Assembly bracket for structured light 3D module, structured light 3D module and assembly method

An assembly method and a technology for assembling brackets, which are applied in the field of photography, can solve problems such as unfavorable miniaturization and lightness, mismatched size design, and large space occupation, and achieve the effect of miniaturization, small occupied space, and avoiding structural interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

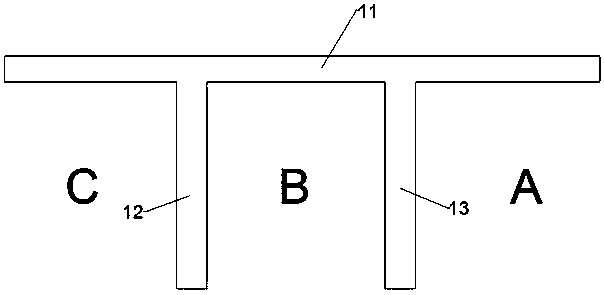

[0037] Such as figure 2 and 3 As shown, an assembly bracket for a structured light 3D module has a first assembly frame A for assembling a structured light camera, a second assembly frame B for assembling a structured light projector, and a second assembly frame B for assembling an RGB camera Three assembly frames C, wherein at least one of the first assembly frame A, the second assembly frame B and the third assembly frame C forms an outward side opening structure.

[0038] The assembly bracket removes part of the outer side wall, so that an outward side opening structure is formed on at least one of the first assembly frame A, the second assembly frame B and the third assembly frame C, and the space it occupies is smaller. Small size reduces the volume of the structured light 3D module, which is conducive to miniaturization and thinning, and the components of the structured light 3D module (structured light camera, structured light projector and RGB camera) that need to be...

Embodiment 2

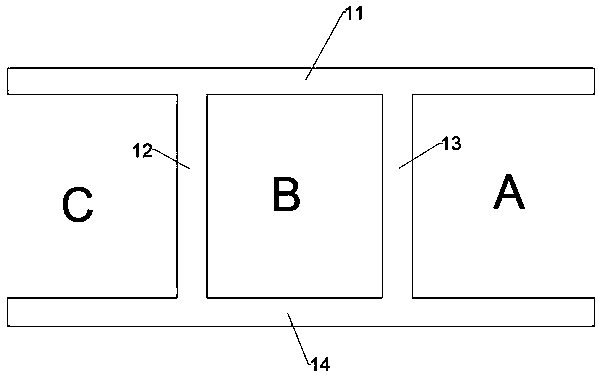

[0044] Such as Figure 4 As shown, a structured light 3D module includes the assembly bracket 1 described in Embodiment 1, a structured light projector, a structured light camera 21 and an RGB camera 23, and the structured light projector, structured light camera 21 and RGB The camera 23 is respectively fixed in the first assembly frame A, the second assembly frame B and the third assembly frame C by glue.

[0045] The glue is at least one of AA glue, UV glue or thermosetting glue.

Embodiment 3

[0047] Such as Figure 4 and 5 As shown, an assembly method of a structured light 3D module includes:

[0048] Step 1: Provide the assembly bracket 1 described in the first embodiment, the structured light camera 21, the structured light projector 22 and the RGB camera 23;

[0049] Step 2: Fix the structured light camera 21 , the structured light projector 22 and the RGB camera 23 in the first assembly frame A, the second assembly frame B and the third assembly frame C respectively by glue.

[0050] Preferably, in step 2, at least one of the structured light camera 21 , the structured light projector 22 and the RGB camera 23 is assembled into the corresponding assembly frame from the side opening structure of the corresponding assembly frame.

[0051] This step 2 specifically includes:

[0052] Step 2.1: Fix the structured light camera 21 in the first assembly frame A with glue;

[0053] The step 2.1 includes:

[0054] Step 2.1.1: point glue on the inner edge of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com