Turbine disk fir-shaped mortise broaching tool

A fir tree-shaped and turbine disk technology is applied in the structural field of broaches, which can solve the problems of difficult machining, large plastic deformation, and high cutting temperature, so as to reduce broaching allowance, reduce elastic deformation, and reduce broaching resistance. and the effect of broaching heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

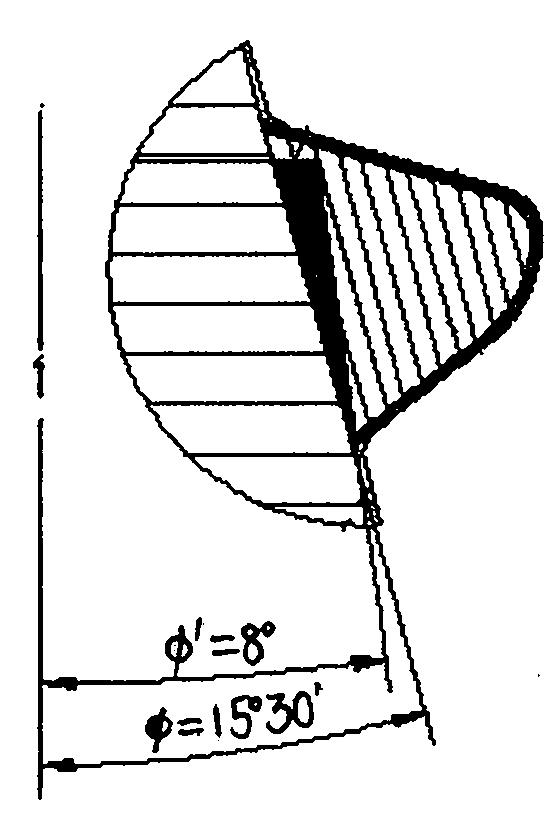

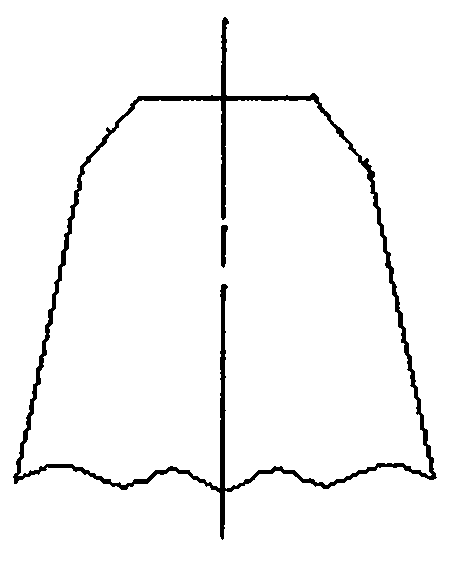

[0022] This embodiment provides a turbine disk fir tree-shaped tongue and groove broaching tool, which is characterized in that: the two sides of the blade width of the turbine disk fir tree-shaped tongue and groove broaching tool have sharp corners of 0.2× 45-degree chamfering, that is, there is a feed amount in the direction of the top surface, and there is also a feed amount in the direction of the chamfering. The original single-edged broaching is changed to multi-edged broaching, and the length of the chip edge is increased. This small chamfer Greatly reduces the cutting resistance, makes the broaching go smoothly, reduces the frequency of sharpening and the scrap rate of parts,

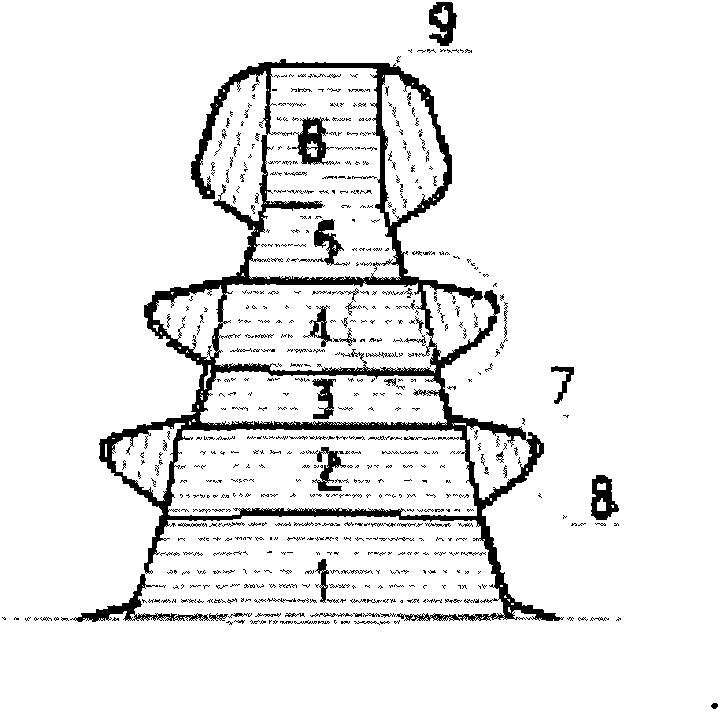

[0023] Rough grooving at parts 1 to 6, rough drawing of the tenon and groove tooth profile at the seventh part, fine drawing of the tenon and groove tooth profile at the eighth part, and fine drawing of the top surface of the ninth part;

[0024] 6 slotting knives are used for parts 1 to 6, 1 ro...

Embodiment 2

[0028] This embodiment provides a turbine disk fir tree-shaped tongue and groove broaching tool, which is characterized in that: the two sides of the blade width of the turbine disk fir tree-shaped tongue and groove broaching tool have sharp corners of 0.2× 45-degree chamfering, that is, there is a feed amount in the direction of the top surface, and there is also a feed amount in the direction of the chamfering. The original single-edged broaching is changed to multi-edged broaching, and the length of the chip edge is increased. This small chamfer Greatly reduces the cutting resistance, makes the broaching go smoothly, reduces the frequency of sharpening and the scrap rate of parts,

[0029] Rough grooving at parts 1 to 6, rough drawing of the tenon and groove tooth profile at the seventh part, fine drawing of the tenon and groove tooth profile at the eighth part, and fine drawing of the top surface of the ninth part;

[0030] 6 slotting knives are used for parts 1 to 6, 1 ro...

Embodiment 3

[0034] This embodiment provides a turbine disk fir tree-shaped tongue and groove broaching tool, which is characterized in that: the two sides of the blade width of the turbine disk fir tree-shaped tongue and groove broaching tool have sharp corners of 0.2× 45-degree chamfering, that is, there is a feed amount in the direction of the top surface, and there is also a feed amount in the direction of the chamfering. The original single-edged broaching is changed to multi-edged broaching, and the length of the chip edge is increased. This small chamfer Greatly reduces the cutting resistance, makes broaching go smoothly, reduces the frequency of sharpening and the scrap rate of parts,

[0035] Rough grooving at parts 1 to 6, rough drawing of the tenon and groove tooth profile at the seventh part, fine drawing of the tenon and groove tooth profile at the eighth part, and fine drawing of the top surface of the ninth part;

[0036] 6 slotting knives are used for parts 1 to 6, 1 rough-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com