Tool change device with vertical and horizontal conversion function and tool change method thereof

A technology of tool changing device and conversion function, which is applied in the field of mechanical engineering, can solve the problems of low utilization rate of tool changing device, low work efficiency, and insufficient machining accuracy, and achieve high hydraulic drive precision, simple gear processing, stable and perfect functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the technical solution proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. described as follows.

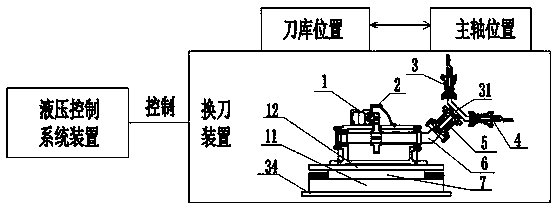

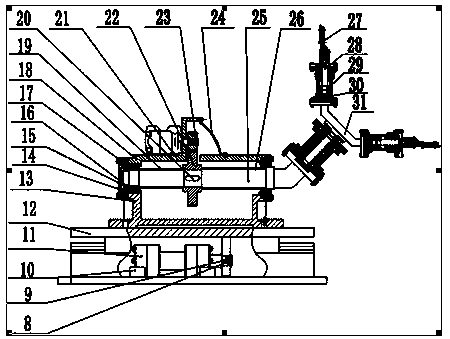

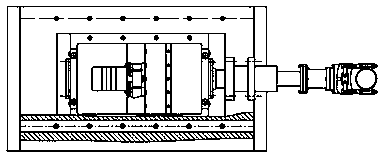

[0048] See attached Figure 1-9 , a tool changing device with vertical and horizontal conversion functions, including a hydraulic control system device, and also includes an open gear reduction mechanism 2, a crankshaft 6, and a manipulator; the open gear reduction mechanism 2 and the workbench 12 are connected by bolts; the workbench 12 It is connected with the linear guide rail 7 by bolts, and the linear guide rail 7 and the plunger hydraulic cylinder 11 are respectively fixed on the base 34 by bolt connection; The plug hydraulic cylinder 11 can push the workbench 17 to move fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com