A Fan Formed Processing Method of Microlens Array Optical Components

A microlens array and optical element technology, applied in the direction of optical surface grinders, metal processing equipment, manufacturing tools, etc., can solve the problems of tool wear, material limited surface accuracy, etc., to improve surface accuracy and ensure surface accuracy And dimensional consistency, the effect of strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

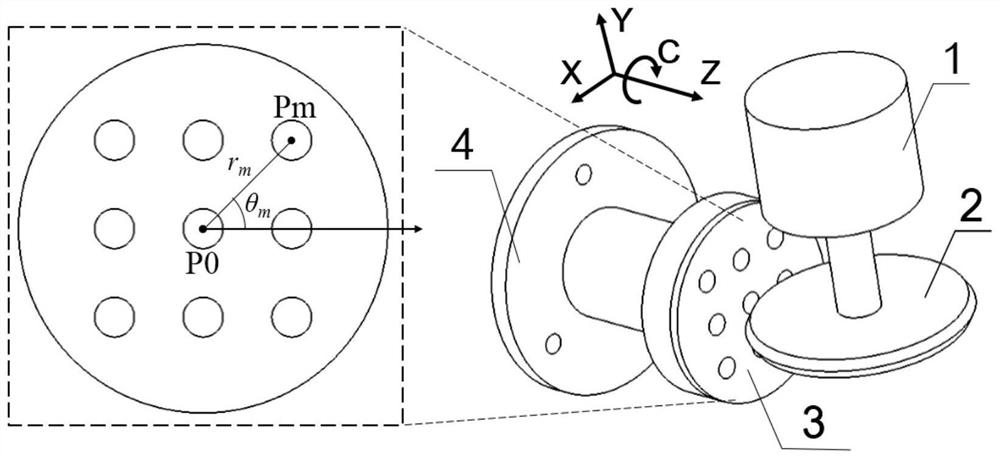

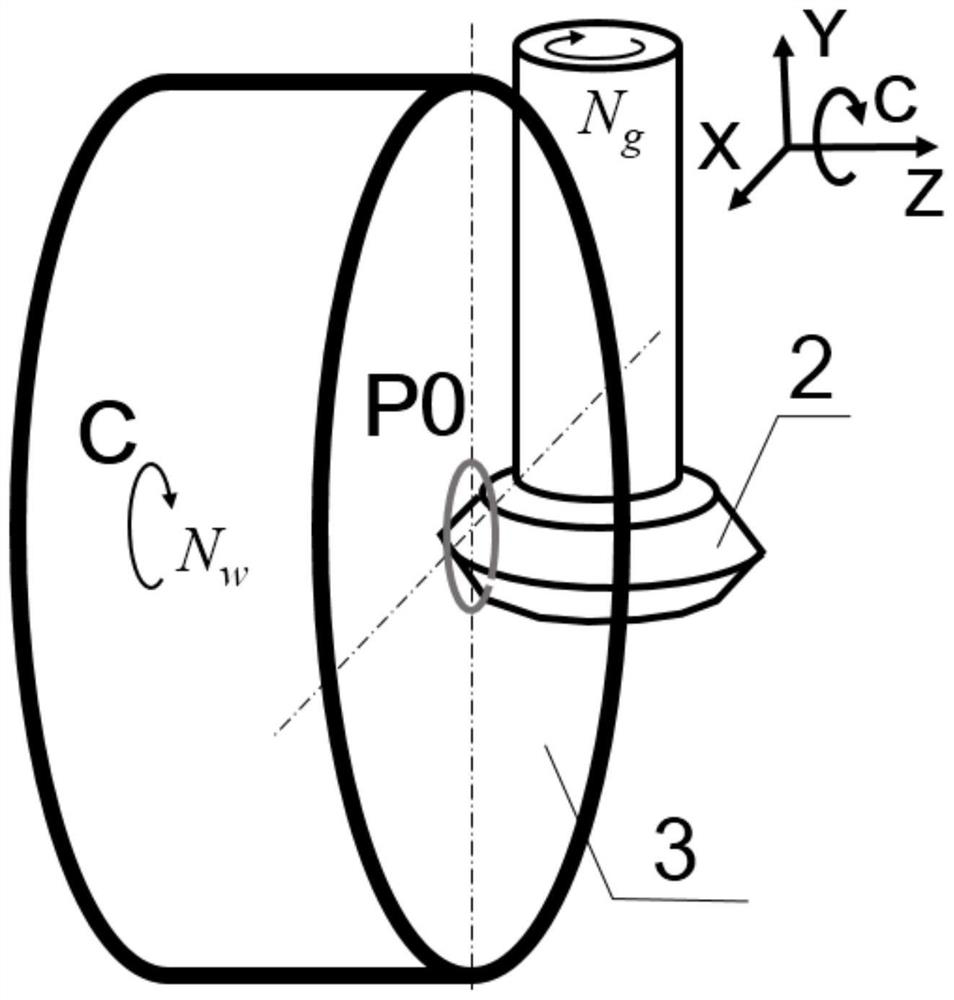

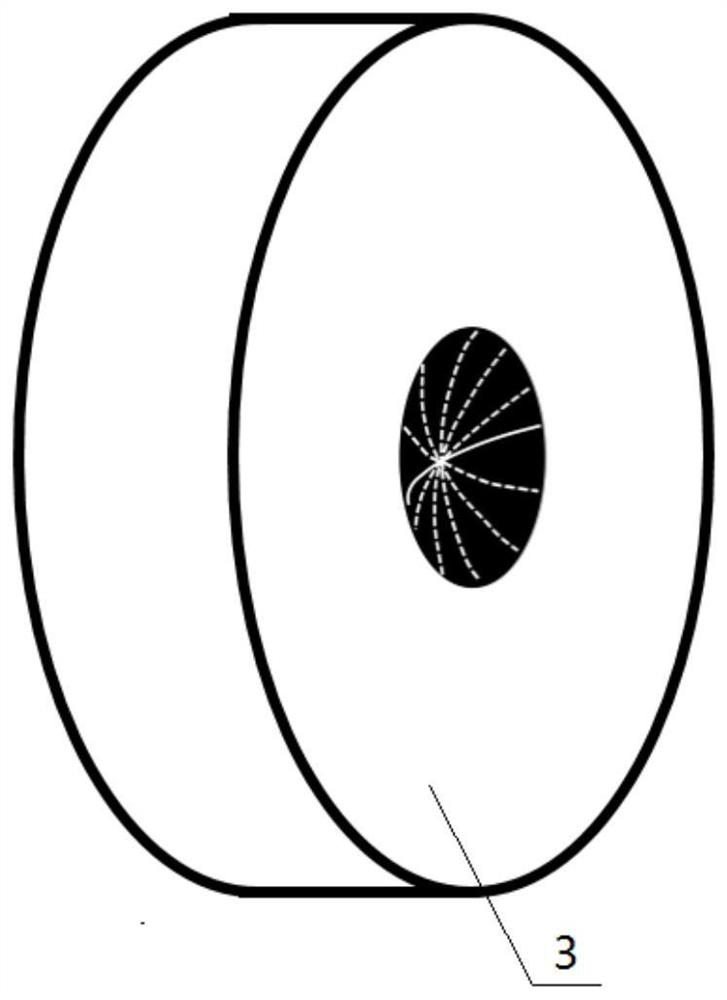

[0035] Specific implementation mode one: combine Figure 1 to Figure 5 Describe this embodiment mode, a kind of microlens array optical element of this embodiment mode forms the formula processing method, comprises the following steps:

[0036] Step 1: According to the spherical diameter R of the lens unit on the microlens array optical element to be processed s , choose a radius larger than the spherical diameter R s V-shaped grinding wheel, install the V-shaped grinding wheel 2 on the grinding shaft 1 of the machine tool, and then perform in-situ precision dressing on the V-shaped grinding wheel 2 to achieve a sharp grinding wheel tip and an accurate grinding wheel radius R g ;

[0037]Step 2: Through the tool setting operation, make the sharp point of the V-shaped grinding wheel 2 along the negative direction of the Z axis of the machine tool coincide with the center line of the C axis of the machine tool;

[0038] Step 3: Fix the workpiece 3 to be processed on the front...

specific Embodiment approach 2

[0042] Specific implementation mode two: combination Figure 1 to Figure 5 Illustrate this embodiment, the specific process of processing any microlens Pm of non-workpiece center position in the step 5 of this embodiment is:

