A tic-based steel-bonded cemented carbide fine-tooth external thread milling device

A technology of steel-bonded cemented carbide and milling device, applied in thread cutting tools, positioning devices, tangent devices, etc., can solve the problems of surface quality decline, external thread structure processing, low processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

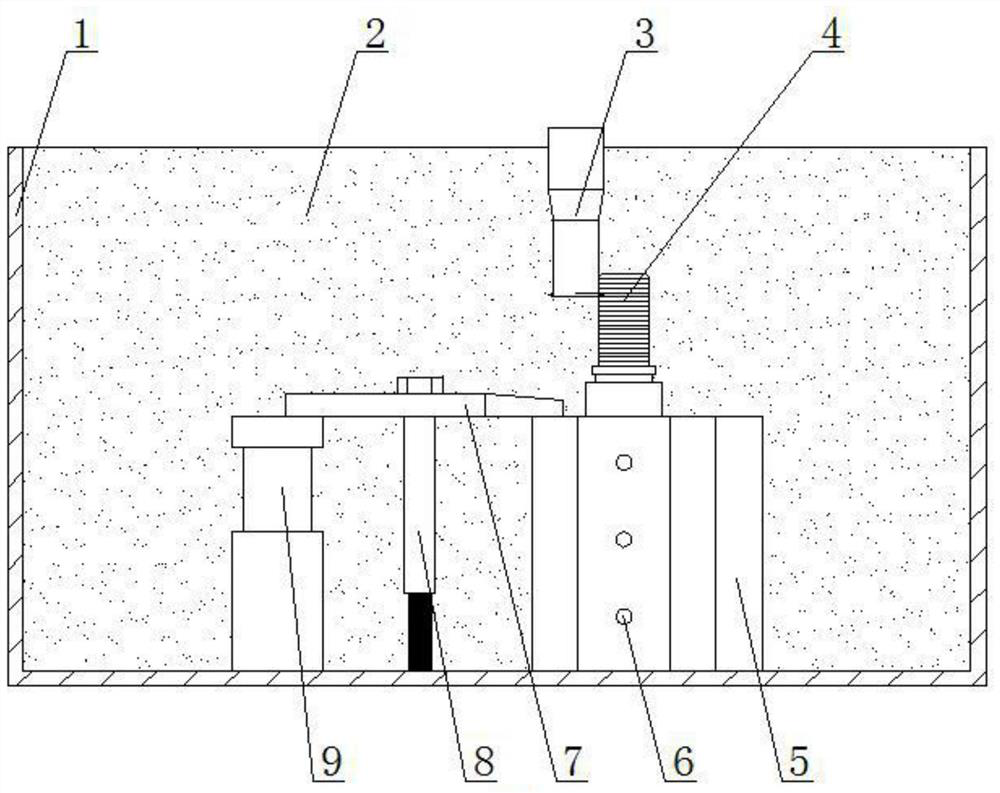

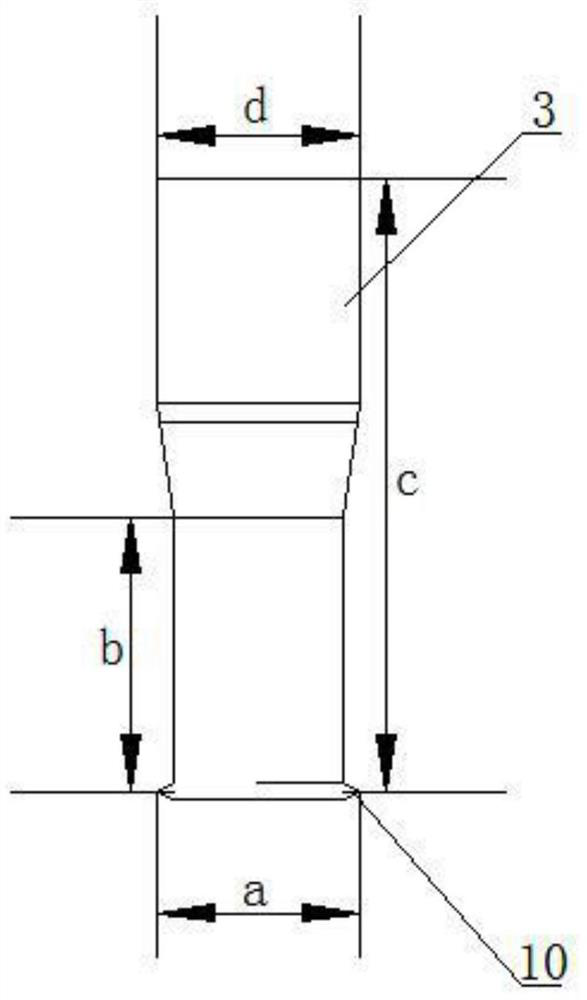

[0025] A TiC-based steel-bonded hard alloy fine-tooth external thread milling device. The innovation of the present invention is that it includes a box body 1 with an opening on the upper end, the box body is filled with cooling liquid 2, and a bottom surface of the box body is installed. Fixed seat 5, a spring chuck 4 is installed on the upper end of the fixed seat, and the spring chuck is used to fix the parts to be milled. In the fixed state of the parts, the height of the upper end of the parts is lower than the height of the side wall of the box body. A milling cutter 3 is hung on the side of the part. The milling cutter adopts polycrystalline diamond coating, and the material of the milling cutter substrate adopts hard alloy.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com