Patents

Literature

31results about How to "Won't run out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

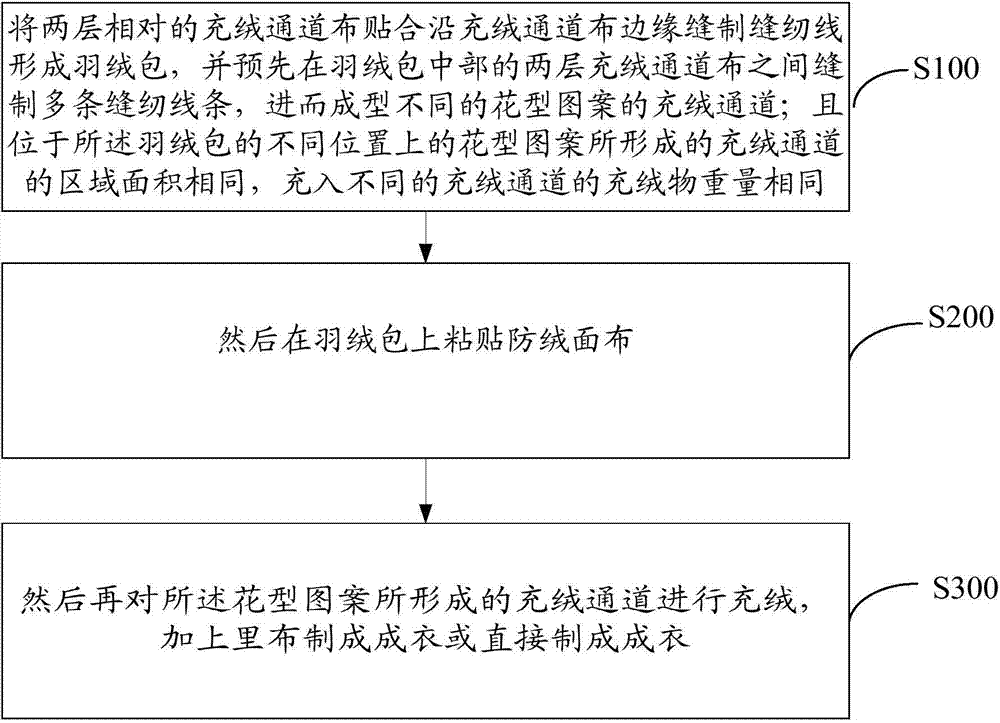

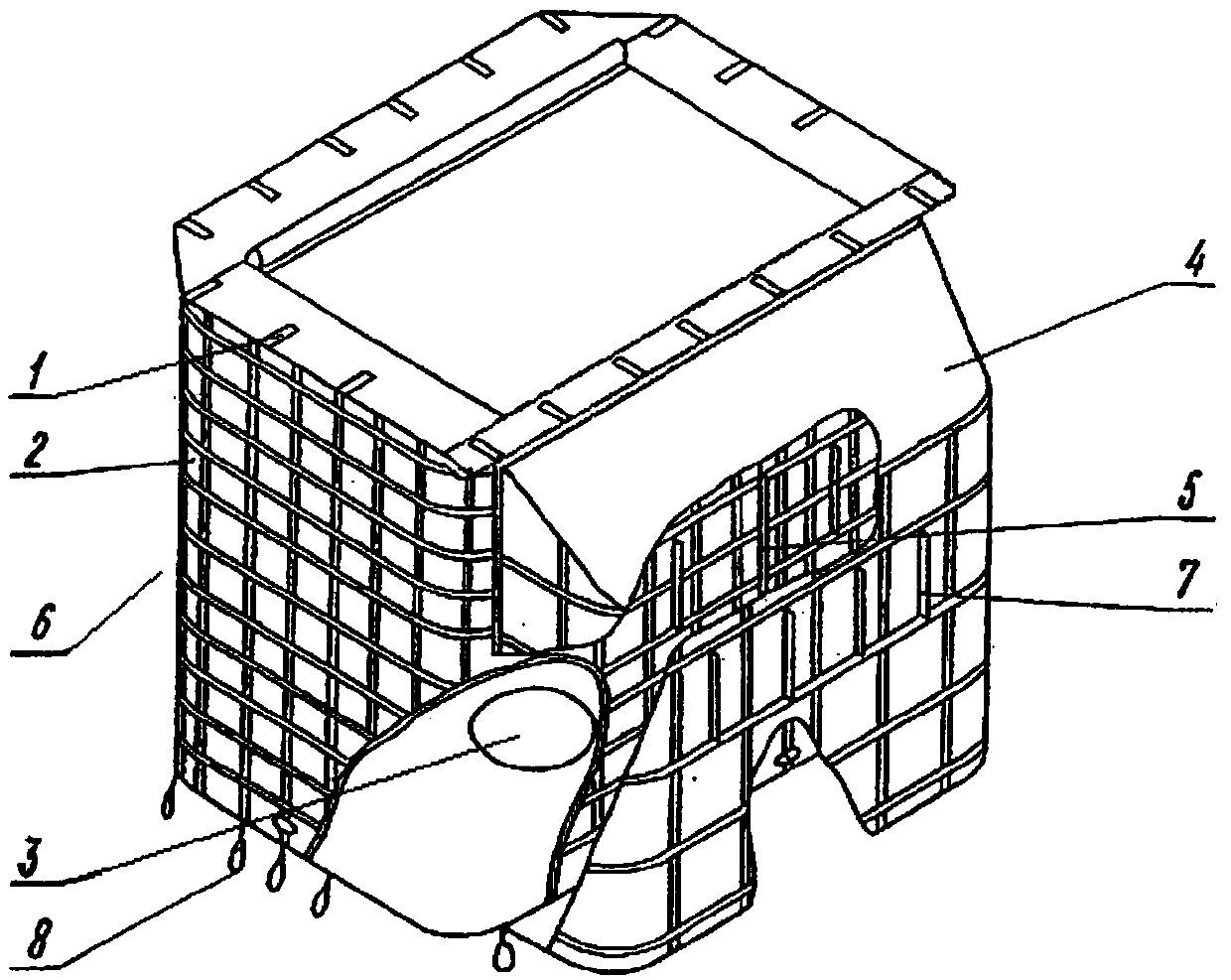

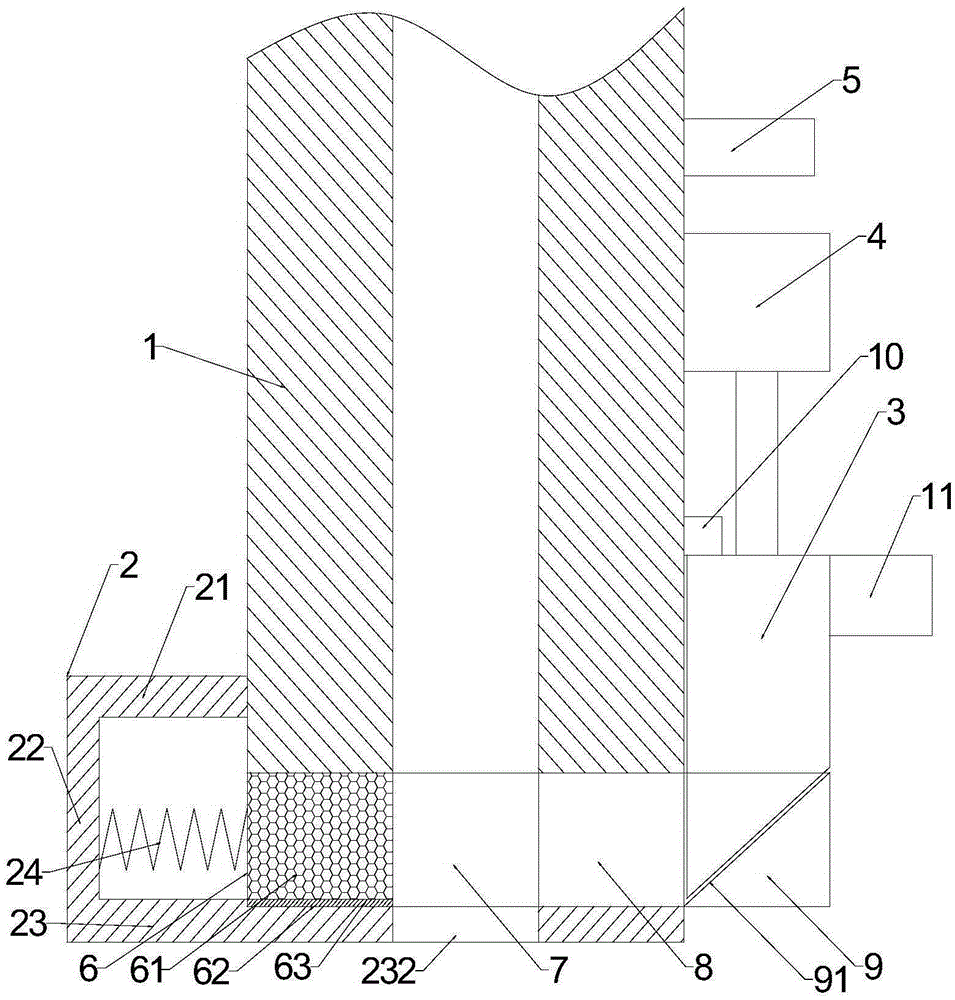

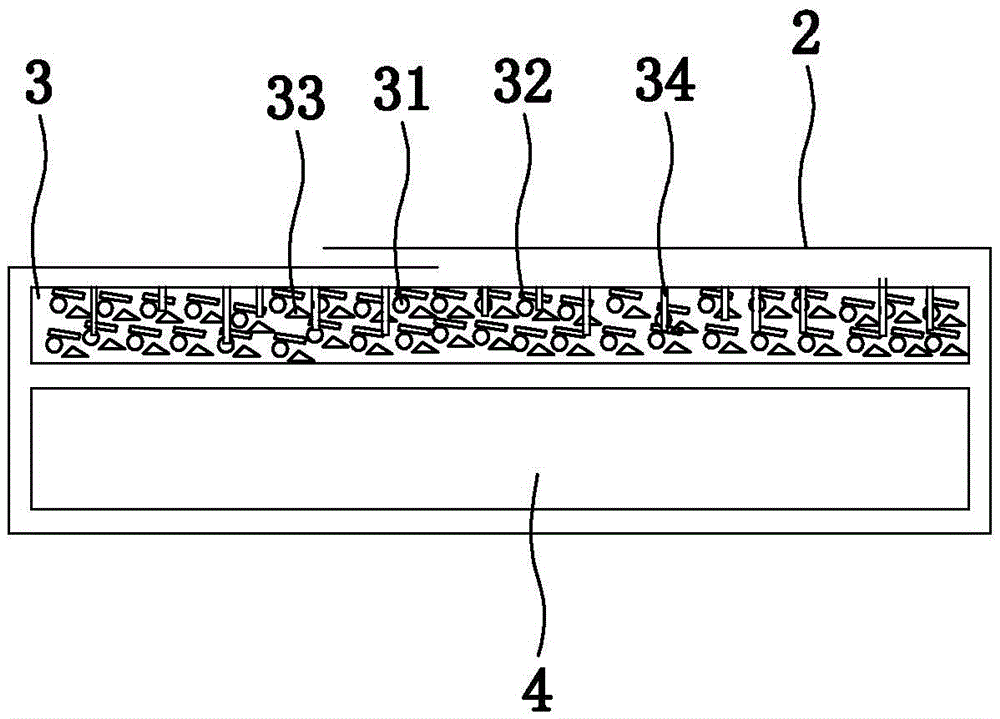

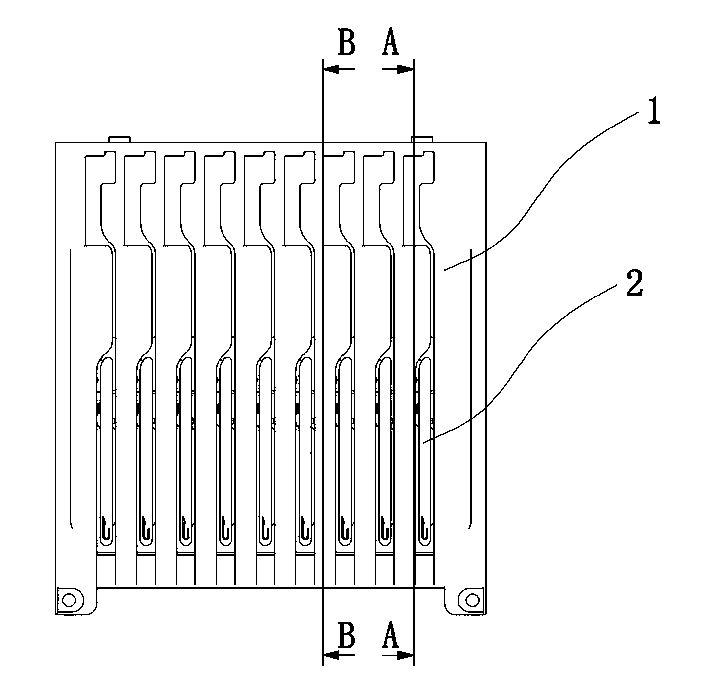

Manufacturing method of down feather escape-free down jacket and down feather escape-free down jacket

InactiveCN104705880AAvoid uneven thicknessWon't run outOvergarmentsProtective garmentEngineeringMechanical engineering

The invention discloses a manufacturing method of a down feather escape-free down jacket and the down feather escape-free down jacket. The manufacturing method comprises the following steps: pre-sewing a plurality of sewing threads between two pieces of down feather filling channel cloth in the middle of a down feather bag so as to mould down feather filling channels with different patterns; then adhering down feather resisting shell cloth on the down feather bag; and then filling down feather into the down feather filling channels formed by the patterns and adding liner cloth to prepare product clothes or directly preparing product clothes. The manufacturing method of the down feather escape-free down jacket and the down feather escape-free down jacket disclosed by the invention can be used for mainly solving the problems that down feather of a conventional down jacket in the market escapes, is pressed and split in a nonuniform manner and the like.

