Patents

Literature

37results about How to "Uniform technical effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

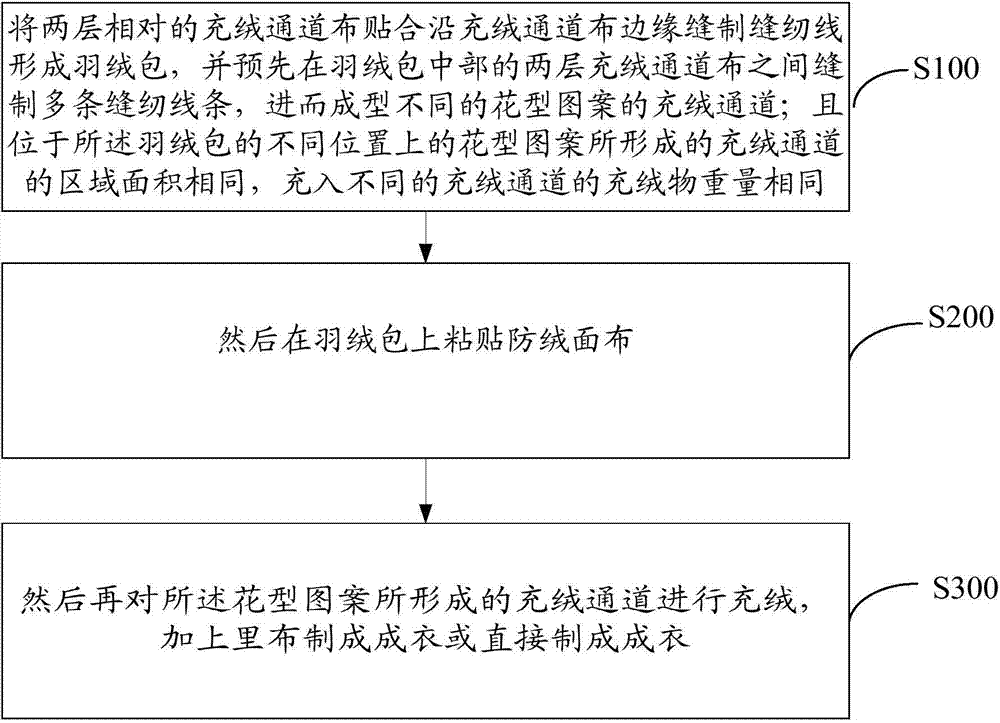

Manufacturing method of down feather escape-free down jacket and down feather escape-free down jacket

InactiveCN104705880AAvoid uneven thicknessWon't run outOvergarmentsProtective garmentEngineeringMechanical engineering

The invention discloses a manufacturing method of a down feather escape-free down jacket and the down feather escape-free down jacket. The manufacturing method comprises the following steps: pre-sewing a plurality of sewing threads between two pieces of down feather filling channel cloth in the middle of a down feather bag so as to mould down feather filling channels with different patterns; then adhering down feather resisting shell cloth on the down feather bag; and then filling down feather into the down feather filling channels formed by the patterns and adding liner cloth to prepare product clothes or directly preparing product clothes. The manufacturing method of the down feather escape-free down jacket and the down feather escape-free down jacket disclosed by the invention can be used for mainly solving the problems that down feather of a conventional down jacket in the market escapes, is pressed and split in a nonuniform manner and the like.

