Anti-spilling flow rate standard device and calibration method applicable to large flow rate liquid entrance

A flow standard device and high flow technology, applied in measuring devices, test/calibration devices, liquid/fluid solid measurement, etc. The effect of reducing the residual medium hanging on the wall and avoiding the interference between the container and the water separator structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

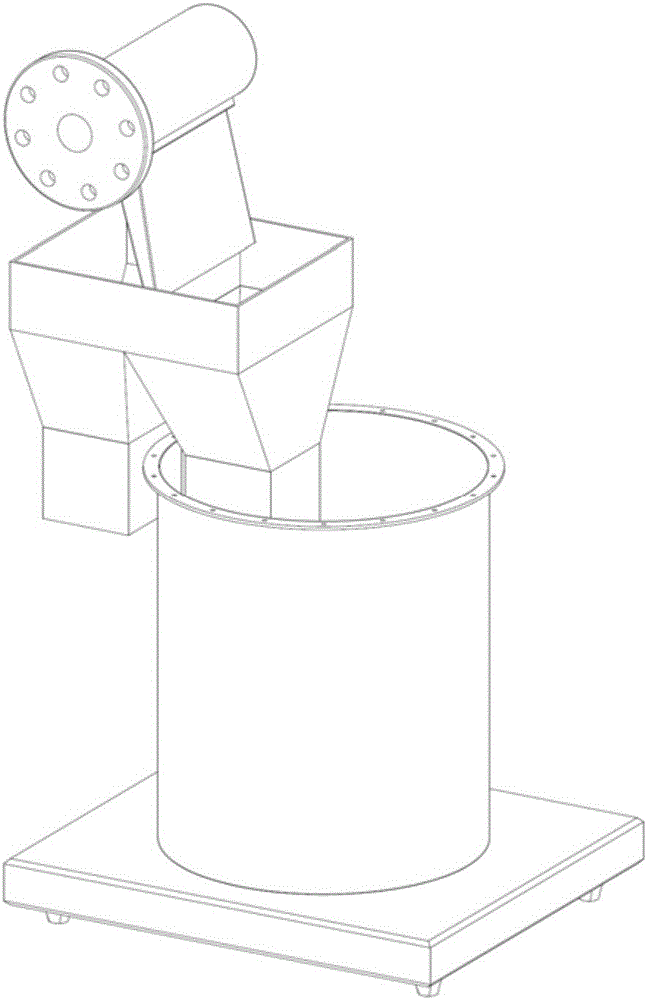

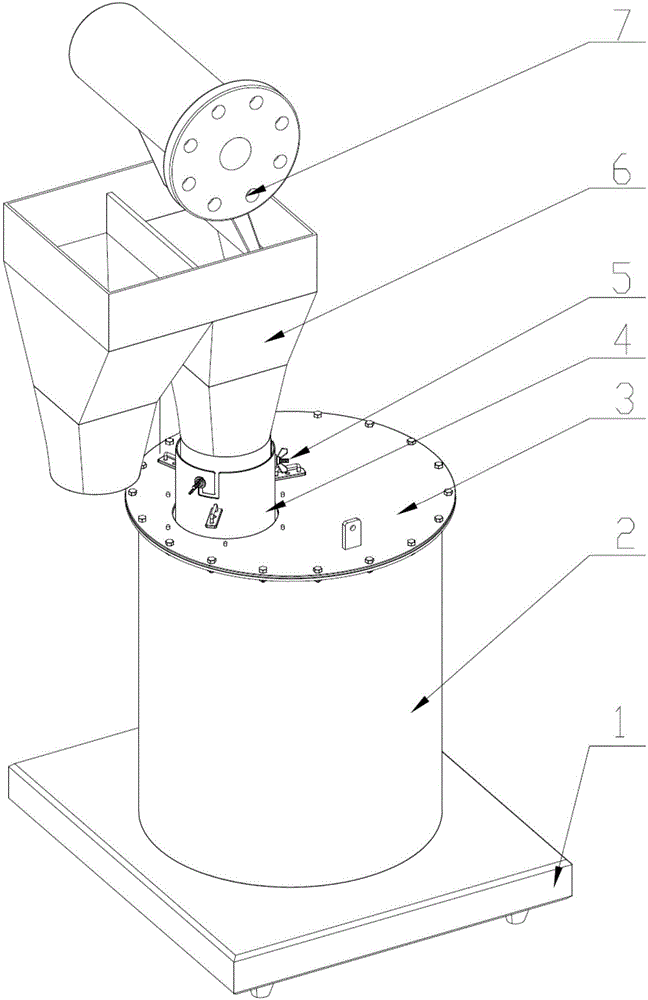

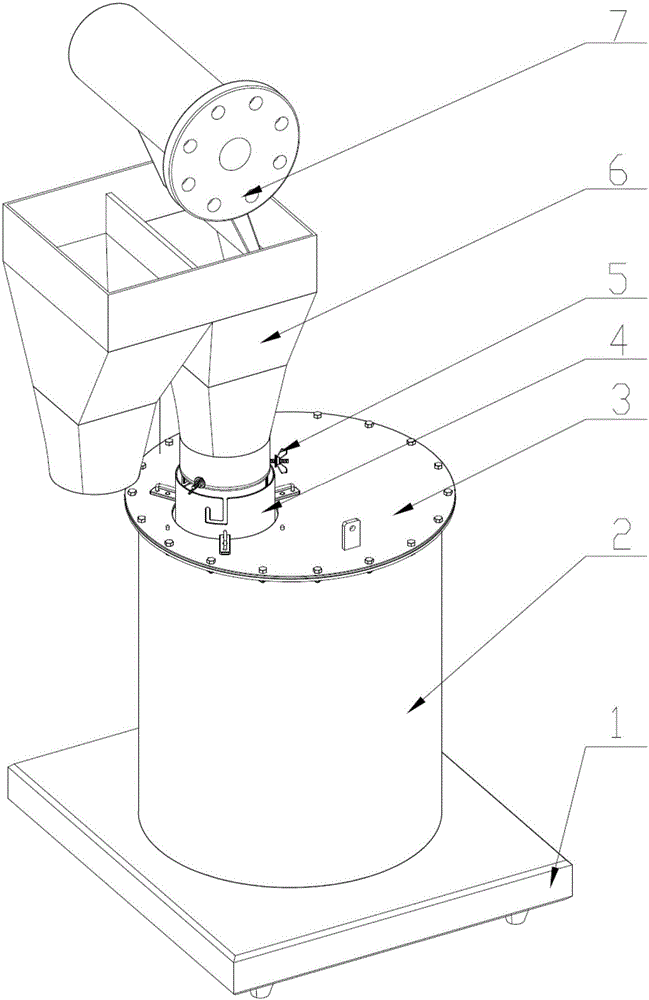

[0039] like figure 1 , figure 2 , image 3 and Figure 4 As shown, an anti-spill flow standard device for large-flow liquid inlet, the flow standard device includes a scale (electronic scale) 1, a container 2, a top cover 3, an anti-spill device 4, a stud 5, a water divider 6 and commutator 7.

[0040] The top cover 3 is provided with a through hole, and 6 protrusions are evenly distributed in the circumferential direction around the through hole. A pair of lifting lugs are arranged on the top cover 3 to facilitate overall hoisting. The top cover 3 and the container 2 are fixedly connected by 16 sets of bolt fasteners in the circumferential direction, forming a unified whole.

[0041] The anti-overflow device 4 is a hollow cylinder, and three "J"-shaped installation grooves 45 are opened on the top of the hollow cylinder in the circumferential direction, and three groups of wing plates 43 are uniformly distributed on the side wall of the hollow cylinder in the circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com