Owner:江志宏

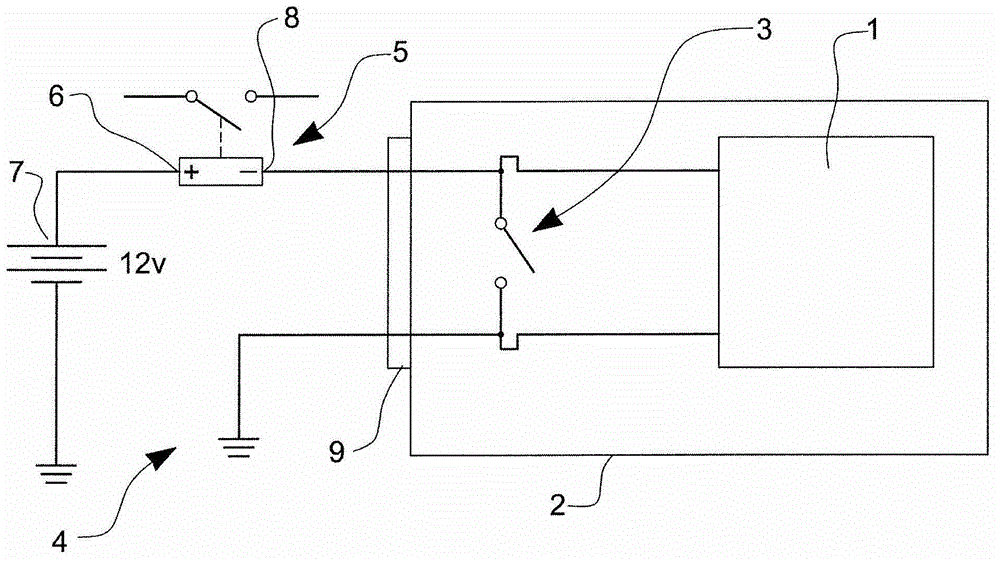

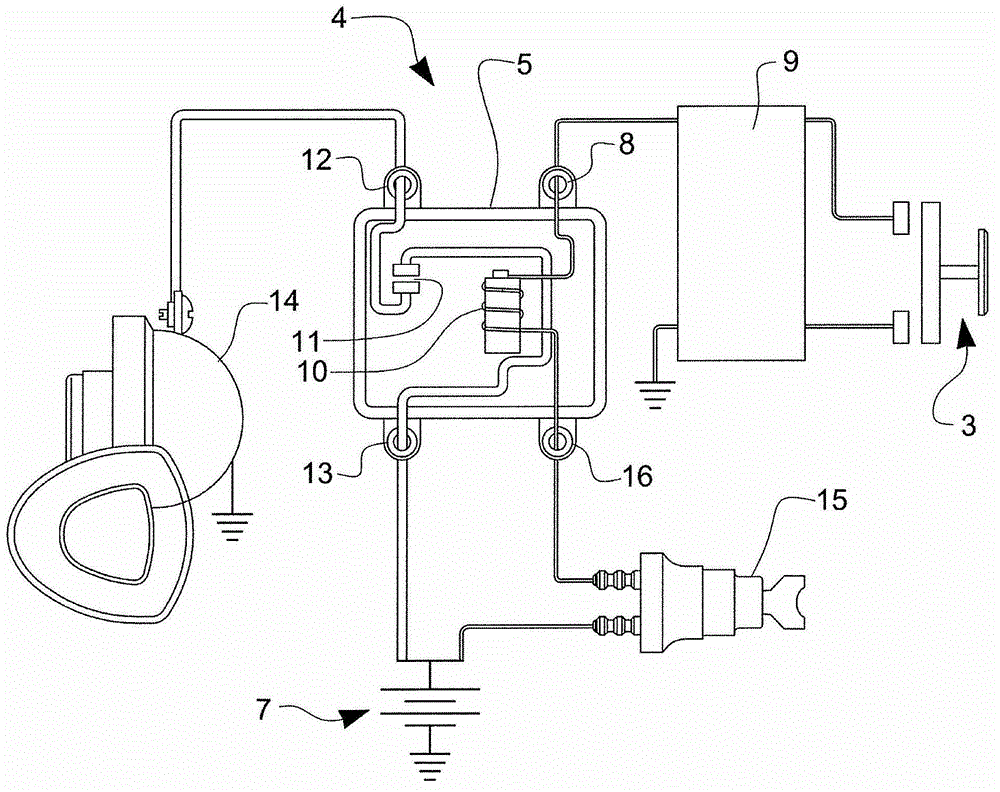

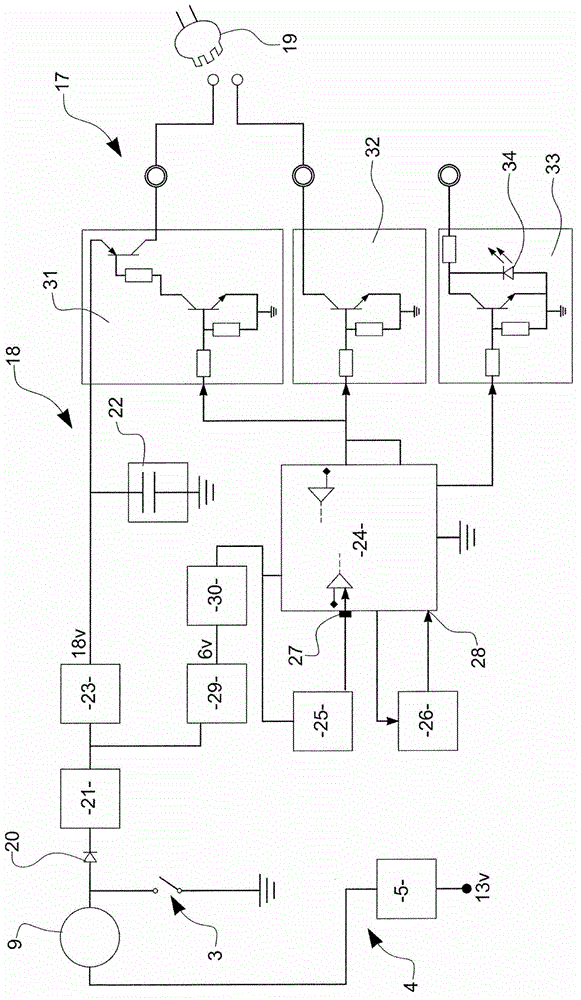

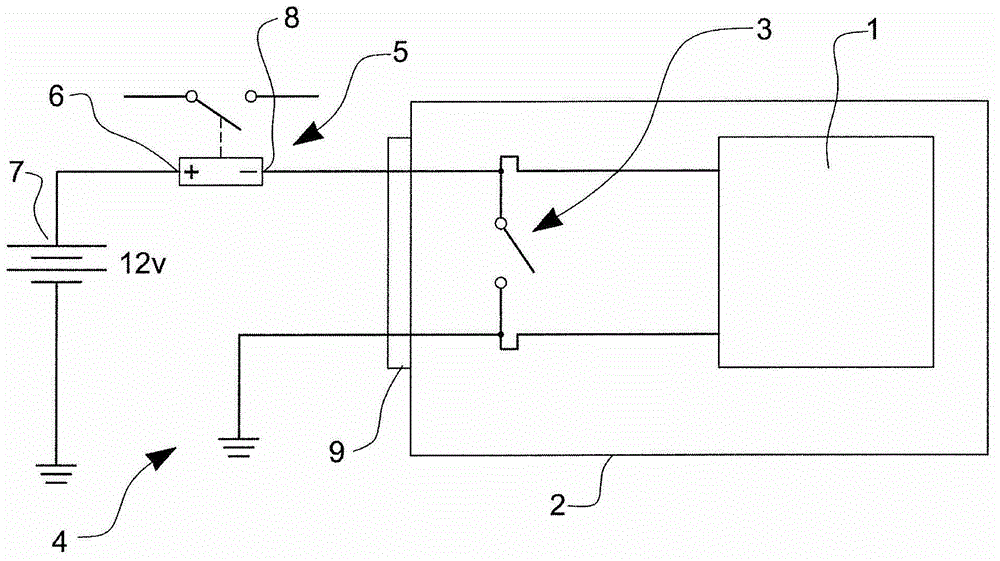

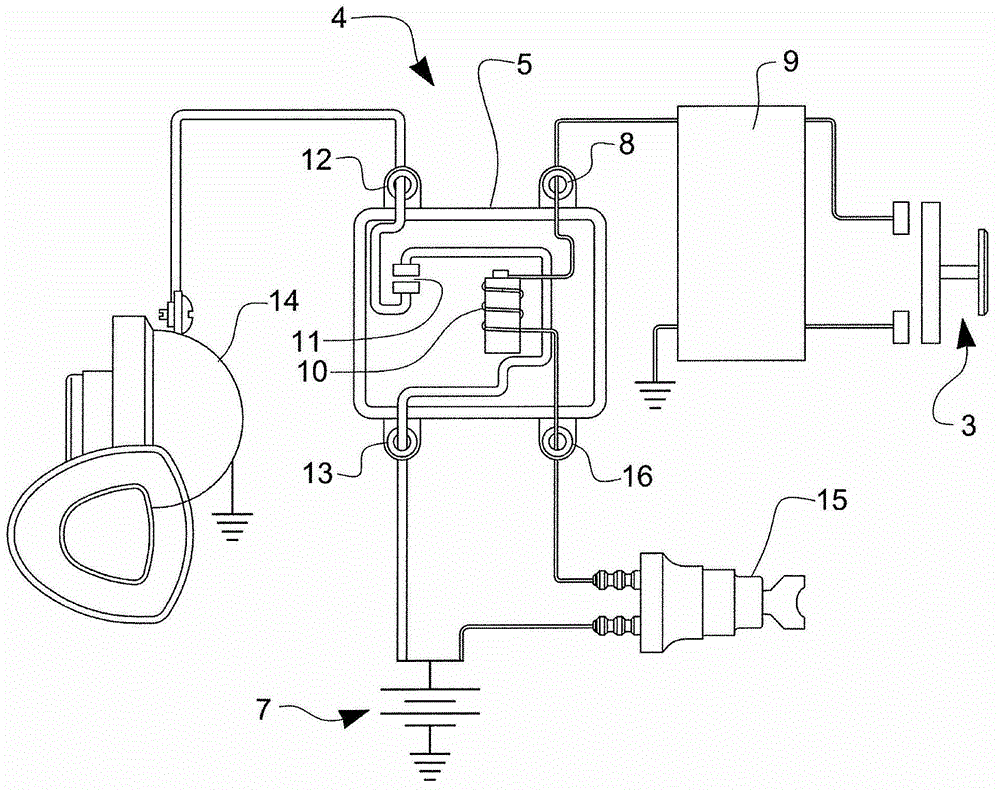

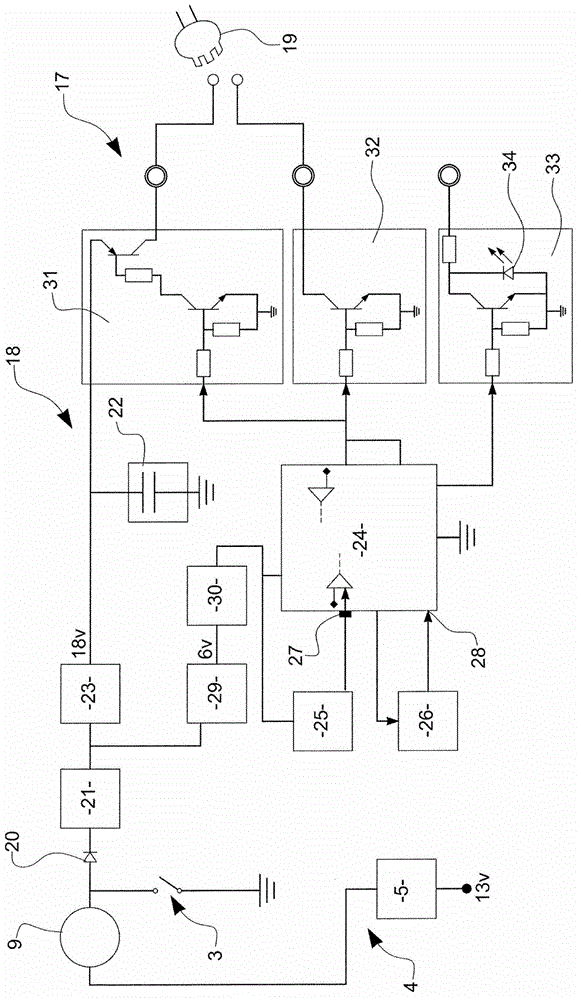

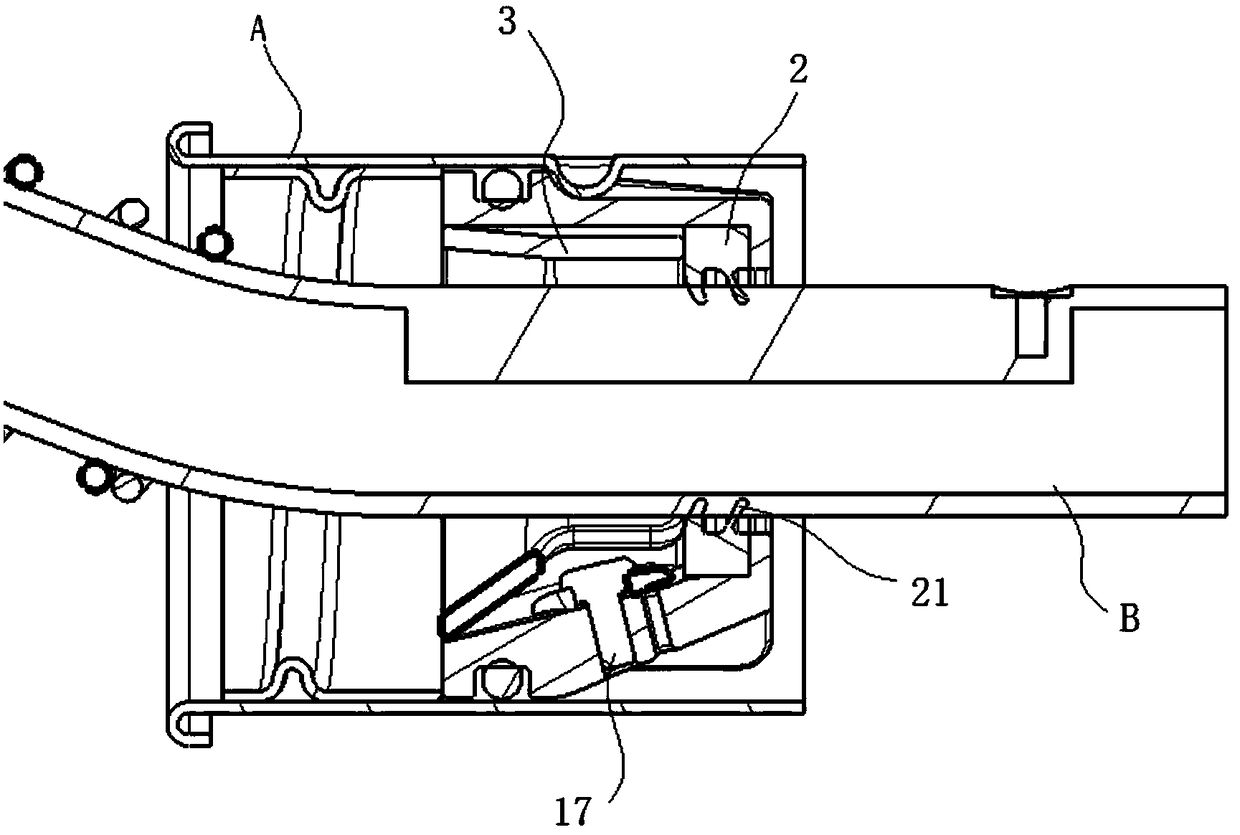

An airbag control arrangement

There is disclosed an airbag control arrangement for a steering-wheel mounted airbag in a motor vehicle having a steering-wheel mounted function switch, such as horn-switch. The arrangement comprises an airbag control circuit mounted to the steering wheel and including a first acceleration sensor, a second acceleration sensor, and a controller. The airbag control circuit is electrically connected to an auxiliary function circuit (e.g. a horn circuit) incorporating said function switch so as to derive operative electric power from the auxiliary function circuit. The controller is configured to output an actuating signal only in response to the receipt of signals from both acceleration sensors. The airbag control circuit is configured to switch from a sleep mode to an operative mode in dependence on an output signal from the first acceleration sensor; the second acceleration sensor being off and the controller drawing a low sleep-current current in said sleep mode, but both being energised and operable in said operative mode.

Owner:维宁尔瑞典安全系统公司

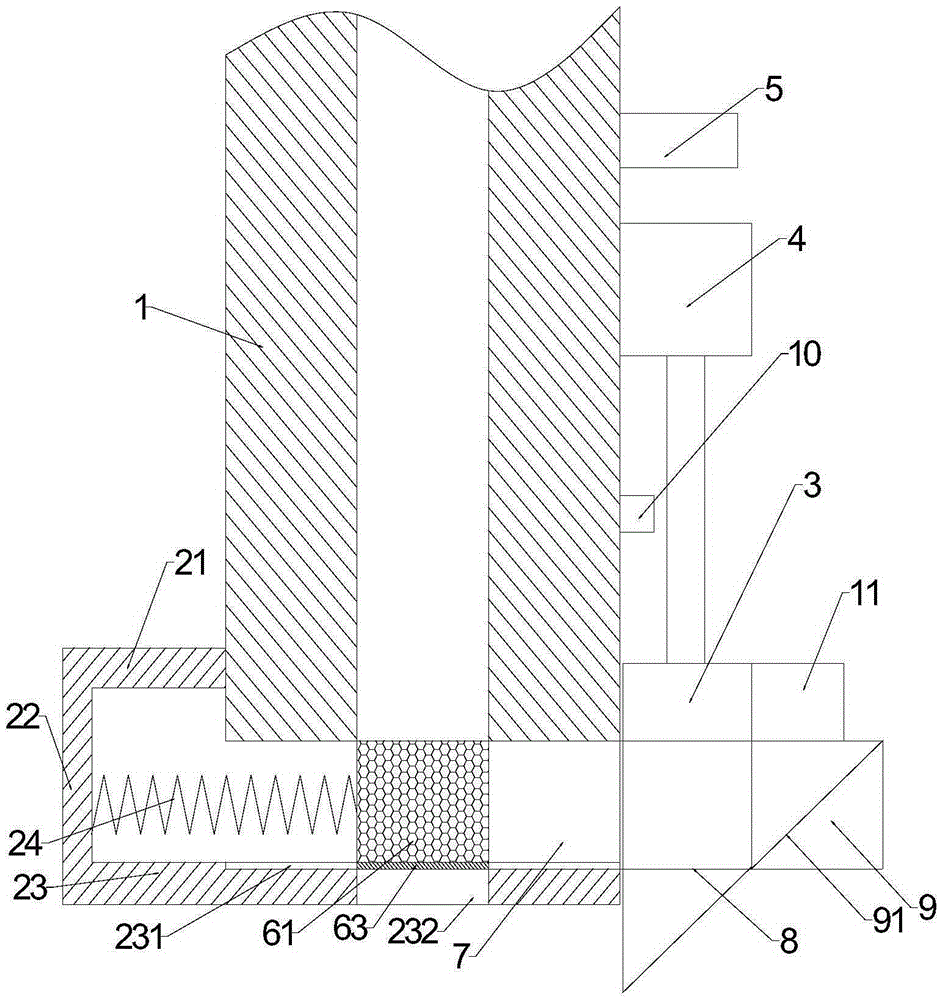

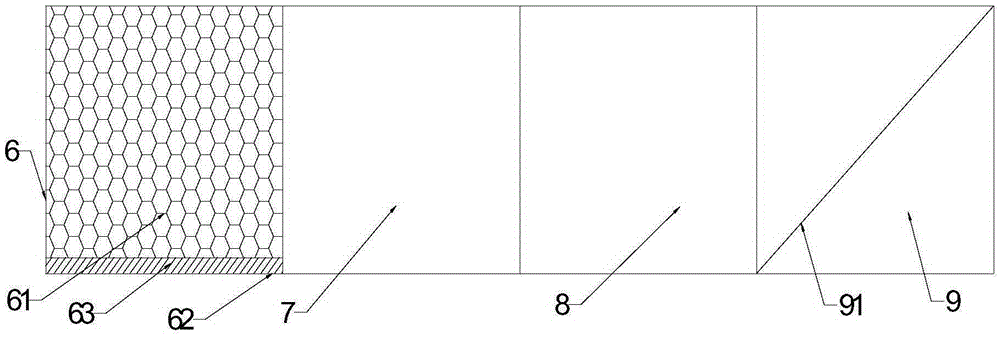

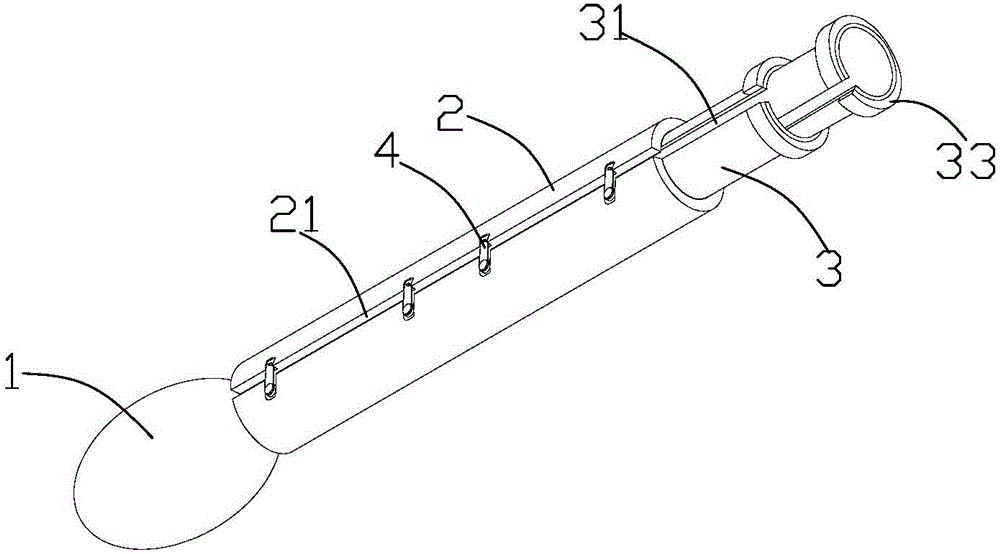

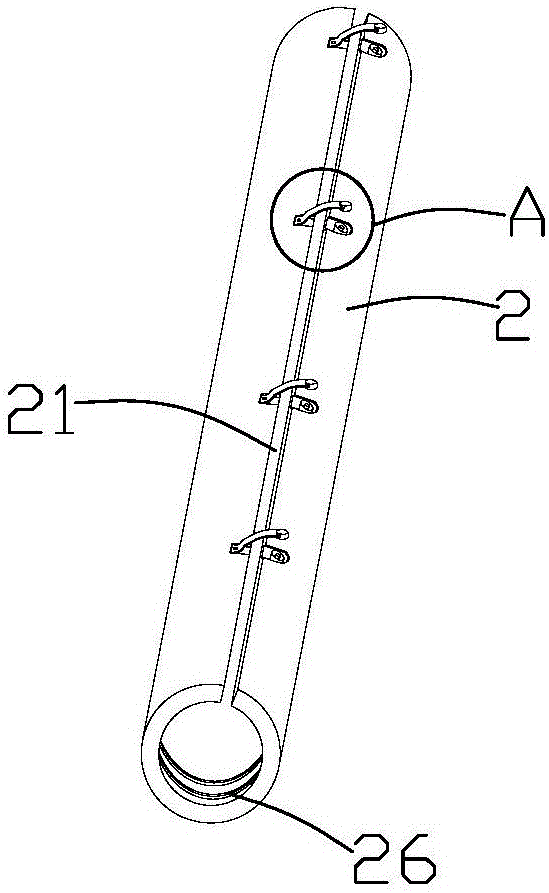

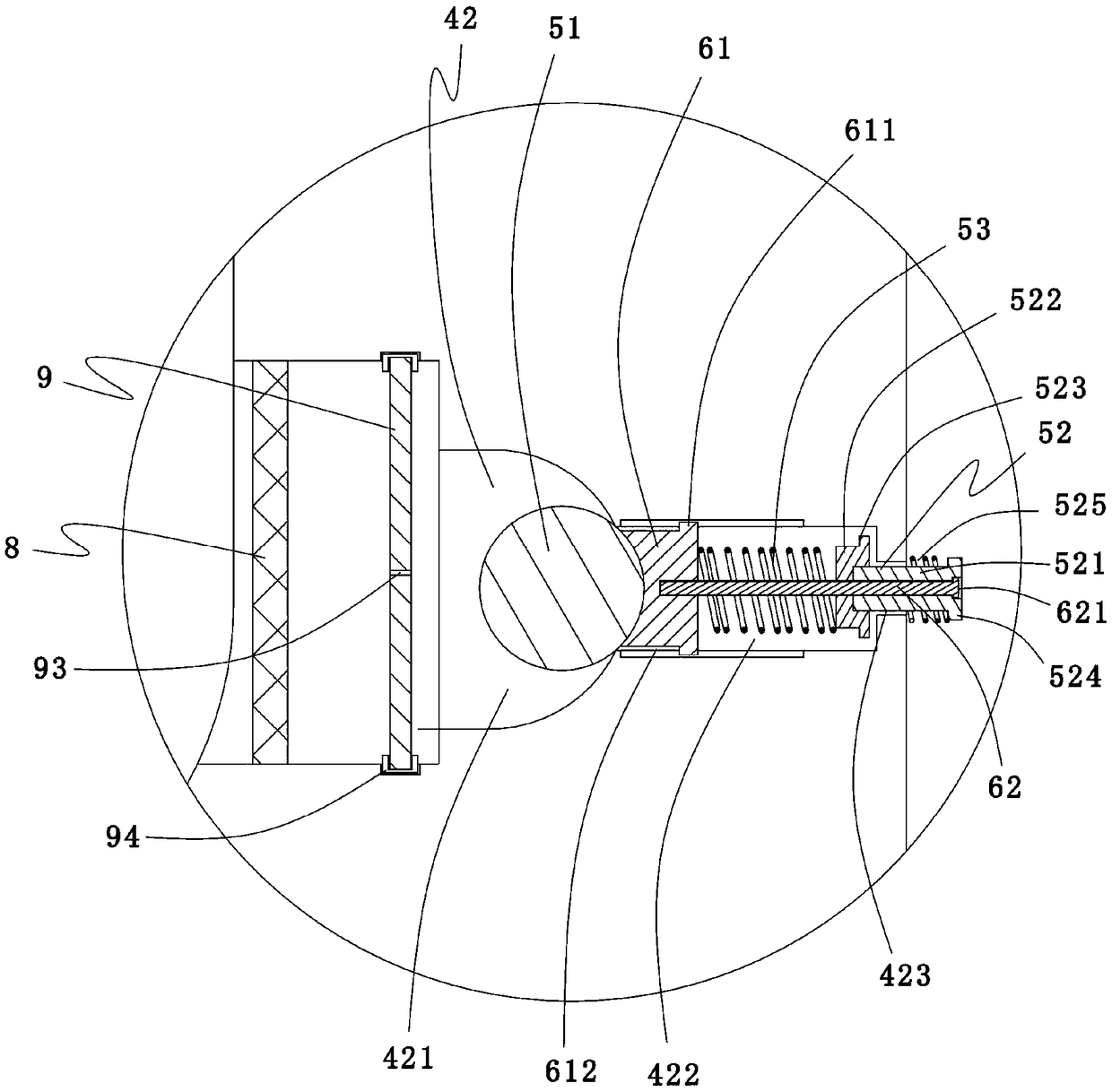

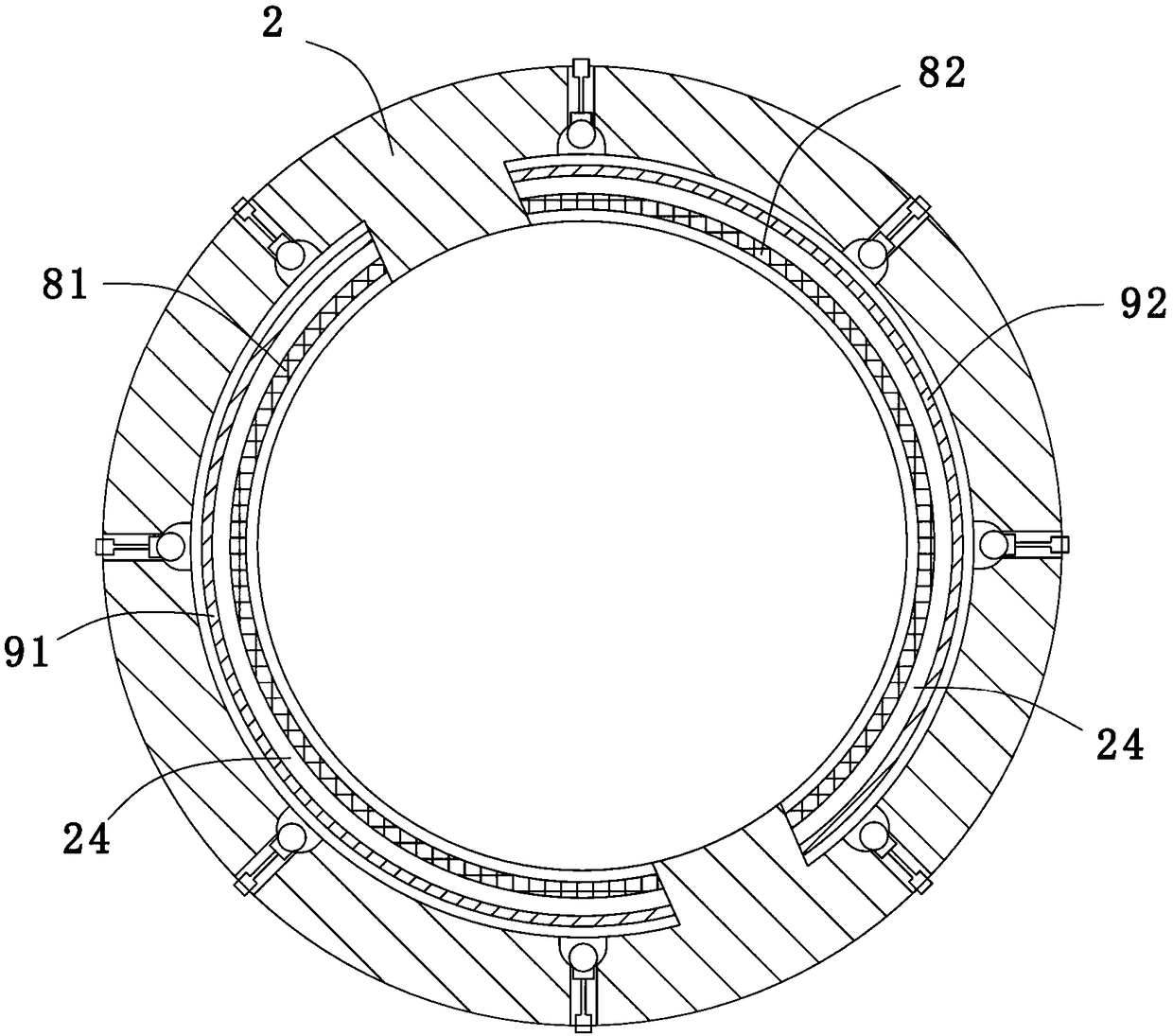

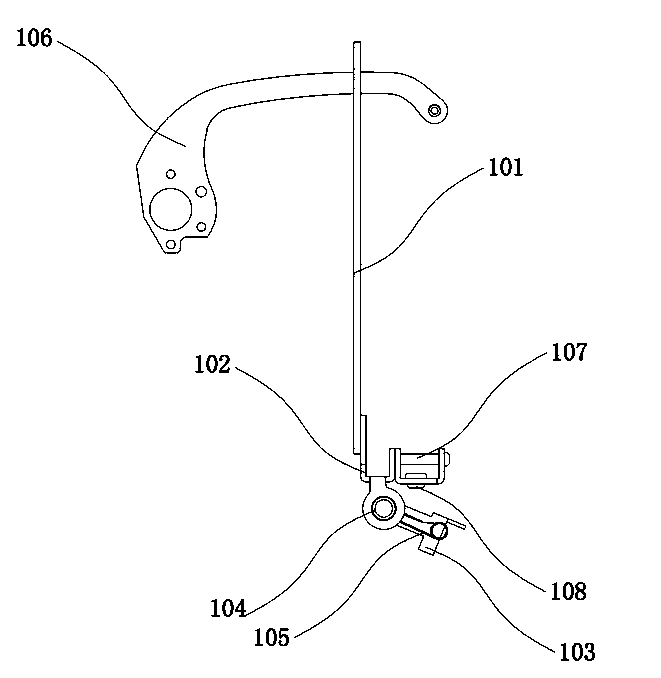

Threader for information room

A threader for an information room comprises a guide head and a telescopic rod body formed by at least two sleeves sleeved together; the guide head comprises two semi-shells, a placement block is arranged in one semi-shell, a cable groove is formed in the placement block, and a pressing block is arranged in the other semi-shell; one semi-cylinder is arranged at the tail end of each semi-shell, and a groove is formed in each semi-cylinder; each sleeve is provided with a strip-shaped opening; a first chute and a second chute are arranged on the inner side of each sleeve, and a first through hole and a second through hole are respectively formed in the first chute and the second chute; except the outermost sleeve, a wave bead screw is arranged at the front end of each sleeve. According to the threader for the information room, the floor with large area is not required to be lifted, the threading is convenient and damage-free, cables can be arranged in order, and the wiring is facilitated.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