Owner:江志宏

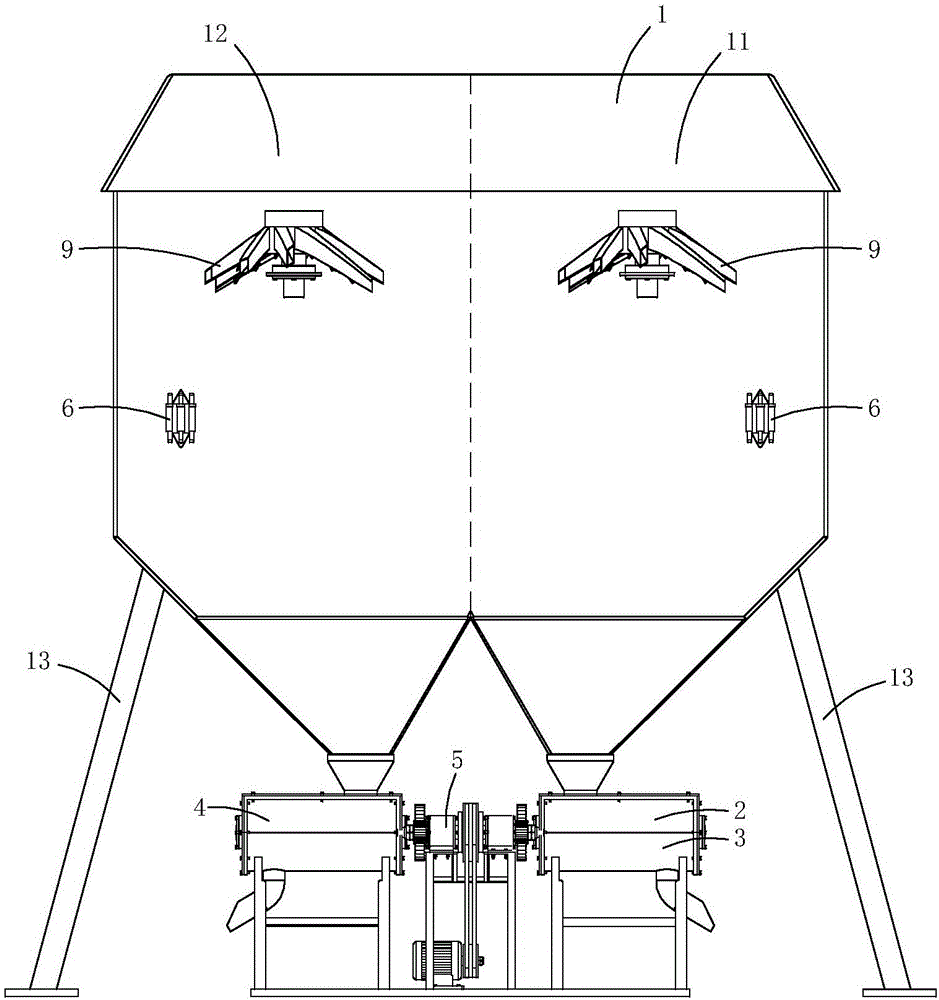

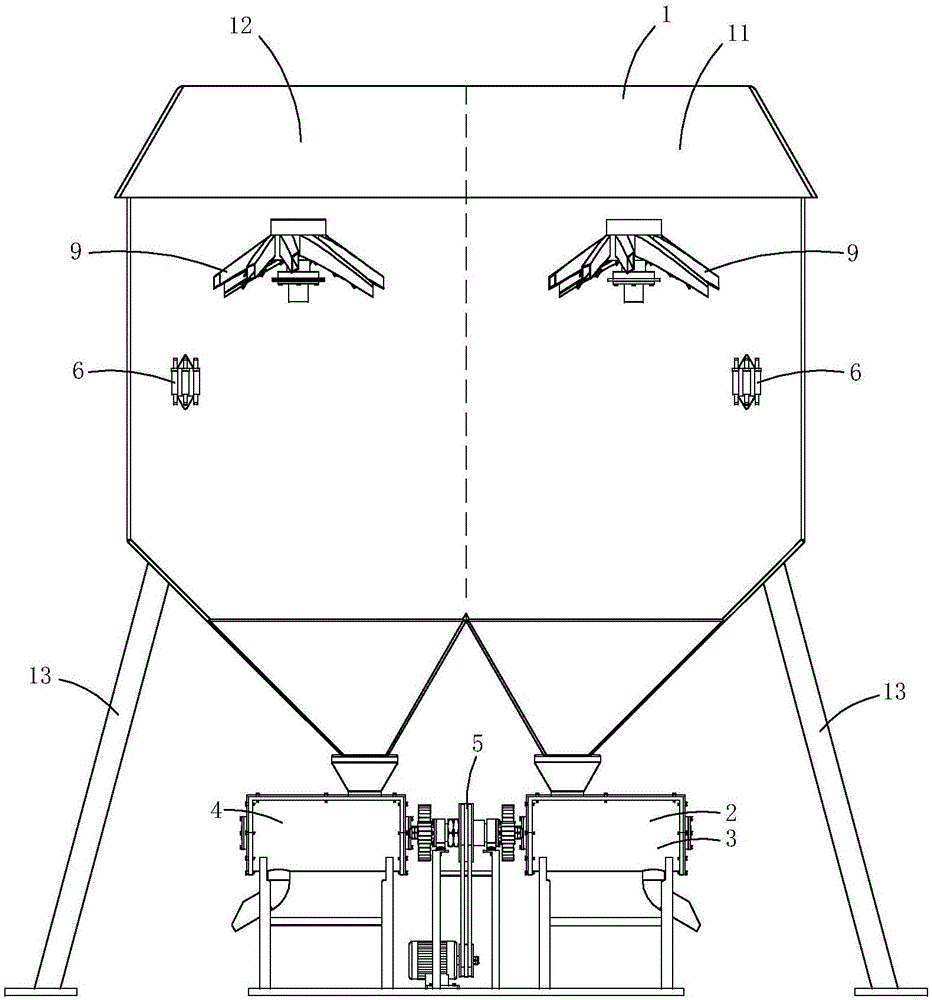

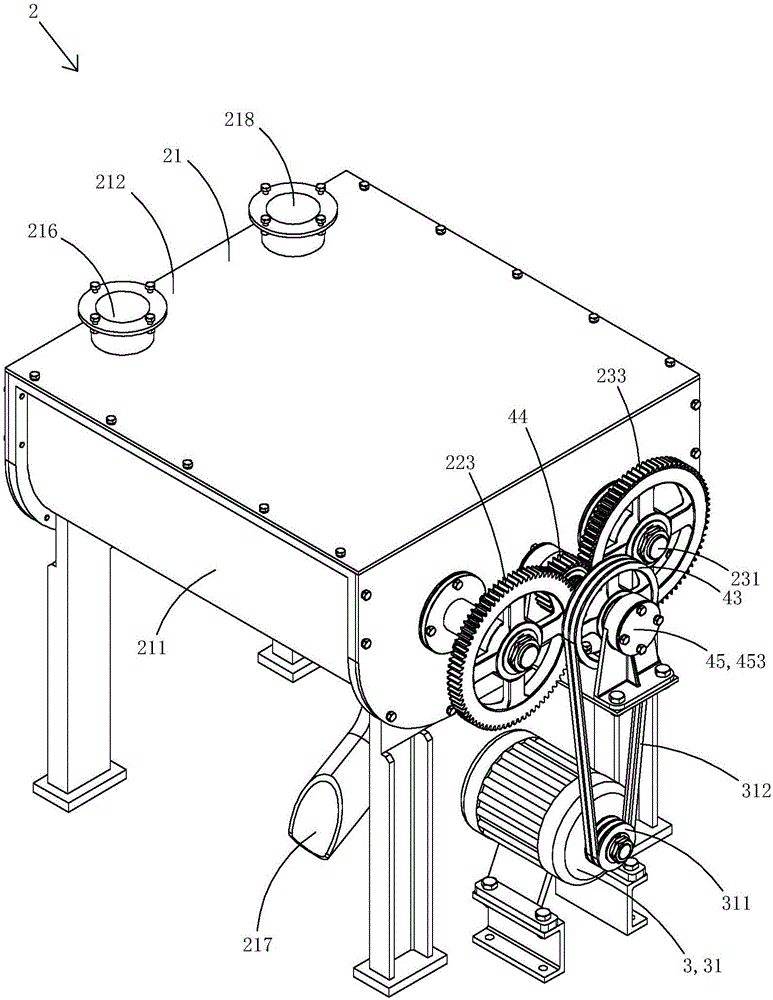

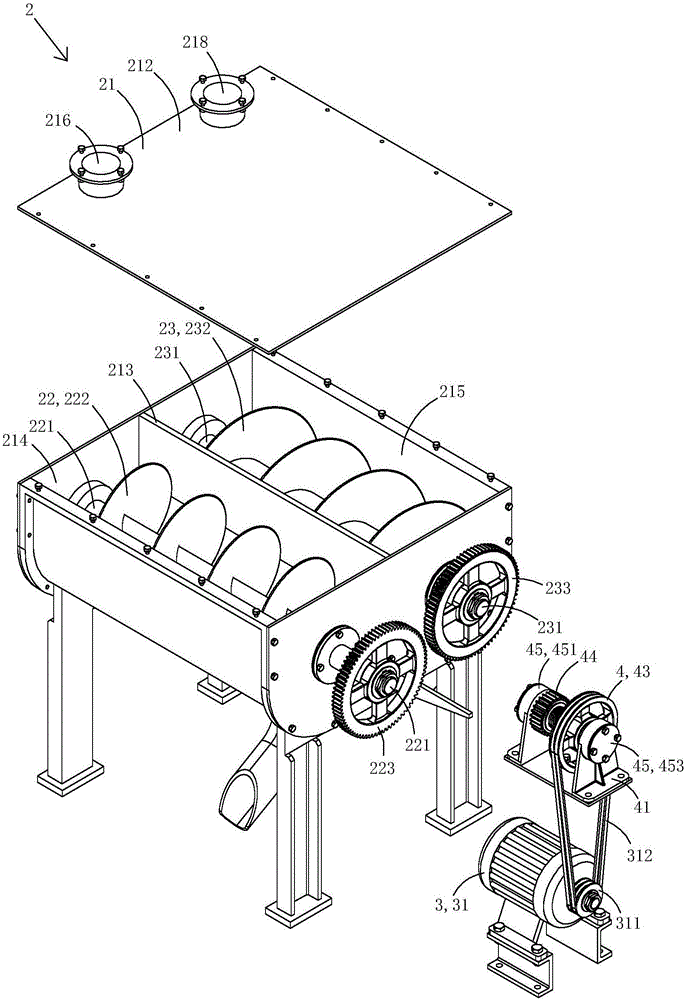

