Method for accurately adjusting concentricity of telephoto folding axis lens group

An installation and adjustment method and concentricity technology, applied in installation, optics, instruments, etc., can solve the problems of low installation and adjustment accuracy, unstable quality, and lack of installation and adjustment methods, so as to solve the problem of alignment, ensure imaging quality, and guarantee The effect of adjustment accuracy and quality consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

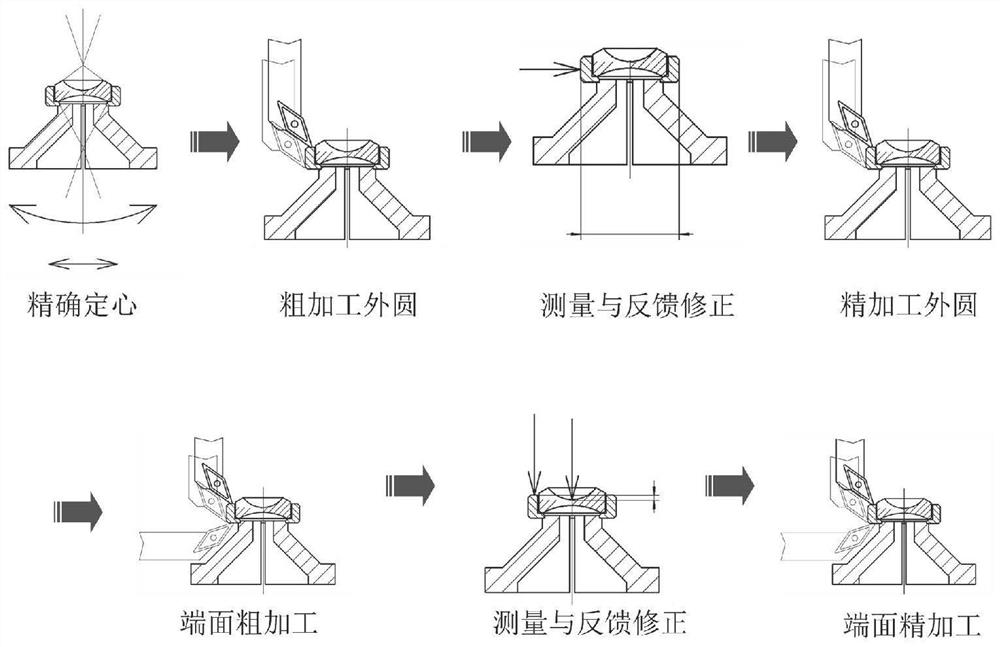

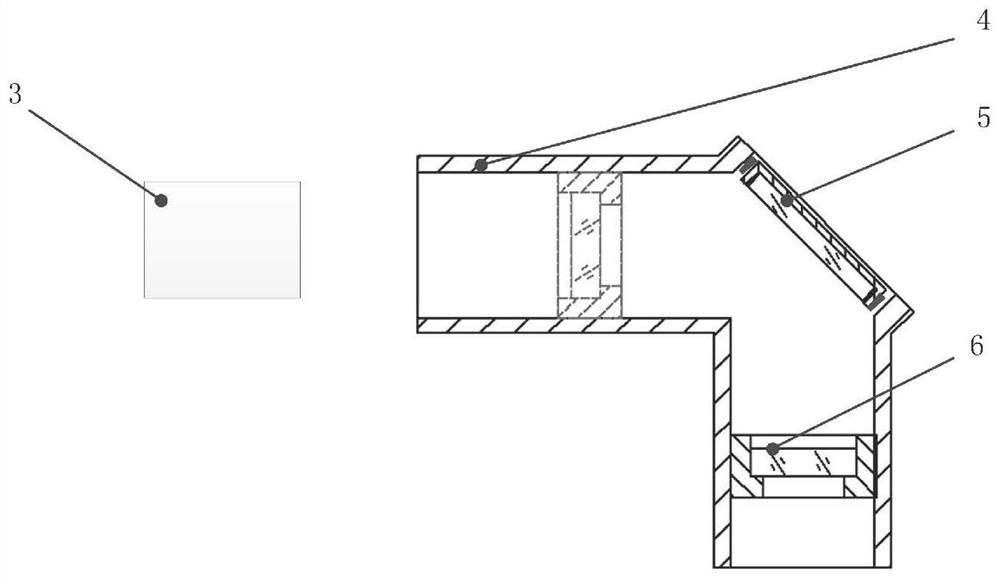

[0043] refer to Figure 1 to Figure 3 As shown, the specific implementation steps of the precise adjustment method for the concentricity of the telephoto folding axis lens group are as follows:

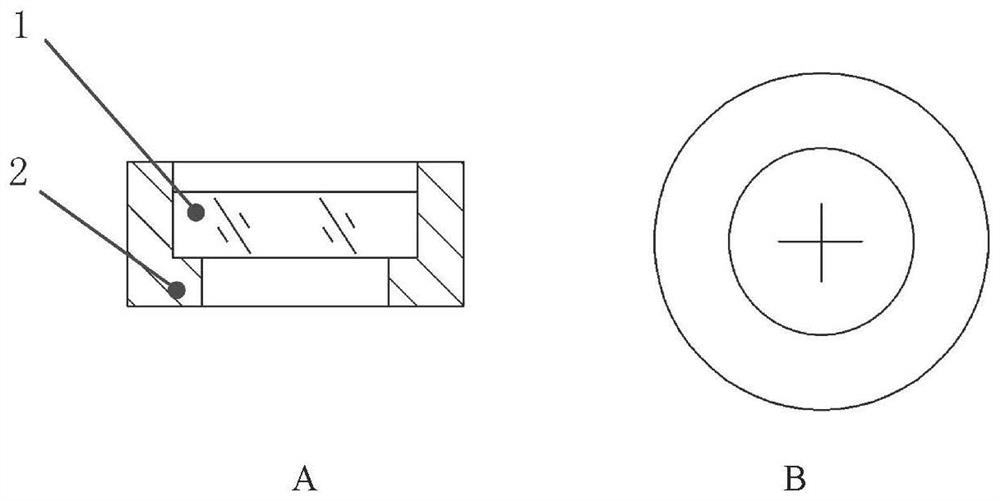

[0044] S1: Design semi-reflective and semi-transparent tooling reticles, which are glass reticles, including tooling frame 2 and reticle glass 1 installed in tooling frame 2; use centering turning calibration method for position calibration to meet the requirements of reticle glass 1. The reticle on the surface is concentric with the outer circle of the tooling frame 2, and the outer circle of the tooling frame 2 matches the inner hole of the folding lens barrel of the telephoto folding lens group;

[0045] S2: Through the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com