Multidirectional load bearing prestressed wire winding pre-tightening frame

A technology of prestressed steel wire and frame, which is applied in the direction of presses, forging/pressing/hammering machinery, manufacturing tools, etc. It can solve the problems of dispersion, non-existence, and low pressure of steel wires, and achieve the effect of avoiding structural interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

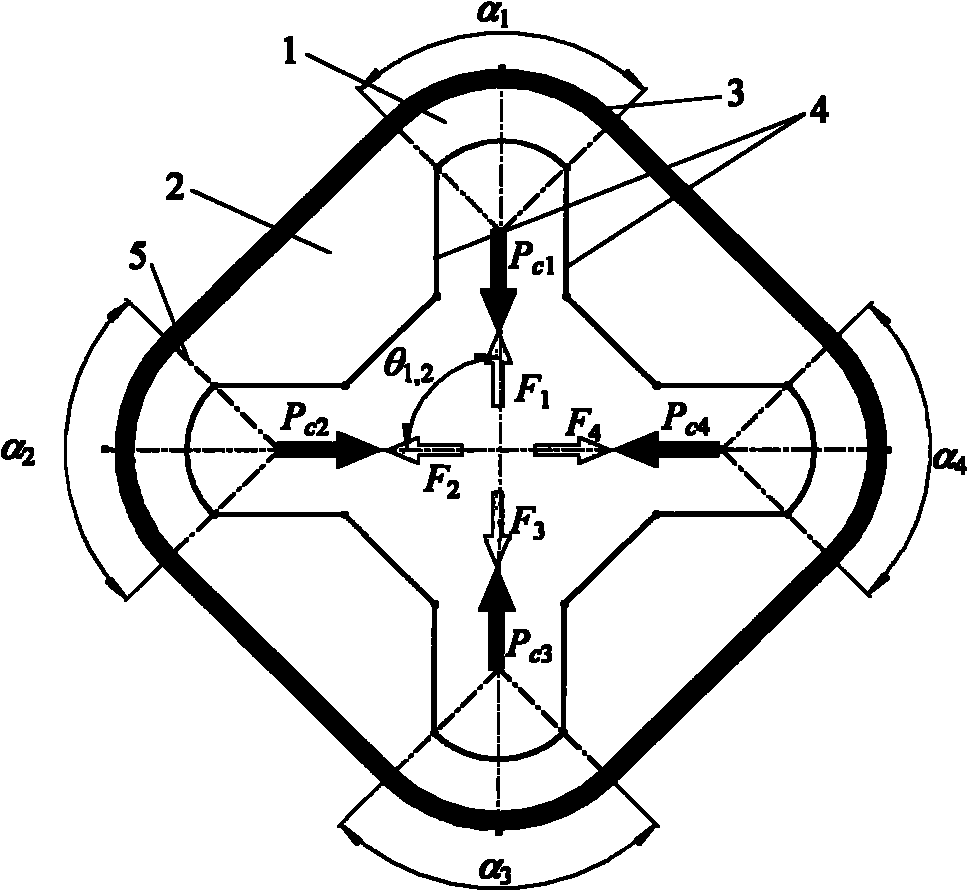

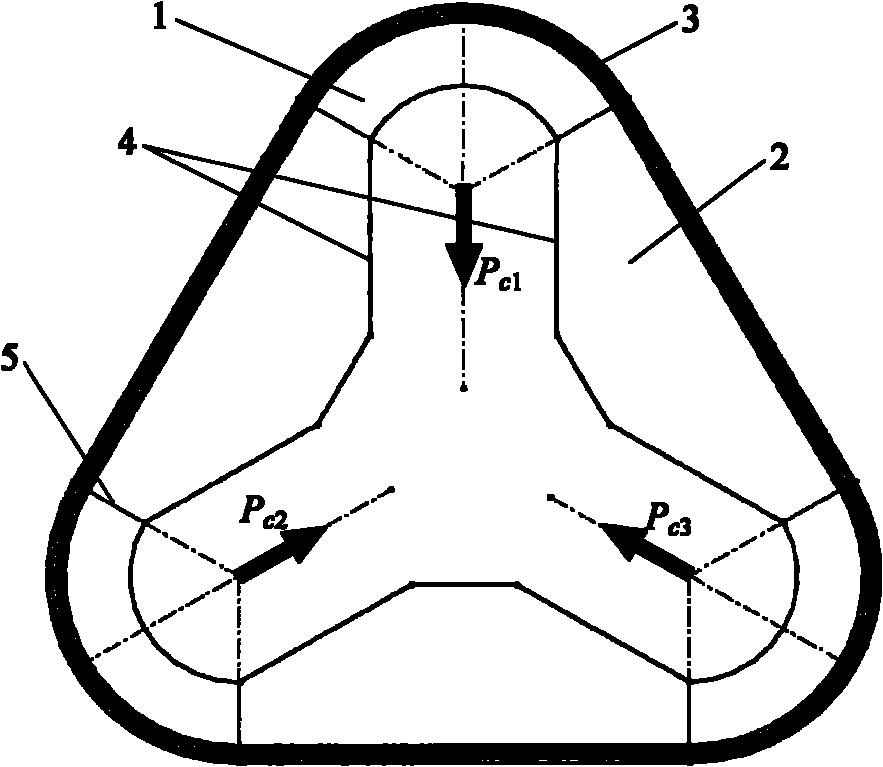

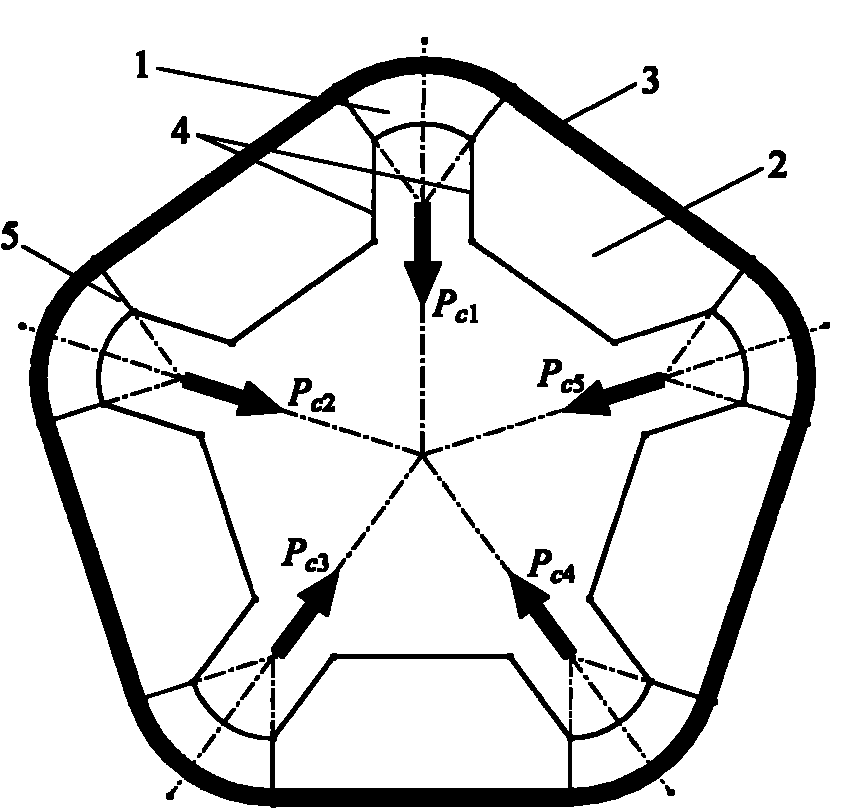

[0024] The present invention provides a prestressed steel wire winding pretensioning frame bearing multi-directional loads, the outer peripheral profile of which includes at least three sections of circular arc beams 1 equal in number to the pressing reaction force and opposite in direction and at least three sections of straight beams 2, The outer contour of the straight section beam is tangent to the outer arc contours of two adjacent arc beams, and the arc beams and straight section beams are arranged alternately to form a frame, and on the outer peripheral contour of the frame Wrap prestressed steel wire 3. That is, a section of arc beam is set in the counter force direction of each pressing force, and the arc angle of the arc beam can be determined according to the required pre-tightening force or the corresponding pressing force and pre-tightening coefficient. The sum of the radian angles of all arcs should be equal to 360° or 2π.

[0025] And the inner profile of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com