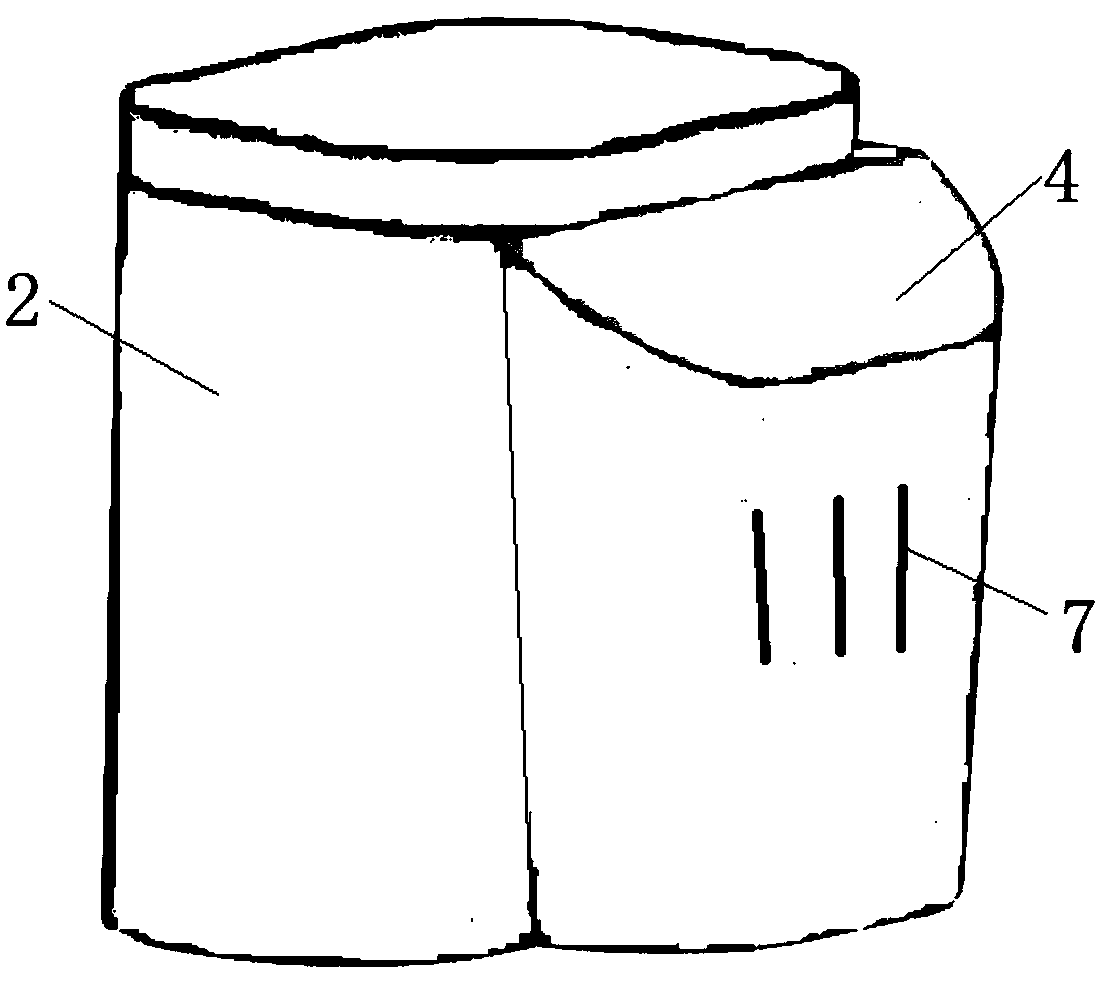

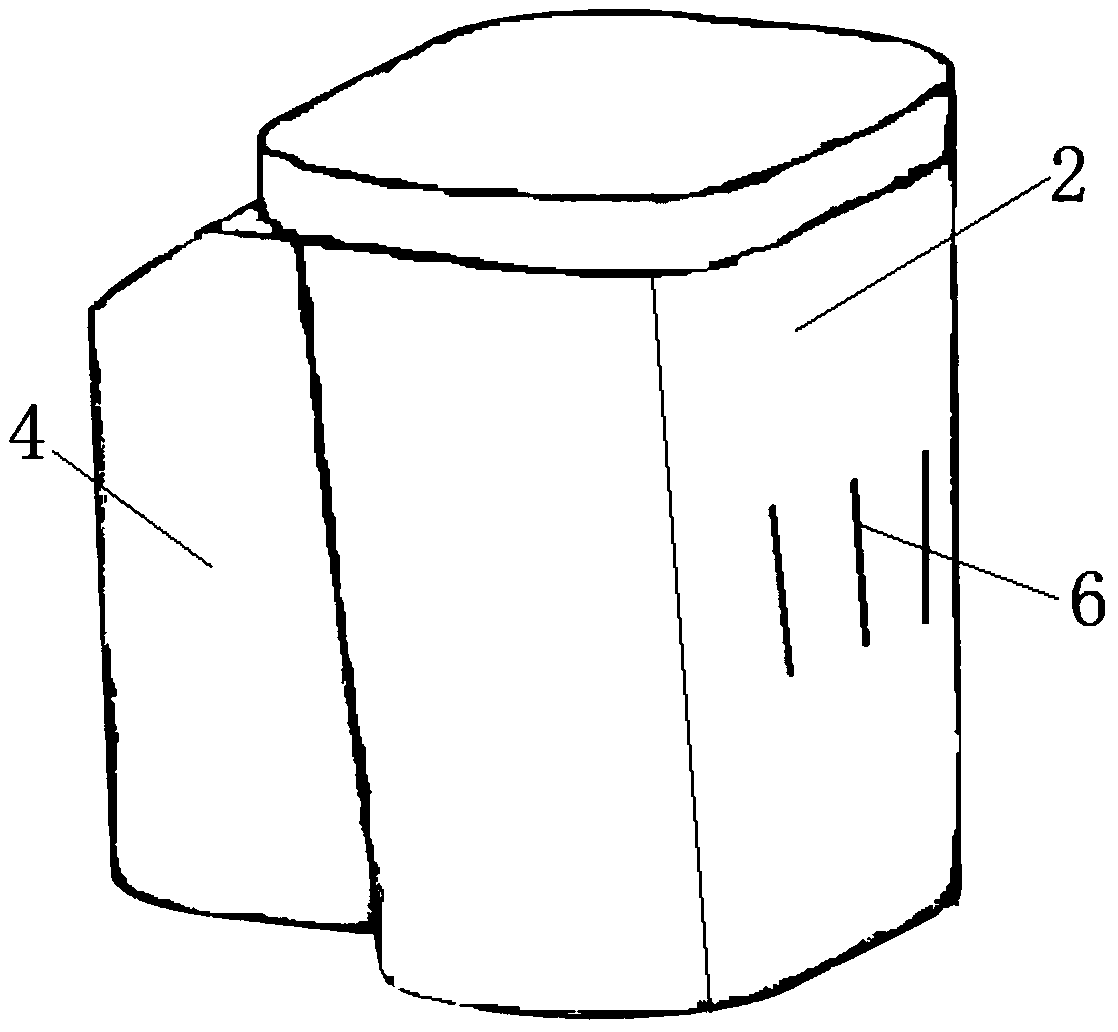

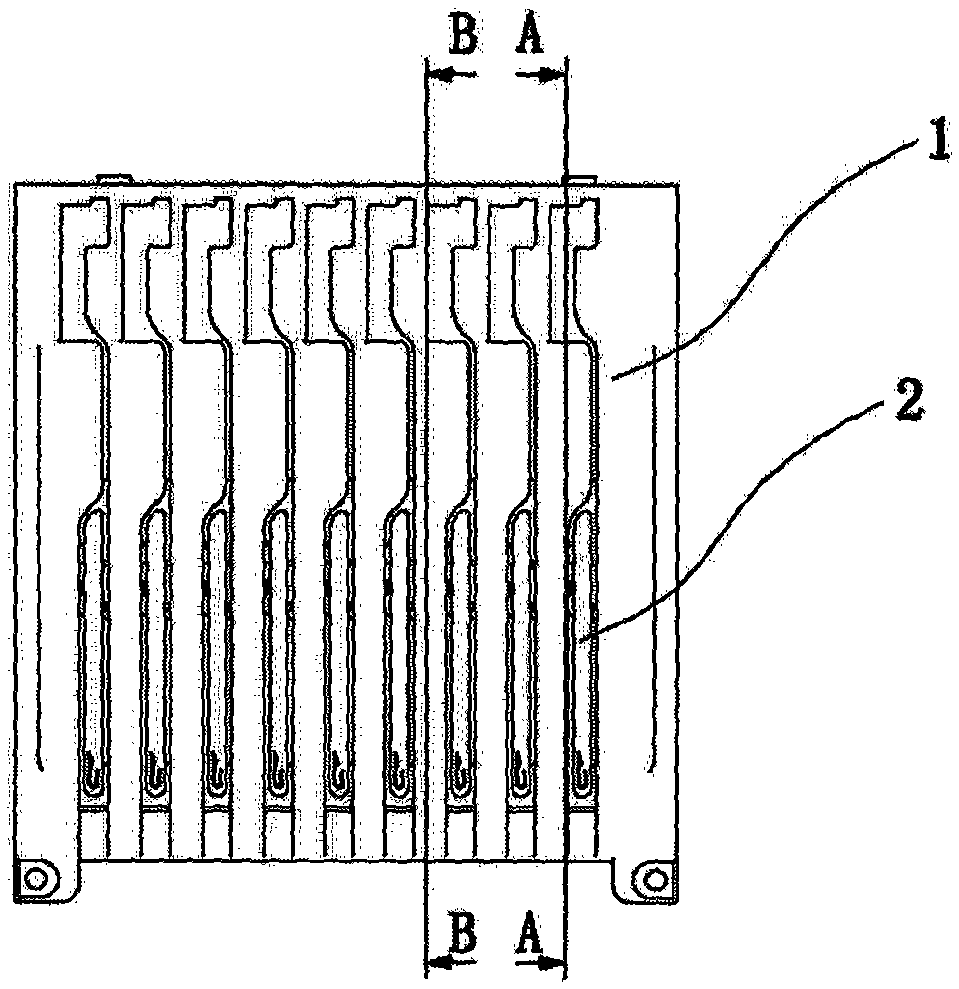

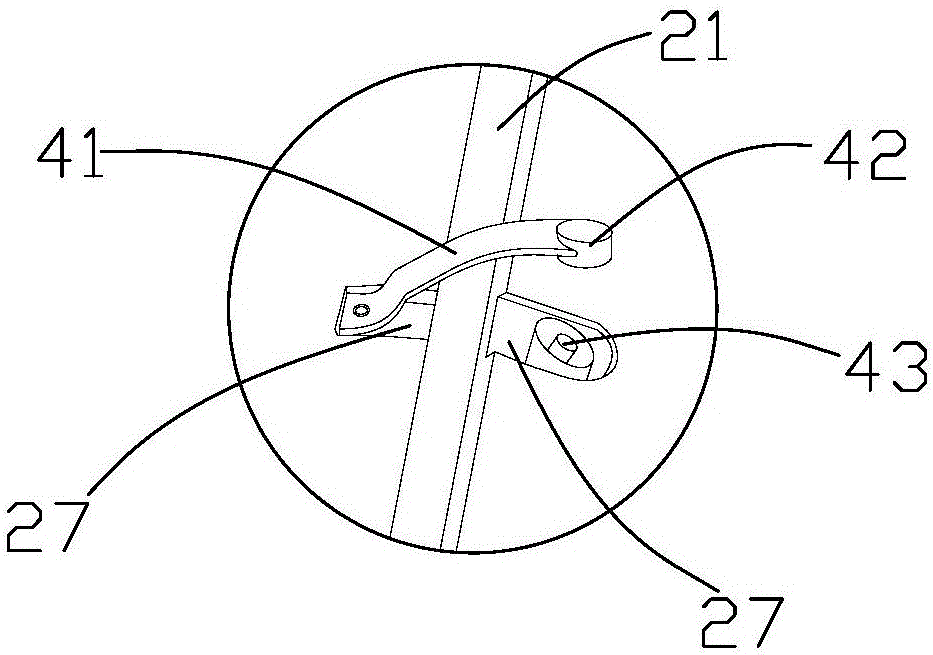

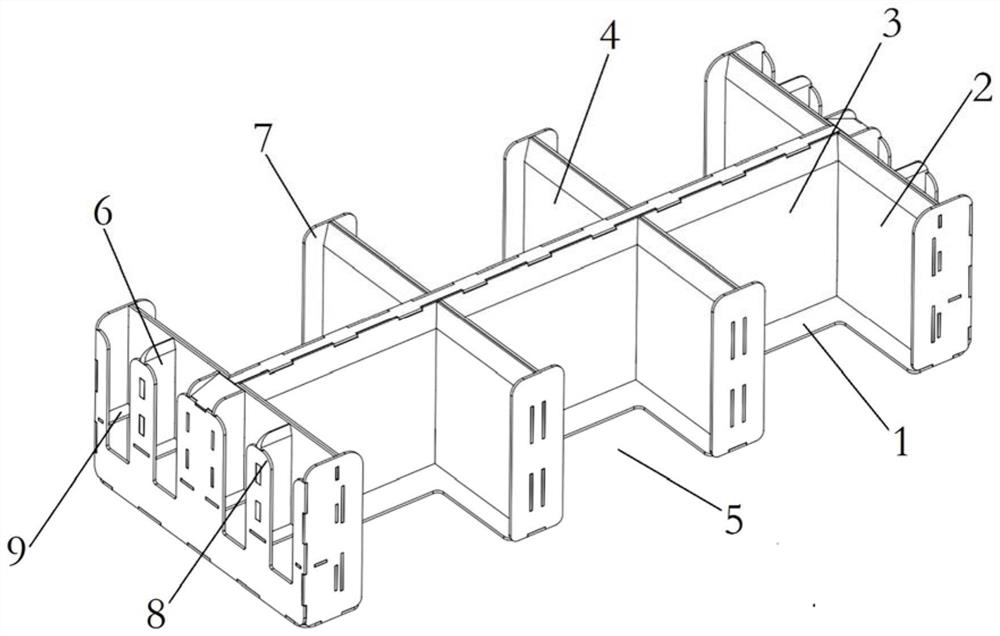

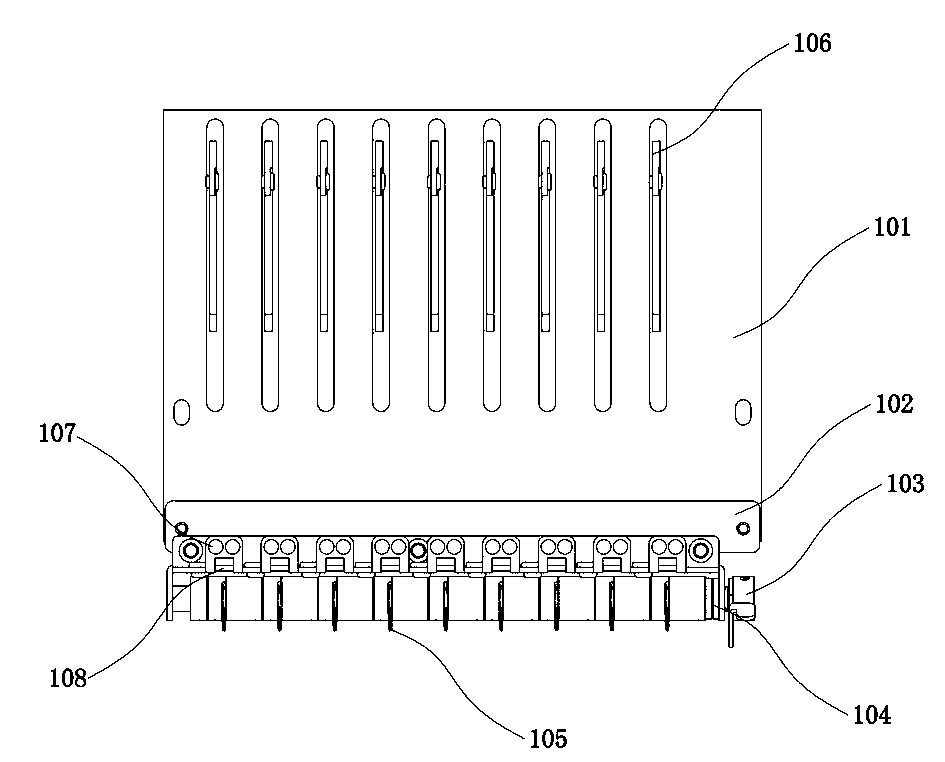

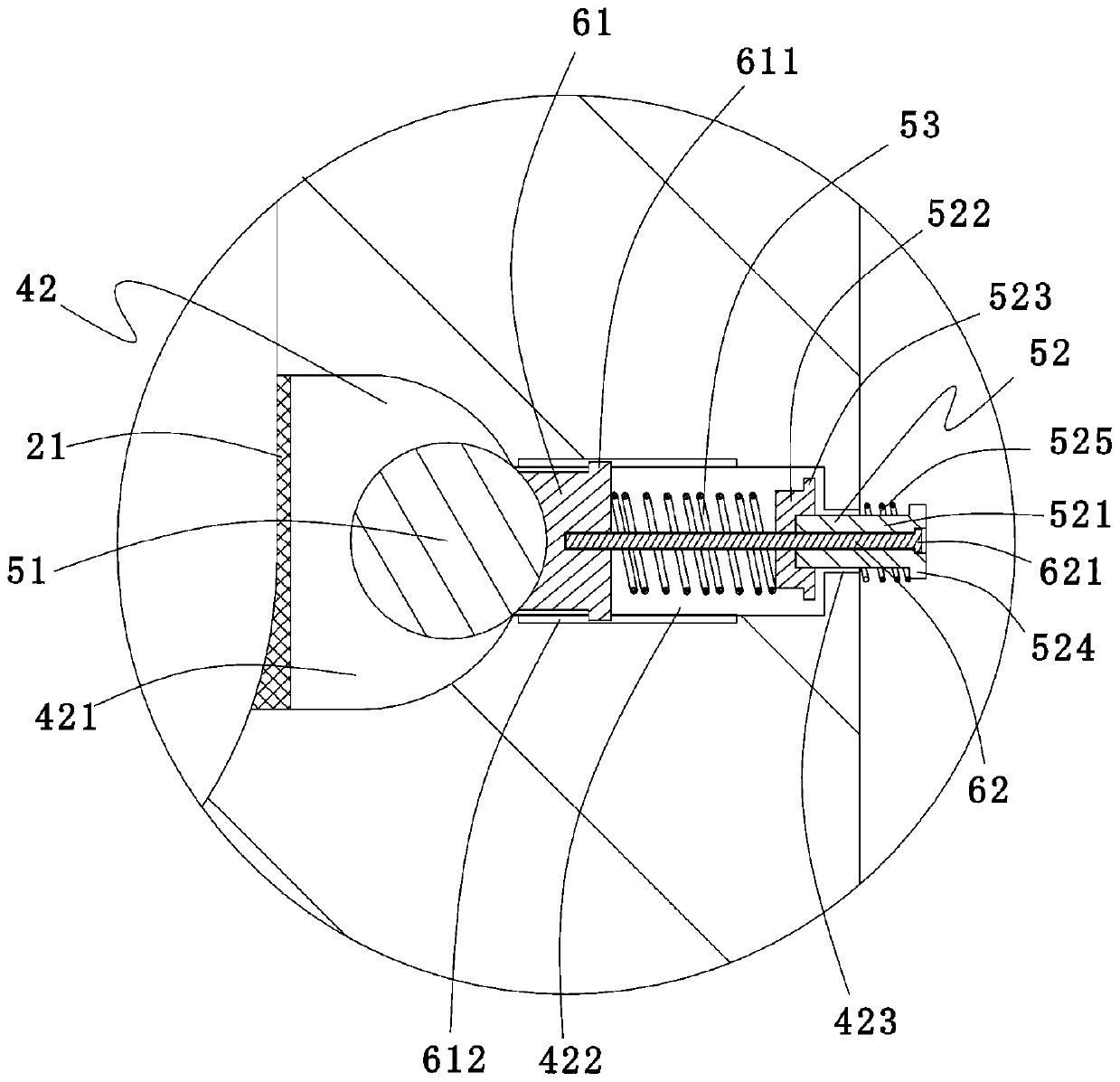

Yarn-passing device of embroidery machine

InactiveCN102140742AIncrease production capacityNo damageEmbroidering machines apparatusYarnEngineering

The invention discloses a yarn-passing device of an embroidery machine, which comprises a base, wherein the base comprises a bottom plate and a face plate, the middle of the face plate is bulged outwards, both sides of the face plate are connected to the bottom plate, and a hollow cavity is formed between the face plate and the bottom plate; a plurality of yarn-passing assemblies are arranged in the cavity and respectively comprises a holding plate arranged on the bottom plate, the front sides of the holding plates extend out of the cavity from the face plates, and both sides of the holding plates, passing through the face plates, are provided with yarn-passing slots; and a tension regulator is arranged on one of the side face of the holding plates, and a take-up spring is arranged on thetension regulator and is provided with a tension spring end sleeved on the tension regulator and a take-up hook end extending out of the tension regulator. The whole yarn-passing device is a claddingbody; all assemblies are covered in the base so that the operators can not touch the moving parts of the yarn-passing device, thereby not resulting in part damages and personnel injuries.

Owner:DONGYANG JIALUN ELECTRONICS MACHINERY

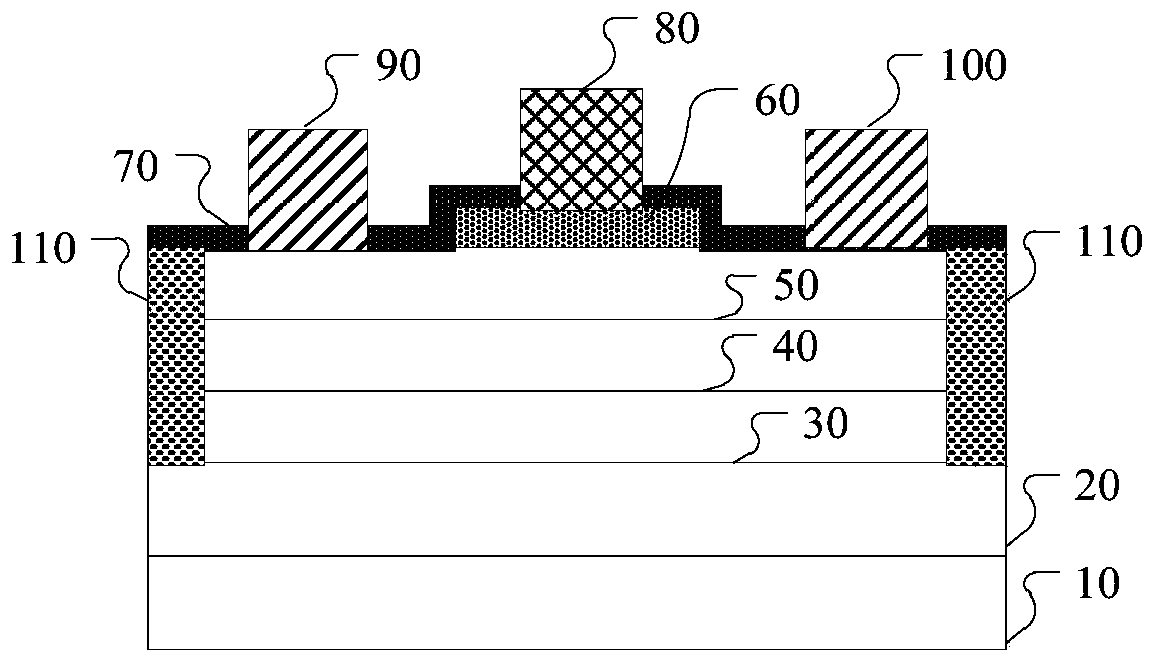

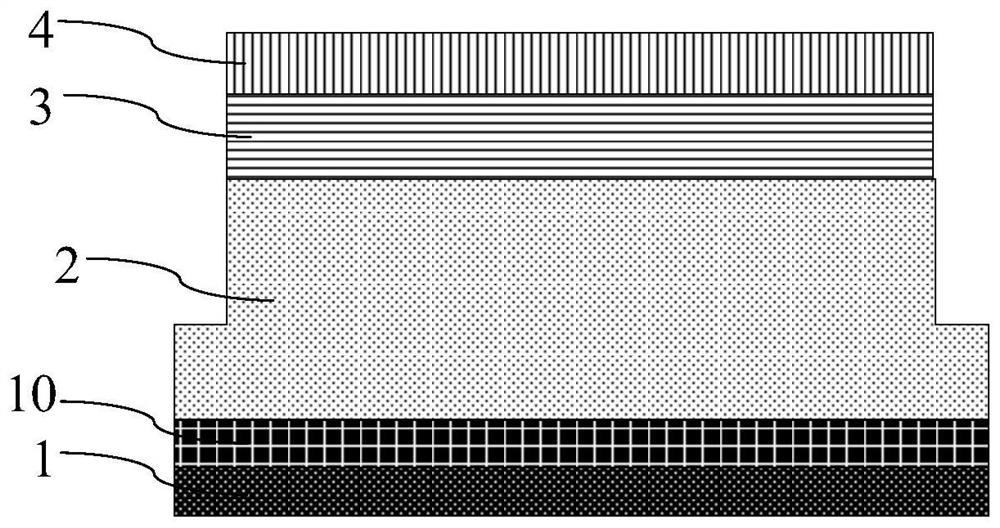

GaN-based field effect transistor and preparation method thereof

InactiveCN110690284ANo damageWon't run outSemiconductor/solid-state device manufacturingSemiconductor devicesDopantEtching

The embodiment of the invention discloses a GaN-based field effect transistor and a preparation method thereof. The GaN-based field effect transistor structurally comprises a substrate, a buffer layer, a back barrier layer, a channel layer, a barrier layer, a p-type gate layer and a passivation layer; a gate electrode which is in contact with the p-type gate layer; a source electrode and a drain electrode which are in contact with the barrier layer, wherein the gate electrode is located in the first region, the source electrode and the drain electrode are located in the second region, and thep-type dopant of the p-type gate layer in the film layer of the second region is not activated. According to the technical scheme, the gate etching process is remarkably improved, the problem that p-type materials must be completely removed in a traditional process is solved, the error-tolerant rate of etching is lower, the method is suitable for mass production, the width of a process window of gate etching is increased through the technical method, the method is not limited by the precision of the etching process, and gate electrode etching is high in controllability and good in repeatability.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

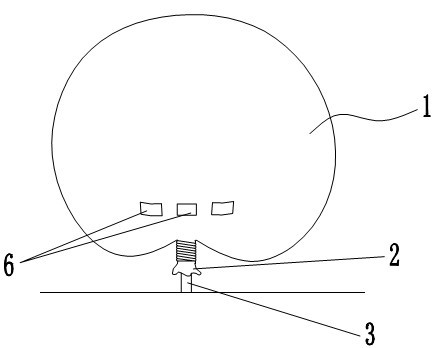

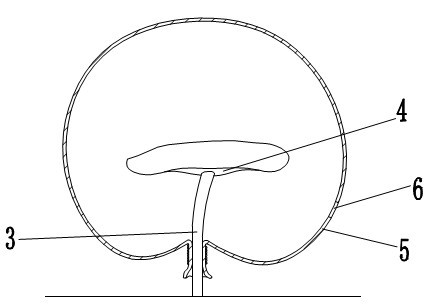

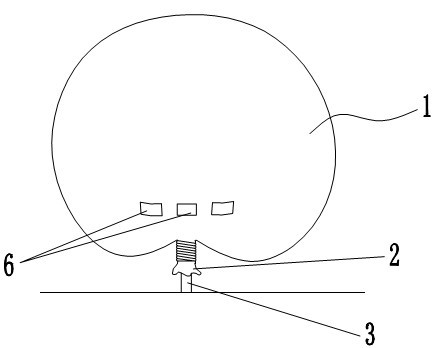

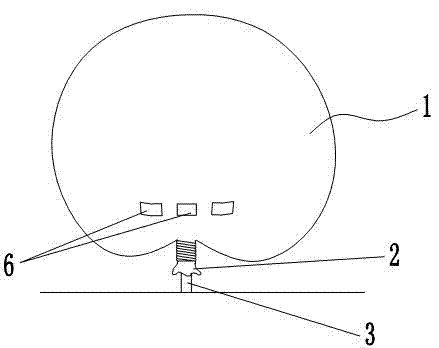

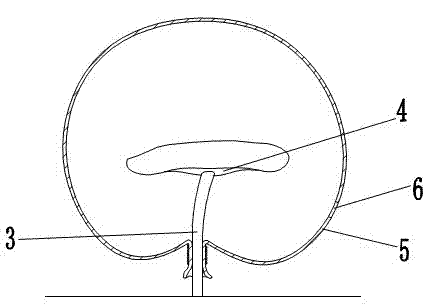

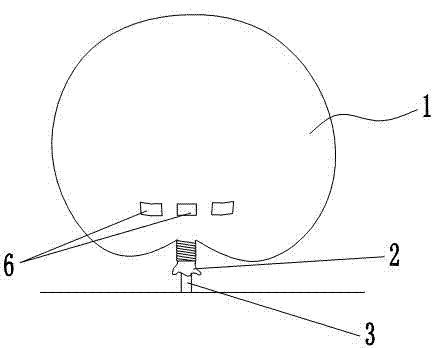

Ganoderma spore powder acquisition method and acquisition bag thereof

The invention discloses a ganoderma spore powder acquisition method, comprising the following steps: when acquiring the ganoderma spore powder, covering an acquisition bag outside the ganoderma pileus; fastening the opening of the acquisition bag on the ganoderma stipe; arranging a group of air vents at the lower part of the acquisition bag; the air vents are positioned below the ganoderma pileus; taking down the acquisition bag after acquiring for a while; and collecting the pore powder in the acquisition bag and on the ganoderma stipe. In the invention, a light acquisition bag with a transparent film is fastened on the ganoderma stipe to carry out ganoderma pore powder acquisition; air vents are arranged on the side wall of the acquisition bag and below lamella horizontal position to lead the inner and outer conditions of the acquisition bag to reach unanimity, thus all the ganoderma spore powder ejected from lamella can be collected; and the ganoderma spore powder has high yield, is not affected by damp, and has good quality. The method of the invention has simple and convenient operation, can be used in no need of guidance of technical personnel, and is suitable for popularization and application.

Owner:浙江龙泉佳宝生物科技有限公司

Air-drop self-falling gasbag with buffering effect

PendingCN107640319AWon't run outPlay a buffer roleAircraft componentsLaunching weaponsButt jointEngineering

The invention discloses an air-drop self-falling gasbag with a buffering effect. The gasbag comprises a buffering gasbag body and a base plate, the lower end of the buffering gasbag body is fixedly connected with the base plate, the bottom of the buffering gasbag body is provided with an air inlet, a through hole is formed in the base plate and is in butt joint with the air inlet of the bufferinggasbag body, cord fasteners or hooks are distributed at the periphery of the upper end of the buffering gasbag body and used for being connected with the bottom of air-drop equipment, and the buffering gasbag body contains no gas before air drop. The air-drop self-falling gasbag can achieve automatic air inflation in a self-falling mode, it is not required to carry air sources, and when the air-drop equipment falls to the ground, an adjustable buffering effect can be achieved; the operation is convenient, and the gasbag can be applied to air-drop equipment different in weight and different altitudes, and is universally used in uplands and plains.

