a processing box

A technology of processing box and box body, applied in the field of processing box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

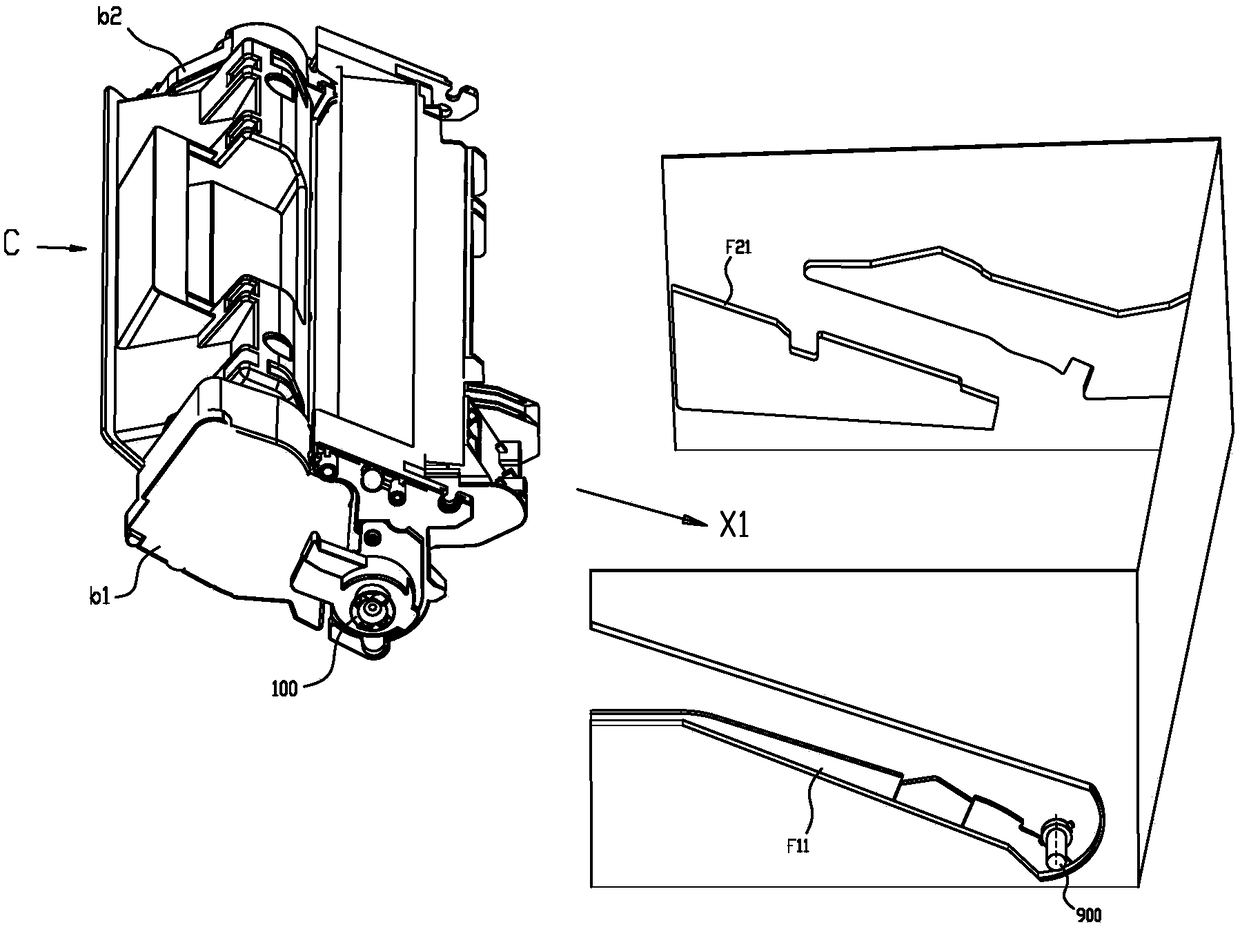

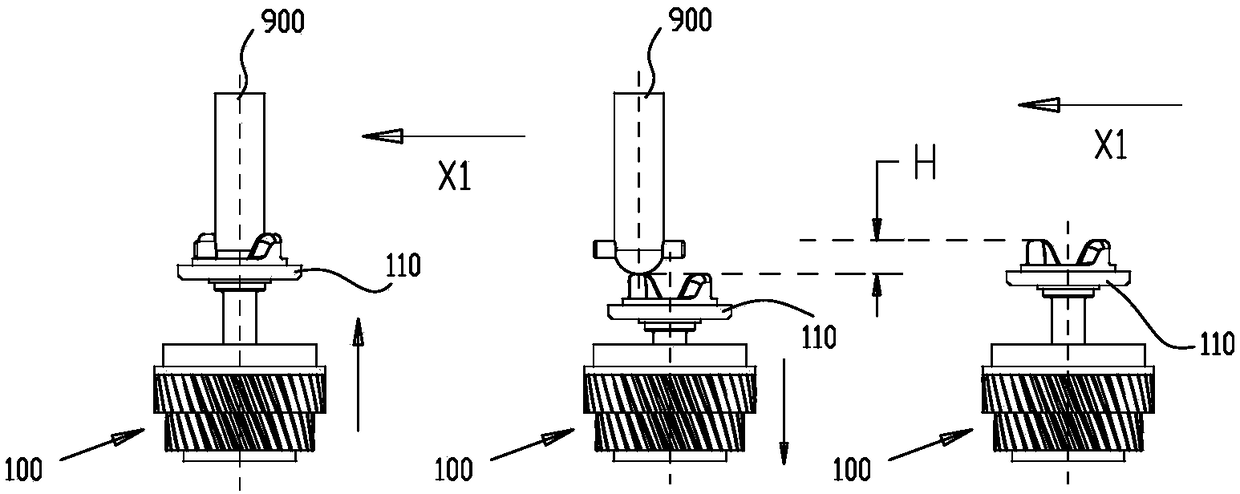

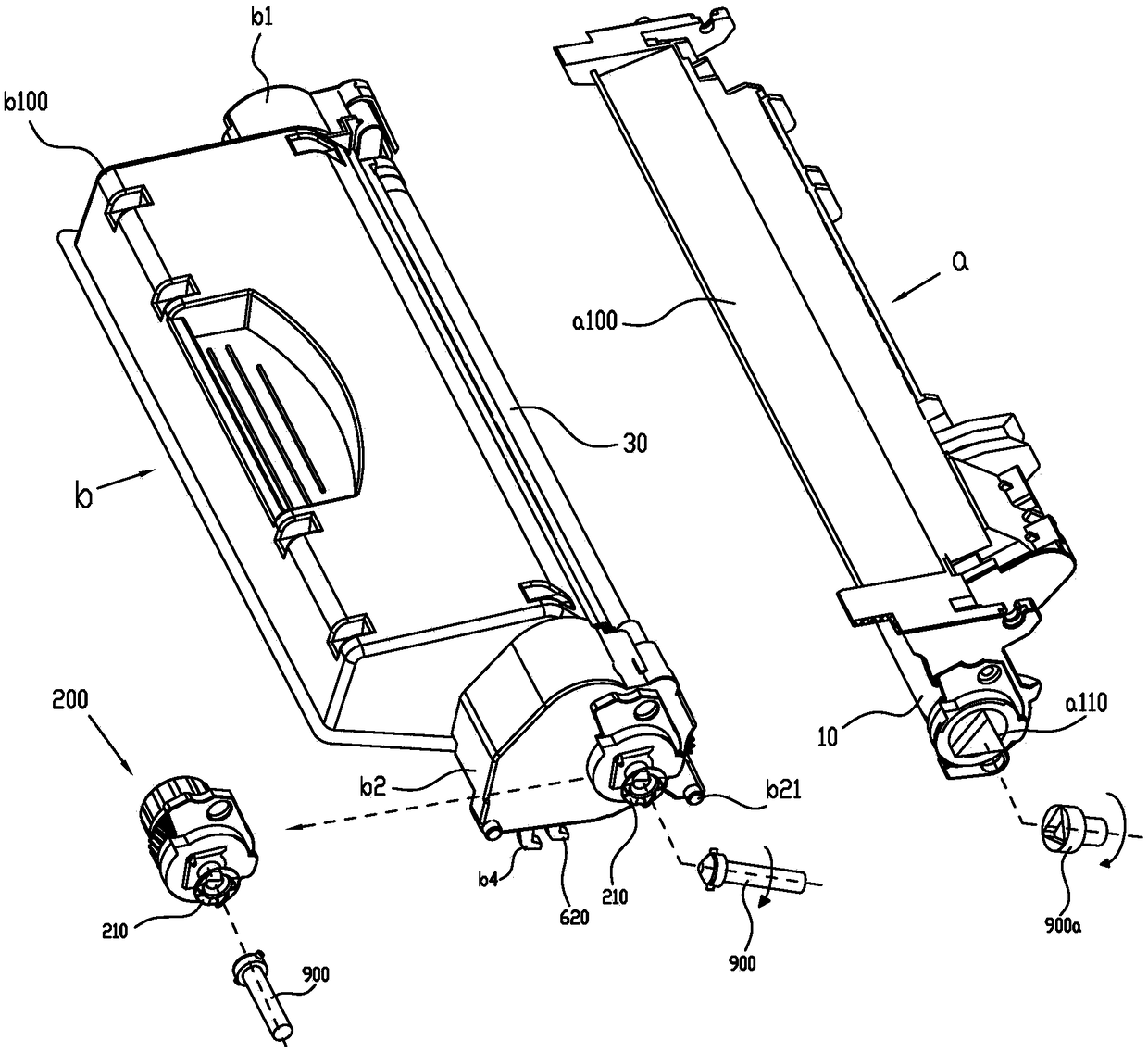

[0107] Such as image 3 As shown, it is a schematic structural diagram of the process box b. The process box b includes a developing chamber b100 and side plates b1 and b2 arranged on both sides of the developing chamber b100. The driving assembly 200 receiving the rotational driving force is installed on the side plate b2. In addition, there is a photosensitive assembly a that cooperates with the process cartridge b to perform developing operations. The photosensitive assembly a includes a photosensitive chamber a100 and a driving member a110 arranged on one side of the photosensitive chamber a100. The driving member a110 and another driving head in the electronic imaging device 900a engages to receive the driving force of rotation and transmit the driving force to the photosensitive unit 10 in the photosensitive chamber a100, and the driving part a110 is preferably a convex triangular structure.