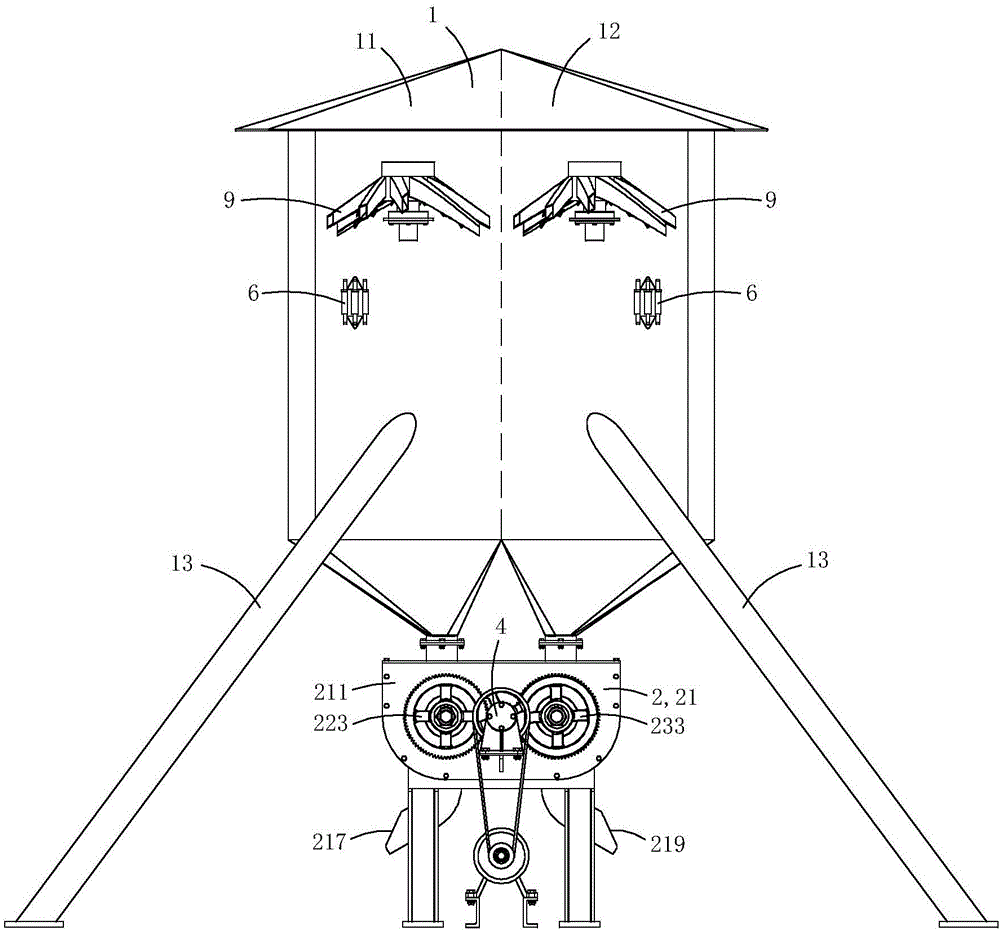

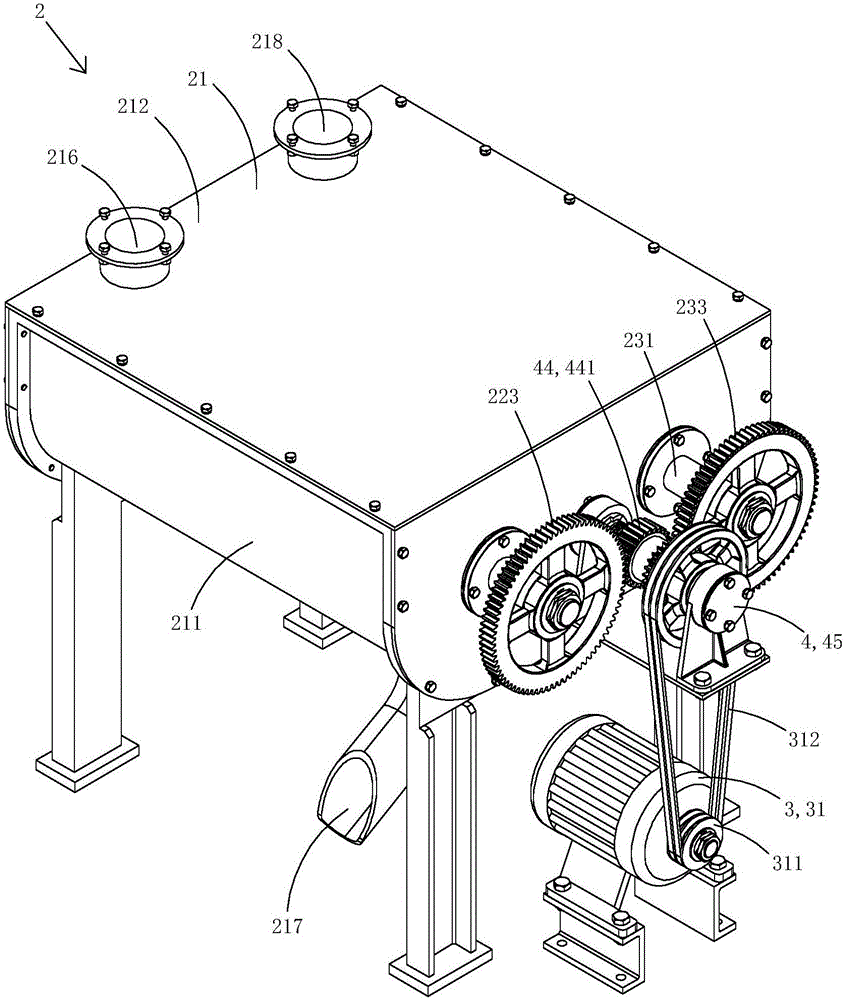

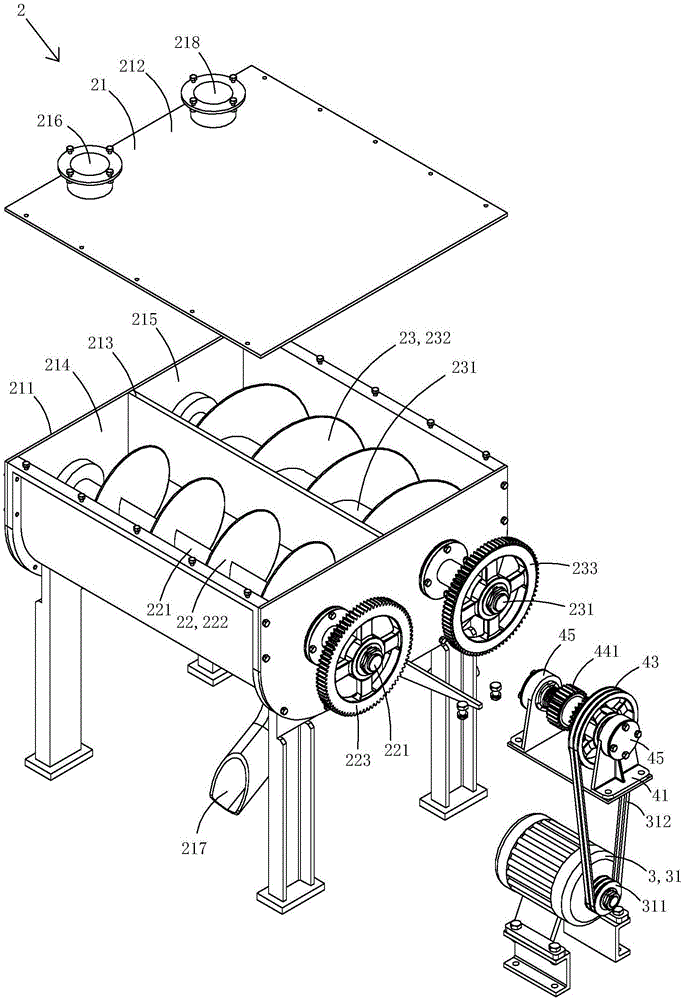

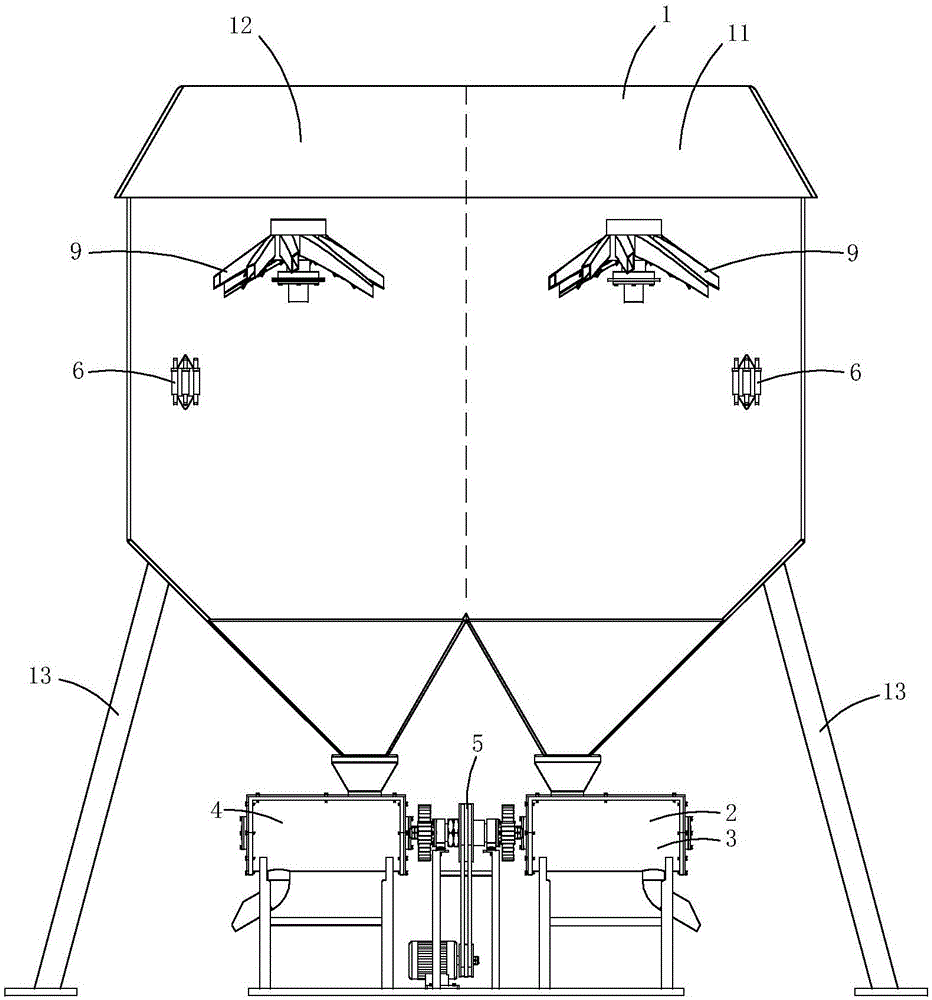

