Multi-cone-section deep hole measuring device and using method thereof

A technology of measuring device and deep hole, applied in the direction of measuring device, instrument, etc., can solve the problems of long hole body, difficult measurement, low measurement efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

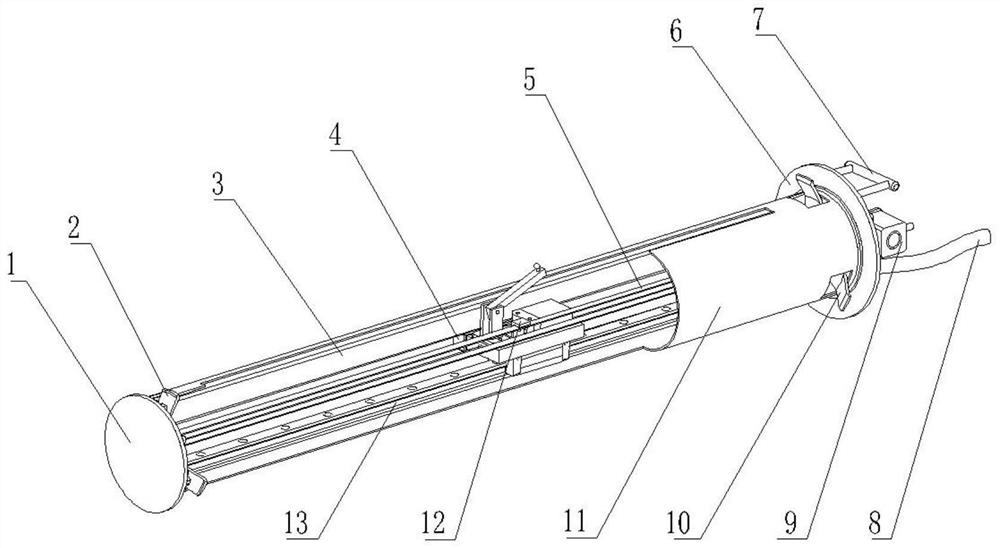

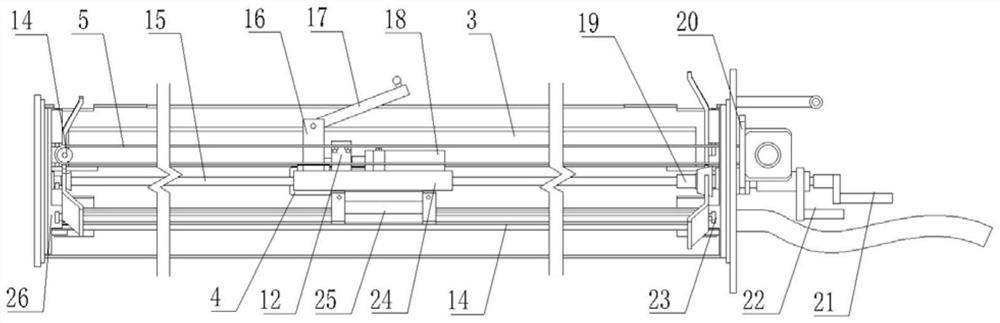

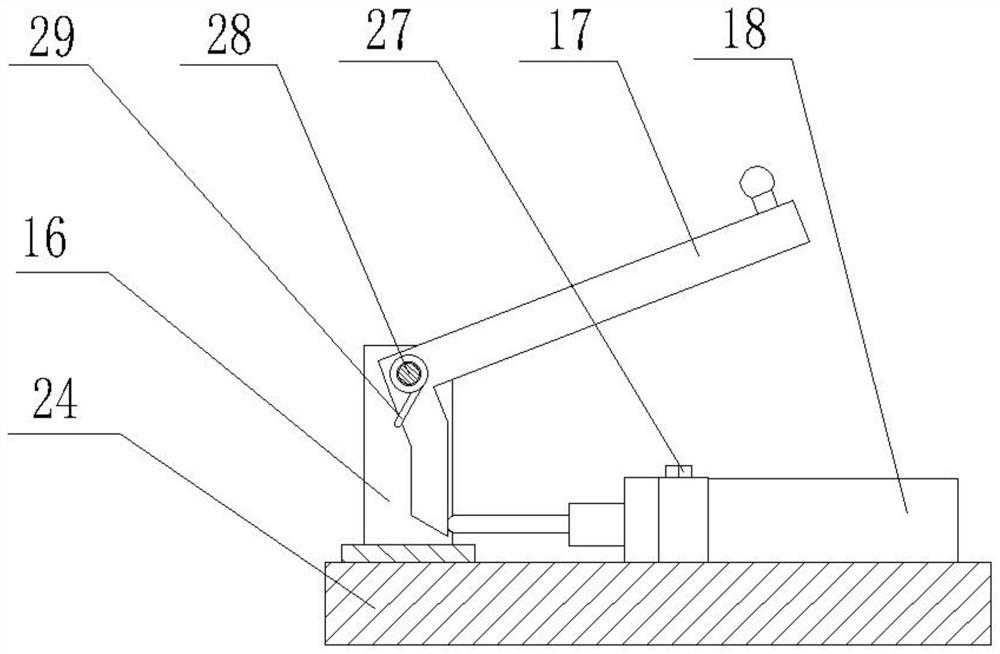

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] like Figure 1-5 As shown, when the present invention works, the multi-cone section deep hole measuring device is put into the corresponding position inside the measured deep hole part 35, and the front end adjustment rocker 21 is manually shaken first, and the front end adjustment rocker 21 drives the front center adjustment shaft 15 to rotate, The front center adjustment shaft 15 is threadedly connected with the front base cover plate 1 to form a screw pair, which can make the front center adjustment shaft 15 move in the radial direction, and the front center adjustment shaft 15 is equipped with a small tapered block 30. The conical surface of the conical block 30 is in contact with the conical surfaces at the bottom of the three front-end claws 2. When the front central adjustment shaft 15 rotates and moves forward along the axis, the small conical block push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com