Boom frame system and operation vehicle

A boom and component technology, which is used in hoisting devices, fire rescue, building construction, etc., can solve the problems affecting the stability of the boom system and the working area, and achieve the effects of simple structure, reduced manufacturing difficulty, and easy tilting processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

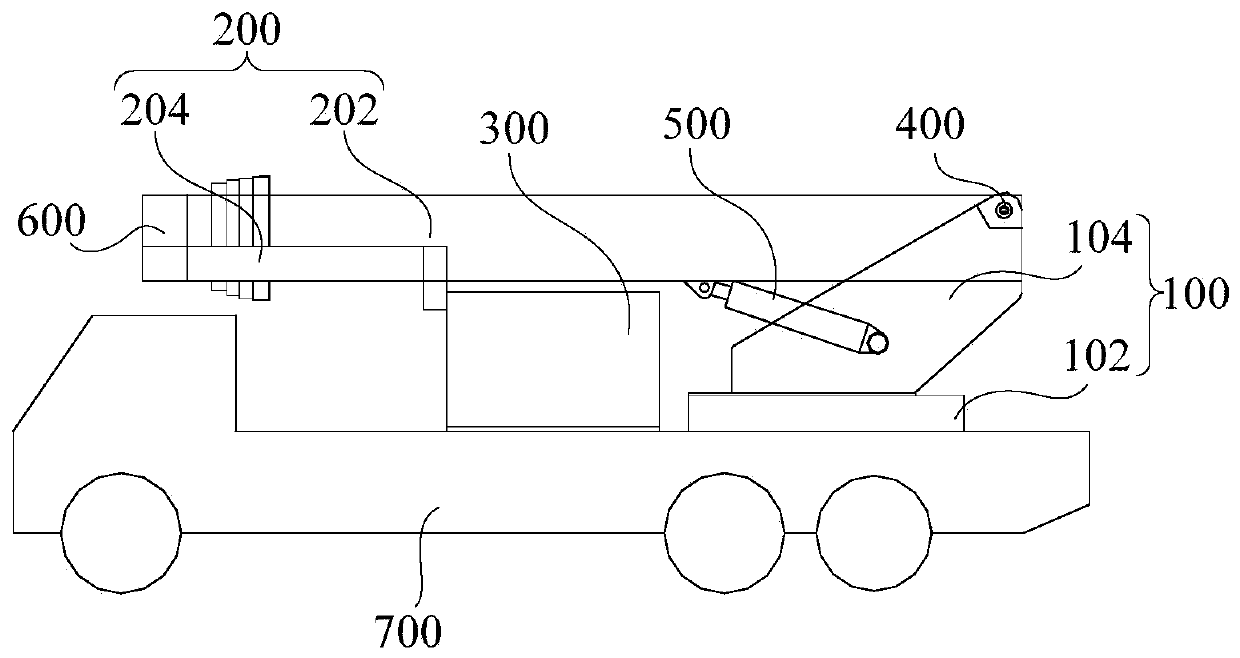

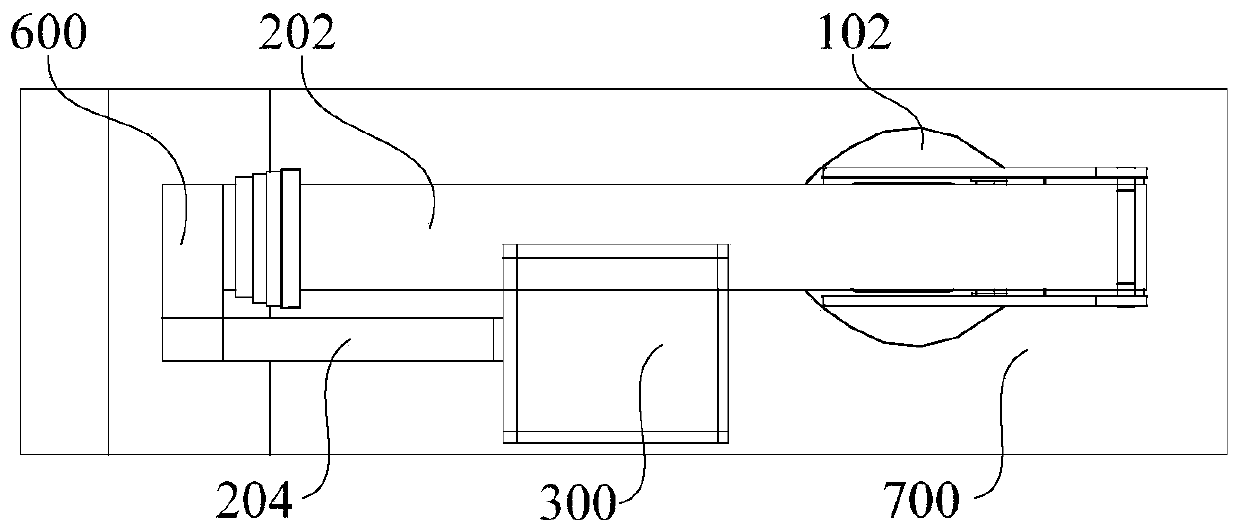

[0047] like figure 1 , figure 2 and image 3 As shown, the first embodiment of the present invention proposes a jib system, including: a turntable 100 and a jib 200 .