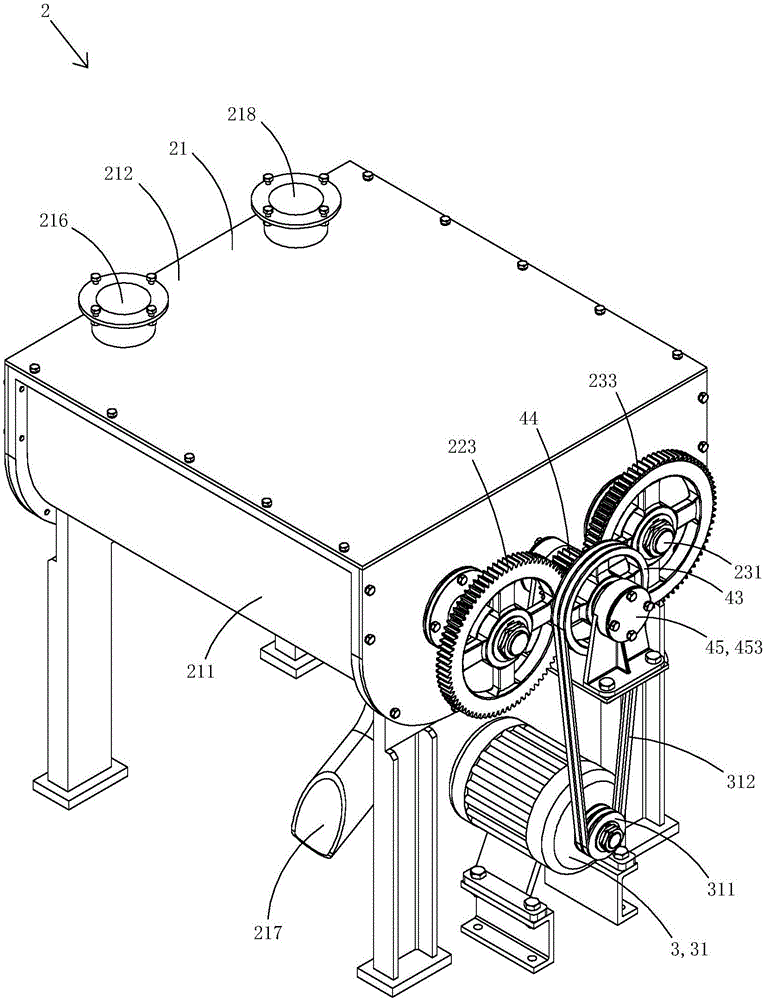

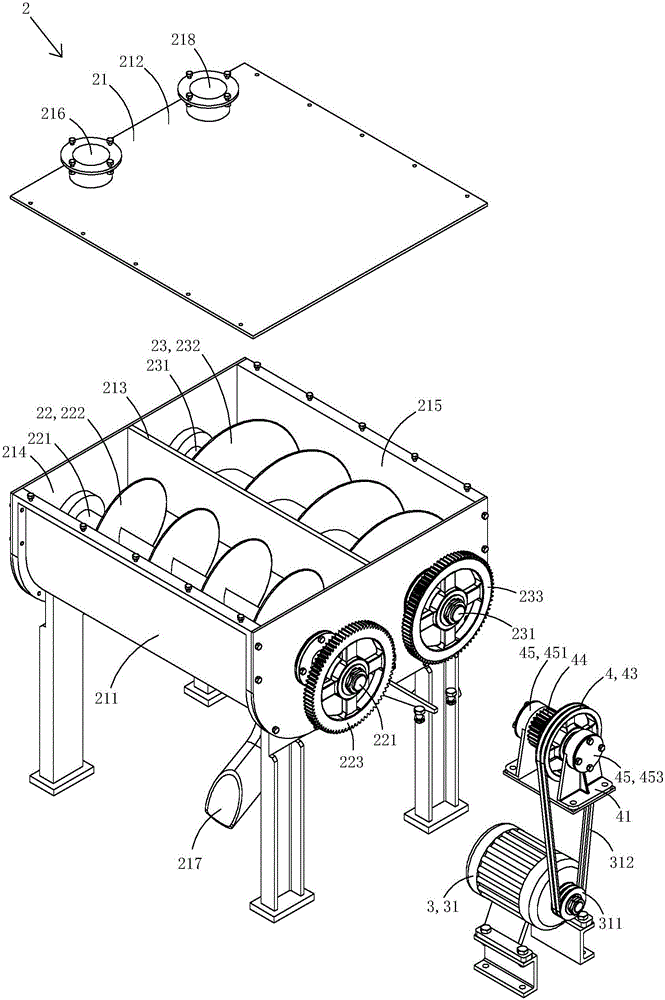

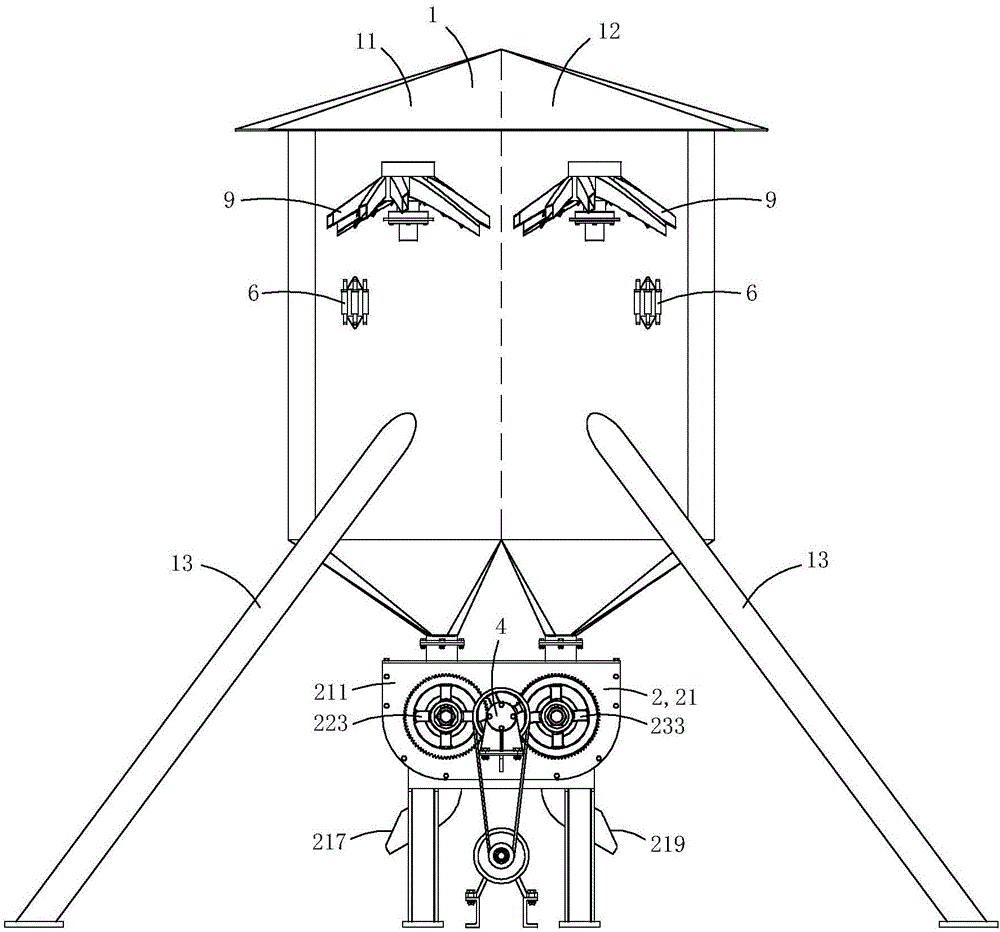

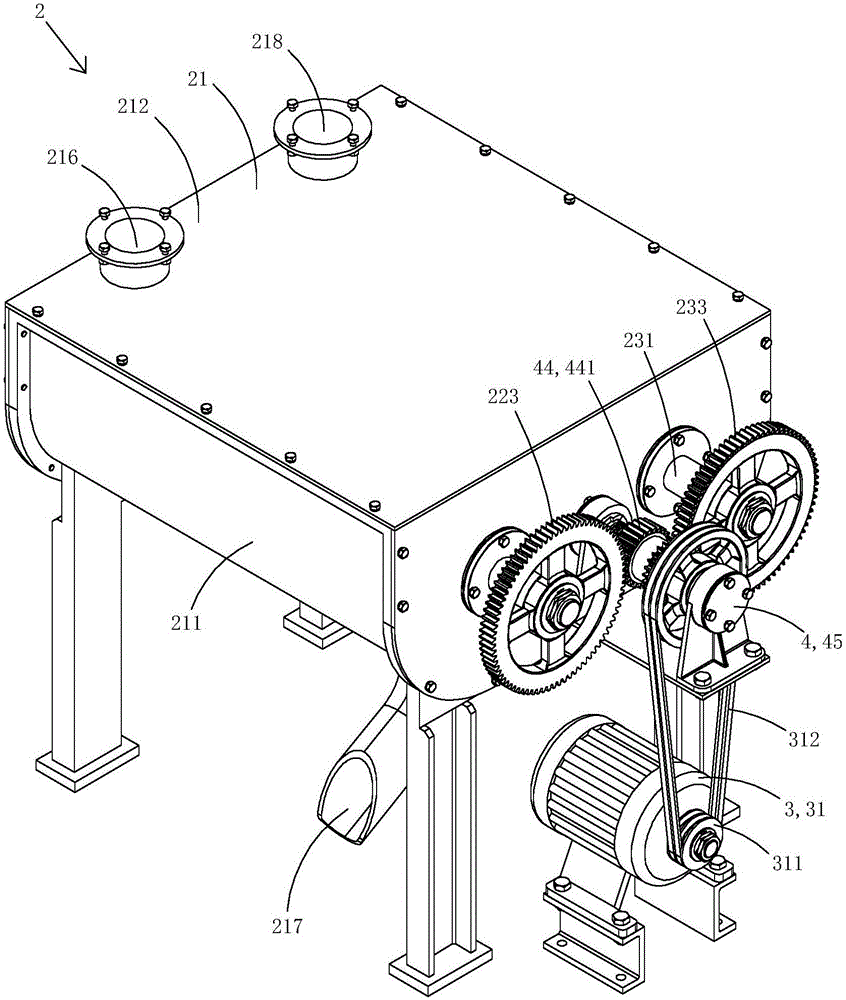

