Equipment for shearing diode pins

A diode and pin technology is applied in the field of equipment for cutting diode pins, which can solve the problems of inability to guarantee the length consistency, no positioning measurement of the pins to be cut, poor pin length accuracy, etc., and achieve the guaranteed cutting length. Effects of Precision and Length Consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

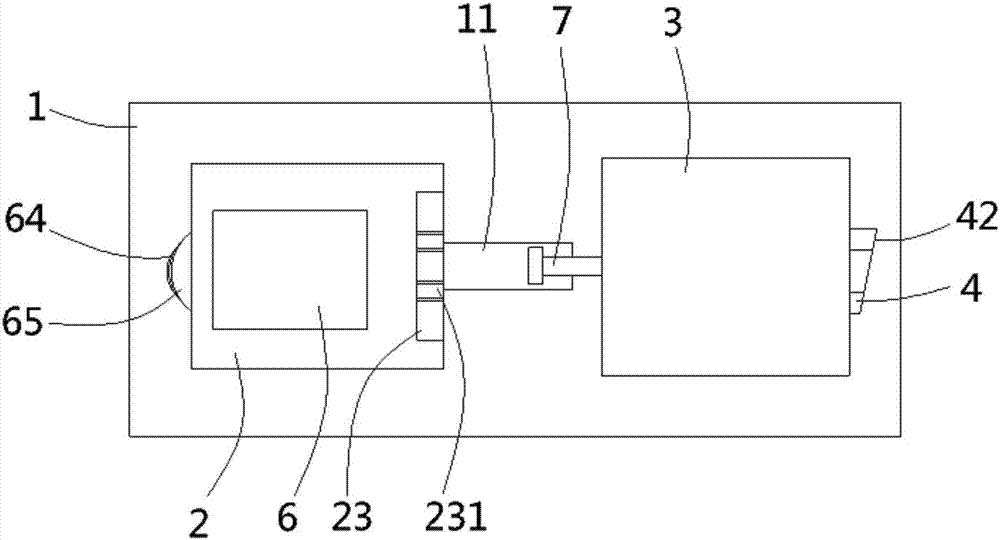

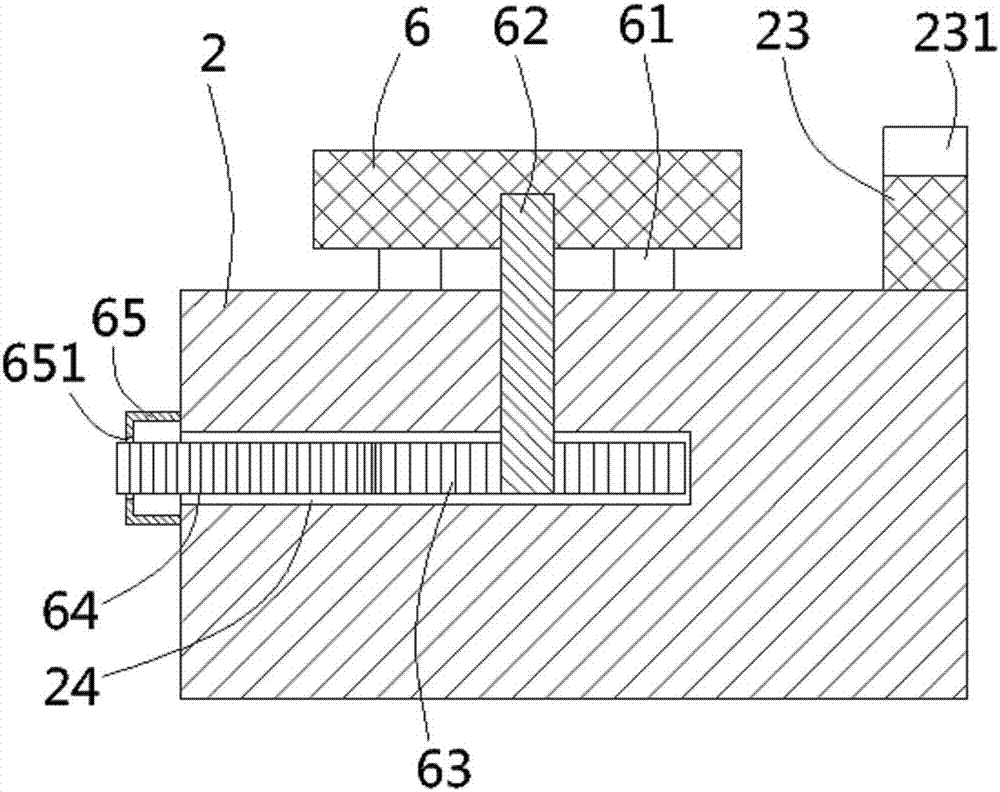

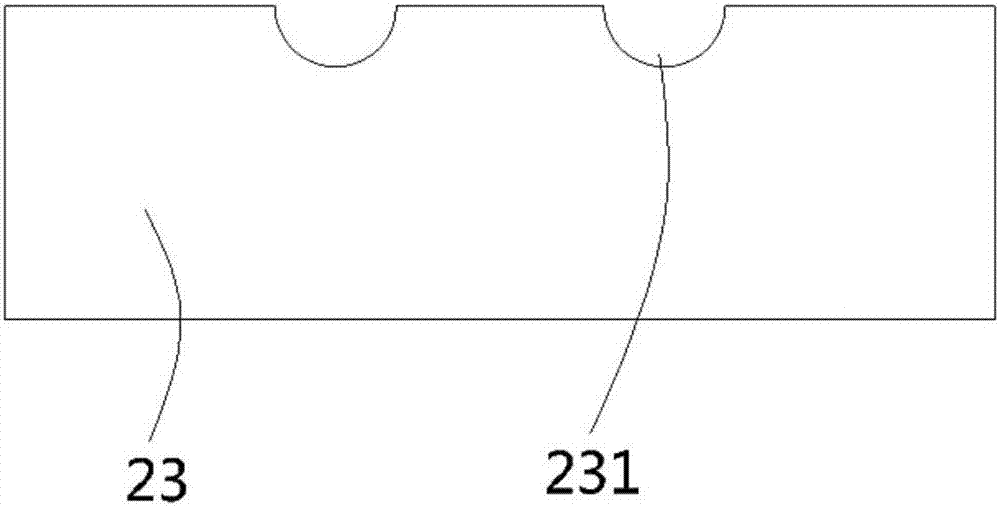

[0022] see figure 1 , Figure 4 , Figure 5 , a device for cutting diode pins according to the present invention, including a base 1, on which a moving seat 2 and a fixed seat 3 are arranged oppositely, and a T is plugged into the fixed seat 3 The T-shaped template 4 is formed with two jacks 41 that run through the front and rear ends of the T-shaped template 4. The moving seat 2 is pressed against the base 1, and the bottom of the moving seat 2 is formed with guiding protrusions. 21. A moving groove 11 is formed on the base 1, and the guide protruding bar 21 is inserted into the moving groove 11. The bottom of the guiding protruding bar 21 is formed with a rack 22, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com