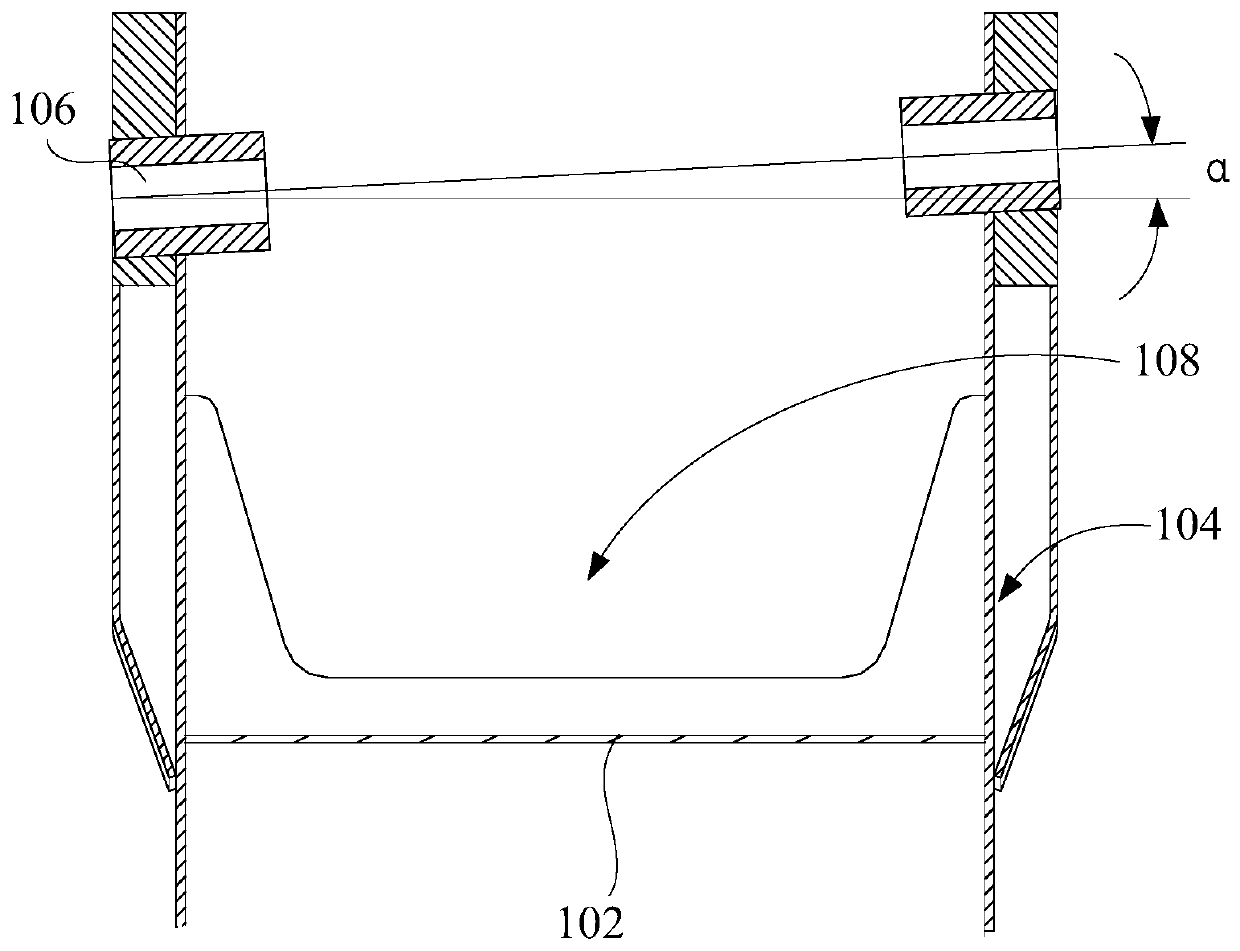

[0048] Wherein, the boom 200 includes a first boom assembly 202 and a second boom assembly 204 , the first boom assembly 202 is hinged to the turntable 100 , and the second boom assembly 204 is located at one side of the first boom assembly 202 . In particular, as image 3 As shown, the hinge axis of the first boom assembly 202 and the turntable 100 forms a preset angle α with the horizontal plane, so that the first boom assembly 202 is inclined on the turntable 100, and the first boom assembly 202 itself will have a certain Pre-twist and pre-deflection. Also, from one side of the first boom assembly 202 to one side of the second boom assembly 204, the axis of articulation slopes upward. That is, the first boom assembly 202 is inclined toward the side away from the second boom assembly 204, so that the pr...

Embodiment 2

[0053] like figure 1 , figure 2 and image 3 As shown, the second embodiment of the present invention proposes a boom system, including: a turntable 100 and a boom 200 ; the turntable 100 includes a bottom plate 102 and a vertical plate 104 .

[0054] Wherein, the boom 200 includes a first boom assembly 202 and a second boom assembly 204 , the first boom assembly 202 is hinged to the turntable 100 , and the second boom assembly 204 is located at one side of the first boom assembly 202 . In particular, as image 3 As shown, the hinge axis of the first boom assembly 202 and the turntable 100 forms a predetermined included angle α with the horizontal plane, and from one side of the first boom assembly 202 to one side of the second boom assembly 204, the hinge axis is inclined upward , so that the pre-torsion and pre-deflection of the boom 200 itself, and the eccentric load and torque M generated by the installation position of the second boom assembly 204 T or side bending m...

Embodiment 4

[0068] like figure 1 , figure 2 and image 3 As shown, the fourth embodiment of the present invention proposes a boom system, including: a turntable 100 , a boom 200 and an operating platform 300 .

[0069] Wherein, the boom 200 includes a first boom assembly 202 and a second boom assembly 204 , the first boom assembly 202 is hinged to the turntable 100 , and the second boom assembly 204 is located on one side of the first boom assembly 202 . In particular, as image 3As shown, the hinge axis of the first boom assembly 202 and the turntable 100 forms a predetermined included angle α with the horizontal plane, and from one side of the first boom assembly 202 to one side of the second boom assembly 204, the hinge axis is inclined upward , so that the pre-torsion and pre-deflection of the first boom assembly 202 itself, and the eccentric load and torque M generated by the installation position of the second boom assembly 204 T or side bending moment M 0 Balance each other t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com