High-precision crank shaft for speed reducer and machining method thereof

A processing method and crankshaft technology, applied in directions such as crankshafts, can solve the problems of numerous parts, high manufacturing costs, and high failure rates, and achieve the effects of reducing processing errors, reducing assembly errors, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] The present invention will be further explained below in conjunction with the drawings.

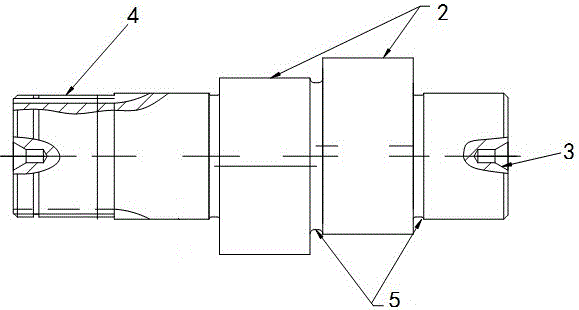

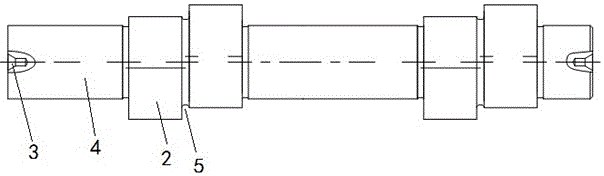

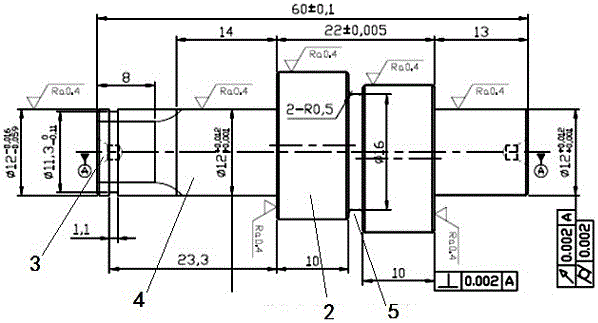

[0025] Such as Figure 1~Figure 3 As shown, a high-precision crankshaft for a reducer includes a crankshaft body, the crankshaft body is a cylinder, and at least two eccentric wheels 2 with a phase difference of 180° are provided on the crankshaft body. Both ends of the crankshaft body are provided with precision center holes 3 as the positioning reference of the spline 4 and the eccentric wheel 2. The processed spline 4 is located at the end of the crankshaft body, and the processed spline 4 is at least The two eccentric wheels 2 are located in the middle of the crankshaft body, and both ends of the eccentric wheel 2 are provided with annular relief grooves 5.

[0026] The two eccentric wheels 2 with a phase difference of 180° form a group, and the number of groups is 1 group or 2 groups.

[0027] The cross section of the relief groove 5 is a concave arc shape.

[0028] The tolerances o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com