Device for simultaneous handling of several multi-filament threads

A technology for simultaneous processing and multifilament yarns, applied in textile and papermaking, etc., can solve the problems of difficult control, low efficiency, monitoring cross-section, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

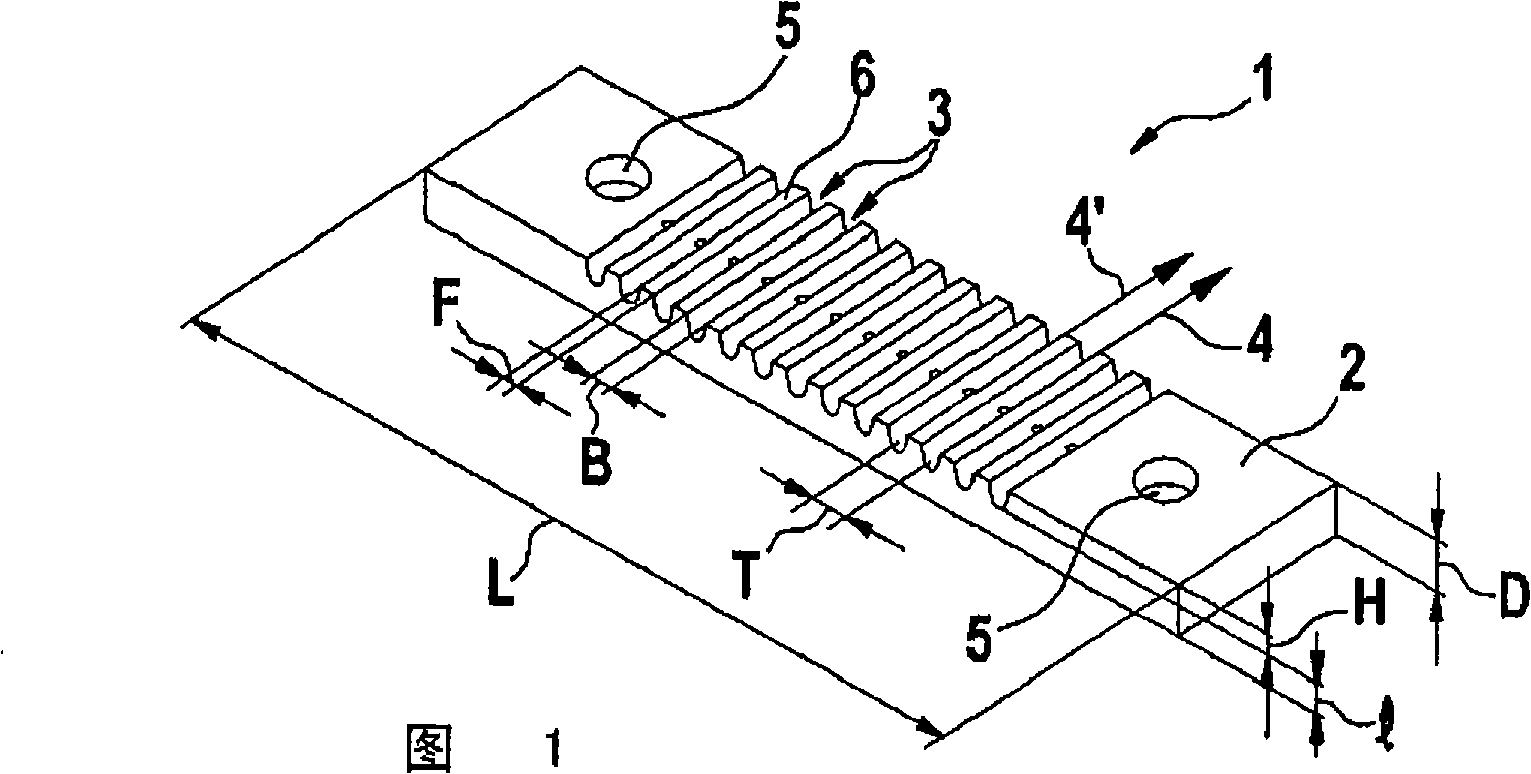

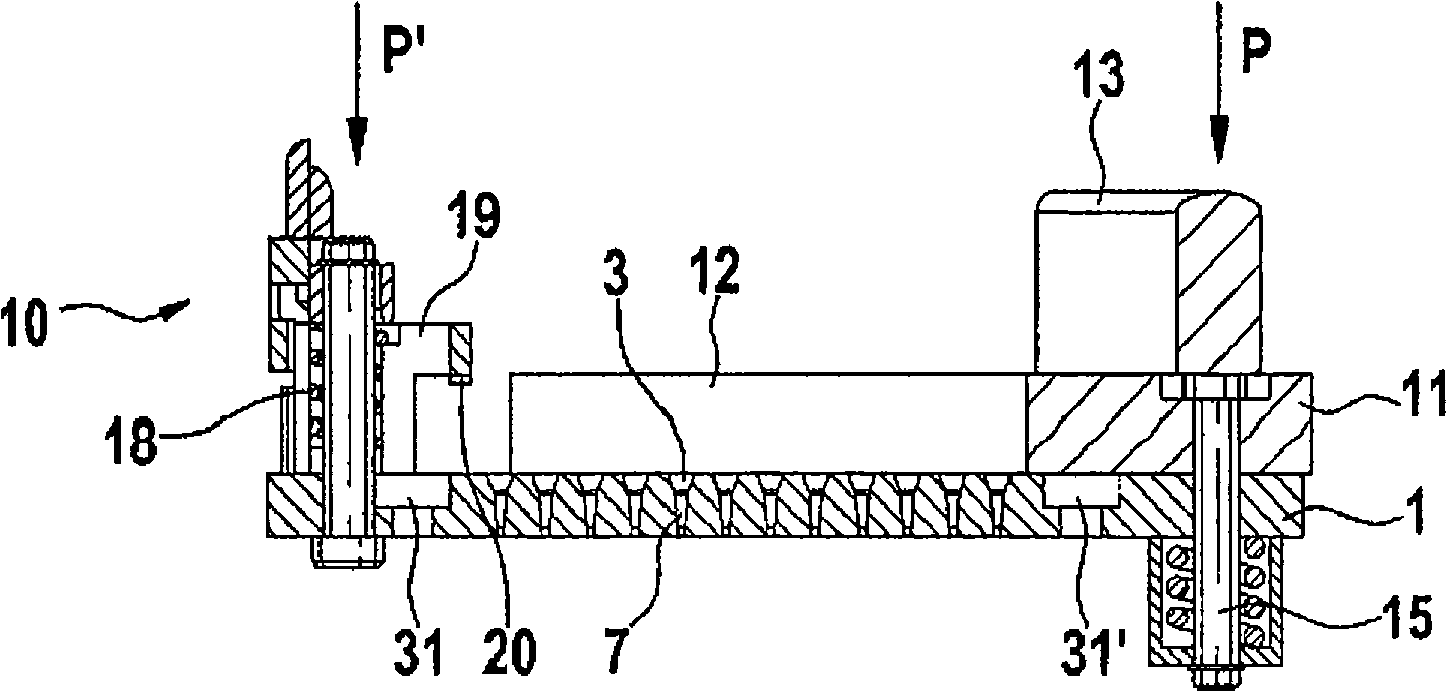

[0057] FIG. 1 shows a nozzle body 1 . The nozzle body 1 is a flat elongated plate 2 on which twelve yarn grooves 3 are introduced. In most cases, all yarn slots 3 of the present application are arranged in parallel, corresponding to the yarn directions 4, 4'. Holes 5 for fastening screws are provided on both lateral end faces of the plate 2 . The thickness of the nozzle body 1 is denoted by D. On the one hand, the thickness D is as important as the height H of the yarn groove 3, and on the other hand, the length 1 of the air duct 7 (see image 3 ) can be fixed or freely preferred. The yarn course or the division of the yarn groove 3 is indicated by T. The overall length of the plate 2 is denoted by the letter L and depends on the number and width B of the thread grooves 3 and the width F of the corresponding surface portion between two thread grooves 3 . In the case of twisting nozzles or moving nozzles, the air duct 7 ( image 3 ) vertically or obliquely. The shape and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com