Vehicle air-conditioning pipe mold assembly, brazing device and working method thereof

A technology for vehicle air conditioning and air conditioning pipes, which is applied to auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of difficult air conditioning pipe brazing, labor and time costs, and difficulty in welding positioning of multi-angle air conditioning pipe joints. The effect of ensuring the consistency of accuracy, saving labor cost and time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

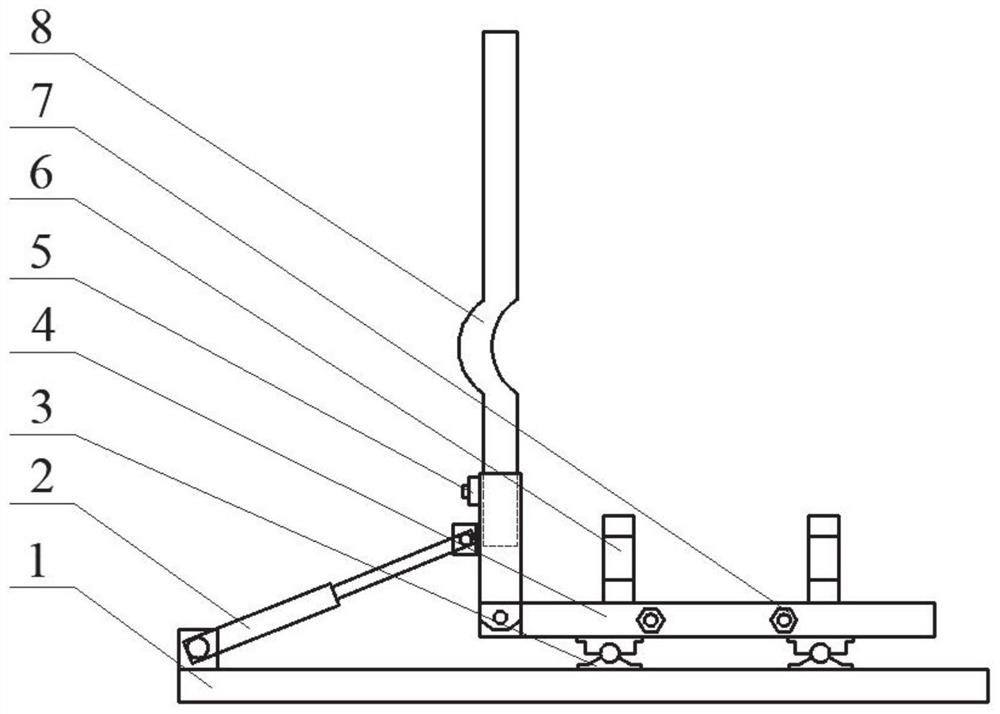

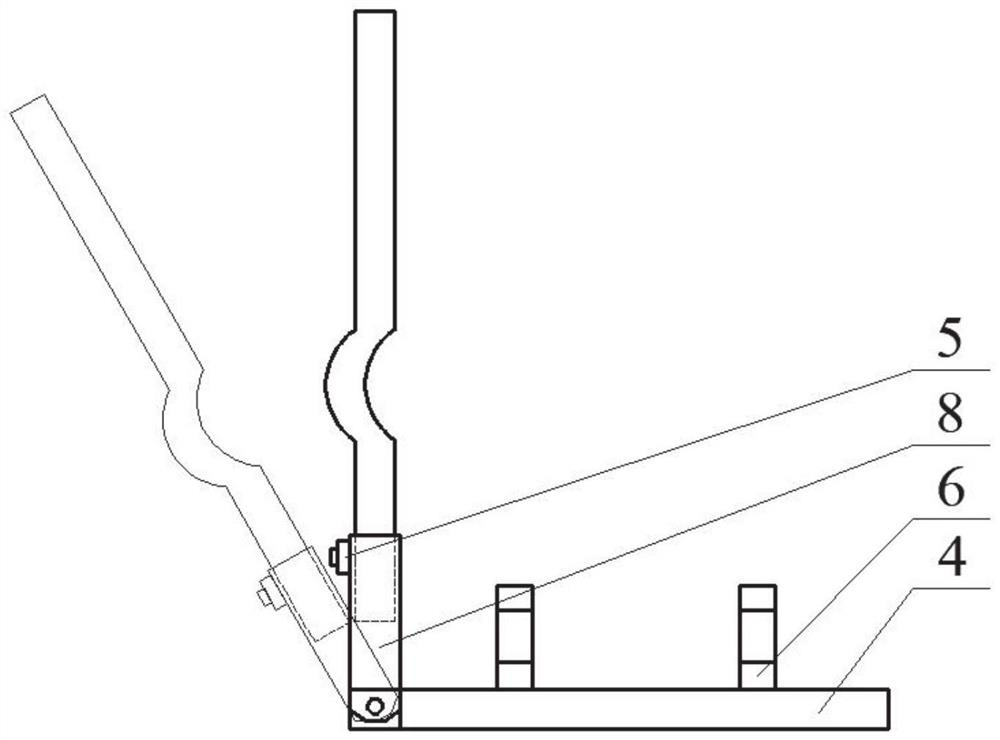

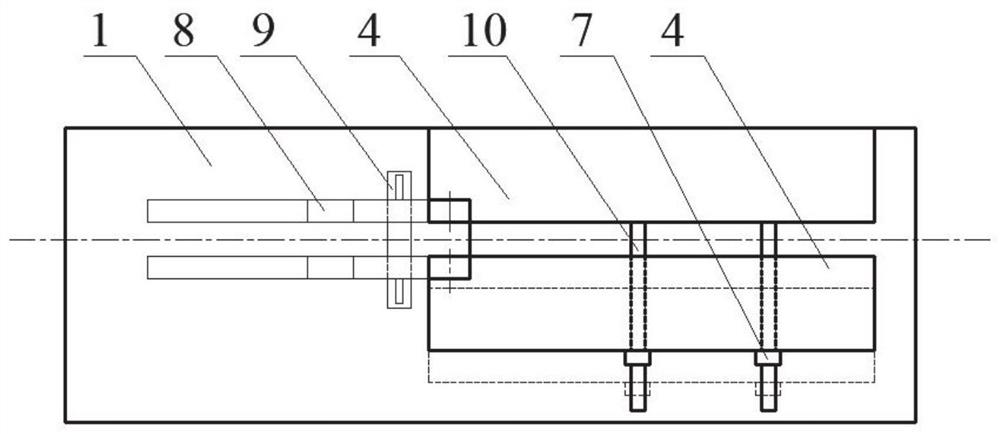

[0042] figure 1 A front view of a vehicle air-conditioning pipe profile assembly of this embodiment is given. image 3 A top view of a vehicle air-conditioning pipe master assembly of this embodiment is given. like figure 1 and image 3 As shown, the vehicle air-conditioning pipe profile assembly of this embodiment includes two clamping parts 4 and two equivalent profiles 8 .

[0043] In this embodiment, the distance between the two clamping parts 4 is adjustable, so that air-conditioning pipes of different diameters can be matched and clamped.

[0044] The clamping member 4 here can be other structures such as plate-like structure or columnar body structure.

[0045] like image 3 As shown, the two clamping parts 4 of this embodiment are connected by a screw 10, and a nut 7 is fixed at the end of the screw rod 10, and by adjusting the tightness of the screw rod through the nut, the distance between the two clamping parts can be adjusted. . image 3 The dotted line show...

Embodiment 2

