Hydrogen-corrosion-preventing sealing device, hydrogen-corrosion-preventing motor and hydrogen circulating pump

A sealing device and hydrogen-proof technology, which is applied in the direction of pump devices, electromechanical devices, electrical components, etc., can solve the problems of sealing failure, motor stator corrosion, etc., and achieve the effect of good sealing, simple installation structure, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

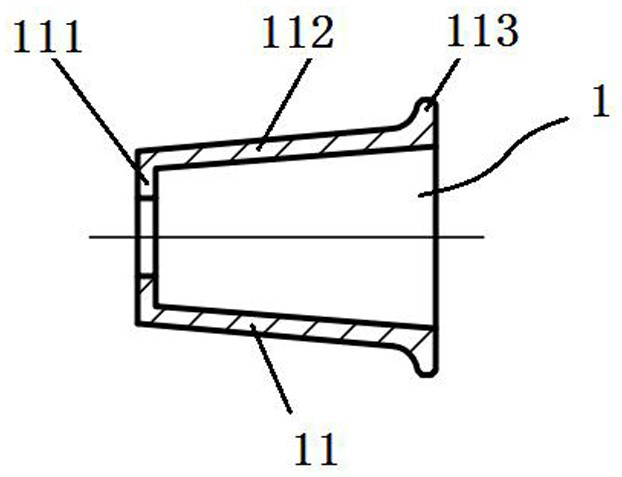

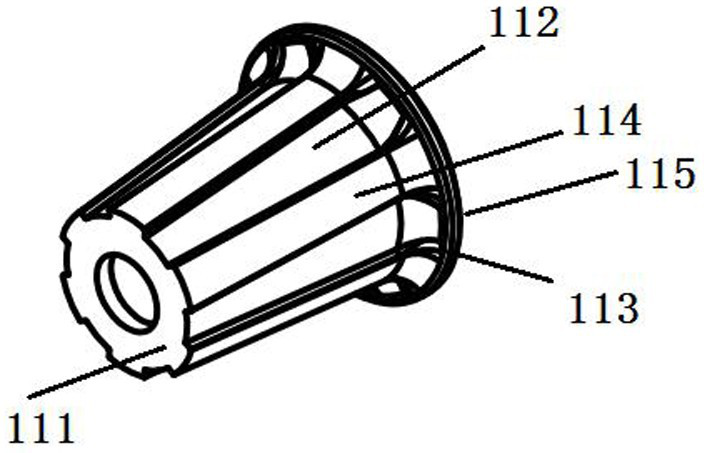

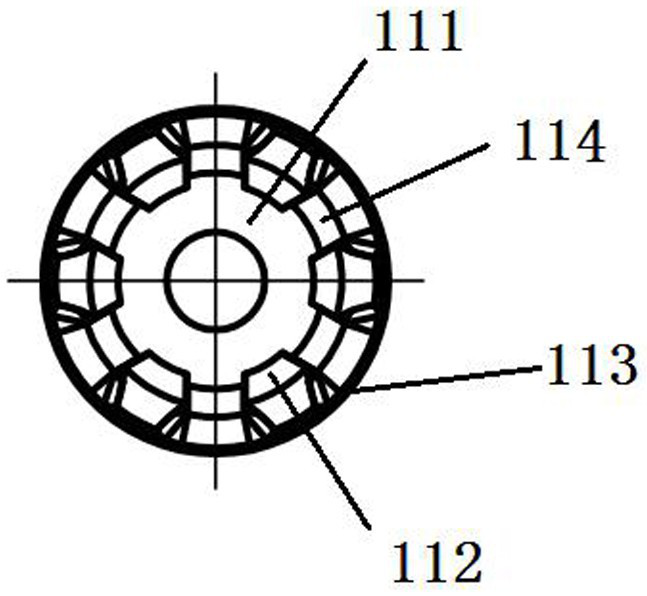

[0036] A hydrogen-corrosion-proof sealing device 1, as shown in Figure-3, includes a cone-shaped basin-shaped body made of hydrogen-corrosion-proof non-metallic composite materials (such as PEEK+30%GF polyether ether ketone+30% glass fiber material) 11. The tapered basin-shaped body 11 includes a basin bottom 111 , a conical portion 112 and an upper edge 113 , and the small-diameter side of the conical portion 112 (that is, the basin bottom 111 of the body) is sealed to form the basin bottom 111 , and the center of the bottom of the pot 111 has a hole so that the three shafts of the rotor of the motor can pass through smoothly; Its large diameter side extends outward along its radial direction.

[0037] Preferably, the taper of the tapered portion 112 of the body 11 is no more than 5 degrees, and the surface of the tapered portion 112 along its axial direction is provided with a rib 114 that fits into the notch 215 of the stator 2 . Such as figure 1 The six ribs 114 shown ar...

Embodiment 2

[0041] A hydrogen corrosion-resistant motor, such as Figure 4-5 As shown, the stator 2 and the rotor 3 of the motor are isolated by using the above-mentioned hydrogen corrosion prevention sealing device 1. The hydrogen corrosion prevention sealing device 1 is now an anti-hydrogen corrosion lining, and its basin bottom 111 passes through the first A sealing positioning protrusion 1151 cooperates with the front positioning groove provided by the motor front end cover 4 to realize sealing positioning, and the upper edge 113 is connected with the rear end of the motor through the second sealing positioning protrusion 1152 provided thereon. The cover 7 is hermetically positioned, and the stator 2 is isolated in a closed space formed by the hydrogen corrosion prevention sealing device 1 and the casing 6 of the motor.

[0042] Inside the anti-hydrogen corrosion motor, the hydrogen gas overflowing into the motor through the booster pump chamber only exists in the anti-hydrogen corros...

Embodiment 3

[0047] A hydrogen circulation pump, using the above-mentioned anti-hydrogen corrosion motor as a power source, and the part where the shaft of the rotor 3 of the hydrogen corrosion prevention motor protrudes from the motor casing 6 is connected with the circulation impeller of the hydrogen gas circulation pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com