[0108] (process cartridge and photosensitive unit)

[0109] Such as Figure...

Embodiment 2

[0178] The process cartridge b and the photosensitive assembly a which are independent of each other in the above-mentioned embodiment one can also be arranged in a structure connected to each other, such as Figure 45 As shown, the side plates b1 and b2 on both sides are respectively provided with a connecting arm b3a with a hole b3, and a positioning column b22 is provided at the top thereof. The connecting arms b3a of the side plates b1 and b2 extend into the two sides of the photosensitive chamber a100 of the photosensitive assembly a, the upper end of the elastic member a4 abuts against the inner wall of the photosensitive chamber a100, and the lower end of the elastic member a4 is inserted into the positioning column b22 . The process cartridge b and the photosensitive assembly a are connected as a whole through a pair of connecting pieces a3 passing through the positioning holes on both sides of the photosensitive chamber a100 and the hole b3 of the developing chamber b...

Embodiment 3

[0182] In the drive assembly 200 of the above-mentioned embodiment 1 / 2, the matching mechanism (pressing member 220) that can make the power receiving part 210 telescopically engage and disengage with the drive head 900 relative to the hub 270 or the end cover 290 along its rotation axis and slider 230) can also be replaced by the structure of the power receiving part 210 described below and achieve substantially the same effect and function.

[0183] Such as Figure 48 As shown, the claw 211 on the upper end of the power receiving part 210 is set to be tiltable or swingable relative to the main body of the power receiving part 210, that is, the center line of the claw 211 can be inclined at a certain angle relative to the rotation axis of the power receiving part 210, preferably Between 5 ° and 65 °, and the outer surface of the claw 211 is provided with a smooth curved surface transition, and an elastic member 810 (rubber band or extension spring) is also provided on the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com