Superhard tungsten carbide deep hole shock-resistant inner-cooling adjustable boring tool

A tungsten carbide boring tool, tungsten carbide technology, applied in boring bars, accessories of tool holders, tools for lathes, etc., can solve problems such as failure to meet the requirements of drawings, achieve low cost, ensure dimensional accuracy requirements, and manufacture short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

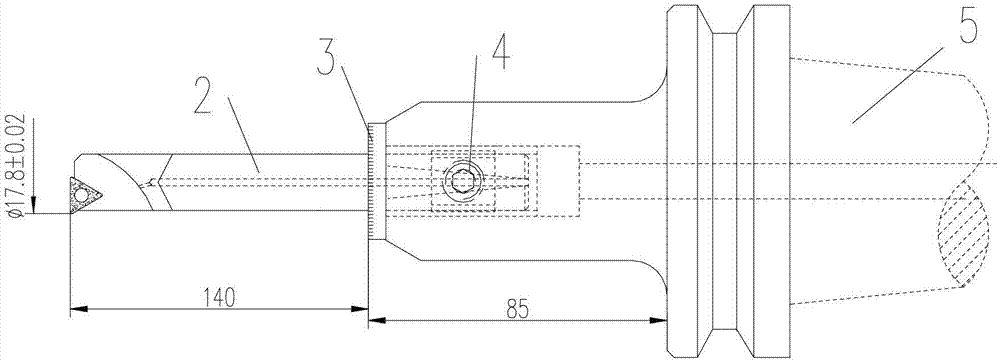

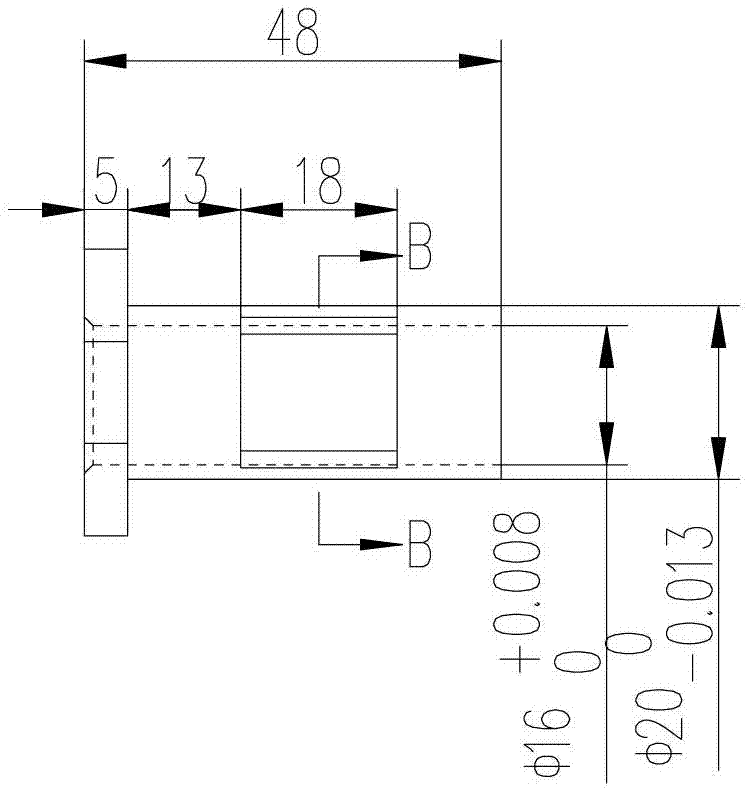

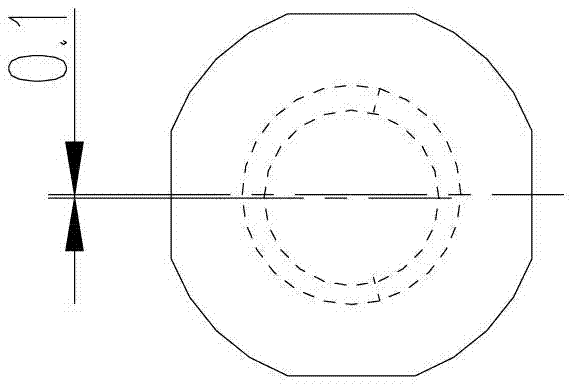

[0021] Embodiment 1 of the present invention provides a superhard tungsten carbide deep hole shock-resistant adjustable boring tool with internal cooling, such as Figure 1 to Figure 3 As shown, it includes: hard alloy tool holder 2, which is connected with the scale end of eccentric sleeve 3 with scale through screw 4, and the other end of eccentric sleeve 3 with scale is connected with non-standard side fixed tool handle 5. The diameter of the eccentric sleeve 3 is adjustable. Among them, the cemented carbide tool holder 2 can be made of super-hard tungsten carbide boring tool holder and made of high-toughness formula material to achieve high hardness, high shock resistance, built-in water hole, and direct cooling. It can improve the straightness, surface quality and dimensional accuracy of processed deep holes, involving a hole diameter of 6-30mm and an aspect ratio of 5-20mm. The dimensional accuracy and surface quality of the boring hole are stable, the roughness Ra≤1.6u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com