Threading machine used for inserting steel wire into core and threading method

A threading machine and steel wire technology, applied in the coupling of optical waveguides, etc., can solve the problems of low reliability, difficulty in adapting to mass production, time-consuming and labor-intensive problems, and achieve the effect of improving threading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The conception, specific structure and technical effects of the present invention are clearly and completely described below in conjunction with the embodiments and accompanying drawings, so as to fully understand the purpose, scheme and effect of the present invention. It should be noted that the embodiments in the present application and the features in the embodiments can be combined without conflict. In addition, the descriptions such as up, down, left, and right used in the present invention are only relative to the positional relationship of the various components of the present invention in the drawings.

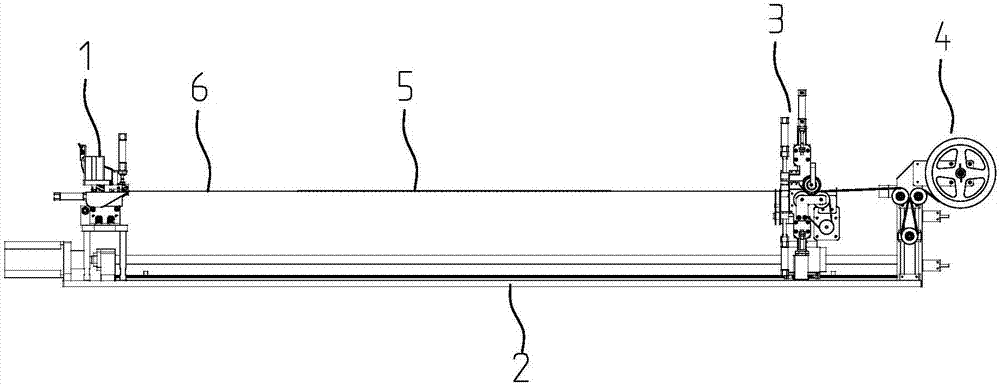

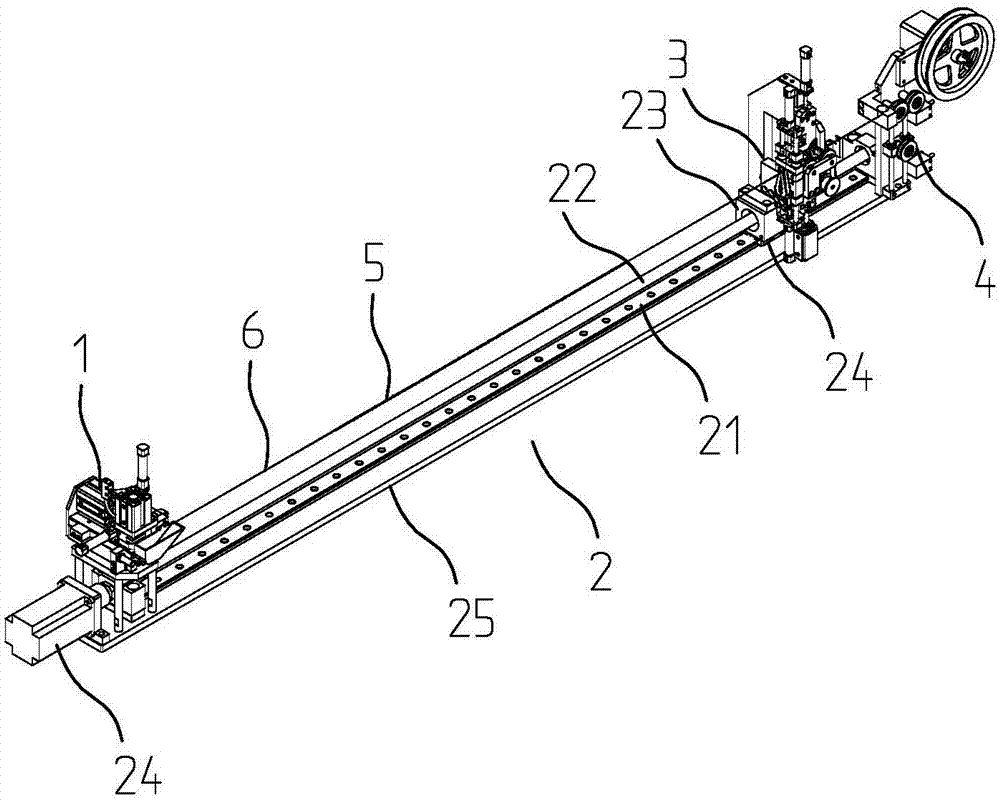

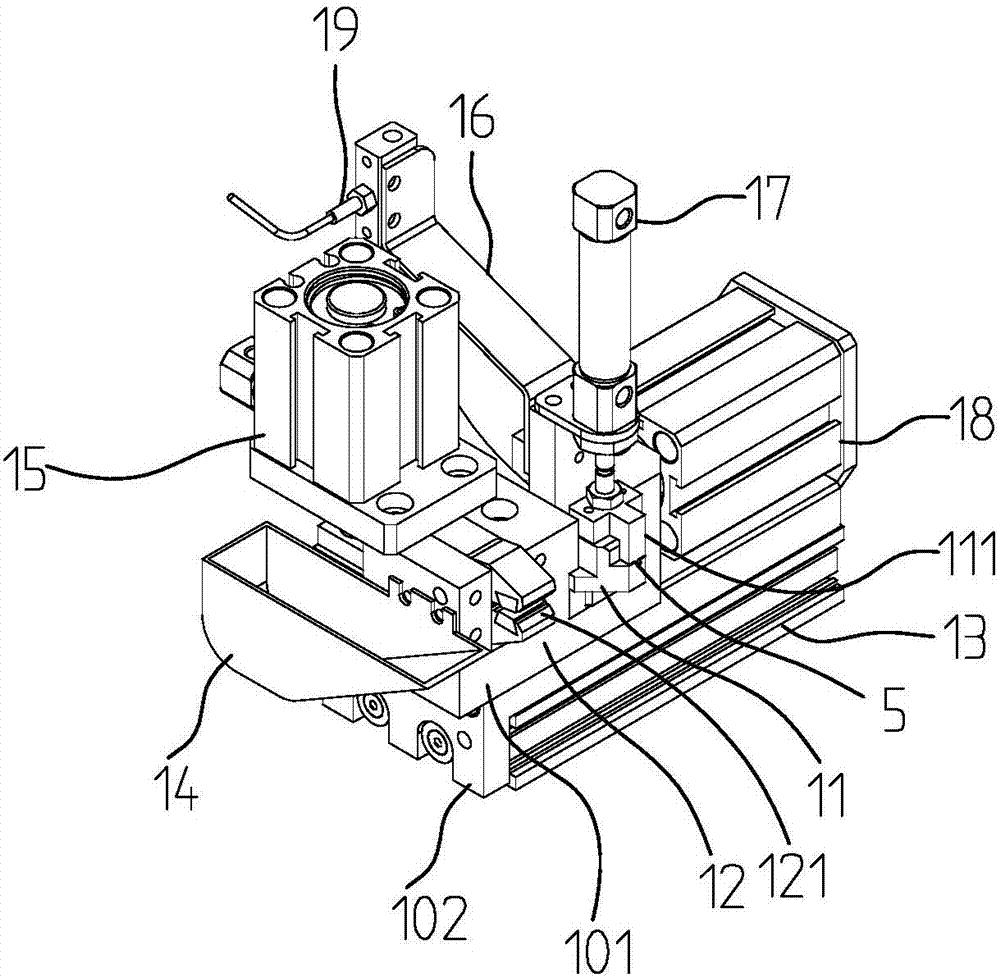

[0036] figure 1 For the stereogram of a kind of threading machine of the present invention, refer to figure 1 , a threading machine for threading steel wires into ferrules includes a feeding and clamping assembly 1, a frame 2, a threading and pulling assembly 3, and a steel wire unwinding device 4; The wire unwinding device 4 is respectively located at the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com