and poor positioning consistency for thin-walled parts. The structure is simple, the production efficiency is improved, and the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

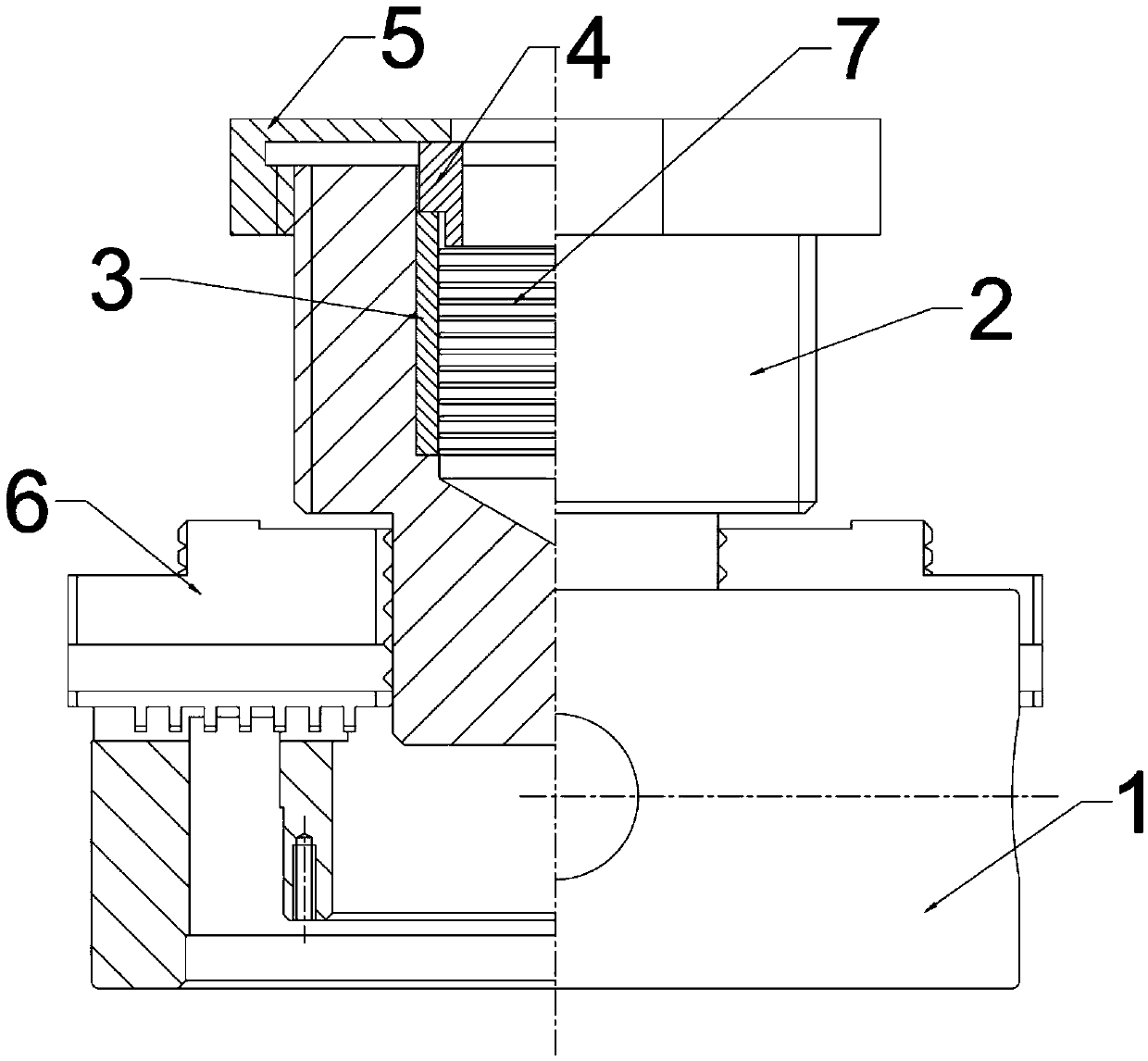

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

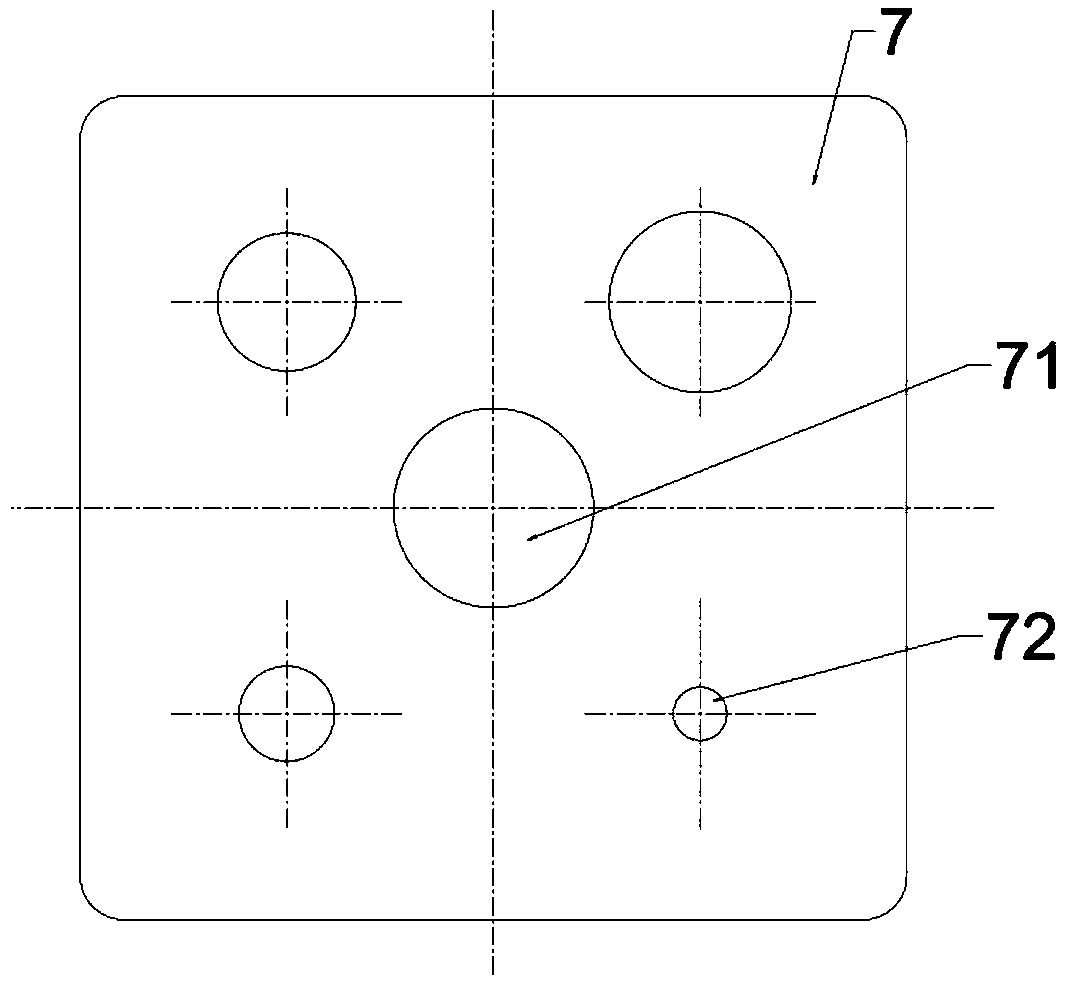

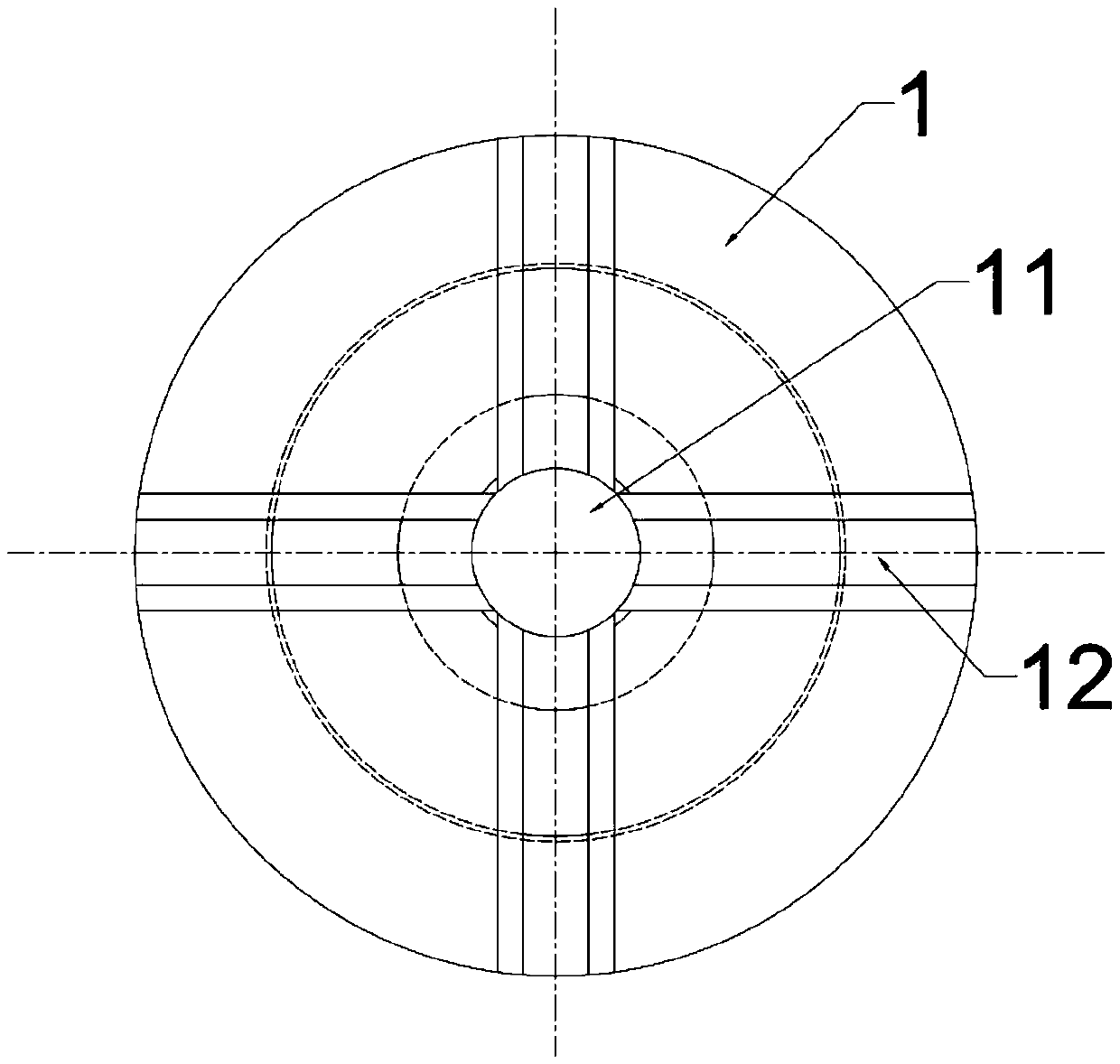

[0026] The specific embodiment of the clamping tool for drilling and reaming of thin-walled parts of the present invention is as figure 2 , Figure 4 and Figure 5 As shown, the clamping tool is applied to the clamping of the thin-walled part 7 to realize the drilling and reaming of the thin-walled part 7 . The clamping tool includes a chuck 1 whose axis extends in the up and down direction and a support seat 2 fixed on the chuck 1. The support seat 2 realizes fixed clamping by slidingly fitting the jaws 6 on the chuck 1. The support seat 2 is composed of An accommodation hole 24 is extended downwards on its upper end, and a positioning sleeve 3 is installed as a guide in the accommodation hole 24. The positioning sleeve 3 and the support base 2 form a support platform. The lower end is against the step surface 25 of the receiving hole 24, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com