Welding method for nickel-based membrane type wall tube panel

A technology of membrane wall tube screen and welding method, which is applied in welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problems of deformation, repair, and large deformation of nickel-based tube screen, so as to prevent deformation and reduce repair. Quantity and the effect of ensuring dimensional accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Nickel-based membrane type wall tube panel welding method of the present invention comprises the following steps:

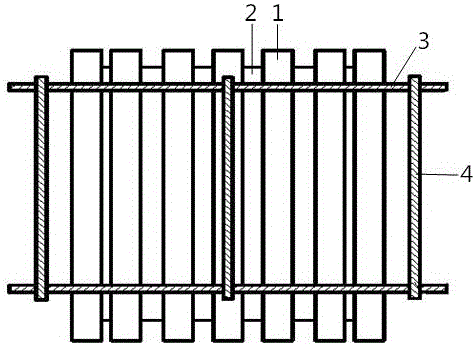

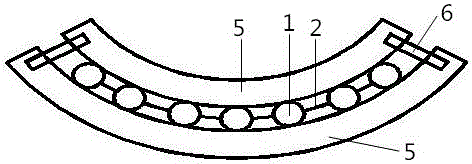

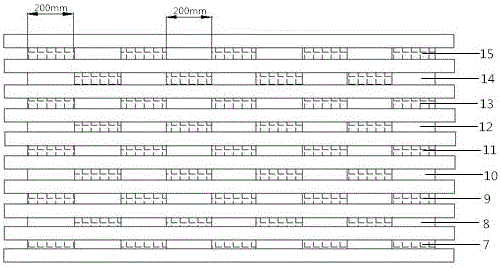

[0039]First, ten nickel-based tubes with a length of 2000mm and nine nickel-based flat steels with a length slightly shorter than the nickel-based tubes are arranged at intervals to form an arc-shaped tube panel; since the length of the tube panel is 2000mm, it can be installed on the tube panel At least two anti-deformation frocks, two anti-deformation frocks are arranged on the tube screen of this embodiment, and the two anti-deformation frocks are respectively arranged on the top and bottom of the tube screen; the manufacturing process of the anti-deformation frocks is: The clamping pieces adapted to the shape of the arc-shaped tube panel are respectively placed on the front and back of the same position of the tube panel along the direction perpendicular to the axis of the nickel-based tube, and the clamping piece is closely attached to the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com