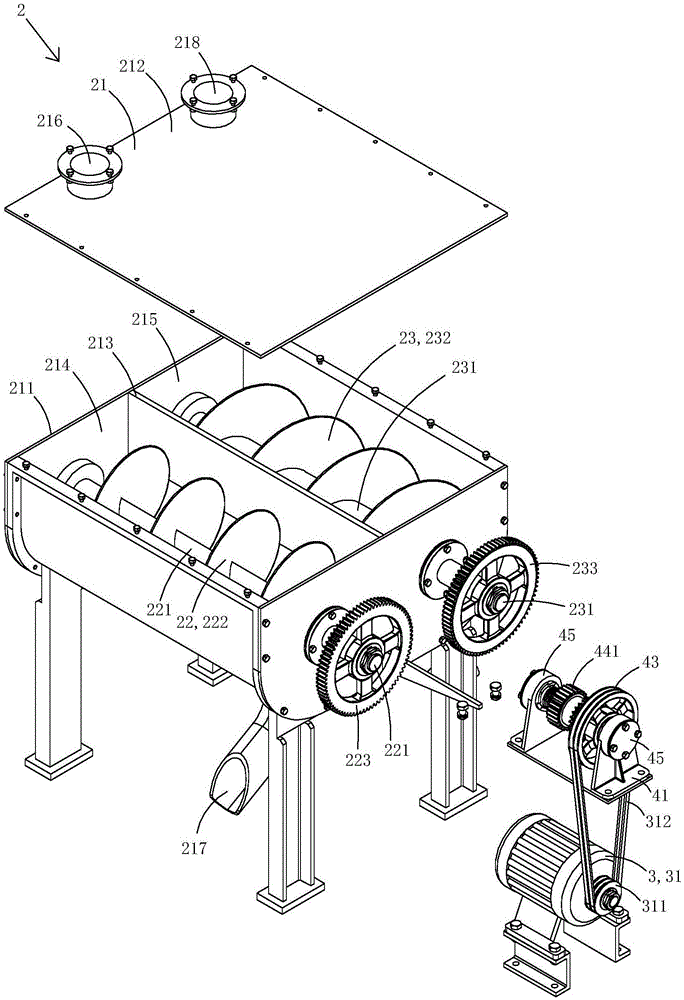

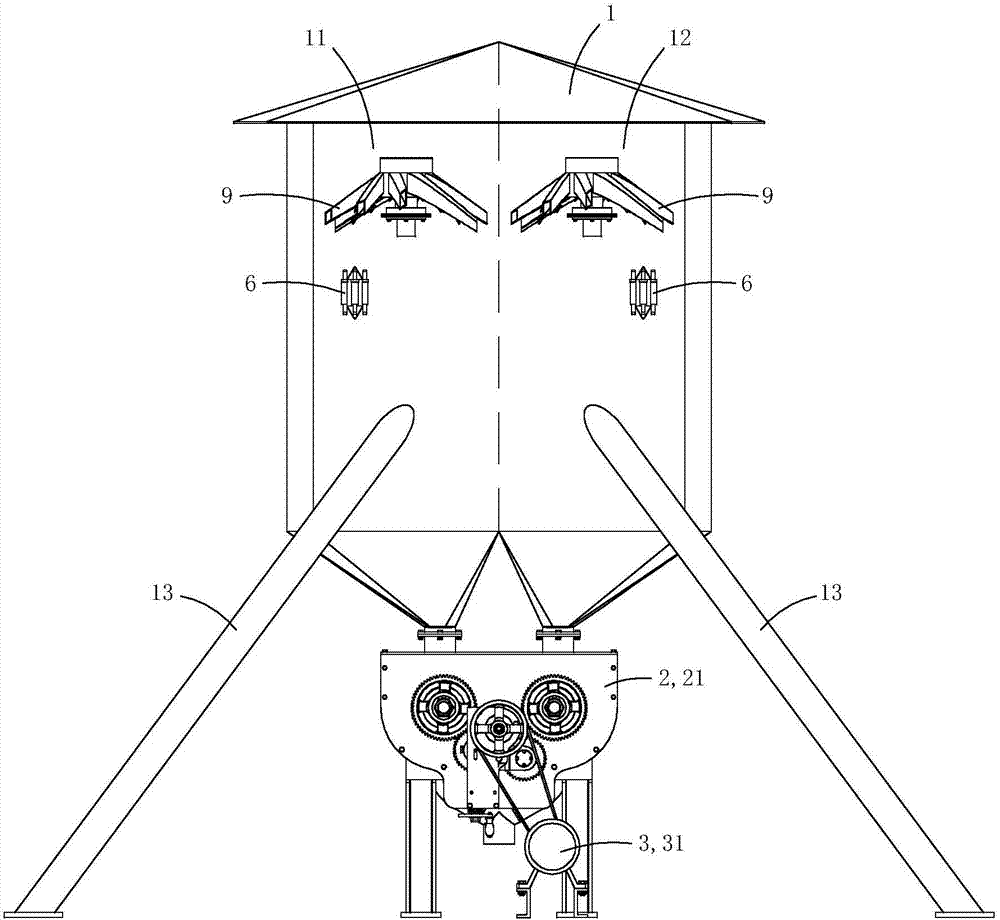

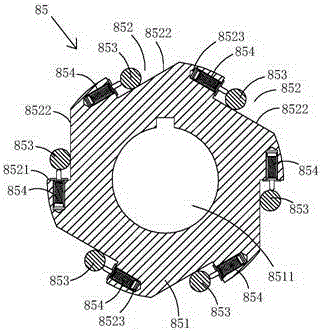

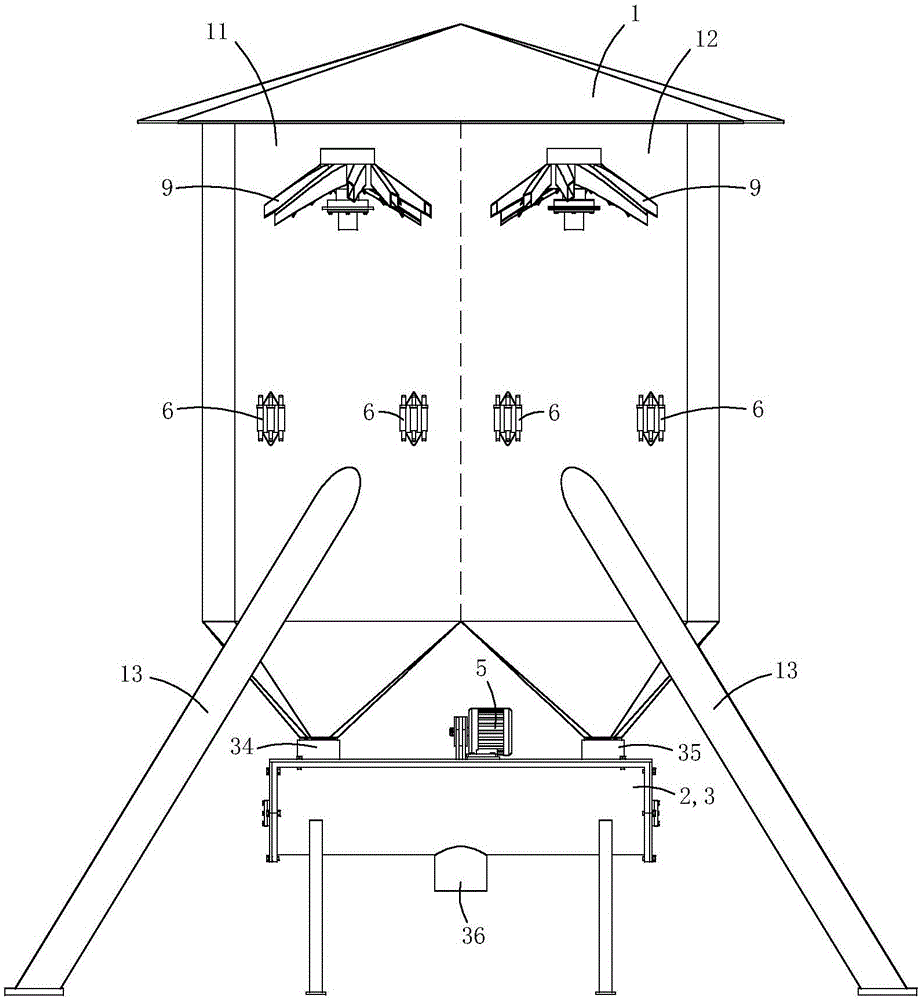