Owner:AEROSPACE LIFE SUPPORT IND LTD

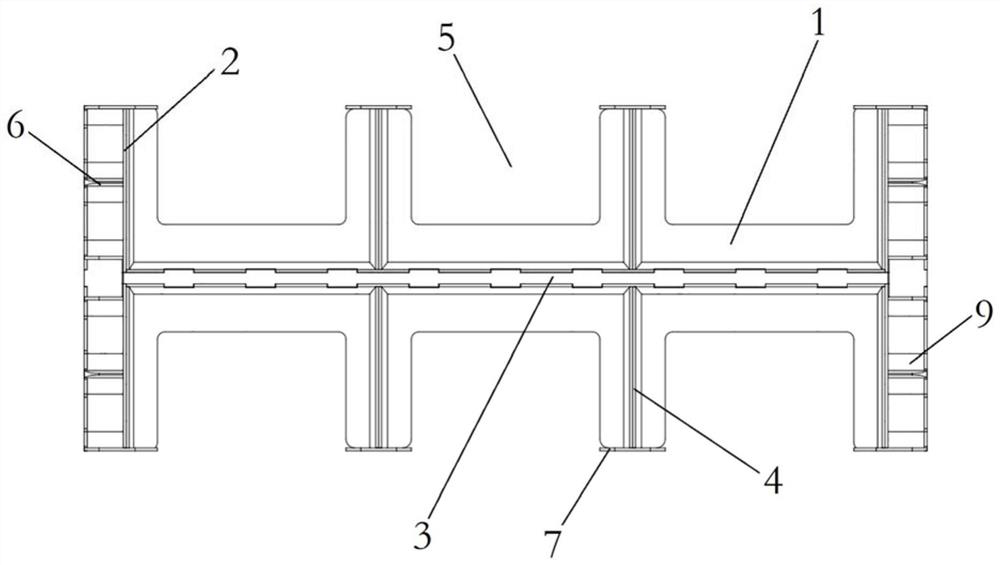

Threading apparatus for embroidery

InactiveCN105483952ASimple threading processReduce workloadEmbroidering machines apparatusTorsion springYarn

A disclosed threading apparatus for embroidery comprises a pedestal, the pedestal is composed of a bottom plate and a surface plate, the central section of the surface plate protrudes outwards, two sides of the surface plate are connected with the bottom plate, and a hollow chamber is formed between the surface plate and the bottom plate; the chamber is inside provided with multiple groups of threading assemblies, each threading assembly comprises a retaining plate perpendicularly arranged on the bottom plate, the front side of the retaining plate is guaranteed to stretch out of the chamber from the surface plate, and two sides, penetrating the surface plate, of the retaining plate are provided with a threading groove; and one lateral side of the retaining plate is provided with a tension regulator, the tension regulator is provided with a yarn take-up spring, and the yarn take-up spring possesses one torque spring end arranged on the tension regulator in a sleeving way, and one yarn take-up hook end extending out of the tension regulator. The whole threading apparatus is a cladding body, and all assemblies are wrapped in the pedestal, so that an operator is guaranteed to uneasily touch the threading-apparatus motion parts and part damage and personnel injury are avoided.

Owner:樊秀英

Printing ink box nozzle antiblocking device

The invention relates to a printing ink box nozzle antiblocking device. The printing ink box nozzle antiblocking device comprises a baffle, an antiblocking block, a push rod, an air cylinder and a controller, all of which are fixed to a nozzle. The baffle comprises a connecting plate, a reset plate and a guide plate, wherein the connecting plate is fixed to the nozzle; the upper end of the reset plate is fixedly connected with the connecting plate, and the lower end of the reset plate is fixedly connected with the guide plate; the reset plate is fixedly provided with a spring connected with the antiblocking block; and the guide plate is provided with a guide sliding groove and a first through hole aligned at the nozzle. The antiblocking block is arranged in the guide sliding groove and is sequentially provided with a closed cavity, a second through hole, a guide cavity and a sliding block cavity, wherein a sponge is arranged in the closed cavity, the guide cavity is provided with a through guide groove corresponding to the push rod, and the sliding block cavity is provided with a slope. The air cylinder is in transmission connection with the push rod. The lower end of the push rod makes contact with the slope of the sliding block cavity. The controller is arranged on the nozzle and fixedly connected with the air cylinder. The printing ink box nozzle antiblocking device is simple and reasonable in structure, convenient to operate and capable of effectively preventing the nozzle from being blocked.

Owner:常州市新北区双全印刷厂

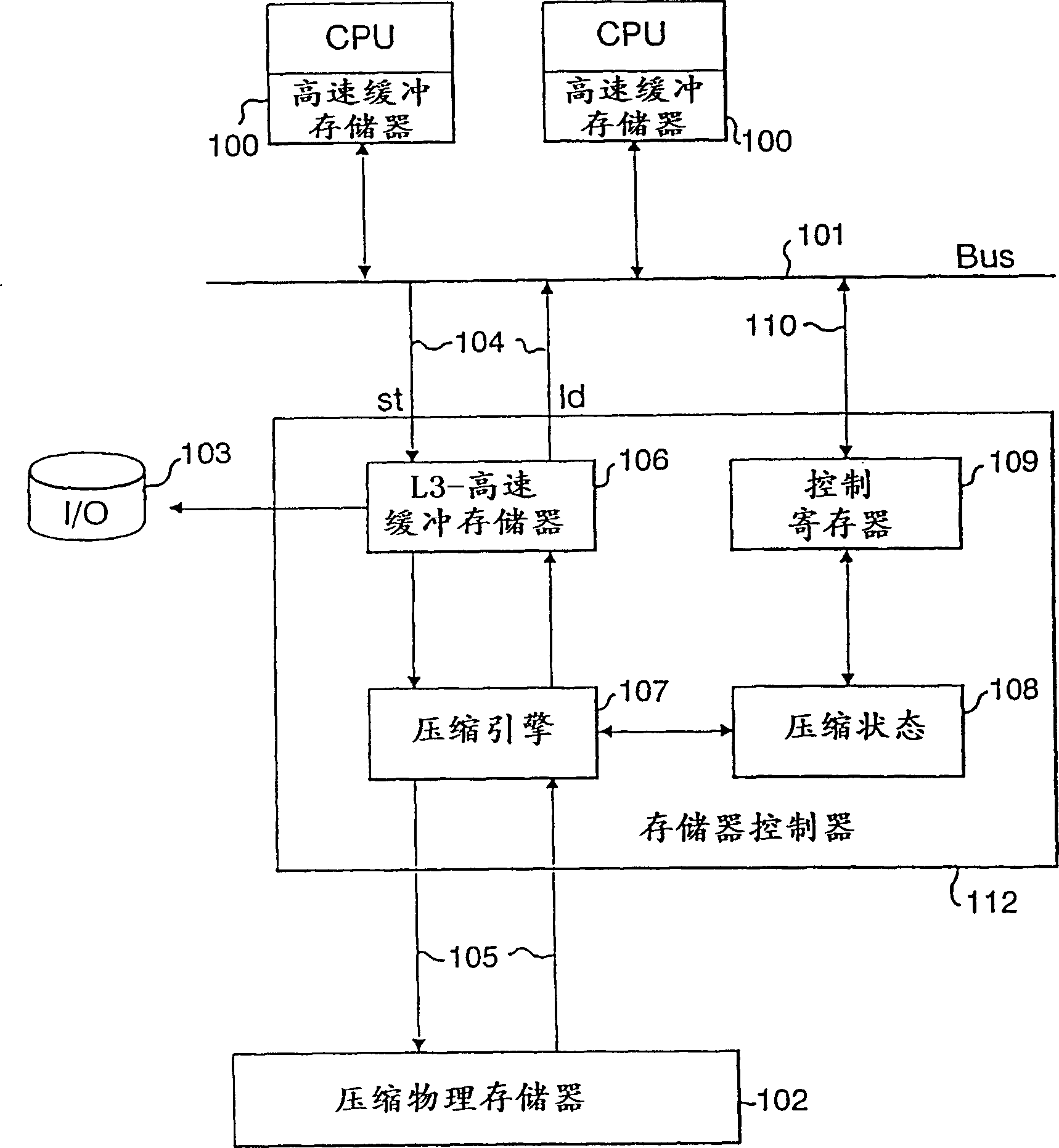

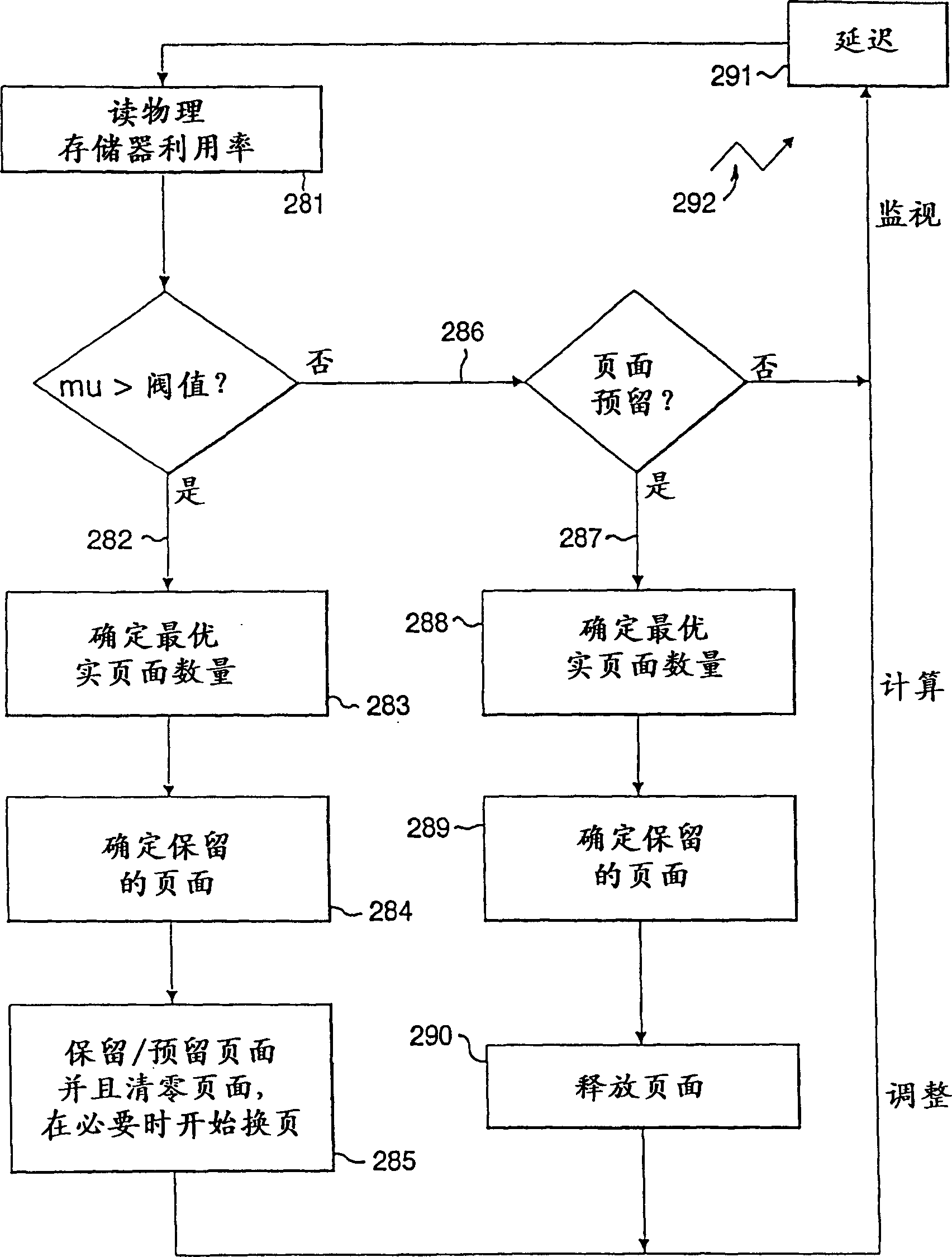

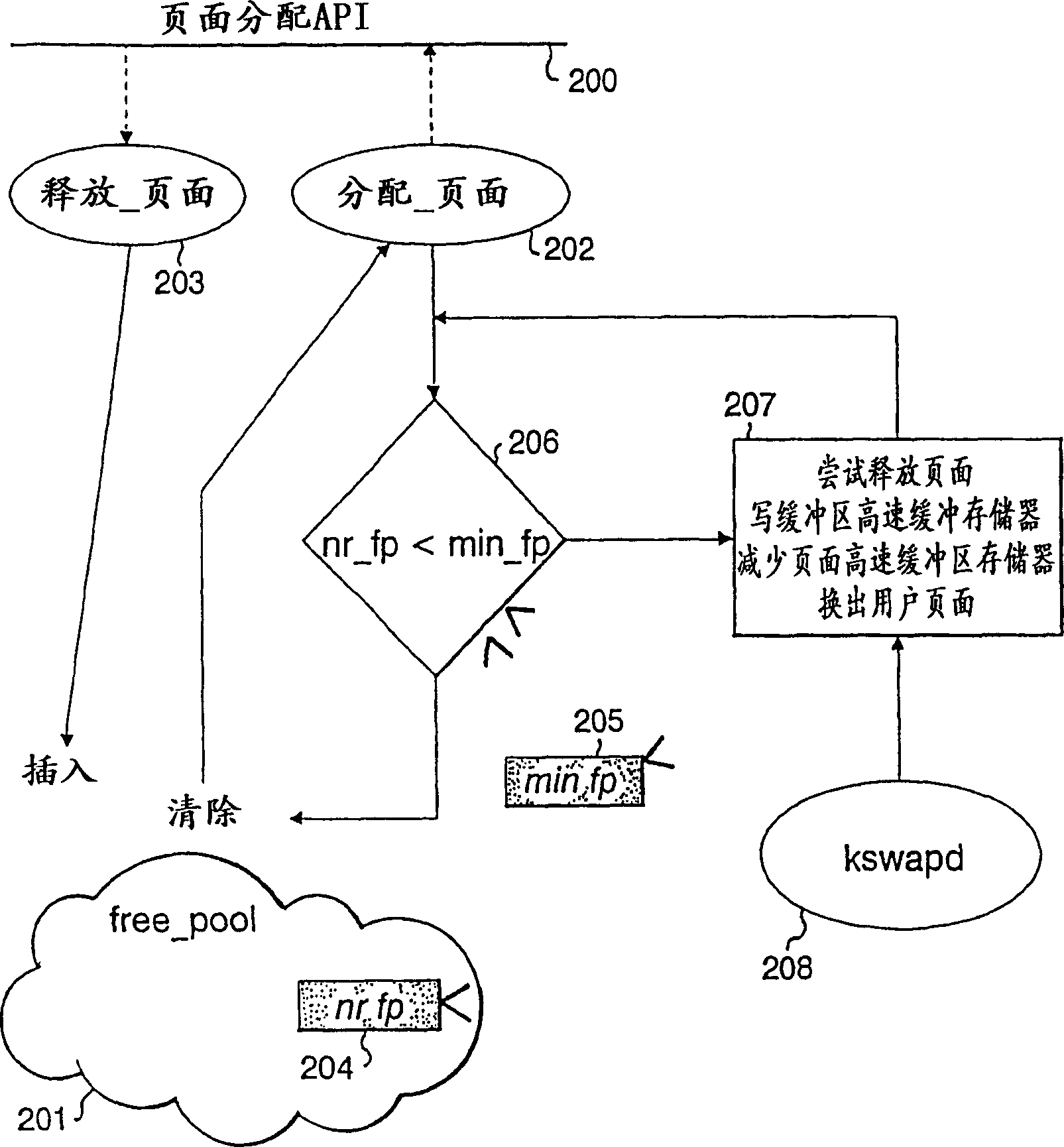

Method for supporting operation system of storage compression

InactiveCN1188784CLarge capacityEffective capacityMemory architecture accessing/allocationProgram control using stored programsOperational systemOperating system

In a system with hardware main memory compression, the method of this invention monitors the physical memory utilization and if physical memory is near exhaustion it forces memory to be paged out, thus freeing up real memory pages. These pages are then zeroed, thus they are highly compressible and therefore reduce the physical memory utilization. Pages that have been forced out due to high physical memory utilization are not made available for allocation. In systems where operating system changes are permitted, this invention dynamically controls the minimum size of the free page pool and zeros pages upon freeing. In systems where operating system changes are not possible, pages are allocated by a module and then zeroed.

