Fully-independent servo drive rapier loom

A servo-driven, rapier loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of inability to adjust the stroke freely, inconvenient process adjustment, lack of adjustability, etc., to achieve convenient maintenance, The effect of simple and reliable mechanical structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

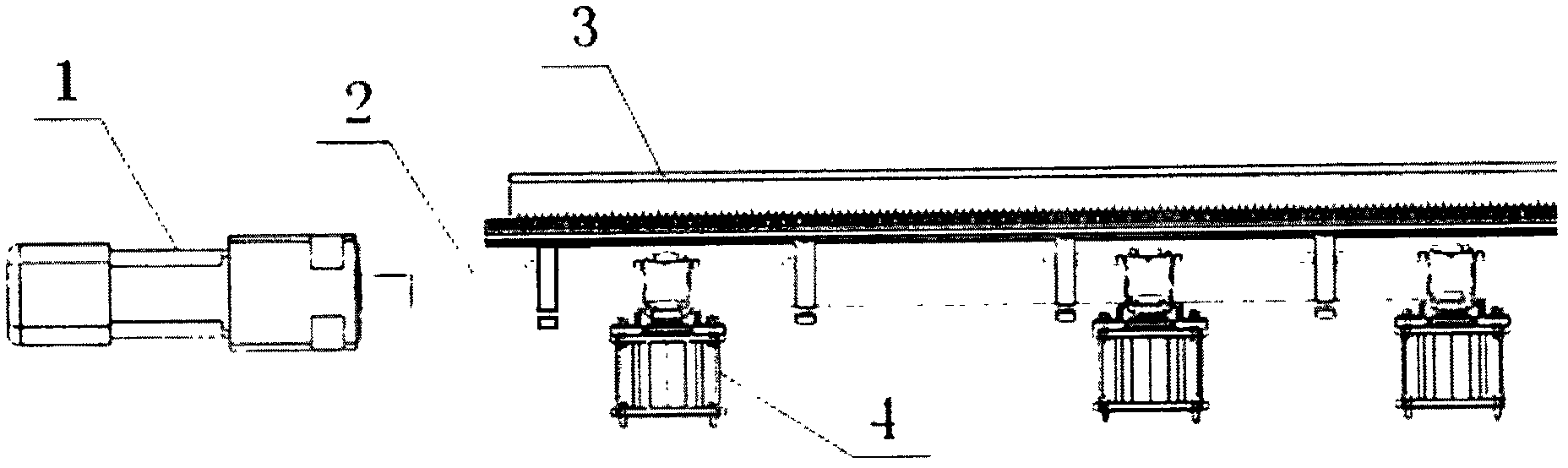

[0019] attached figure 1 The medium motor adopts 8KW 3000r / min large inertia servo motor (1) as the main force for beating-up operation; the servo motor (1) is controlled by the main control unit, and the position information is fed back to the main control unit through the encoder to realize the motor Accurate positioning, the servo motor (1) as the main motor can freely adjust the beating angle each time to meet the requirements of different fabrics. The beat-up shaft (2) is connected with the main shaft of the servo motor (1), and is directly driven by the servo motor (1), and drives the steel buckle (3) fixed on it to complete a beat-up cycle by swinging at the same time. The weft shaft supporting seat (4) fixes the beating-up shaft (2).