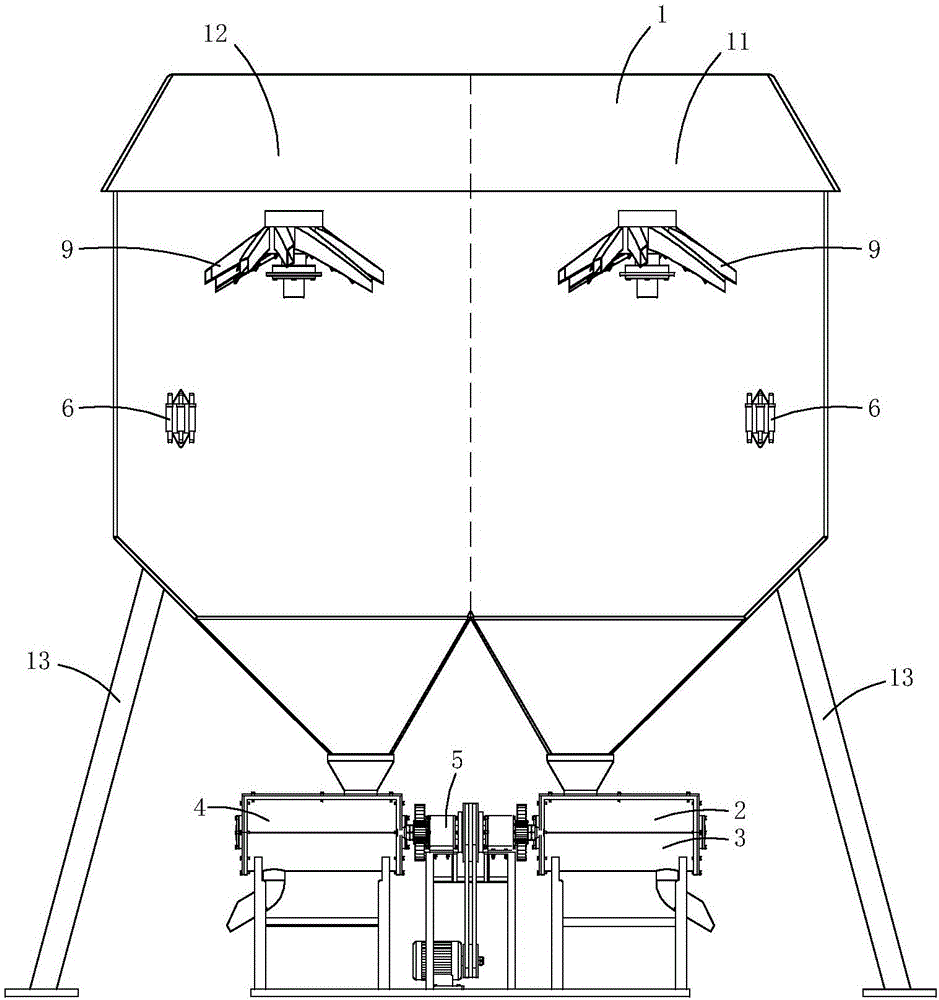

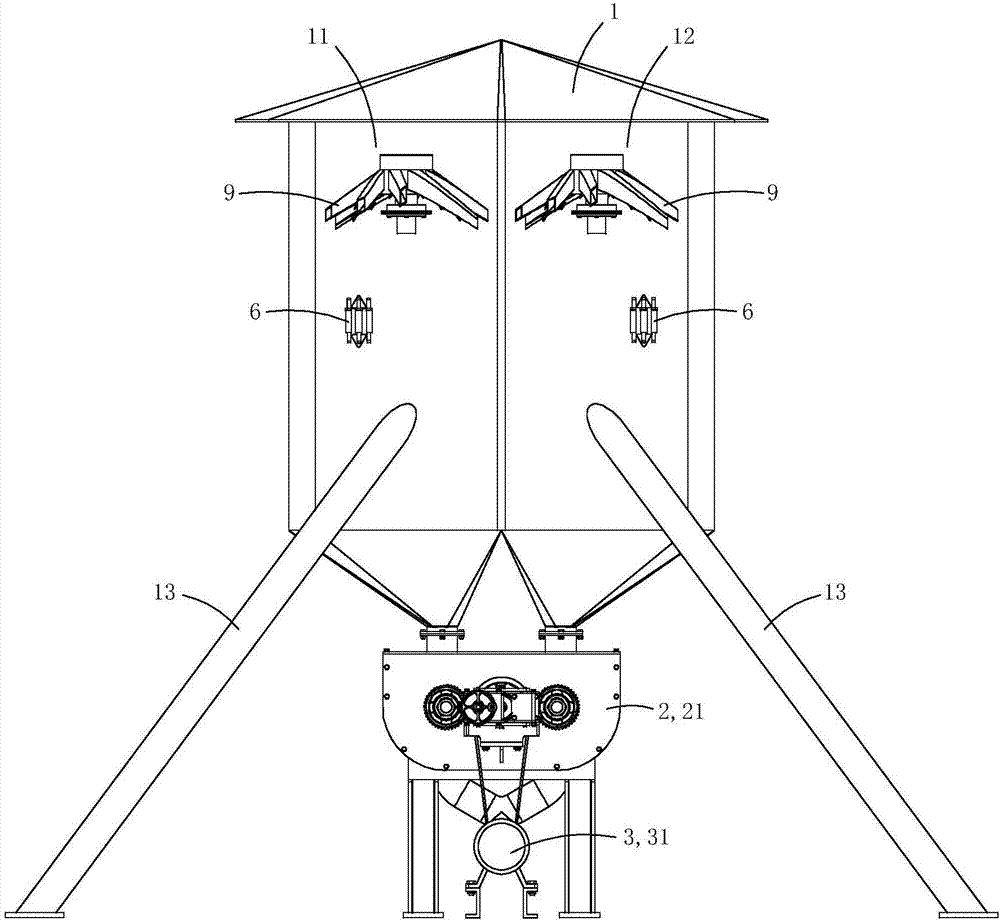

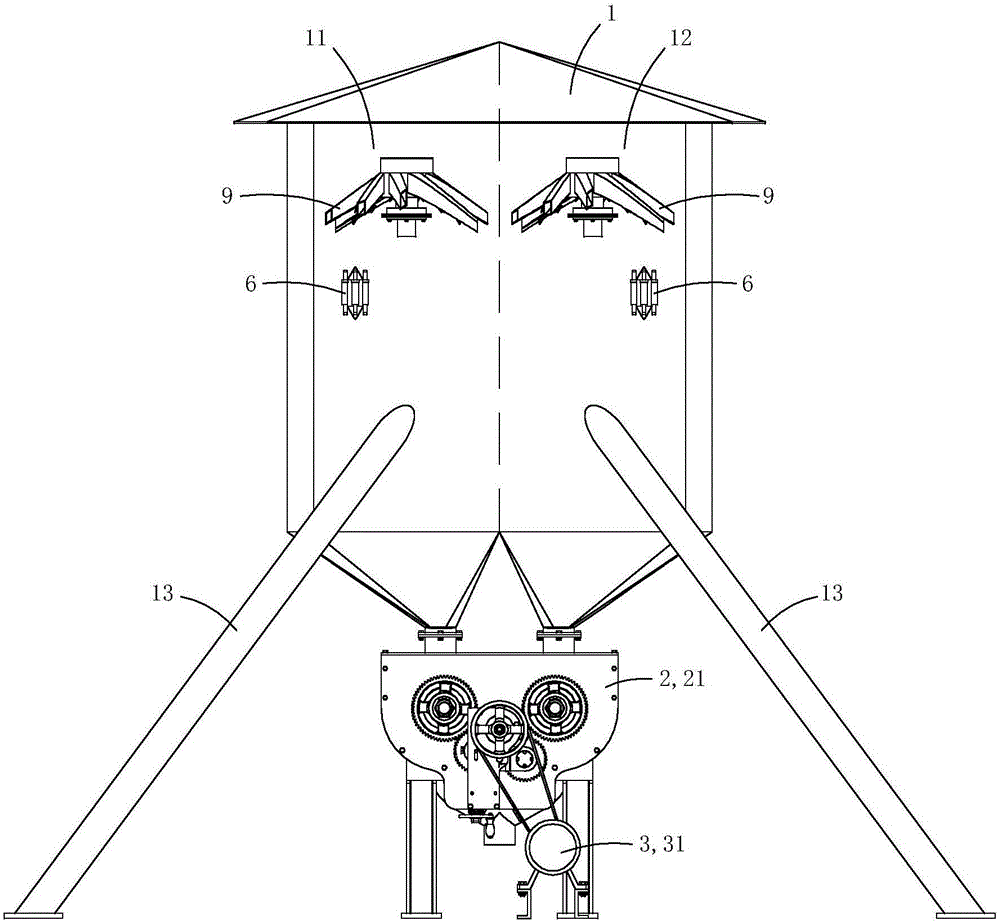

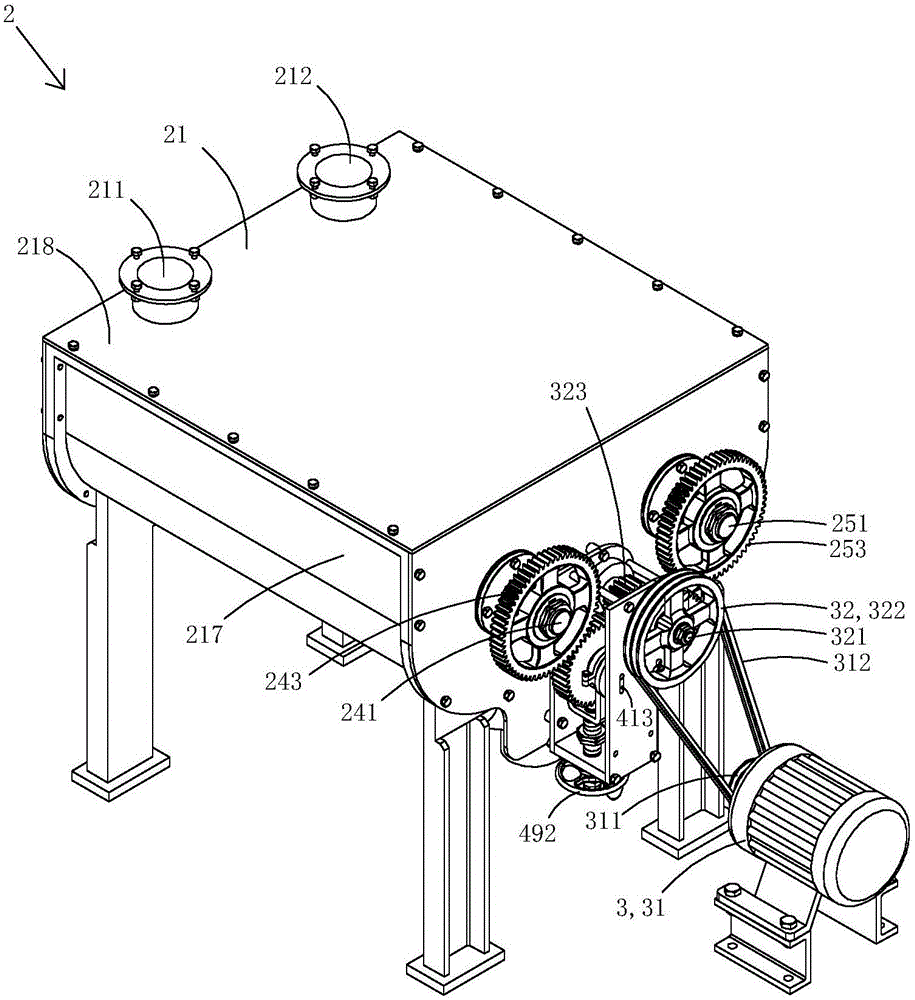