Owner:GOOGLE LLC

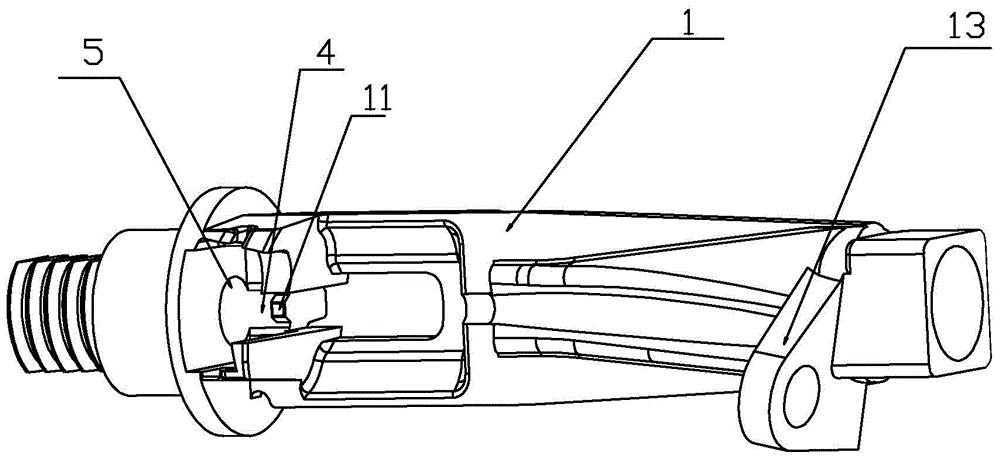

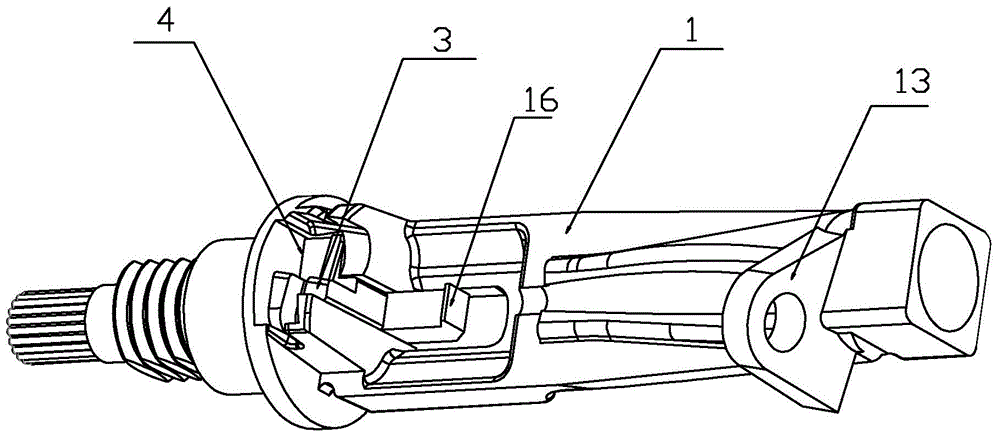

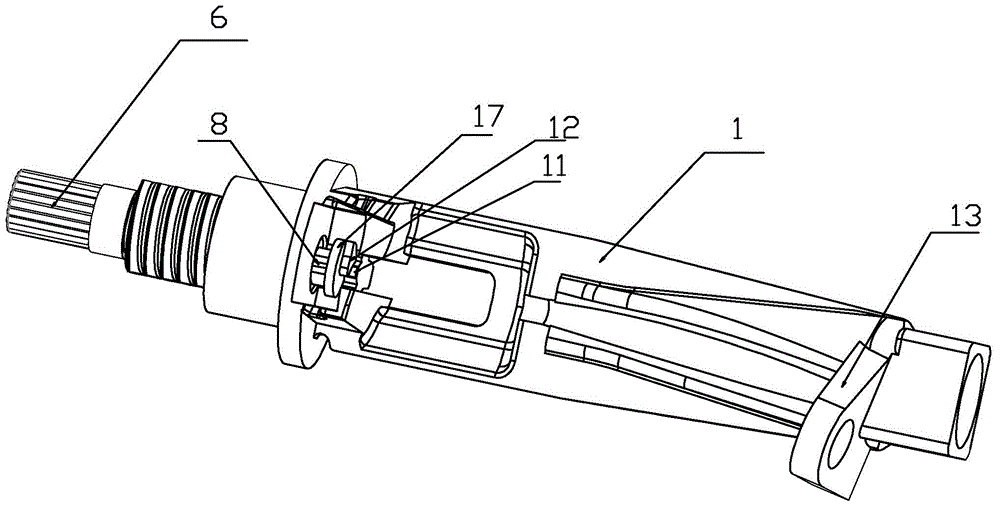

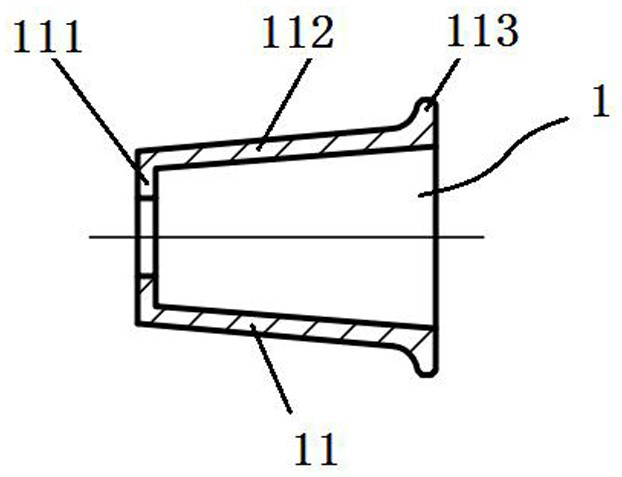

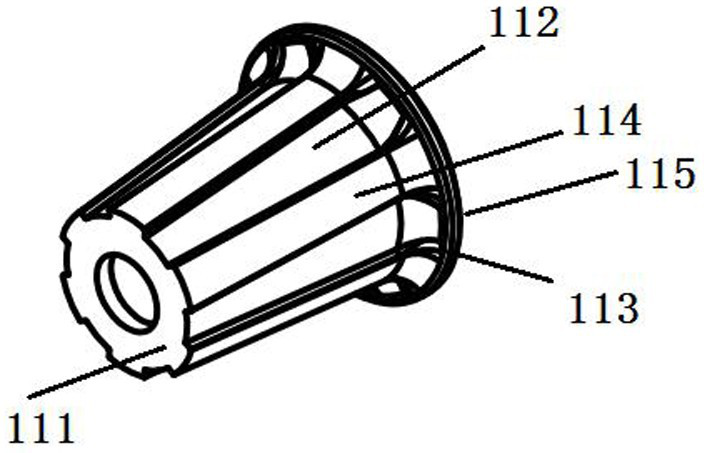

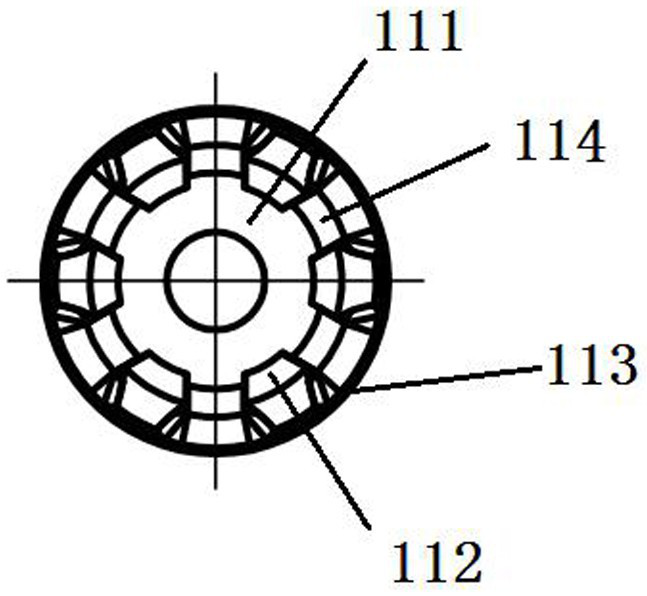

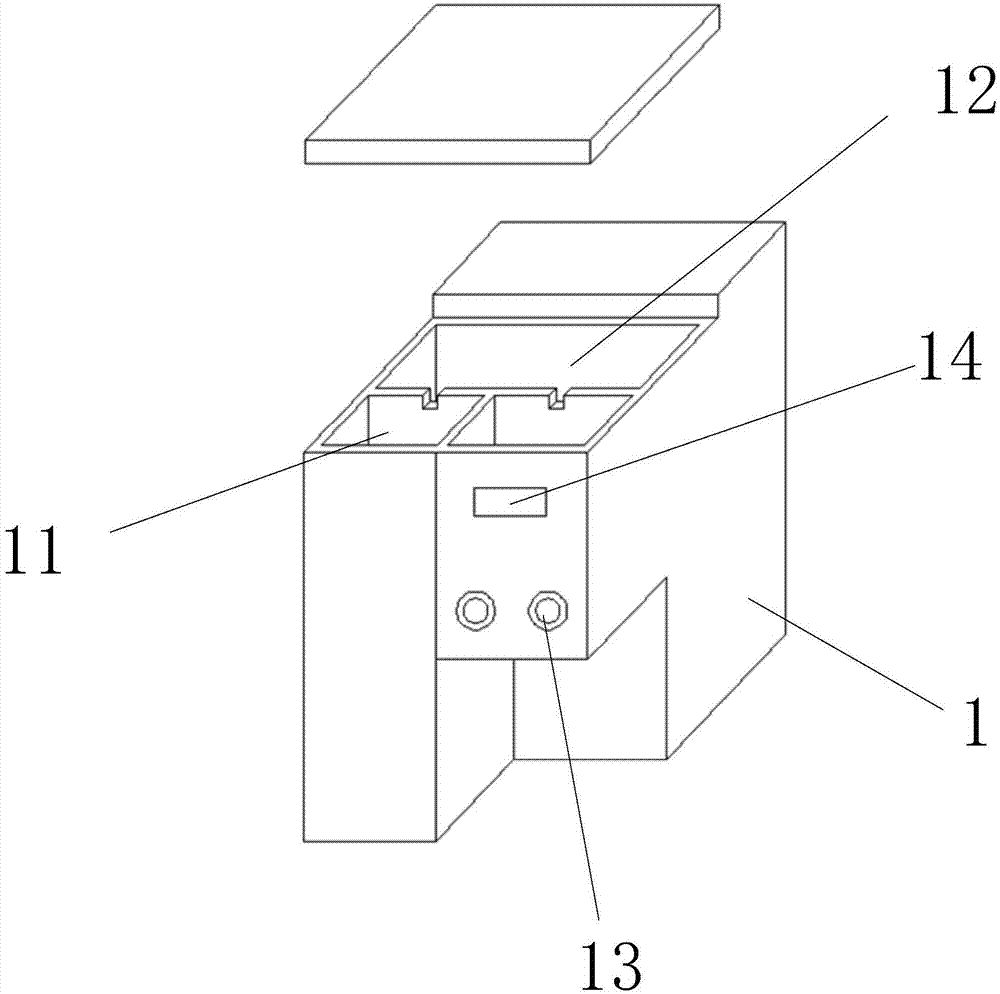

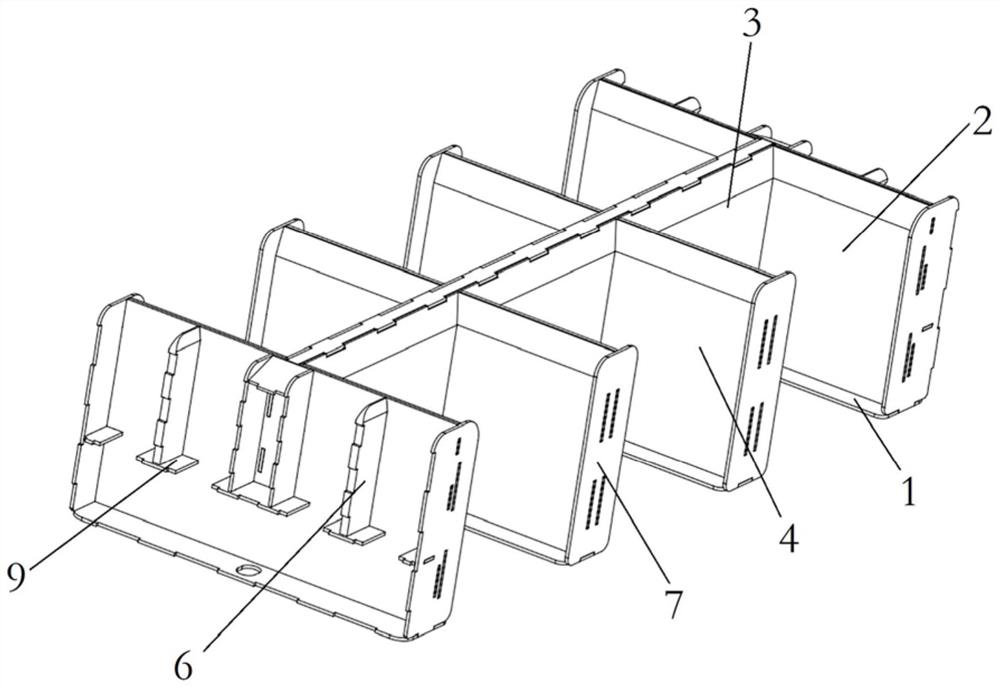

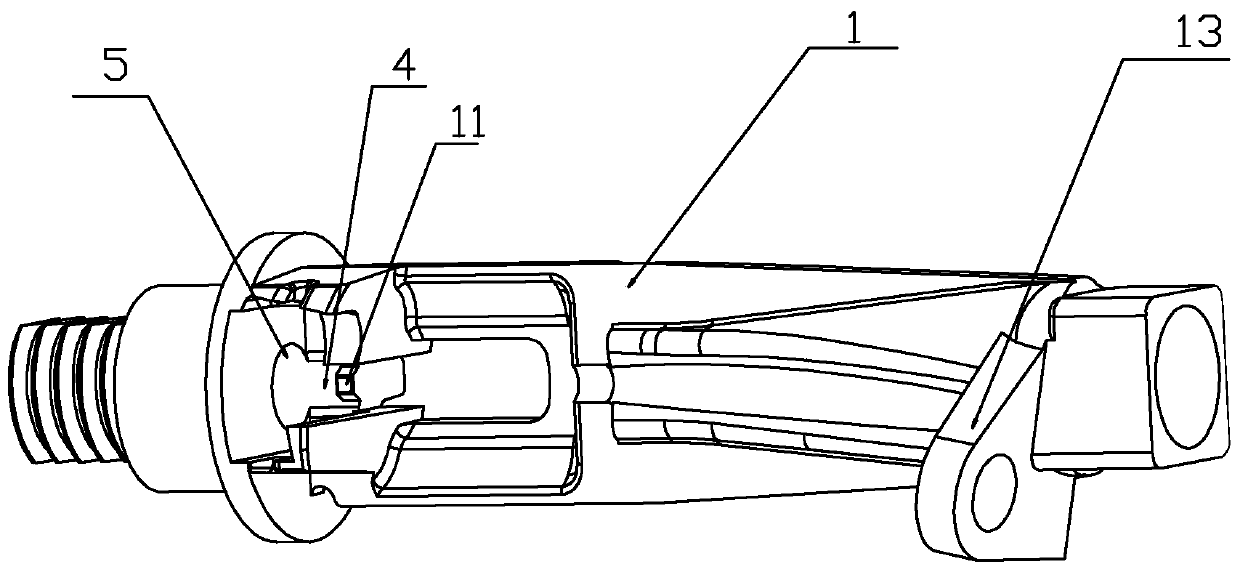

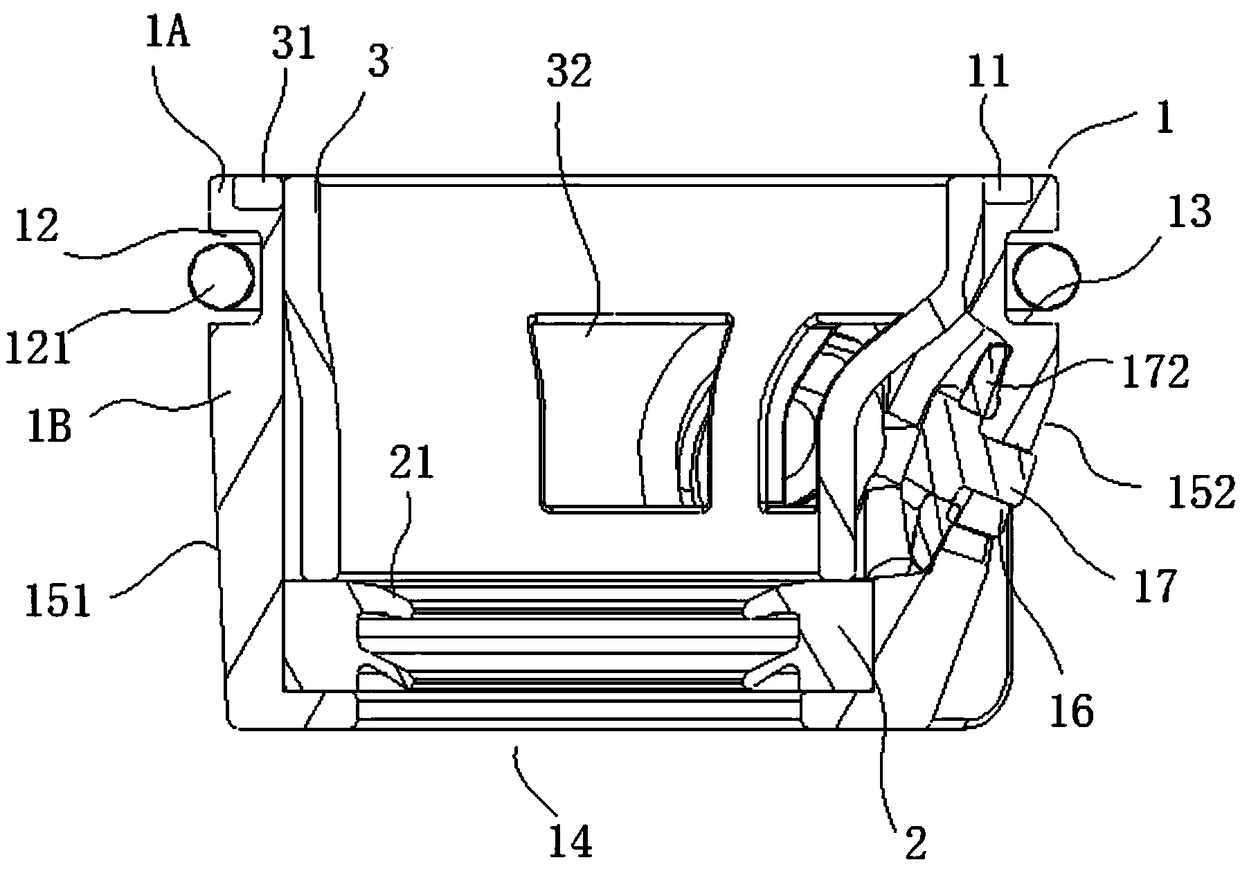

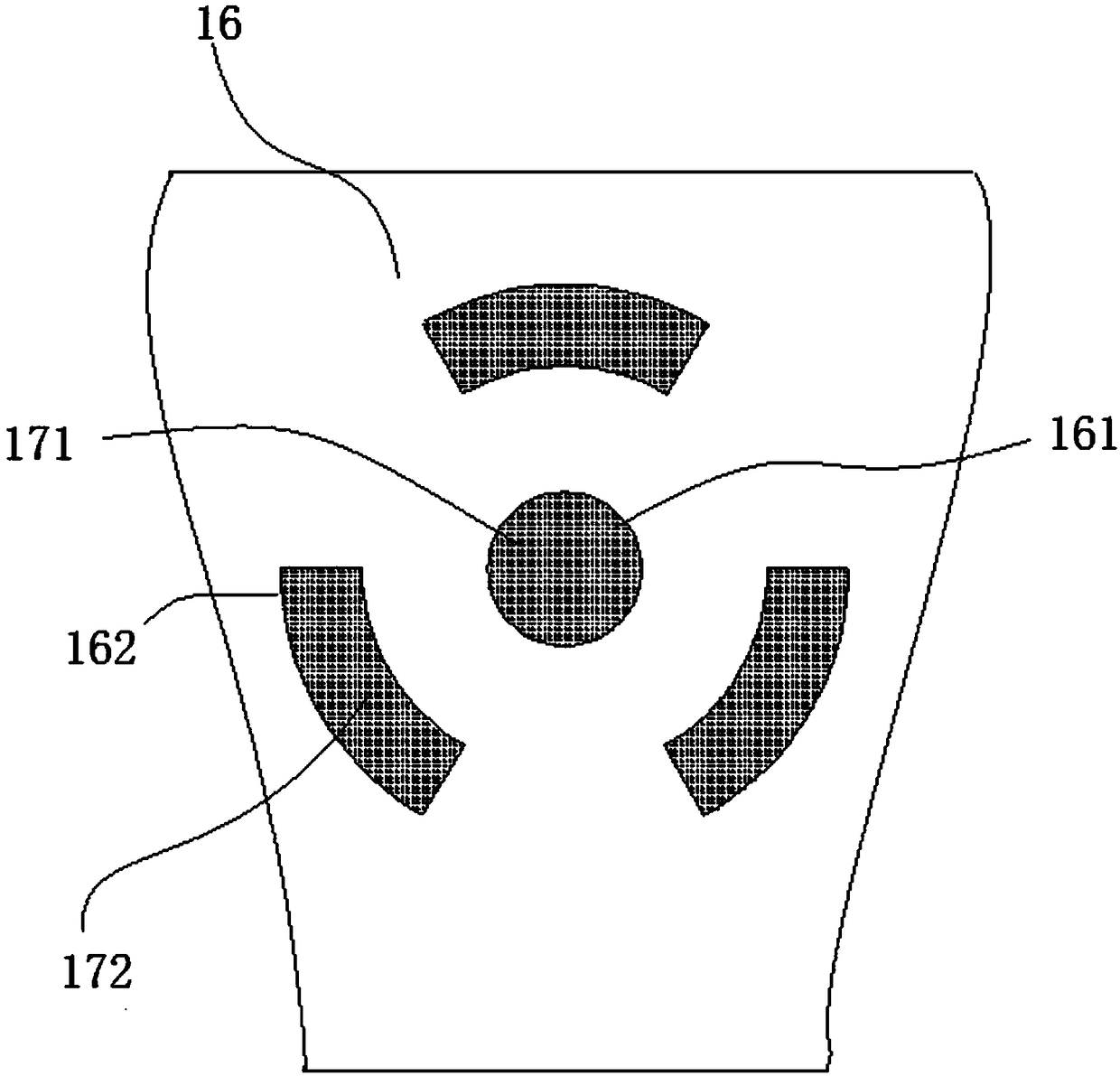

Knife rest of pencil sharpener

The invention discloses a knife rest of a pencil sharpener. The knife rest of the pencil sharpener comprises a knife rest (1) and a hob shaft (2) equipped with a hob (14), wherein a shaft support seat (3) is arranged at one end of the knife rest (1), a shaft support (13) is arranged at the other end of the knife rest (1), two ends of the hob shaft (2) are mounted on the shaft support seat (3) and the shaft support (13) respectively, an angle adjusting device for adjusting the angle of the hob shaft (2) is arranged on the knife rest (1) and specially adopts a chute (4) arranged on the knife rest (1), and the shaft support seat (3) is in sliding fit in the chute (4). The knife rest of the pencil sharpener has the advantages of simple structure, simplicity in operation, low cost, high reliability and good cutting quality and can change the thickness of a pencil lead under the condition that the pencil lead cutting length is not changed.

Owner:雪松

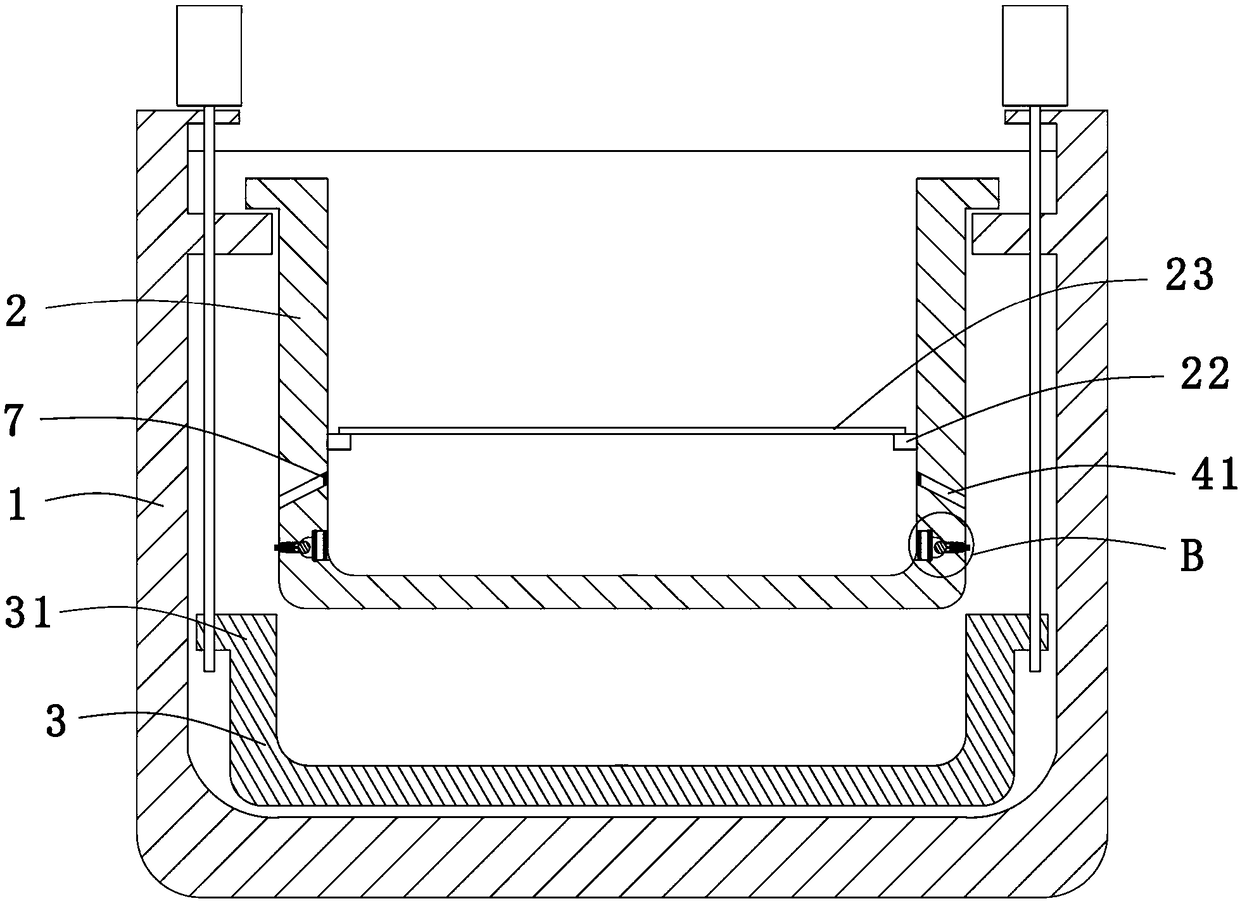

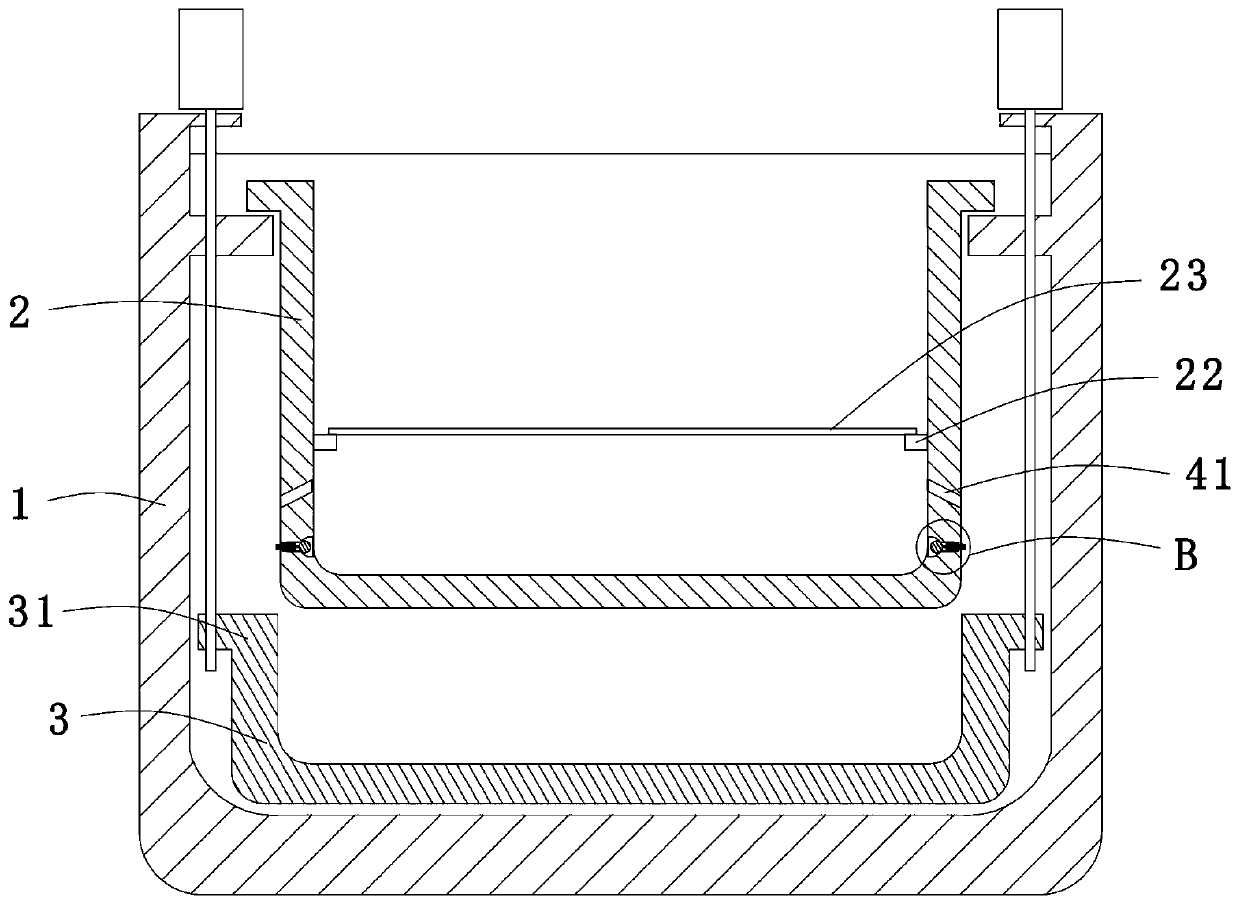

Hydrogen-corrosion-preventing sealing device, hydrogen-corrosion-preventing motor and hydrogen circulating pump

ActiveCN112564379ADoes not affect magnetic field switchingSimple installation structureWindings insulation shape/form/constructionPump componentsStator voltageElectric machine

The present invention provides a hydrogen circulating pump, a hydrogen corrosion prevention sealing device is made of an insulated hydrogen corrosion prevention nonmetal synthetic material into a conical basin-shaped body, and a stator and a rotor of a hydrogen corrosion prevention motor are separated, that is, hydrogen overflowing from the hydrogen circulating pump to the hydrogen corrosion prevention motor is isolated from the stator; a hydrogen corrosion prevention lining is simple in installation structure; and a cone-shaped basin-shaped structure can be adopted to ensure strength, deformation caused by rotation of a stator magnetic circuit and a rotor is avoided, and meanwhile magnetic field conversion between the stator and the rotor is not affected. The hydrogen corrosion preventionmotor uses the hydrogen corrosion prevention sealing device, so that the risk of electric sparks generated by stator voltage arc discharge is reduced. And the stator adopts H-shaped structure teeth,so that the torque and the rotating speed which are twice those of the traditional tooth-shaped stator structure can be obtained, and the material consumption is small.

