Processing box and driving component

A technology for processing boxes and driving heads, applied in the field of electrostatic printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

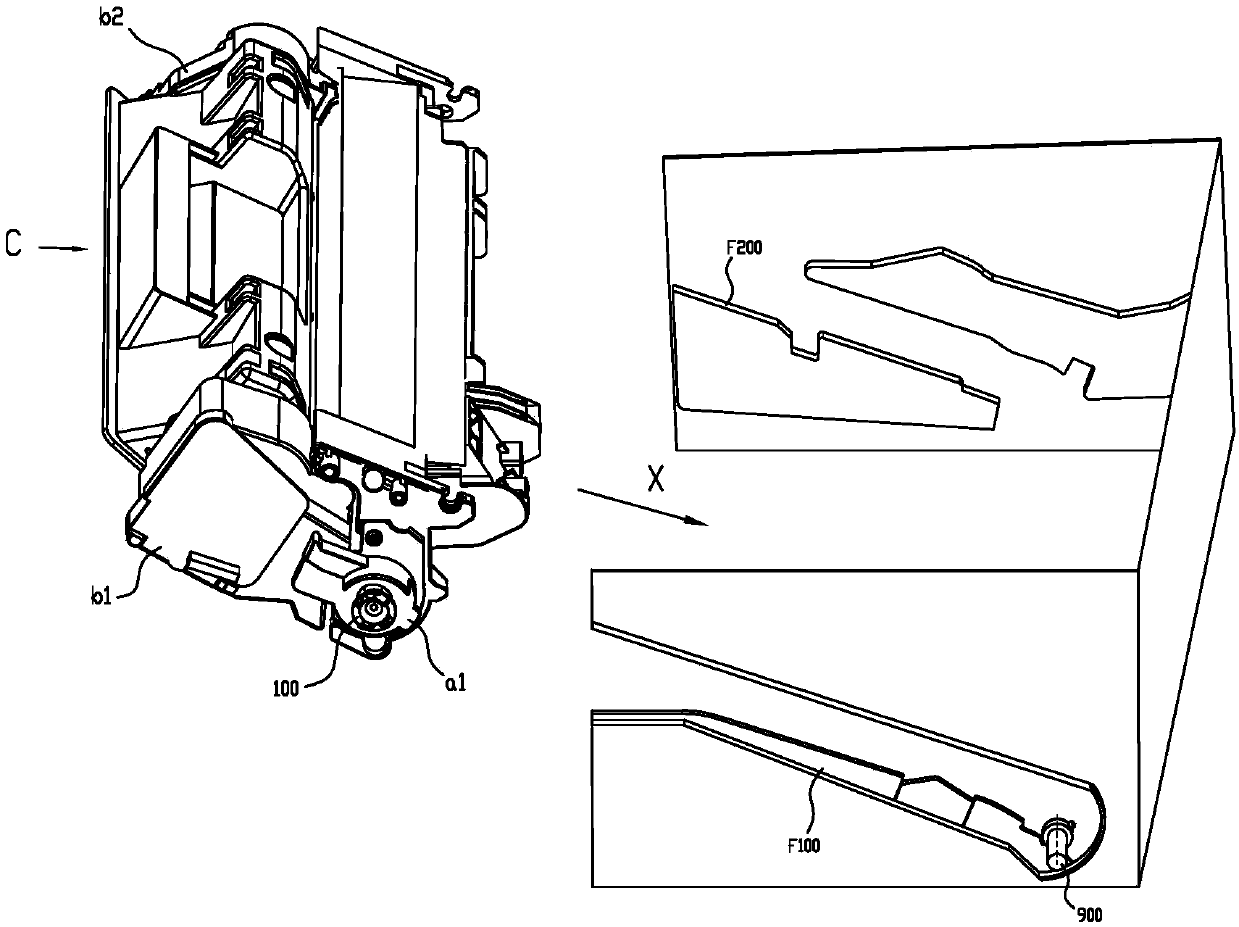

[0100] Such as Figure 6 to Figure 8 As shown, it is a schematic structural view of the process box C1, the process box C1 includes a first shell A and a second shell B, and a first side wall b100 and a second side wall b200 arranged on both sides of the second shell B. The charging element 20 , the cleaning element 40 , the photosensitive element 10 , etc. are accommodated in the first casing A, and the developing element 30 , powder control element 50 , developer, etc. are accommodated in the second casing B.

[0101] (driver components)