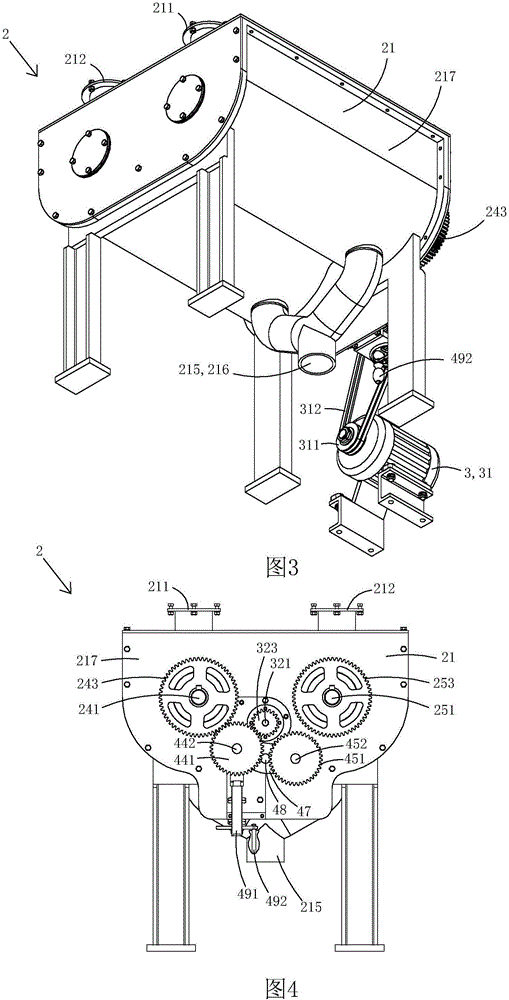

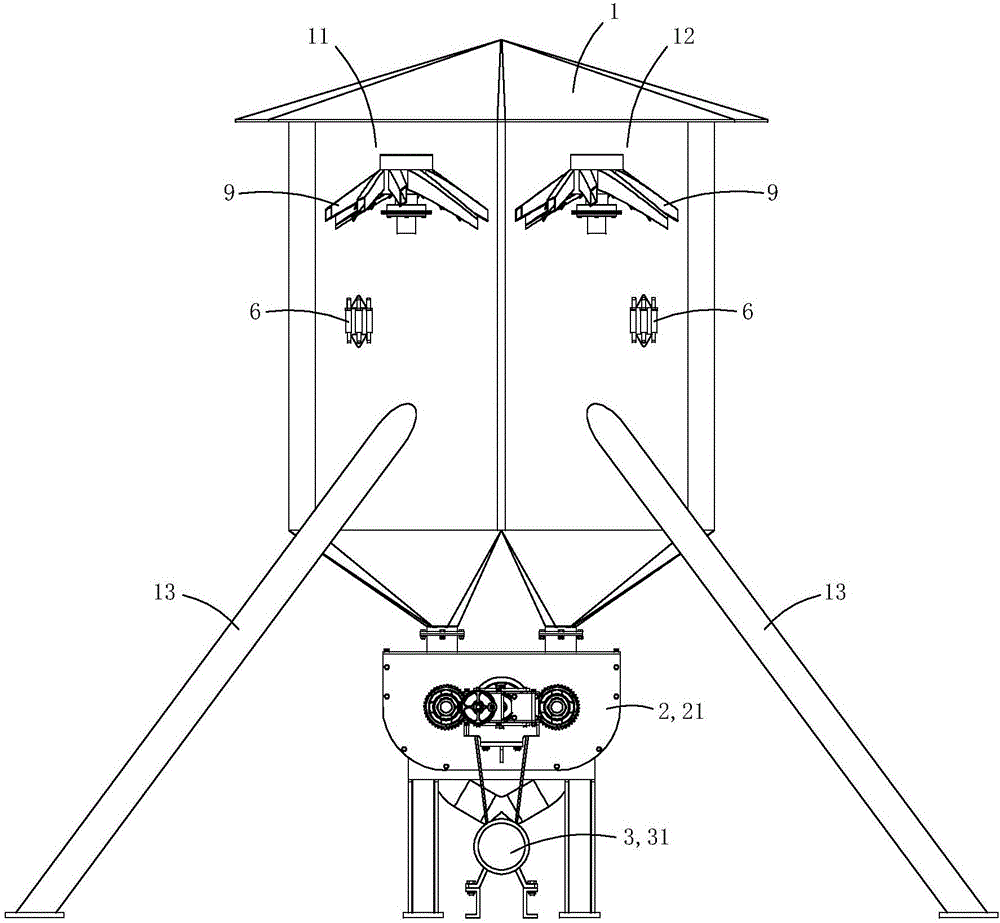

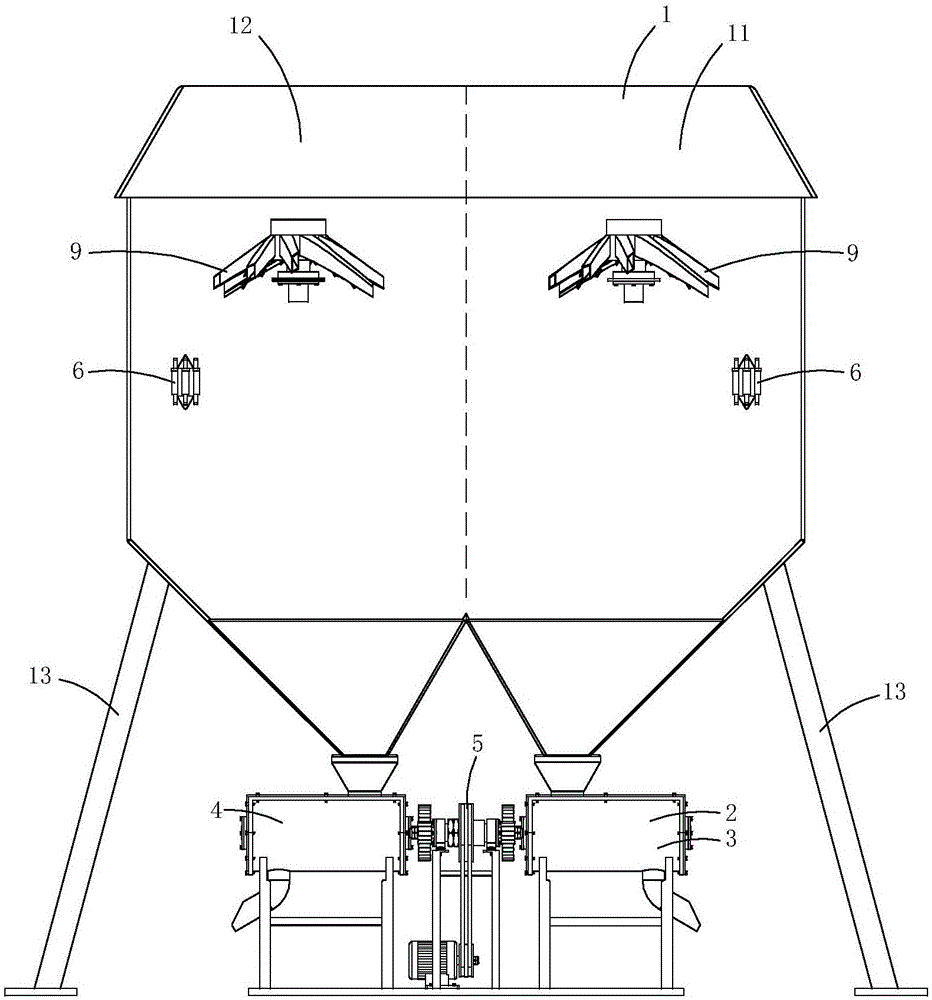

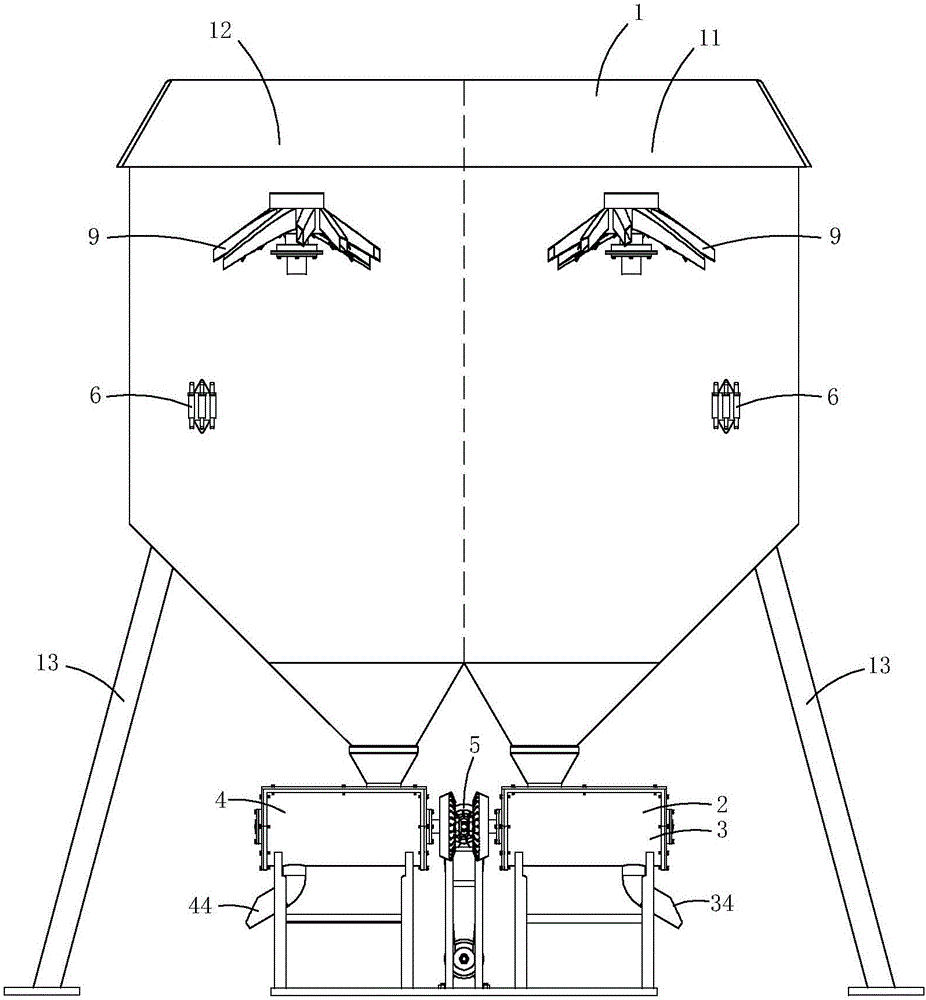