Owner:BEIJING BOLKEN EQUIP +1

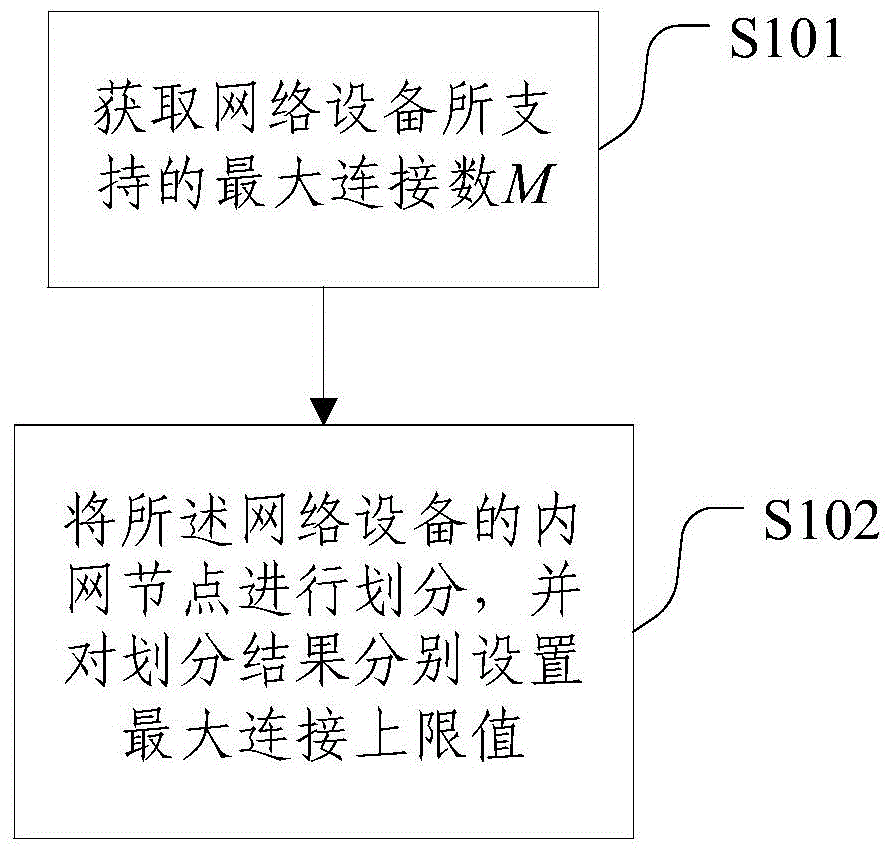

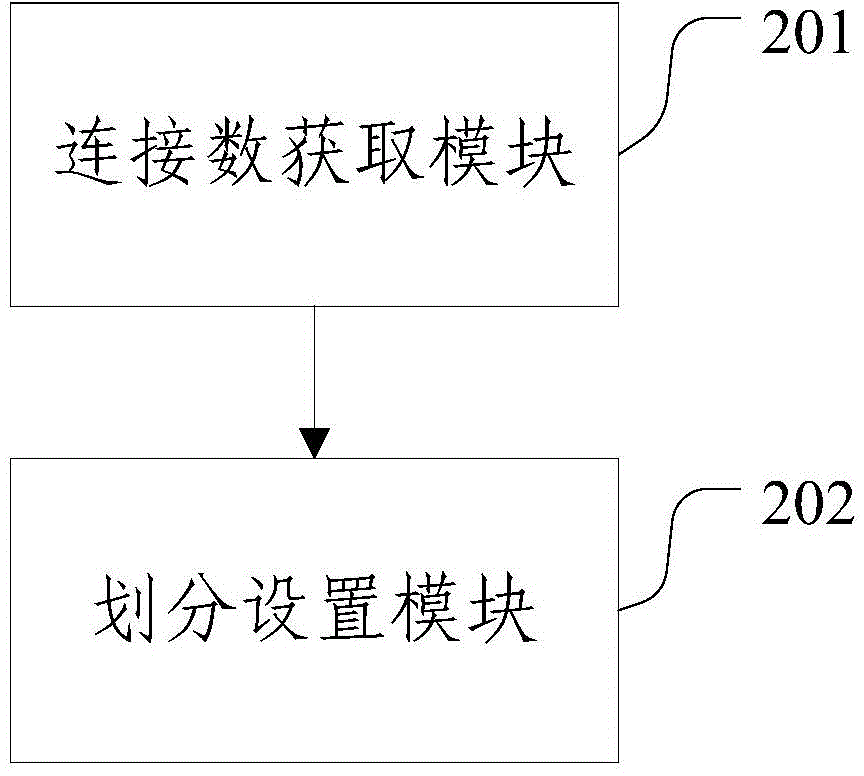

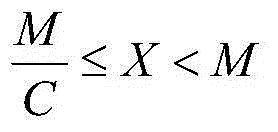

Method and system for preventing semi-join attack

Owner:OPZOON TECH

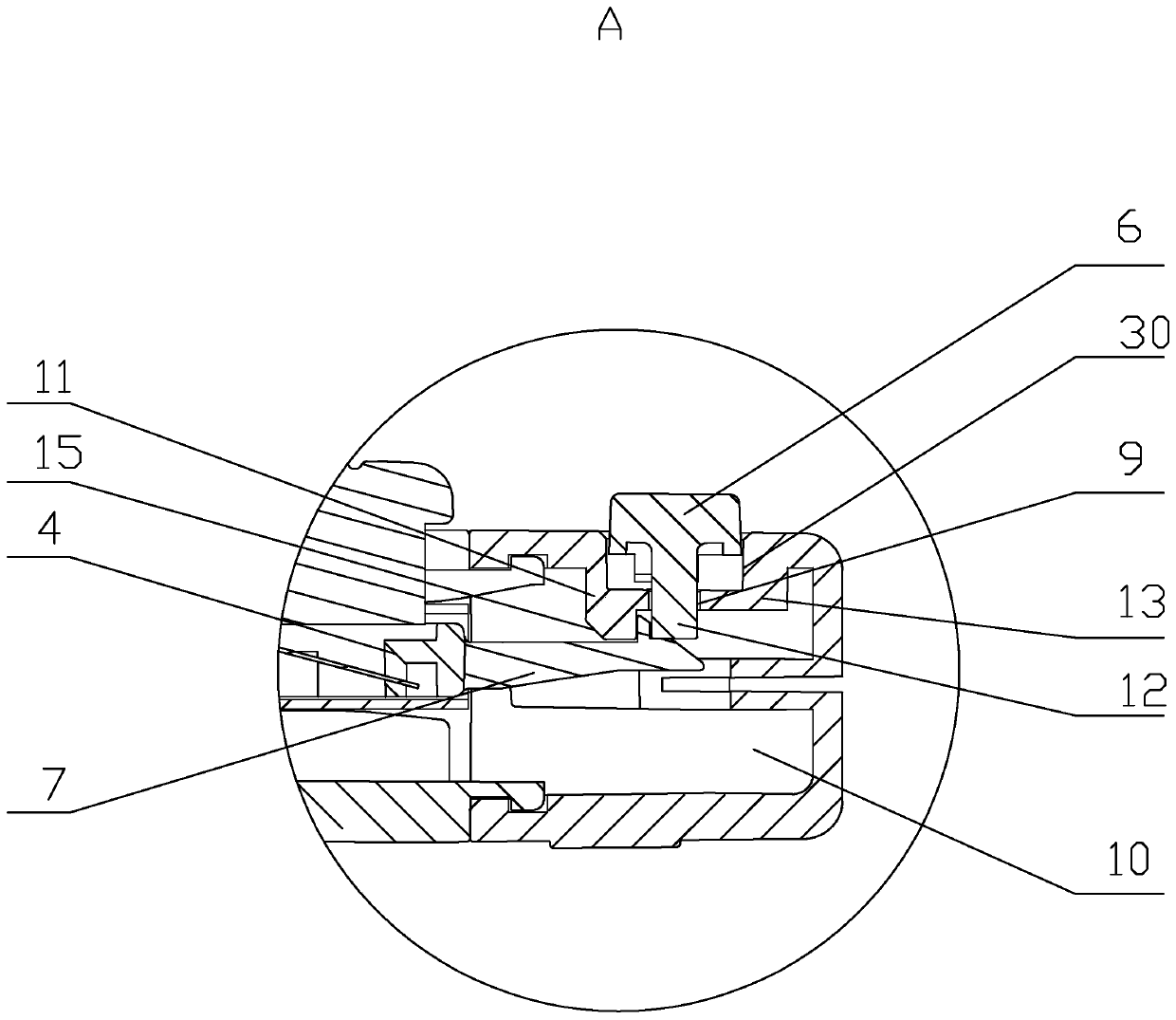

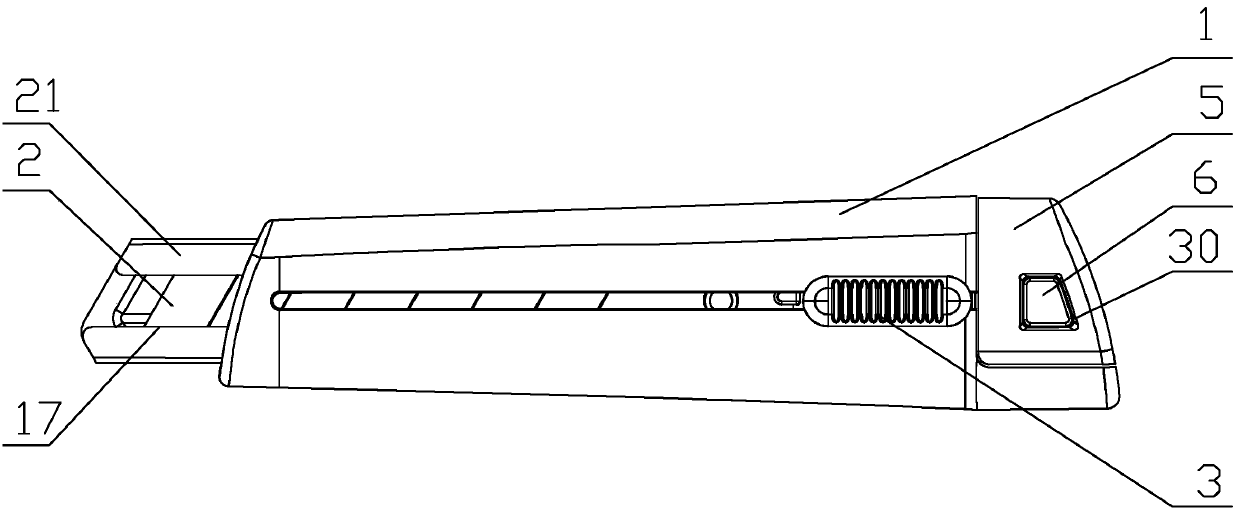

Art knife

PendingCN109834735AImprove securityAvoid forgetting to lockMetal working apparatusLocking mechanismEngineering

The invention discloses an art knife. The art knife comprises a knife shell, a knife blade and an adjusting button, the knife blade is arranged in the knife shell, the adjusting button is arranged onthe knife shell, the art knife further comprises a knife blade support, a tail cover and a tail cover button arranged on the tail cover, the tail cover is arranged on the tail part of the knife shell,the knife blade support is arranged in the knife shell, the tail part of the knife blade is arranged on the head part of the knife blade support, the tail part of the knife blade tail part can extendinto the tail cover, a locking mechanism is arranged between the tail cover and the knife blade support, the locking mechanism can be unlocked when the tail part button is pressed, the tail part of the knife blade support is separated from the tail cover when the locking mechanism is unlocked, the head part of the knife blade support can slide towards the head part of the knife shell when the adjusting button is pushed, and the knife blade moves towards the head part of the knife shell when the tail part button is pressed, and the adjusting button is pushed. The invention provides the art knife with a high safety factor.

Owner:DELI GROUP CO LTD

Absorbing core body

The invention relates to the field of disposable sanitary products, in particular to an absorbing core body. The absorbing core body comprises a body of an absorbing core and a coating layer with liquid permeability, wherein a layer of composite paper is attached to the body of the absorbing core; the inside of the coating layer is coated with the body of the absorbing core and the composite paper; the composite paper is formed by mixing 20 to 40 parts by weight of super absorbent polymer particles, 45 to 60 parts by weight of non-woven fabric fragments and 0 to 20 parts by weight of plastic film fragments.

Owner:QUANZHOU HANWEI MACHINERY MFG

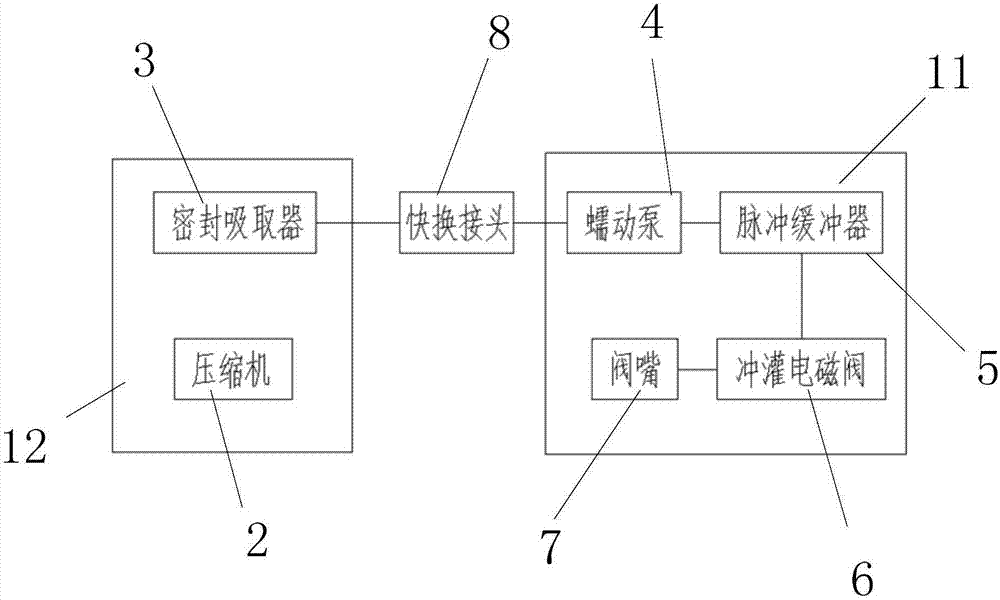

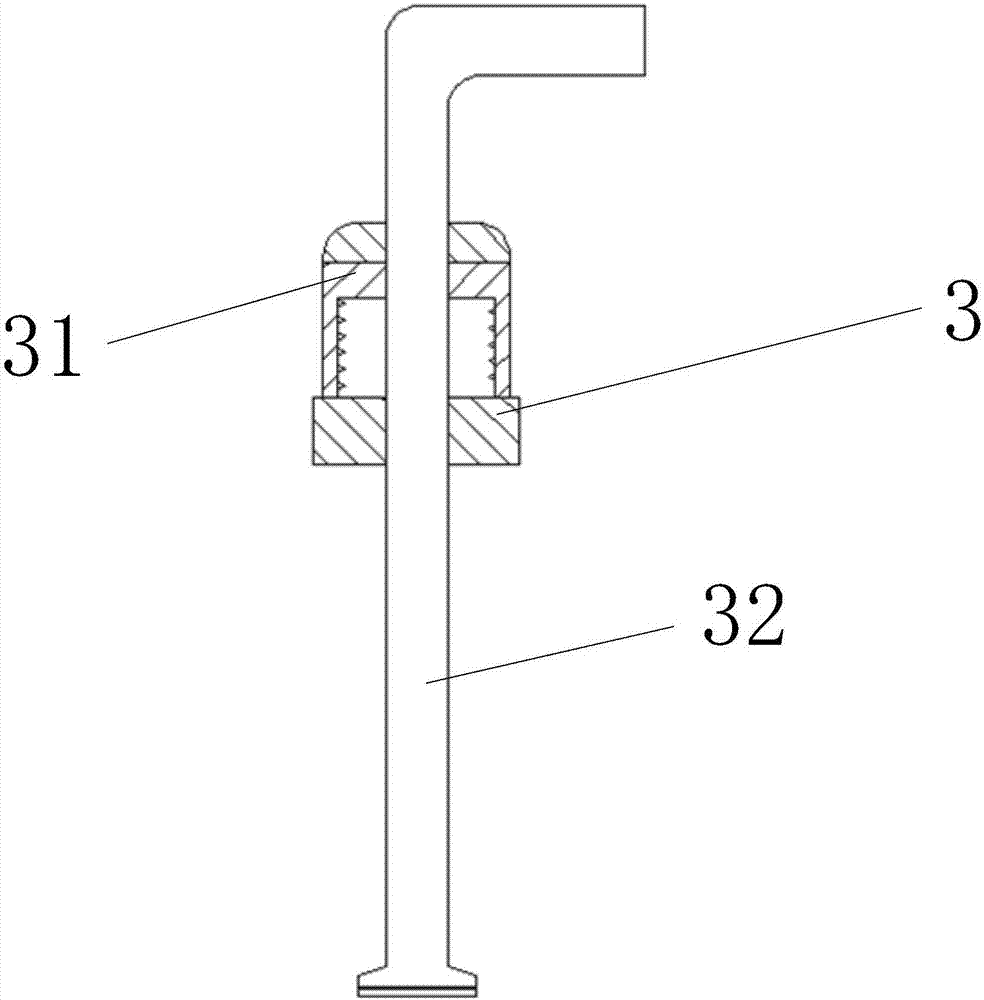

Instant beverage dispensing machine keeping bubbles lasting

PendingCN106887083AWon't run outGuaranteed tasteApparatus for meter-controlled dispensingApparatus for dispensing fluids/granular materialsElectricityEngineering

The invention discloses an instant beverage dispensing machine keeping bubbles lasting and relates to the field of beverage devices. The instant beverage dispensing machine comprises a housing, a sealed sucker, an electric pump, a pulse buffer, a magnetic filling valve, a valve mouth and a compressor, wherein the housing comprises a beverage storage portion and a beverage discharging portion, the compressor and the sealed sucker are arranged in the beverage storage portion, and the electric pump, the pulse buffer, the magnetic filling valve and the valve mouth are connected in sequence and are arranged in the beverage discharging portion. The housing is provided with an electric switch, and the electric switch is electrically connected with the electric pump. By adopting the technical scheme, due to the fact that the compressor arranged in the inside serves as a beverage cooling device, beverage temperature is kept in the range of 0-5 DEG C for a long time, meanwhile sealing suction covers are used, bubbles of beverages in beverage bottles can be prevented from escaping, and it is ensured that discharged beverages have original taste and quality.

Owner:福州洛克机械设备制造有限公司

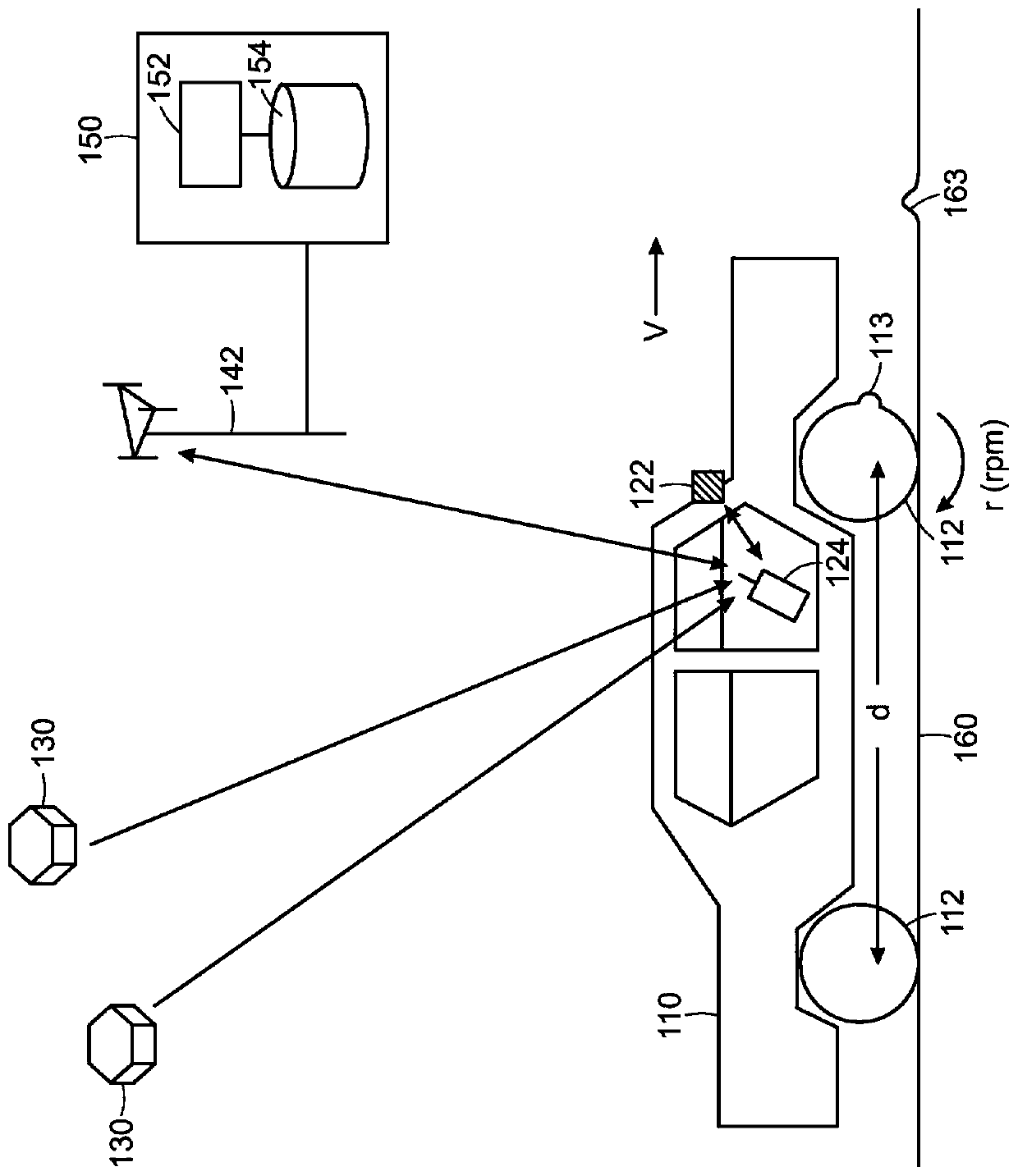

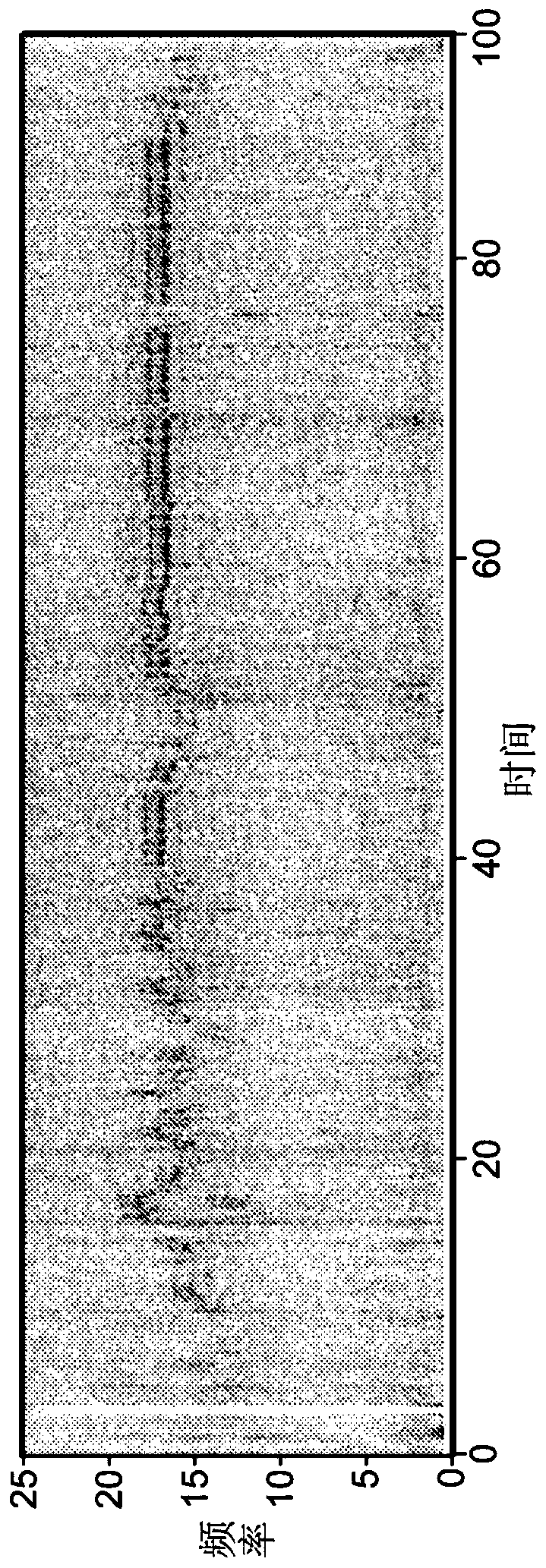

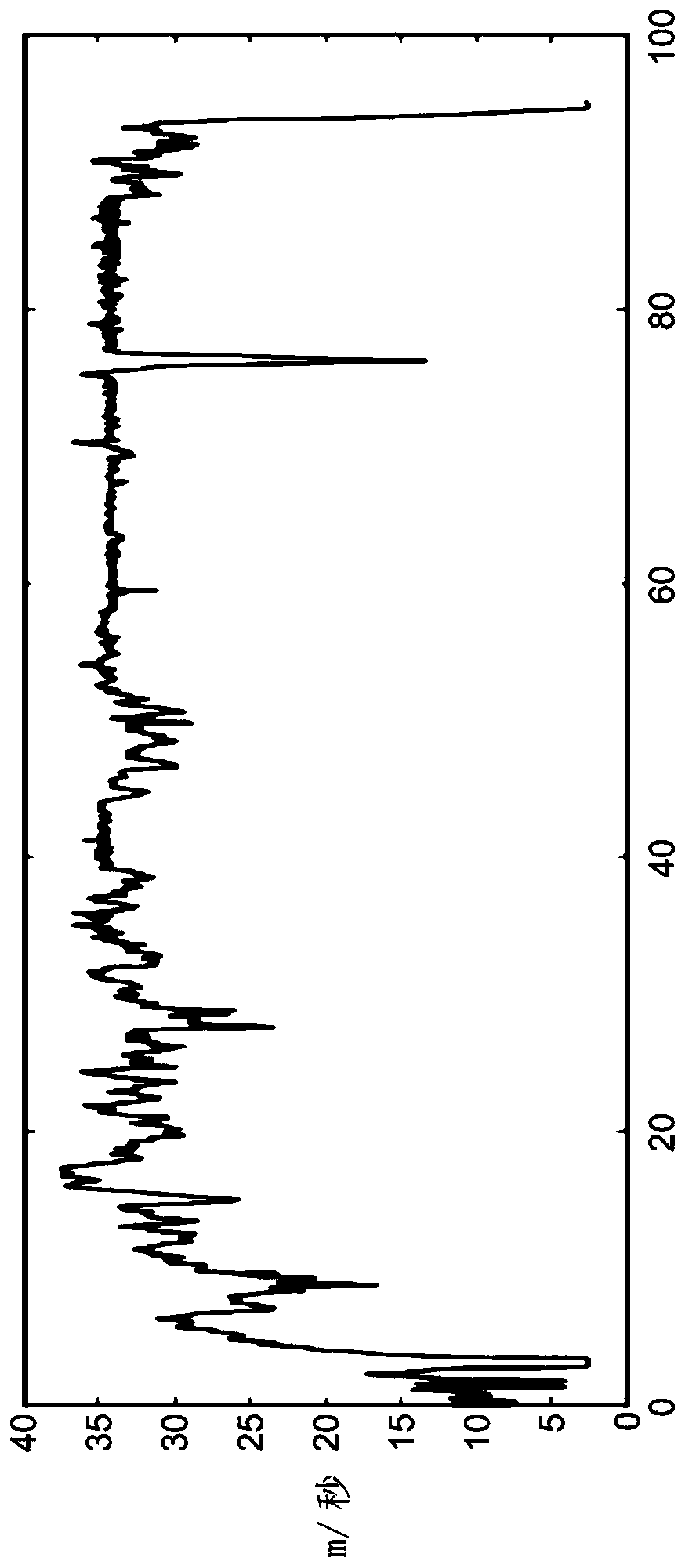

Mileage and speed estimation

InactiveCN109791047ALess errorFew faultsMaterial analysis using acoustic emission techniquesRegistering/indicating working of vehiclesEngineeringTypes of road

An approach to determining vehicle usage makes use of a sensor that provides a vibration signal associated with the vehicle, and that vibration signal is used to infer usage. Usage can include distance traveled, optionally associated with particular ranges of speed or road type. In a calibration phase, auxiliary measurements, for instance based on GPS signals, are used to determine a relationshipbetween the vibration signal and usage. In a monitoring phase, the determined relationship is used to infer usage from the vibration signal.

