Three-degree-of-freedom sliding groove type connector for connecting transfer barge and semi-submersible platform

A semi-submersible platform with a degree of freedom technology, applied to barges/flat-bottomed boats, ship components, ship construction, etc., to achieve the effects of fast connection, tight connection, and reduced load-bearing force requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

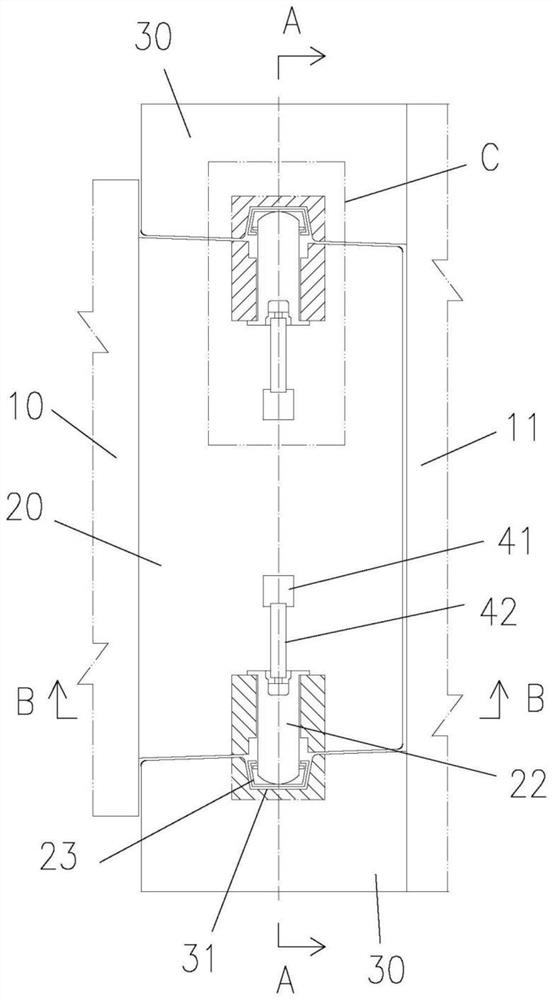

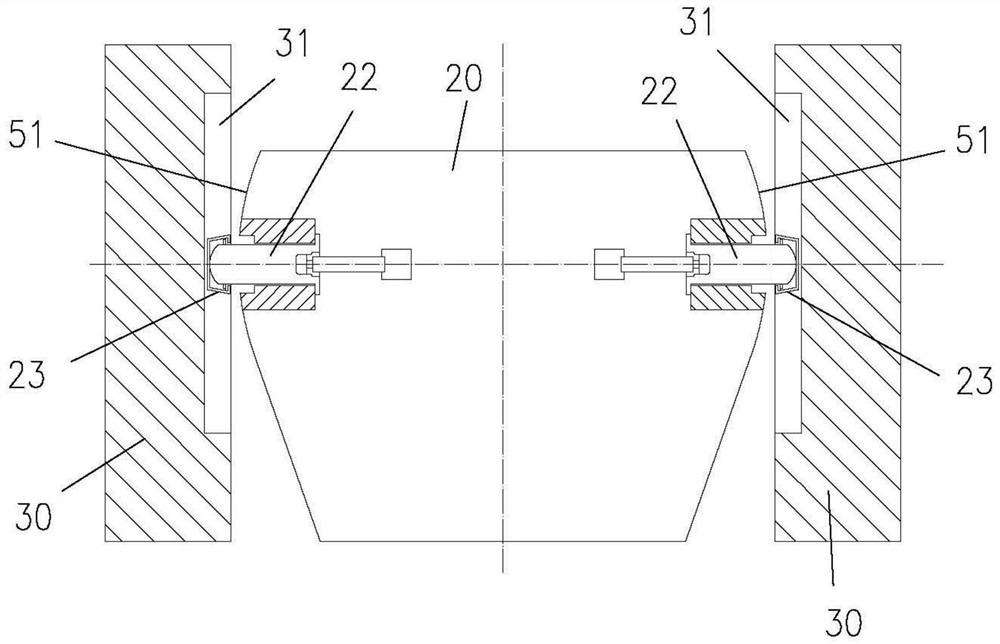

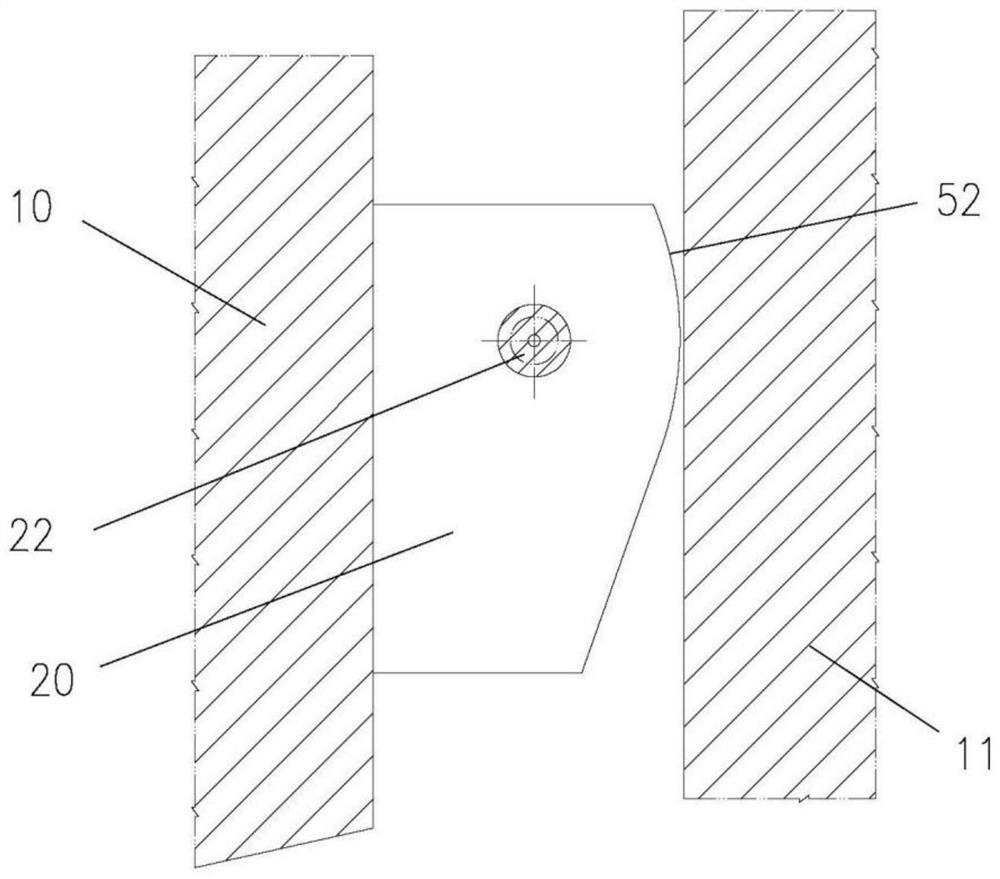

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a three-degree-of-freedom chute connector for connecting a transfer barge to a semi-submersible platform, which includes a boss attachment 20 located on the transfer barge 10 and a channel attachment located on the semi-submersible platform 11 Body 30.

[0025] There are two channel attachments 30 , and the boss attachment 20 is inserted between the two channel attachments 30 .

[0026] The two channel appendages 30 are provided with vertically distributed sliding slots 31 . The cross section of the chute 31 is trapezoidal. The width of the bottom of the chute is smaller than the width of the mouth of the chute.

[0027] Two side surfaces of the boss attachment 20 are respectively provided with a pin shaft hole 21 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com