[0069] The vehicle air-conditioning pipe profile assembly of this embodiment includes two clamping pieces and two equivalent profiles. In this embodiment, the distance between the two clamping parts is adjustable, so that air-conditioning pipes of different diameters can be matched and clamped. The clamping part here can be other structures such as plate-like structure or columnar body structure.

[0070] In this embodiment, the two clamping parts are connected by a screw, and a nut is fixed at the end of the screw, and the tightness of the screw is adjusted by the nut, so that the distance between the two clamping parts can be adjusted. It should be noted here that the distance between the two clamping parts can also be adjusted by using other structures, for example, the two clamping parts are connected through the structure of the chute to realize the adjustable distance.

[0071] In order to improve the fixing effect of the air-conditioning pipe, stabilize the state of th...

Embodiment 3

[0080] The difference between this embodiment and Embodiment 1 is that the clamping part is installed on the base, and the two equivalent profiles are hingedly mounted on the slider, and the slider can move along the base to synchronously adjust the equivalent profile and distance between clamps.

[0081] One end of the angle adjuster in this embodiment is connected to the base, and the other end is hingedly connected with two equivalent formers. In this embodiment, the expansion and contraction of the angle adjuster and the movement of the slider along the base are used to realize the equivalent mastering and clamping. The angle between the holders is adjustable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com