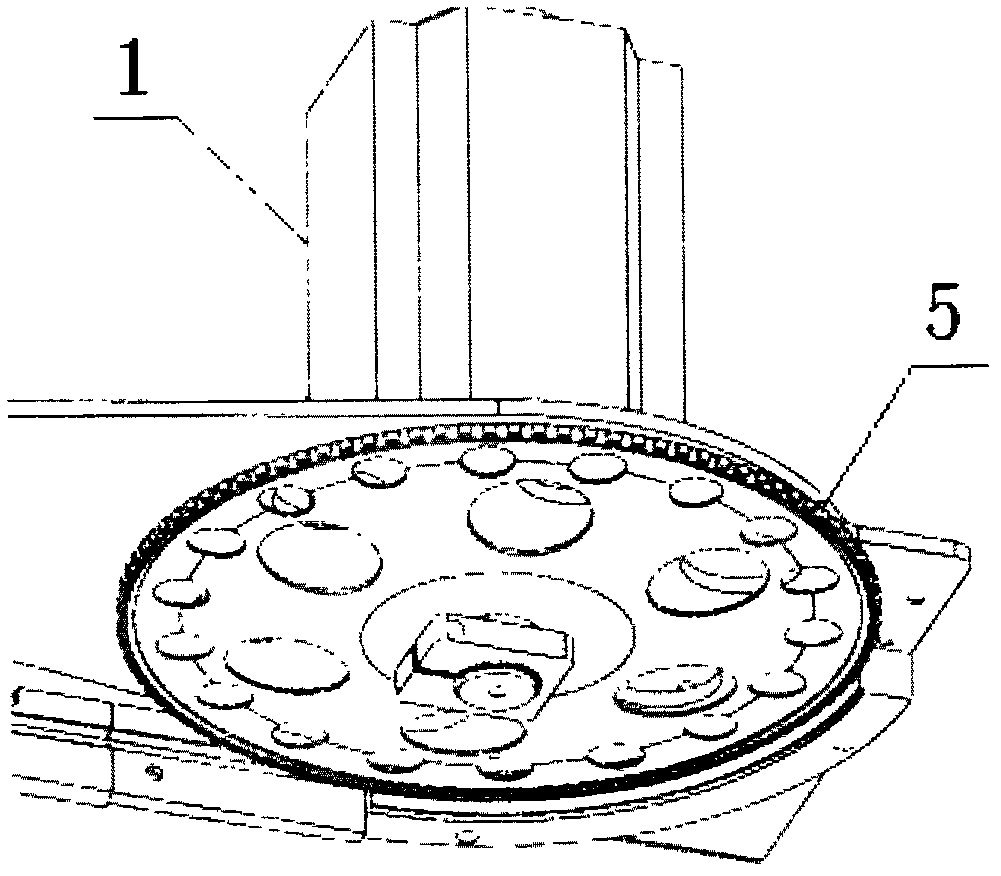

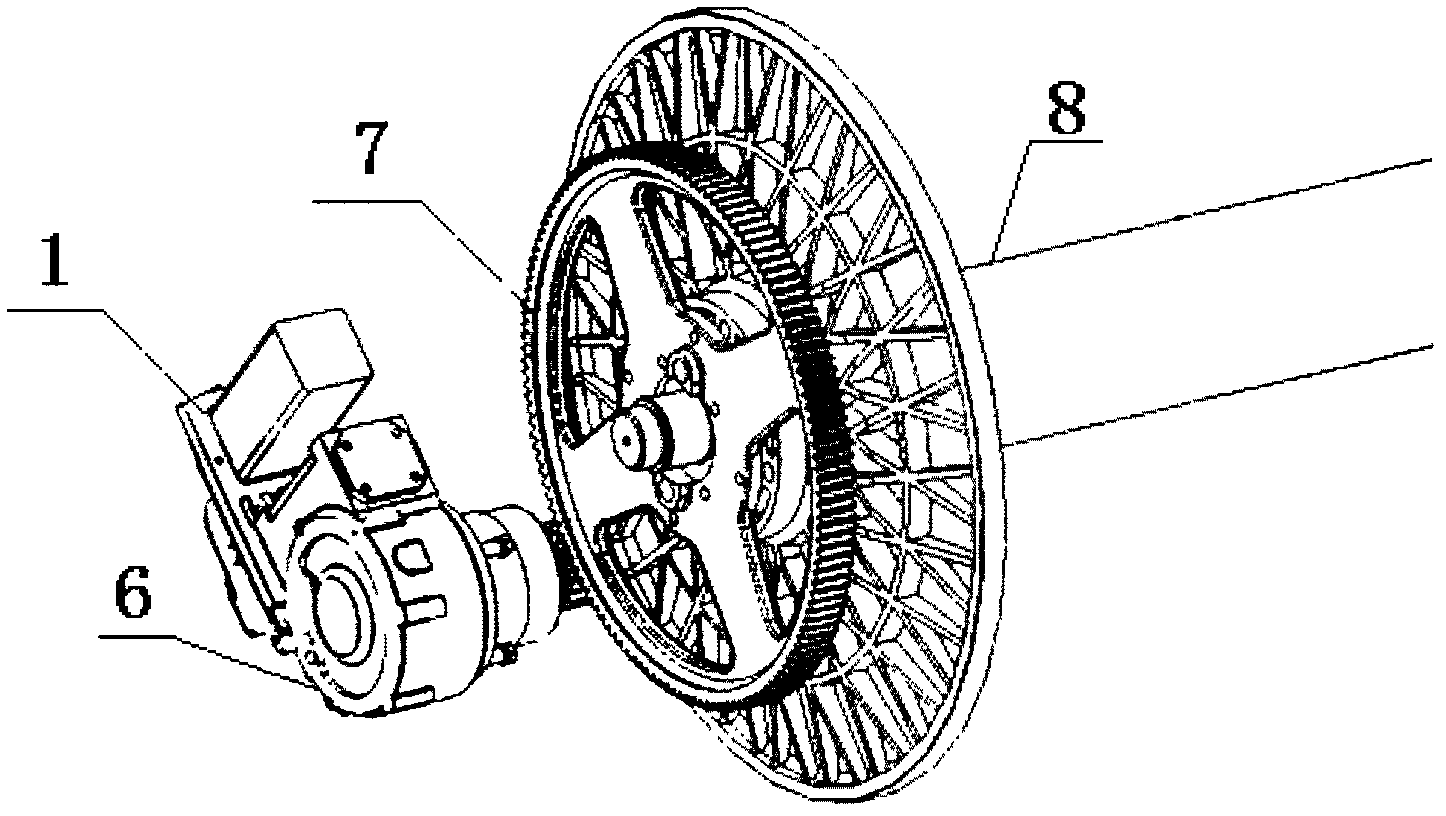

[0020] exist figure 2 Among them, the motor adopts a 4.7KW 3225r / min large inertia servo motor (1), the servo motor (1) is directly driven by the main control unit, and can realize the weft insertion operation to run according to a cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com