Owner:CAMBRIDGE MOBILE TELEMATICS INC

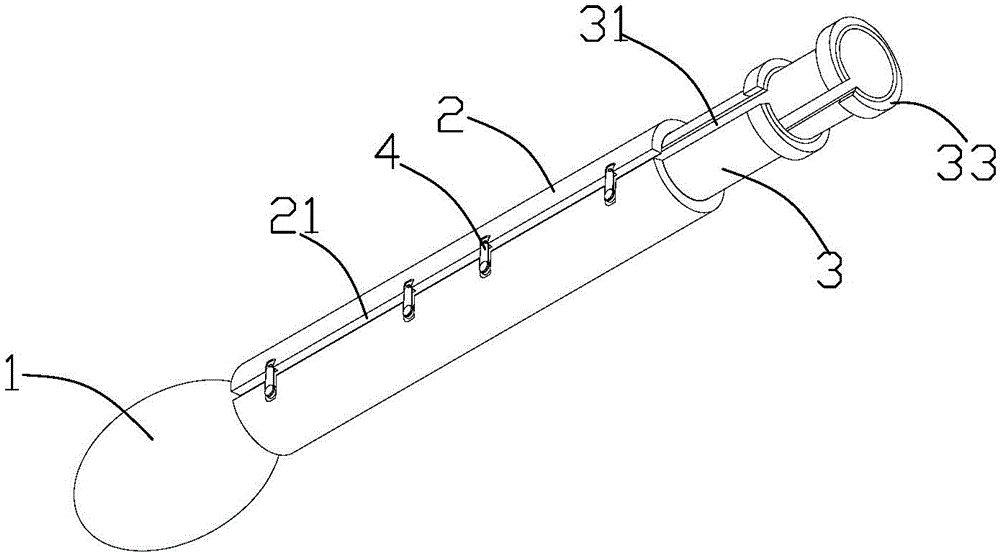

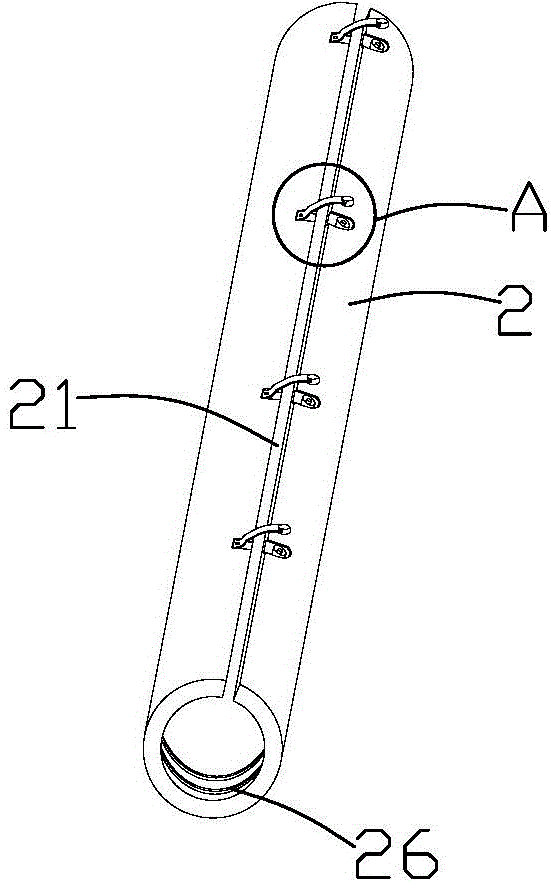

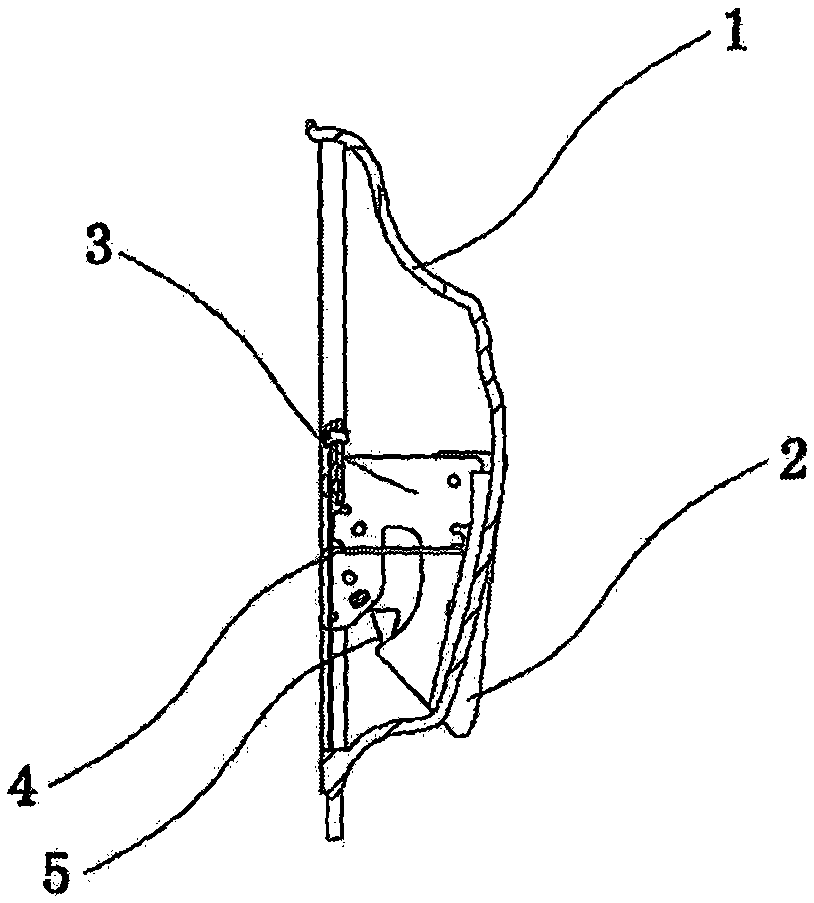

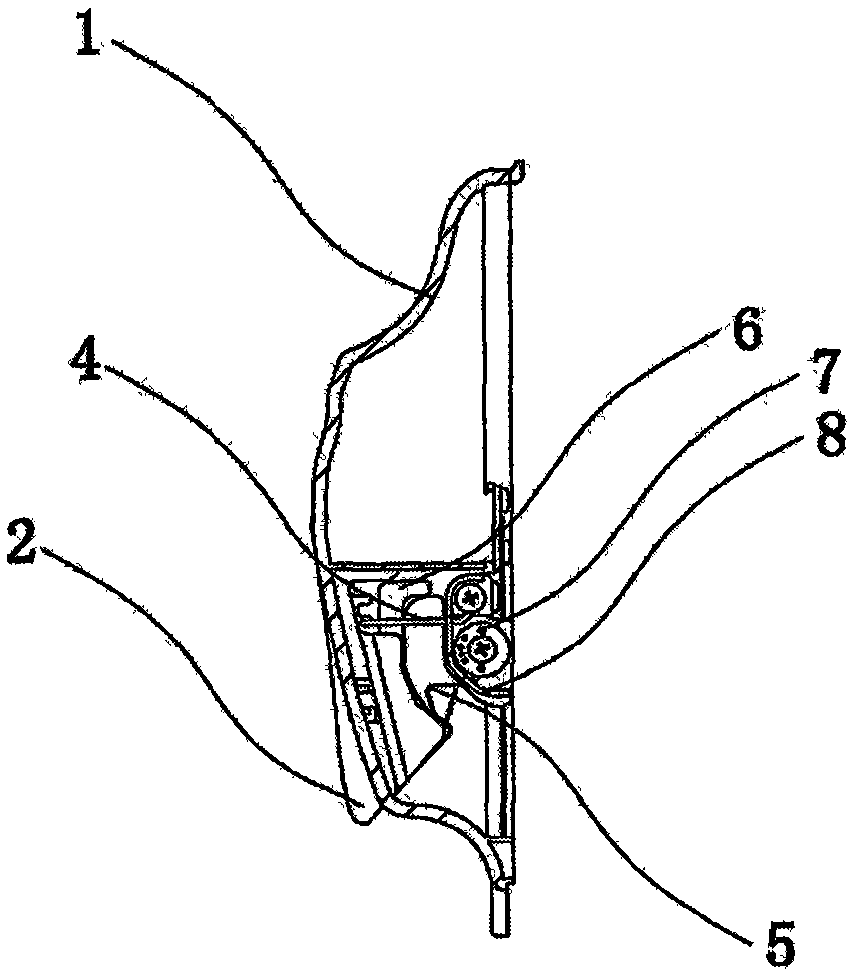

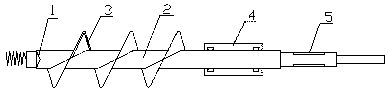

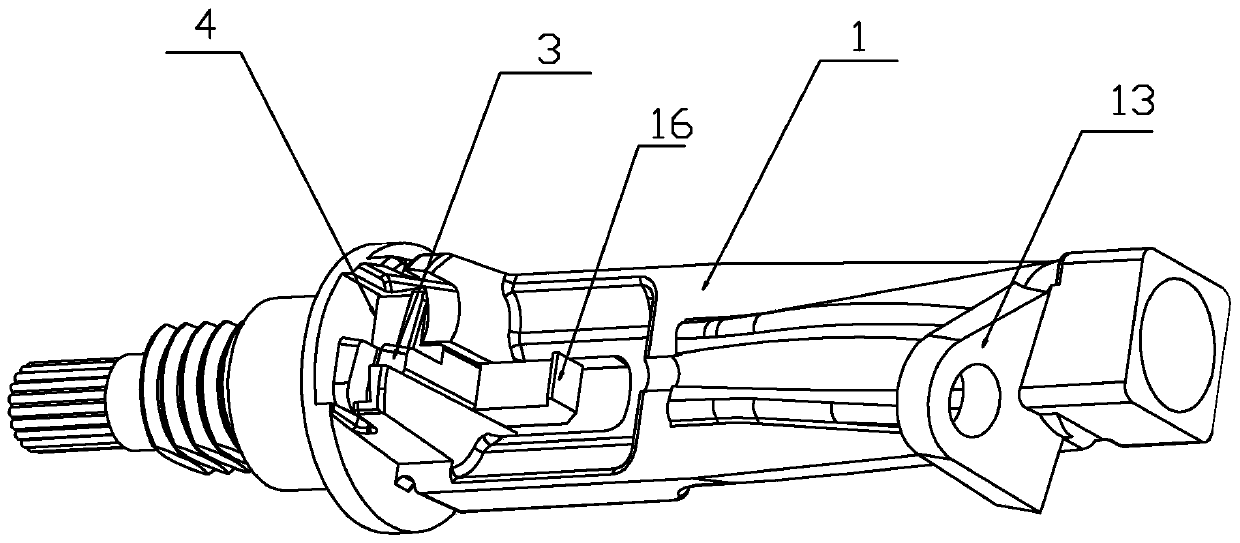

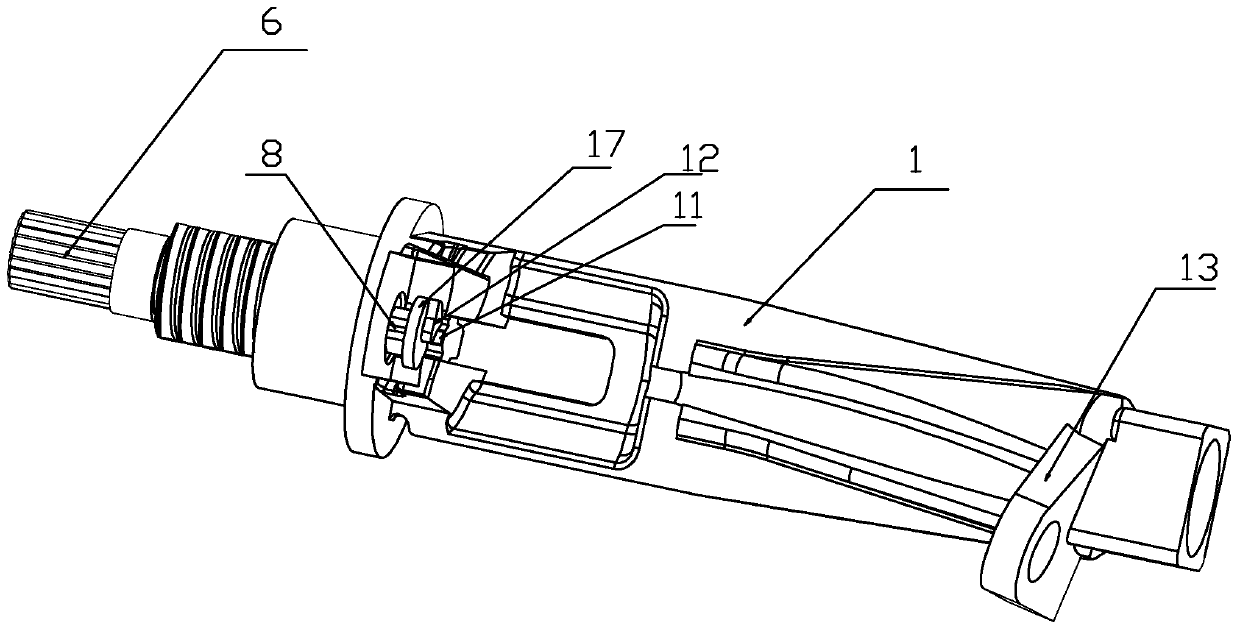

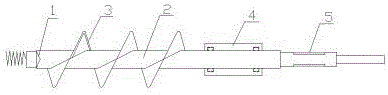

A spiral spindle for a lens vacuum coating machine

A spiral spindle for a lens vacuum coating machine is composed of a V-shaped spindle end (1), a spindle body (2), a spiral blade (3), a sealing spindle sleeve (4) and key grooves (5). The sealing spindle sleeve (4) and the spiral blade (3) are arranged on the spindle body (2). One end of the spindle body (2) is the V-shaped spindle end (1), and the other end of the spindle body (2) is provided with the sealing spindle sleeve (4). The spiral spindle for the lens vacuum coating machine is characterized in that the spiral blade (3) is welded to the spindle body (2), and the key grooves (5) are formed in the stress surface of one side of the spindle body (2) and are symmetrically arranged; and a spring and a V-shaped cone are installed at a port of the V-shaped spindle end (1), and the V-shaped cone is in close fit with the V-shaped spindle end (1). According to the spiral spindle for the lens vacuum coating machine, multiple layers of sealing rings are designed inside the spindle sleeve, so that the effect that no gas leakage occurs between the spindle body and the sealing spindle sleeve is guaranteed, and under the dual guarantee of the port of the V-shaped spindle end and the sealing spindle sleeve, the spindle body ensures that the situation that vacuum gas escapes out of the coating machine from the matching surface of the spindle due to non-tight sealing is avoided.

Owner:JIANGSU RARE OPTICS CO LTD

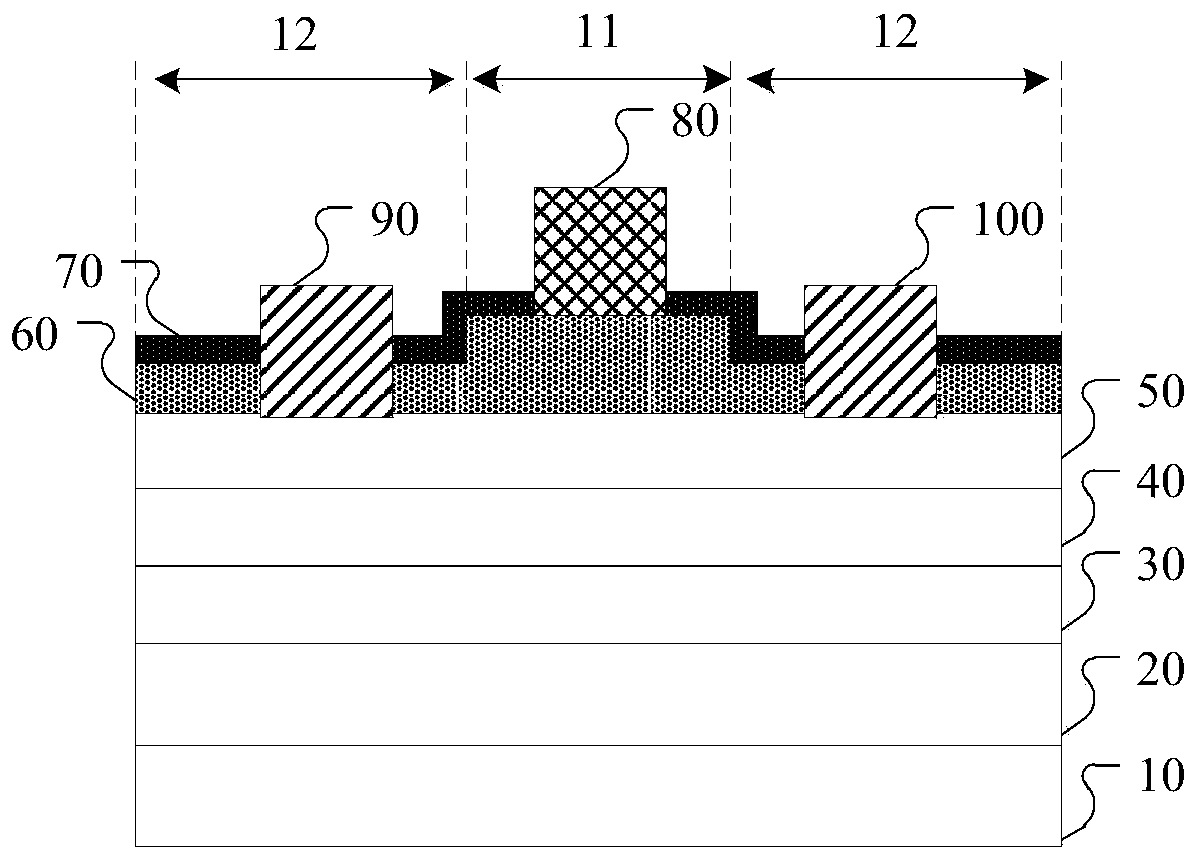

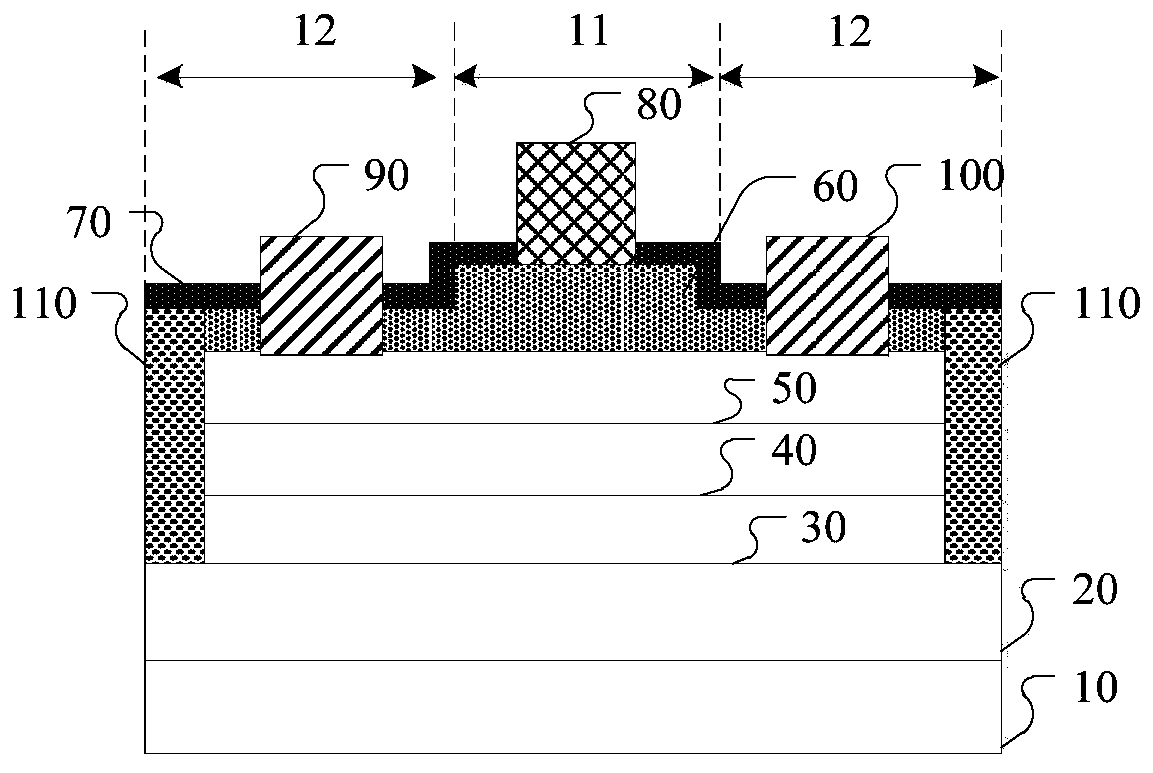

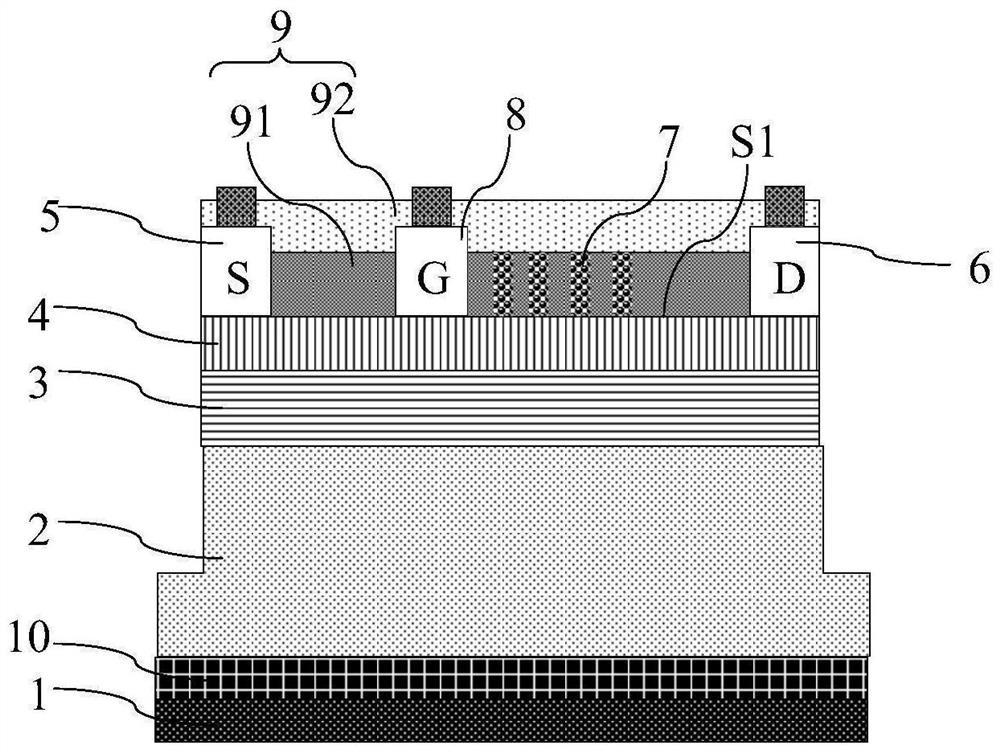

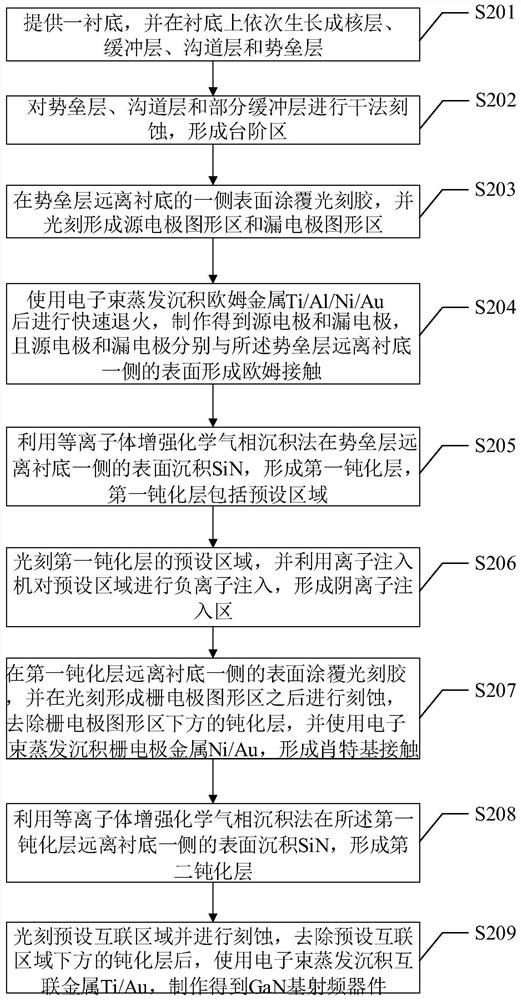

GaN-based radio frequency device with terminal structure and manufacturing method of device

PendingCN113809155AImprove breakdown voltageImprove on-state characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLow leakage

The invention discloses a GaN-based radio frequency device with a terminal structure and a manufacturing method of the device. The radio frequency device comprises a substrate, a nucleating layer, a buffer layer, a channel layer and a barrier layer, wherein the nucleating layer, the buffer layer, the channel layer and the barrier layer are sequentially located at one side of the substrate. In the direction perpendicular to the plane where the substrate is located, the barrier layer comprises a first surface away from the channel layer, the source electrode and the drain electrode are oppositely arranged at the two sides of the first surface, and the gate electrode is located between the source electrode and the drain electrode. The passivation layer is positioned at the side, far away from the substrate, of the barrier layer and comprises a first passivation layer and a second passivation layer; the first passivation layer comprises an anion injection region, and the orthographic projection of the anion injection region is located between the gate electrode and the drain electrode in the direction perpendicular to the plane where the substrate is located, so that a negative charge center can be generated in the first passivation layer, the peak of a gate pin electric field is reduced, the breakdown voltage of the device is improved, the leakage current is reduced, and the on-state characteristic of the device is improved.

Owner:XIDIAN UNIV

Information machine room threader

ActiveCN104917111BPlay a protective effectSo as not to damageApparatus for laying cablesMechanical engineeringEngineering

An information machine room threader, which includes a guide head and a telescopic rod body formed by at least two sleeves sleeved together; A cable groove, with a pressing block in the other half shell; a half cylinder at the end of each half shell, a groove is provided on each half cylinder; a bar-shaped opening is opened on each sleeve; A first slideway and a second slideway are arranged inside each sleeve, and a first through hole and a second through hole are respectively arranged in the first slideway and the second slideway; except for the outermost sleeve, each A ball screw is arranged at the front end of a sleeve. The invention does not need to lift the floor in a large area, is convenient for threading, has no damage, and can arrange the cables in an orderly manner, which is convenient for wiring.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Cigarette case auxiliary material storage box and automatic feeding system

PendingCN112623465AEasy to grabImprove transportation efficiencyDischarging meansInternal fittingsManufacturing engineeringMaterial storage

The invention provides a cigarette case auxiliary material storage box and an automatic feeding system, and belongs to the technical field of cigarette case production. The cigarette case auxiliary material storage box comprises a bearing disc, a first storage position and second storage positions; the first storage position is arranged in the middle of the bearing disc, and the first storage position is suitable for containing packaging paper; the second storage positions are arranged at the two ends of the first storage position; and the second storage positions are suitable for containing seals. According to the cigarette case auxiliary material storage box, the first storage position is used for containing the packaging paper, and the second storage positions are used for containing the seals, so that synchronous transportation of the packaging paper and the seals can be realized; and meanwhile, the relative placement positions of the packaging paper and the seals are not changed, so that grabbing by a mechanical arm is facilitated.