[0043] First rotate the C axis of the machine tool clockwise by an angle θ m , and then let the X-axis of the machine tool move along the positive direction for a distance r m , so that the sharp point of the V-shaped grinding wheel 2 along the negative direction of the Z-axis of the machine tool coincides with the center line of the microlens to be processed, and the speed of the V-shaped grinding wheel 2 is set to N g , the feed rate is V f , so that the V-shaped grinding wheel 2 is fed in the negative direction along the Z axis of the machine tool until a depth of a is produced on the workpiece 3 p Then, the Z axis of the machine tool stops feeding and keeps the position still. Then, the X axis, Y axis and C axis of the machine tool perform three-a...

specific Embodiment approach 3

[0045] Specific implementation mode three: combination Figure 1 to Figure 5 Describe this embodiment, in step 1 of this embodiment, each unit lens in the microlens array is a concave spherical lens, the diameter range of the unit lens is 0.1 mm to 10 mm, and the spherical diameter R of the unit lens is s The range is 5mm ~ 100mm. Such setting is because the processing method proposed by the present invention still has certain limitations. The diameter of the unit lens and the spherical diameter of the microlens array optical element are not within the given range. The diameter of the grinding wheel required for processing is too small or too large. Cannot be installed on the lathe, thereby is not suitable for adopting the processing method that the present invention proposes. Giving these parameter limits here in advance can provide design constraints for the optical design stage of the microlens array optical element, and prevent the designed optical element drawings from b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com