Processing technology and equipment for steel integral heterotype oil control ring wire rod moulding

An oil control ring and wire forming technology is applied in the manufacturing field of steel integral special-shaped oil control ring wire forming. problems, to achieve the effect of good product quality, convenient daily maintenance and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

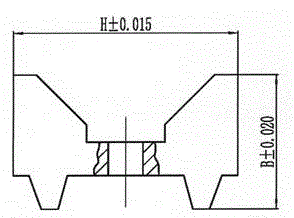

[0039] Processing a kind of (2.03±0.015)×(2.03±0.020) specifications, 6Cr13Mo high chromium stainless steel as the base material piston ring special-shaped integral oil control ring wire, the processing method is as follows:

[0040] (1) Selection of steel wire: Select a wire diameter of φ2.7 mm, and the material is 6Cr13Mo high-chromium stainless steel round steel wire.

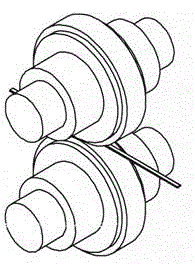

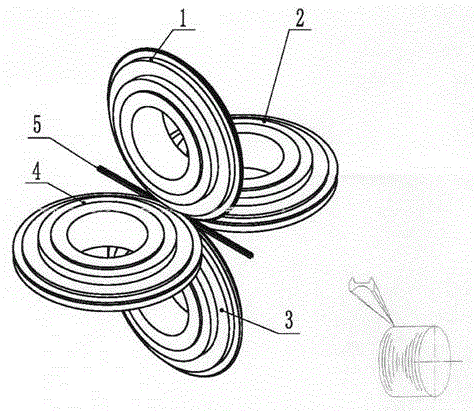

[0041](2) Rolling process: the original wire rod is linearly routed through two narrow strip rolling mills and three four-roller drawing die forming wire rod rolling equipment, drawn by the wire drawing machine, and continuously rolled on the upper, lower, left, and right sides of the wire rod at the same time into a rectangular wire;

[0042] (3) Annealing process: After rolling, the wire rod passes through a special annealing long furnace for continuous annealing at an annealing temperature of 930°C to 680°C. After annealing, it is rolled and annealed to obtain a shaped wire rod with a rectangular cross-se...

Embodiment 2

[0051] Processing a kind of (4.12±0.015)×(2.5±0.020) specifications, 54SiCrV6 high-quality alloy spring steel as the base material of the piston ring integral special-shaped oil control ring wire, the processing method is as follows:

[0052] (1) Steel wire selection: choose a round steel wire with a diameter of φ4.2 mm and a material of 54SiCrV6 high-quality alloy spring steel.

[0053] (2) Rolling process: The raw material wire rod is linearly routed through two narrow strip rolling mills and three four-roller drawing die forming wire rod rolling equipment, drawn by a wire drawing machine, and continuously rolled on the upper, lower, left, and right sides of the wire rod at the same time Made into rectangular wire;

[0054] (3) Annealing process: After rolling, the wire rod is annealed through a special annealing long furnace, the annealing temperature is 930 ° C ~ 680 ° C, after annealing, rolling and annealing are performed, and this is repeated twice to obtain a shaped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com