Owner:CHINA TOBACCO GUANGXI IND

Equipment for preparation of organic fertilizers from solid waste

InactiveCN108821817AGood deadlineWon't run outBio-organic fraction processingInvertebrate treatmentBiogasOrganic fertilizer

The invention discloses equipment for preparation of organic fertilizers from solid waste. The equipment includes: a pool body; a treatment chamber; a liquid collection chamber, which is used for collecting redundant biogas liquid in the treatment chamber, is disposed below the treatment chamber, and can move up and down relative to the treatment chamber; a transfusion component, which is used forcommunicating the treatment chamber and the liquid collection chamber, and includes first liquid channels and a plurality of second liquid channels disposed under the first liquid channels; and a filter device, which includes first filter pieces matching the first liquid channels and second filter parts and flexible liquid flow parts that match the second liquid channels. According to the invention, biogas residue is filtered by the filter pieces and filter parts, outflow of biogas residue from the treatment chamber along with the biogas residue can be avoided, and the circumstance of material loss can be avoided; secondly, the equipment is also equipped with the flexible liquid flow parts, the flexible liquid flow parts can be opened only under the action of an external force, and then can cooperate with an opening-closing device to realize better cut-off of the second liquid channels, thus avoiding leakage.

Owner:陈桂芬

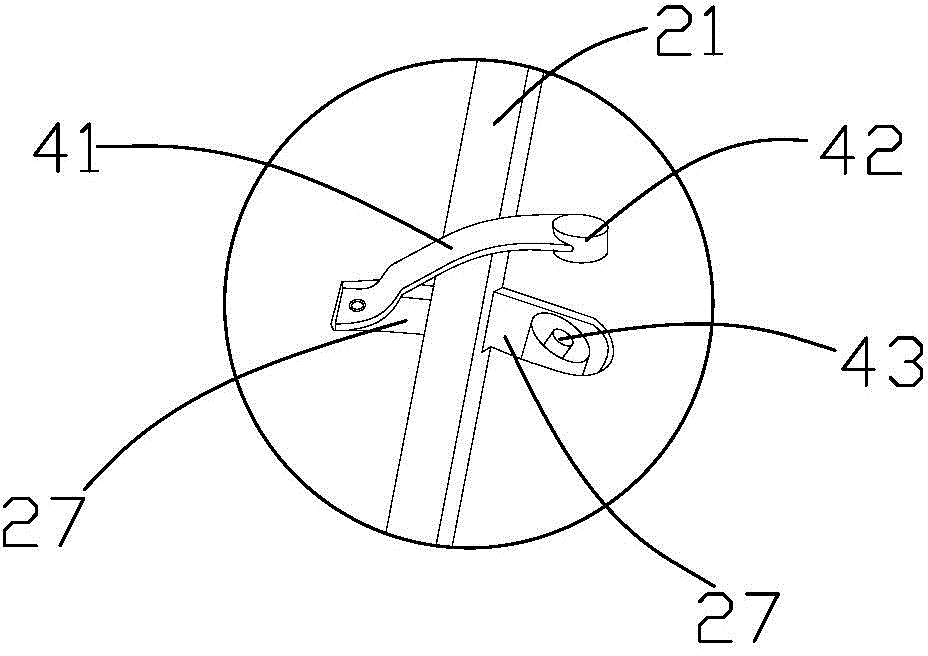

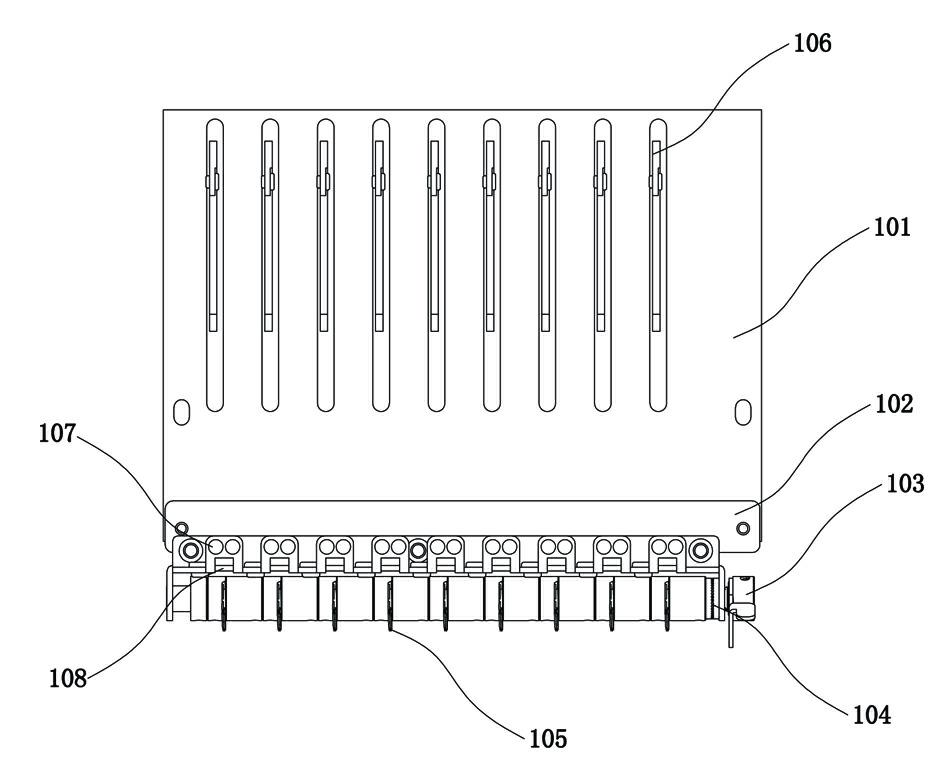

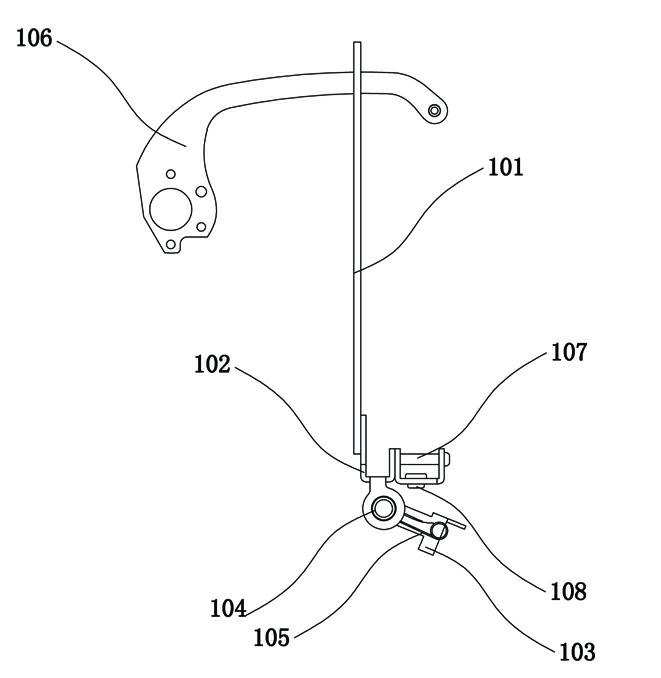

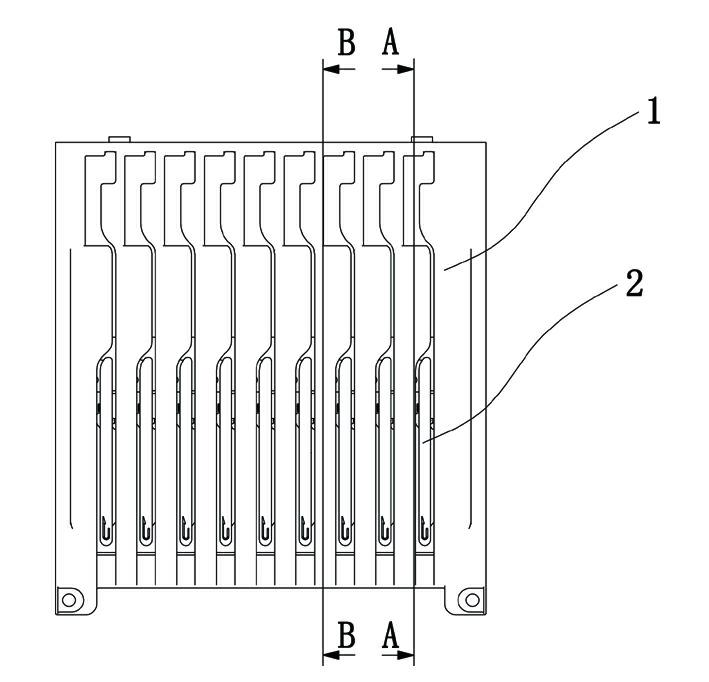

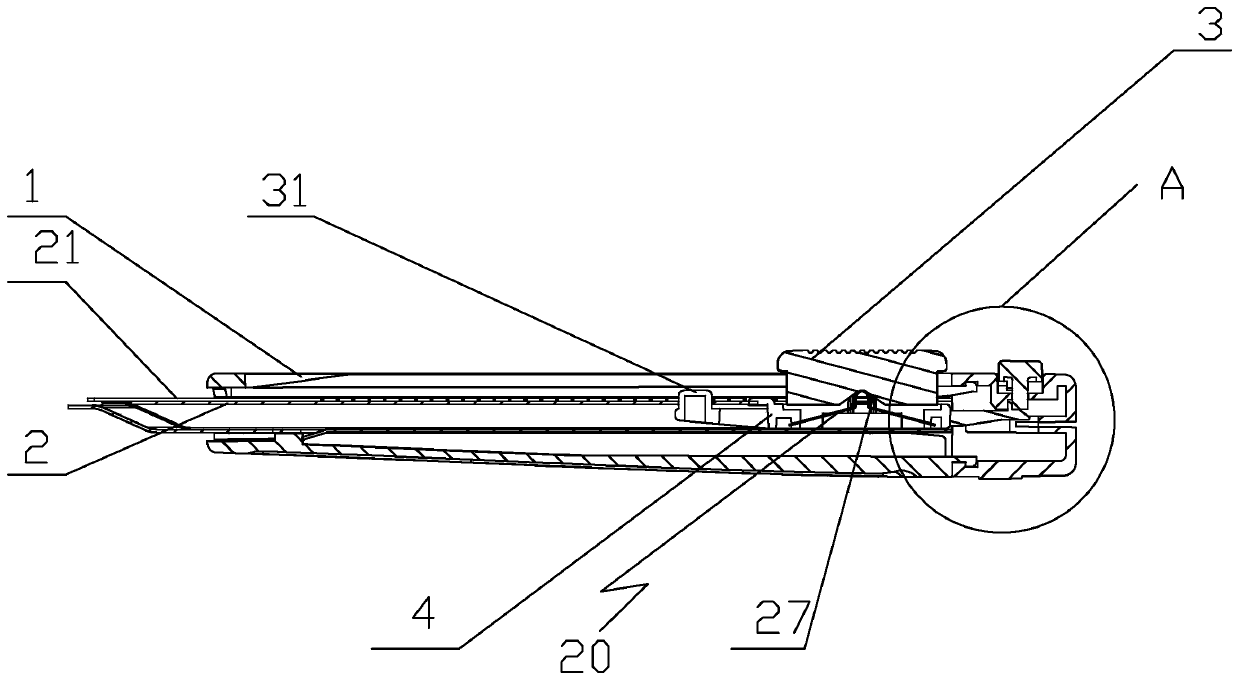

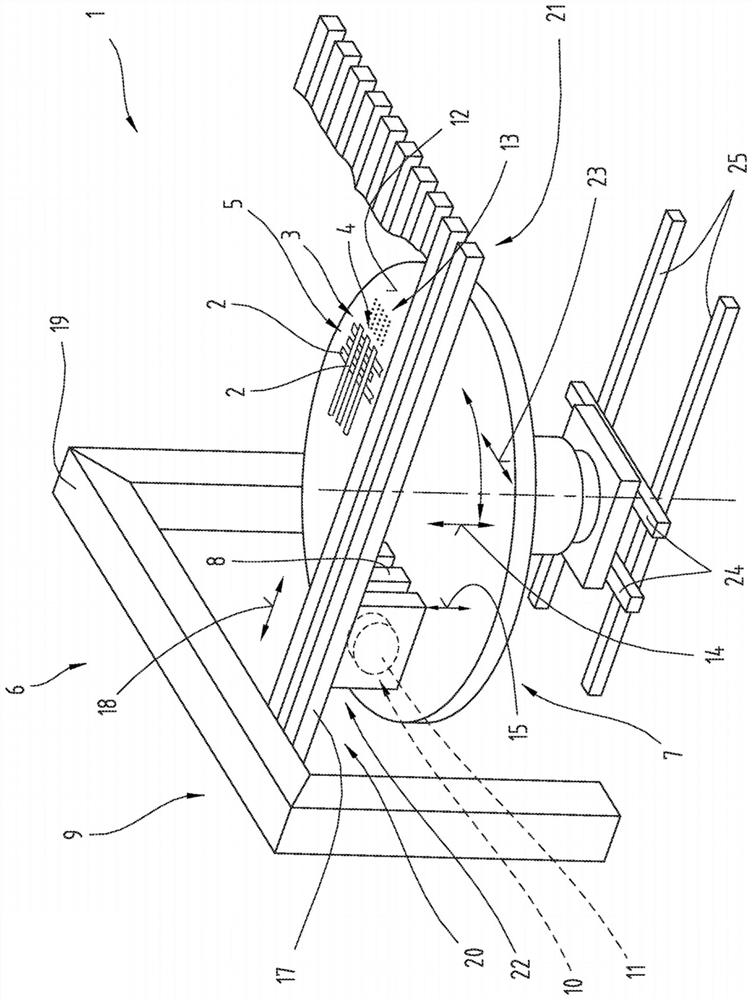

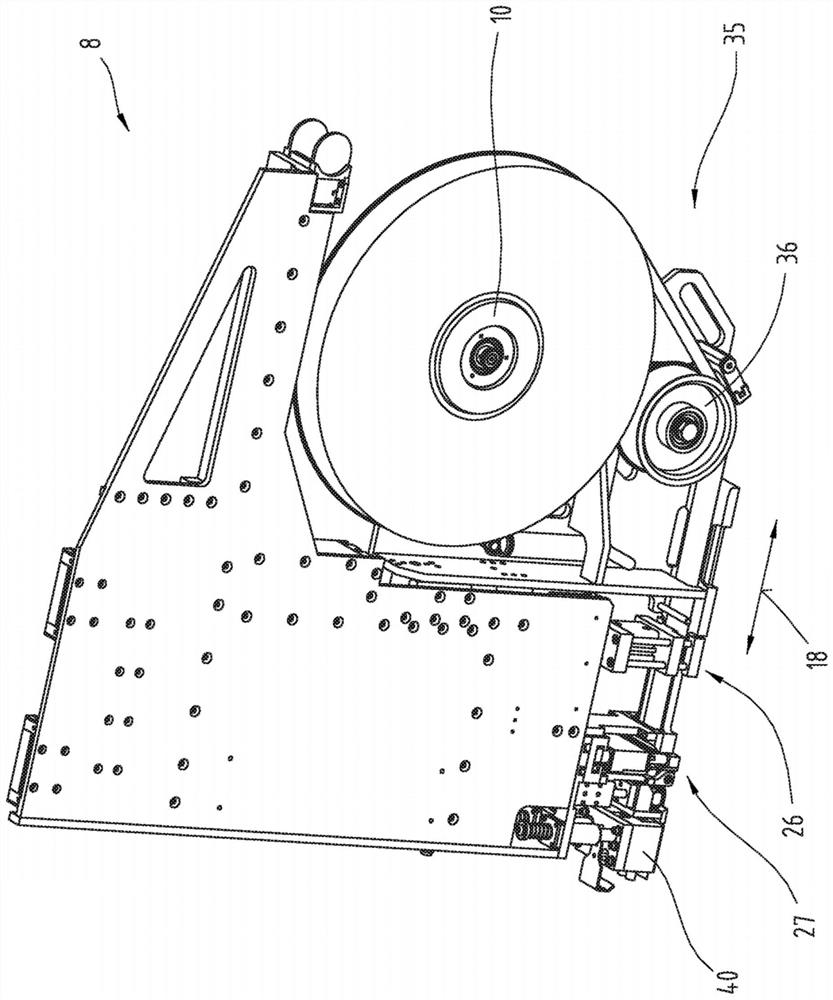

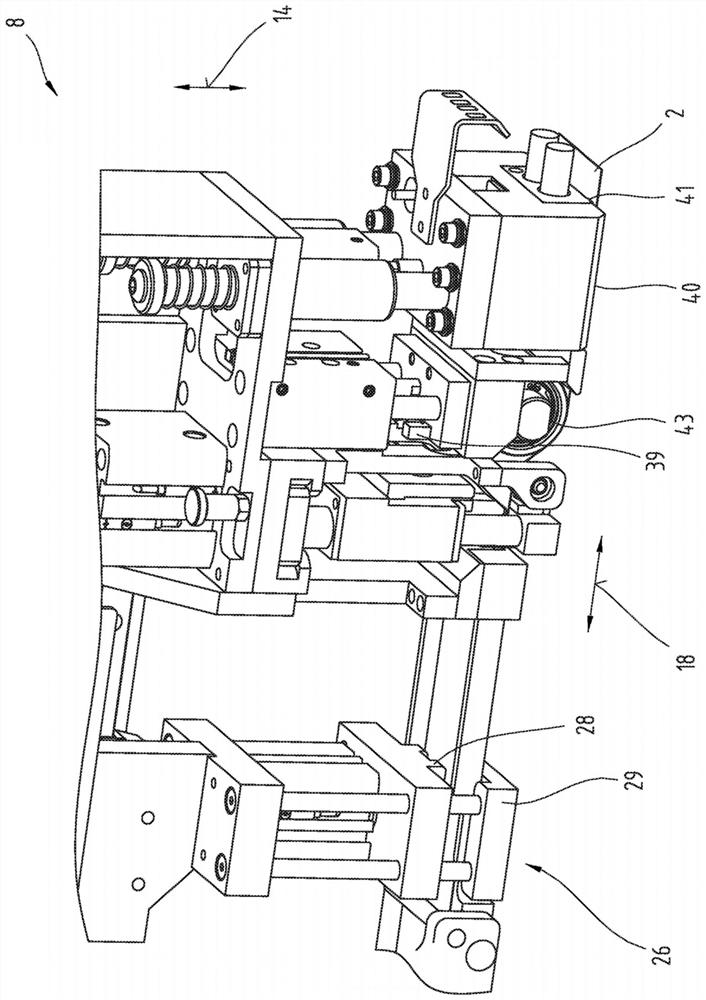

Manufacturing equipment for laying fiber tape

ActiveCN111201125BOptimize layoutShort time3D object support structuresApplying layer meansFiberManufactured material

The invention relates to a production plant (1) for laying fiber strips (2), said production plant (1) comprising a laying device (6) having an unwinding device receptacle (9) and a side-by-side At least two unwinding devices (8) arranged on the unwinding device receiving part (9), each said unwinding device (8) respectively includes a receiving device (10) for receiving a raw material coil (11) ) and a cutting unit (27) for cutting the fiber tape (2); surface (12), wherein the placement surface (12) of the placement device (7) and the unwinding device (8) of the laying device (6) are relatively movable relative to each other along the laying direction (18), whereby the fiber strip (2 ) can be unwound onto the placement surface (12) in strips. The at least two unwinding devices (8) are each coupled to the unwinding device receptacle (9) of the laying device (6) by means of a linear guide (17), and the at least two unwinding devices can be independent of each other The ground moves relative to the unwinder receptacle (9) in the laying direction (18).

Owner:费尔有限公司

Yarn-passing device of embroidery machine

The invention discloses a yarn-passing device of an embroidery machine, which comprises a base, wherein the base comprises a bottom plate and a face plate, the middle of the face plate is bulged outwards, both sides of the face plate are connected to the bottom plate, and a hollow cavity is formed between the face plate and the bottom plate; a plurality of yarn-passing assemblies are arranged in the cavity and respectively comprises a holding plate arranged on the bottom plate, the front sides of the holding plates extend out of the cavity from the face plates, and both sides of the holding plates, passing through the face plates, are provided with yarn-passing slots; and a tension regulator is arranged on one of the side face of the holding plates, and a take-up spring is arranged on thetension regulator and is provided with a tension spring end sleeved on the tension regulator and a take-up hook end extending out of the tension regulator. The whole yarn-passing device is a claddingbody; all assemblies are covered in the base so that the operators can not touch the moving parts of the yarn-passing device, thereby not resulting in part damages and personnel injuries.

Owner:DONGYANG JIALUN ELECTRONICS MACHINERY

pencil sharpener holder

The invention discloses a knife rest of a pencil sharpener. The knife rest of the pencil sharpener comprises a knife rest (1) and a hob shaft (2) equipped with a hob (14), wherein a shaft support seat (3) is arranged at one end of the knife rest (1), a shaft support (13) is arranged at the other end of the knife rest (1), two ends of the hob shaft (2) are mounted on the shaft support seat (3) and the shaft support (13) respectively, an angle adjusting device for adjusting the angle of the hob shaft (2) is arranged on the knife rest (1) and specially adopts a chute (4) arranged on the knife rest (1), and the shaft support seat (3) is in sliding fit in the chute (4). The knife rest of the pencil sharpener has the advantages of simple structure, simplicity in operation, low cost, high reliability and good cutting quality and can change the thickness of a pencil lead under the condition that the pencil lead cutting length is not changed.

Owner:雪松

Airbag Control

There is disclosed an airbag control arrangement for a steering-wheel mounted airbag in a motor vehicle having a steering-wheel mounted function switch, such as horn-switch. The arrangement comprises an airbag control circuit mounted to the steering wheel and including a first acceleration sensor, a second acceleration sensor, and a controller. The airbag control circuit is electrically connected to an auxiliary function circuit (e.g. a horn circuit) incorporating said function switch so as to derive operative electric power from the auxiliary function circuit. The controller is configured to output an actuating signal only in response to the receipt of signals from both acceleration sensors. The airbag control circuit is configured to switch from a sleep mode to an operative mode in dependence on an output signal from the first acceleration sensor; the second acceleration sensor being off and the controller drawing a low sleep-current current in said sleep mode, but both being energised and operable in said operative mode.

Owner:维宁尔瑞典安全系统公司

Spiral spindle for lens vacuum coating machine

A spiral spindle for a lens vacuum coating machine is composed of a V-shaped spindle end (1), a spindle body (2), a spiral blade (3), a sealing spindle sleeve (4) and key grooves (5). The sealing spindle sleeve (4) and the spiral blade (3) are arranged on the spindle body (2). One end of the spindle body (2) is the V-shaped spindle end (1), and the other end of the spindle body (2) is provided with the sealing spindle sleeve (4). The spiral spindle for the lens vacuum coating machine is characterized in that the spiral blade (3) is welded to the spindle body (2), and the key grooves (5) are formed in the stress surface of one side of the spindle body (2) and are symmetrically arranged; and a spring and a V-shaped cone are installed at a port of the V-shaped spindle end (1), and the V-shaped cone is in close fit with the V-shaped spindle end (1). According to the spiral spindle for the lens vacuum coating machine, multiple layers of sealing rings are designed inside the spindle sleeve, so that the effect that no gas leakage occurs between the spindle body and the sealing spindle sleeve is guaranteed, and under the dual guarantee of the port of the V-shaped spindle end and the sealing spindle sleeve, the spindle body ensures that the situation that vacuum gas escapes out of the coating machine from the matching surface of the spindle due to non-tight sealing is avoided.

Owner:JIANGSU RARE OPTICS CO LTD

A solid waste treatment pool

ActiveCN109020658BWon't run outIncrease return speedBio-organic fraction processingInvertebrate treatmentSlurryWaste treatment

The invention discloses a solid waste treatment pool. The solid waste treatment pool comprises: a pool body; a treatment chamber; a liquid collection chamber, which is used for collecting excess biogas slurry in the treatment chamber, is disposed below the treatment chamber and can move up and down relative to the treatment chamber; an infusion component, which is used for communicating the treatment chamber and the liquid collection chamber, and includes a first liquid channel and a second liquid channel disposed under the first liquid channel; and an open-close device, which can close or open the second liquid channel. When the liquid collection chamber moves from the bottom up, the open-close device opens the second liquid channel for conveying of the liquid from the liquid collection chamber to the treatment chamber. When the liquid collection chamber moves from the top down, the open-close device closes the second liquid channel. According to the invention, the treatment chamber is equipped with the first liquid channel and the second liquid channel, so that biogas slurry can flow back into the treatment chamber through the first liquid channel and the second liquid channel, the backflow speed is fast, and the efficiency is high.

Owner:济宁明德环保科技有限公司

Mechanical type seal valve

PendingCN108443543ASolve the problem that the liquid seal cannot be realizedWon't run outEngine sealsEqualizing valvesEngineeringMechanical engineering

The invention relates to a mechanical type seal valve. The seal valve comprises a shell, a seal ring and a lining; the seal ring and the lining are arranged in the shell, the shell is provided with atop portion and a shoulder portion, the top portion is annular, a seal circle is arranged in the middle of the top portion, the shoulder portion is formed in a manner the edge of the top portion extends downwards towards the central axis, the upper end and the lower end of the shoulder portion are arranged eccentrically, the shoulder portion is provided with a first semi-cycle side face and a second semi-cycle side face, at least one ventilation hole is formed in the second semi-cycle side face, and a pressure relief device is arranged in each ventilation hole. A supporting table is arranged on the lower end of the shoulder portion, the seal ring abuts against the supporting table, the lining is in abut joint with the seal ring, the lining is matched with two notches of the shell, and at least one square hole is annularly formed in the position, corresponding to the second semi-cycle side face, of the middle of the lining. The valve is suitable for vehicles below 4.5 tons, and the problem that an oil filling pipe is short, and liquid seal cannot be achieved is solved.

Owner:武汉腾索科技有限公司

Ganoderma spore powder acquisition method and acquisition bag thereof

The invention discloses a ganoderma spore powder acquisition method, comprising the following steps: when acquiring the ganoderma spore powder, covering an acquisition bag outside the ganoderma pileus; fastening the opening of the acquisition bag on the ganoderma stipe; arranging a group of air vents at the lower part of the acquisition bag; the air vents are positioned below the ganoderma pileus; taking down the acquisition bag after acquiring for a while; and collecting the pore powder in the acquisition bag and on the ganoderma stipe. In the invention, a light acquisition bag with a transparent film is fastened on the ganoderma stipe to carry out ganoderma pore powder acquisition; air vents are arranged on the side wall of the acquisition bag and below lamella horizontal position to lead the inner and outer conditions of the acquisition bag to reach unanimity, thus all the ganoderma spore powder ejected from lamella can be collected; and the ganoderma spore powder has high yield, is not affected by damp, and has good quality. The method of the invention has simple and convenient operation, can be used in no need of guidance of technical personnel, and is suitable for popularization and application.

Owner:浙江龙泉佳宝生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com