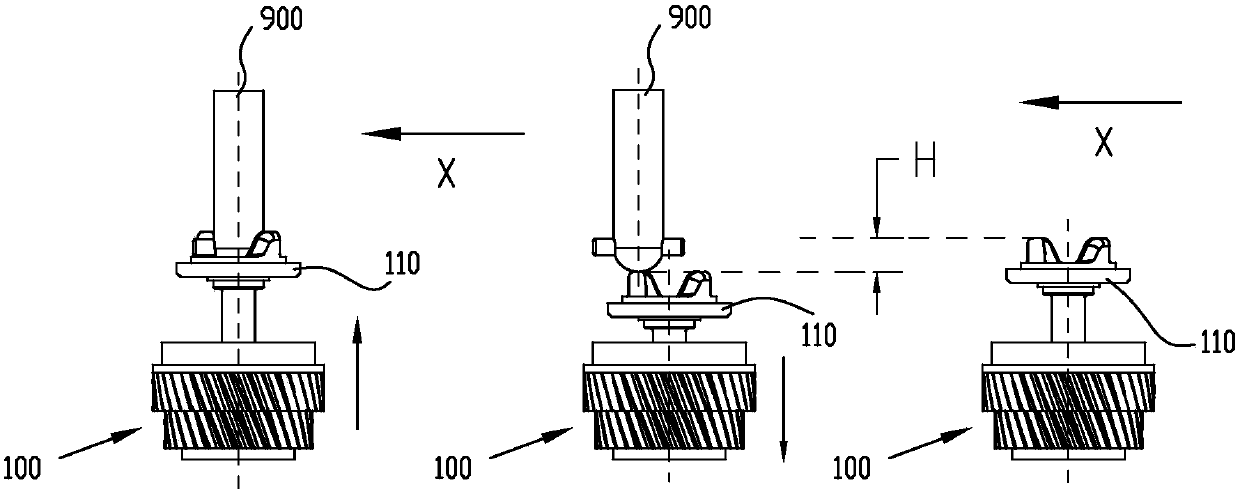

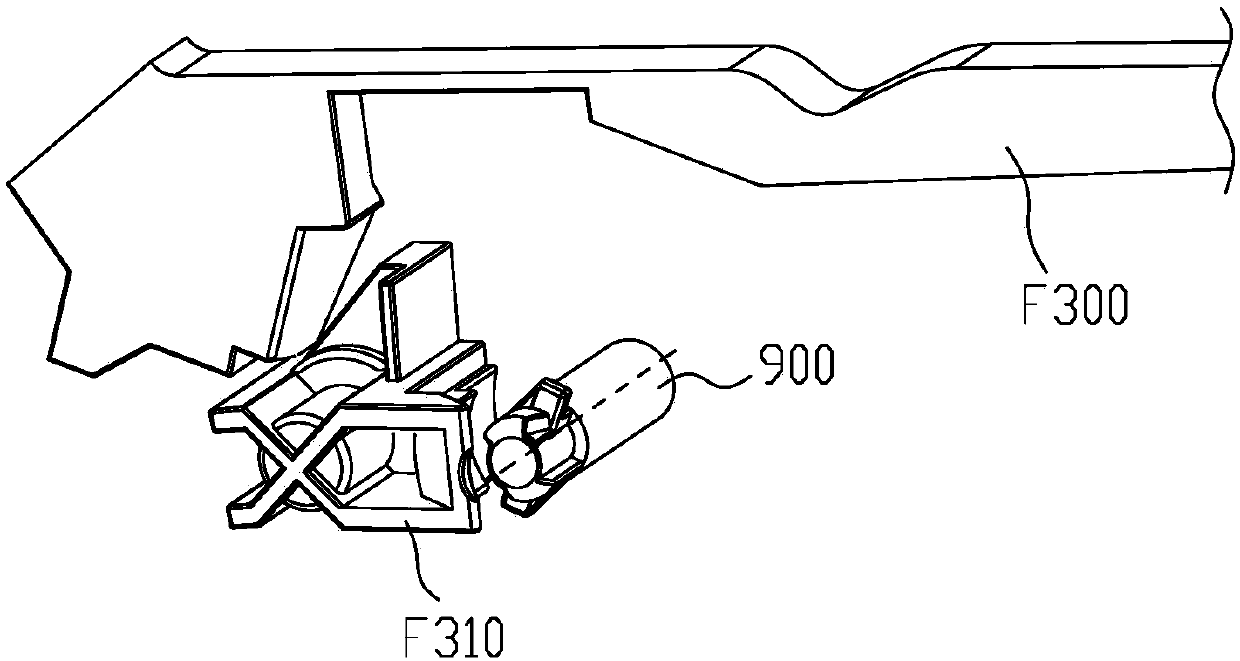

[0102] Such as Figure 7 , Figure 9 As shown, the drive assembly 200, the control mechanism 290 cooperating with the drive assembly 200, and the side plate a100 partially covering the drive assembly 200 are arranged at one end of the process cartridge C1, through the rotational power receiving part 210 of the drive assembly 200 and the electronic imaging device The drive head 900 is engaged to transmit the rotational driving force to the...

Embodiment 2

[0135] Such as Image 6 As shown, it is a schematic structural view of the process box C1, the process box C1 includes a shell (a first shell A and a second shell B) and side walls b100 at both ends of the shell, and a charging element is accommodated in the first shell A 20. The cleaning element 40, the photosensitive element 10, etc., the developing element 30, the powder control element 50, the developer, etc. are accommodated in the second casing B.

[0136] Such as Figure 36 , Figure 37 As shown, the drive assembly 200, the control mechanism 290 cooperating with the drive assembly 200, and the side plate a100 partially covering the drive assembly 200 are arranged at one end of the process cartridge C1, through the rotational power receiving part 210 of the drive assembly 200 and the electronic imaging device The drive head 900 is engaged to transmit the rotational driving force to the process cartridge C1 and drive the rotating components (such as the developing eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com