Tool capable of simultaneously machining magnetic pole face and detection face of medium- and low-speed magnetic levitation F rail

A technology for machining tools and magnetic pole faces, used in manufacturing tools, metal processing equipment, milling cutters, etc., can solve the problems of inability to guarantee the dimensional accuracy requirements of magnetic pole faces, tool errors, etc., to achieve reliable and effective dimensional accuracy requirements, improve processing efficiency, The effect of saving cutting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

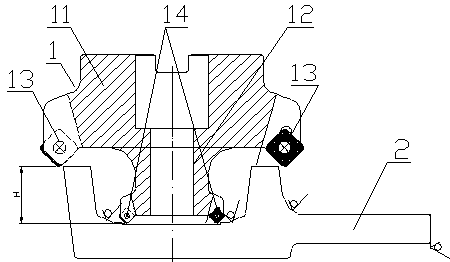

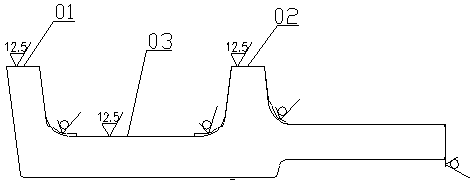

[0014] Embodiment 1: with reference to attached figure 1 . A medium-low speed maglev F-track magnetic pole surface and detection surface processing tool at the same time, the F-rail magnetic pole surface milling cutter tool 11 and the detection surface milling cutter tool 12 cutter bodies are integral cutter bodies in which the bottom end surface of the upper cutter body is larger than the upper end surface of the lower cutter body 1. Install magnetic pole face milling cutters 13 on both sides of the bottom of the upper cutter body, and install detection face milling cutters 14 on both sides of the bottom of the lower cutter body. The distance H between the processing surfaces of the magnetic pole face milling cutter 13 and the detection face milling cutter 14 is equal to the magnetic pole surface to The distance of the detection surface, that is, the distance between the magnetic pole face milling cutter 13 and the detection face milling cutter 14 is equal to the distance H ...

Embodiment 2

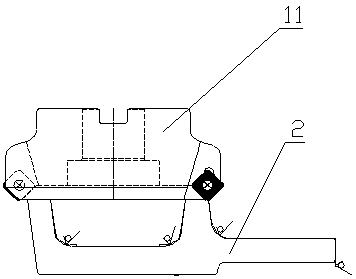

[0015] Embodiment 2: On the basis of Embodiment 1, the F-track magnetic pole face milling tool 11 is superimposed on the detection face milling tool 12 and the (upper) F-rail magnetic pole face milling tool 11 and the (lower) detection face milling tool are passed The position and size relationship of the holes and keys between the tools 12 connect the two cutters and fasten them with bolts or other methods to form a whole. At this time, the magnetic pole face milling cutter 13 and the detection face milling cutter 14 are installed on the cutter body. The magnetic pole face milling cutter 13 processes the magnetic pole face, and the detection face milling cutter 14 processes the detection face, so that the magnetic pole face and the detection face are processed simultaneously, and the distance between the magnetic pole face milling cutter 13 and the detection face milling cutter 14 is equal to the distance from the magnetic pole face to the detection face .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com