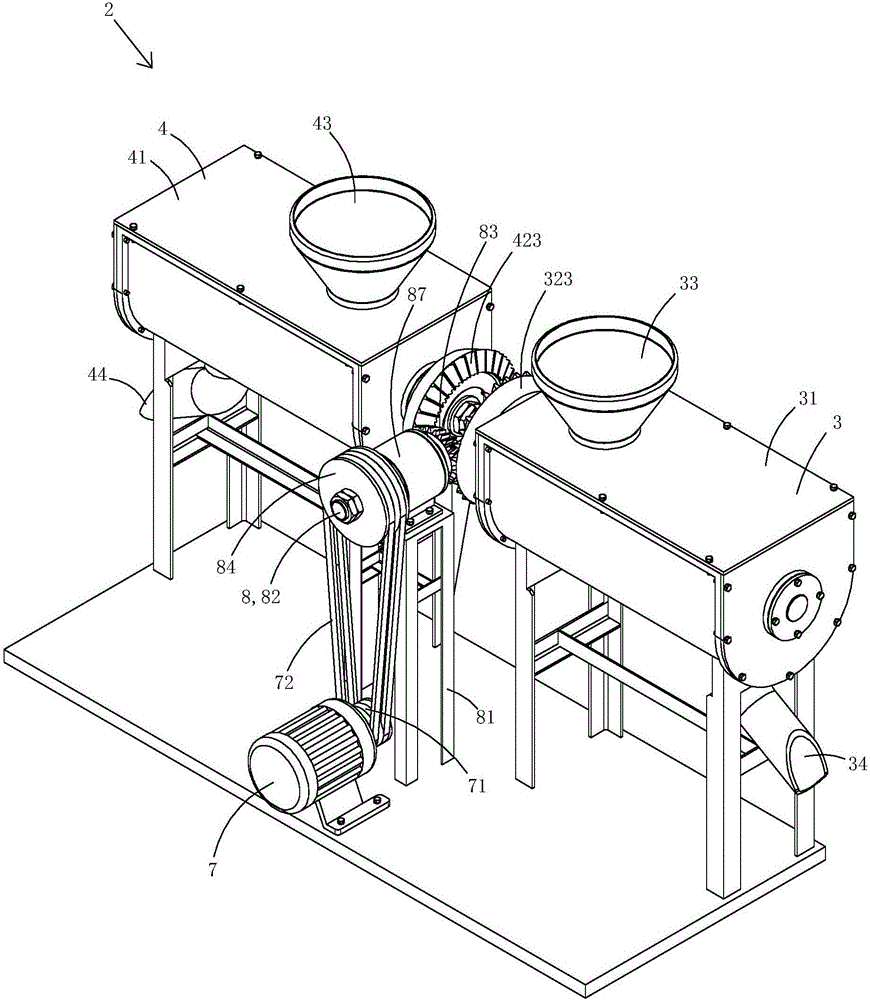

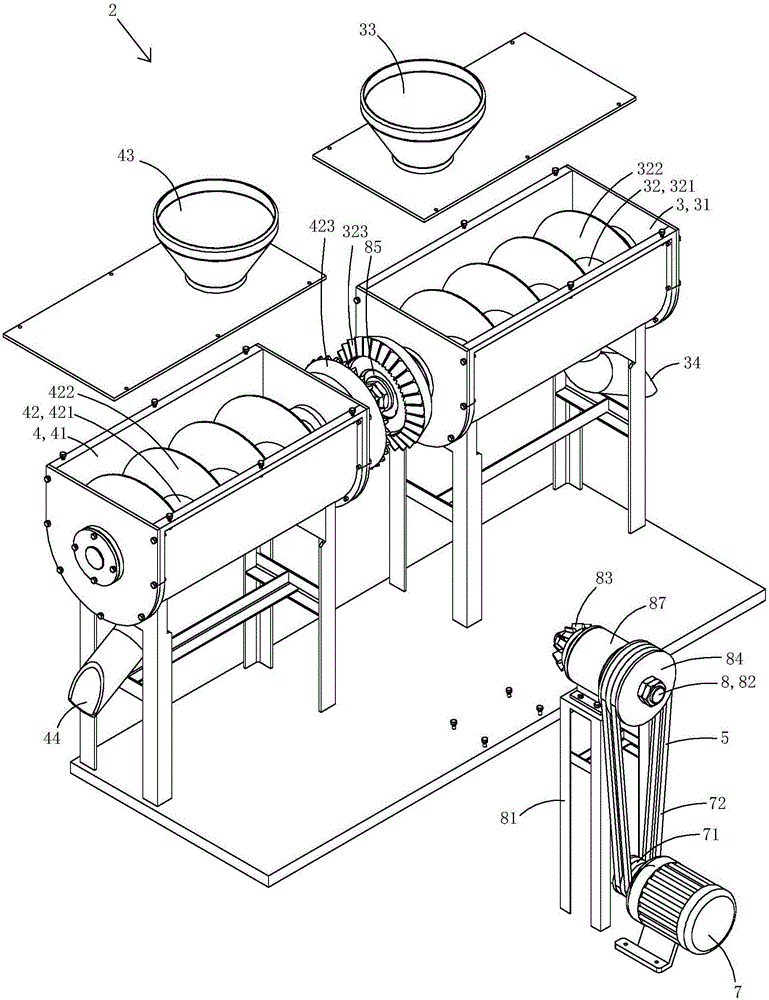

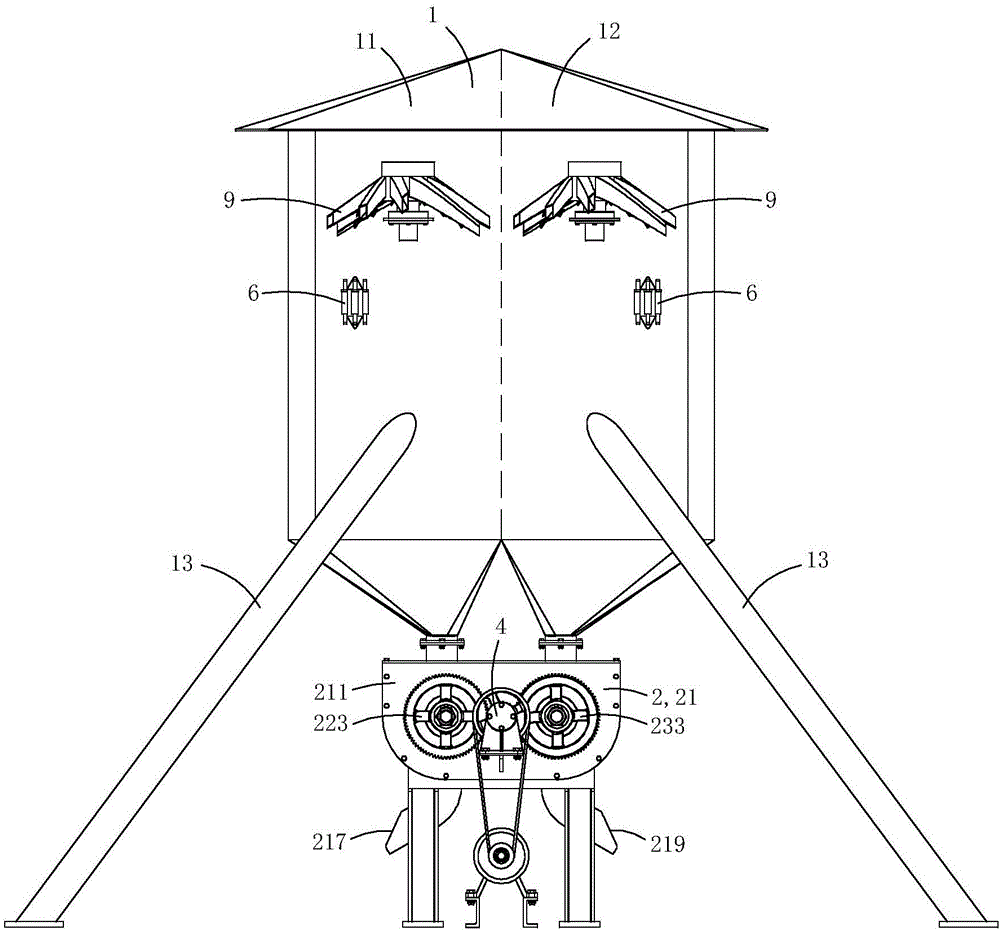

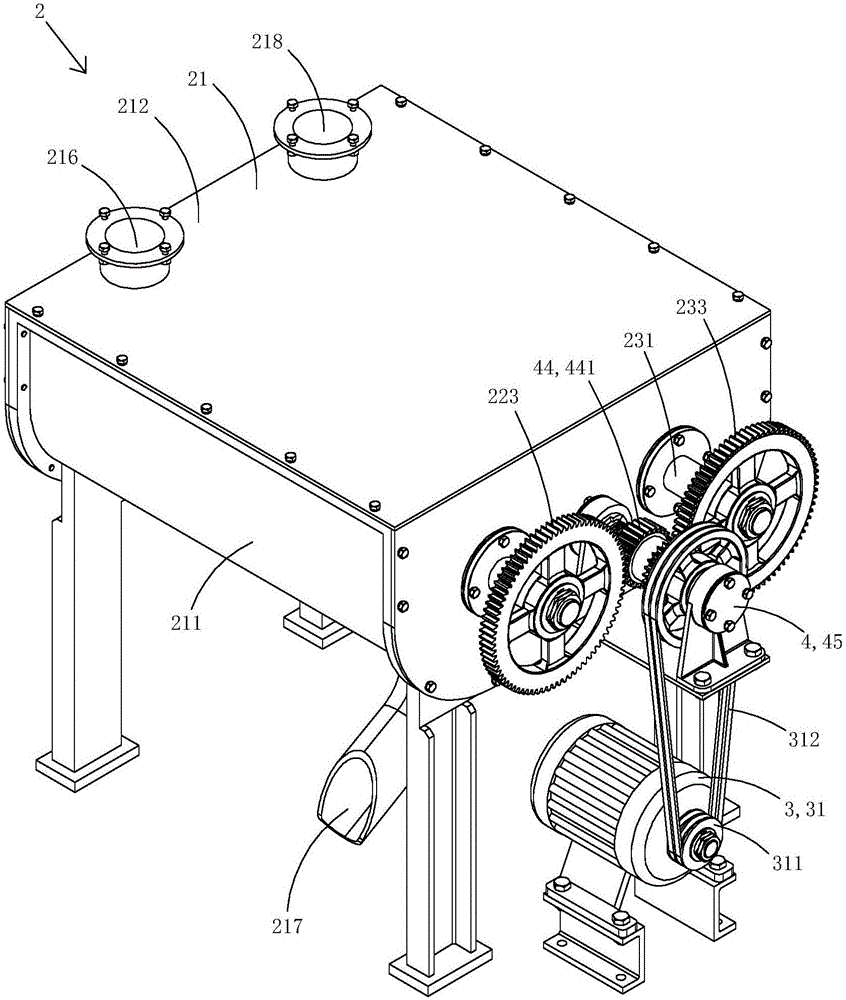

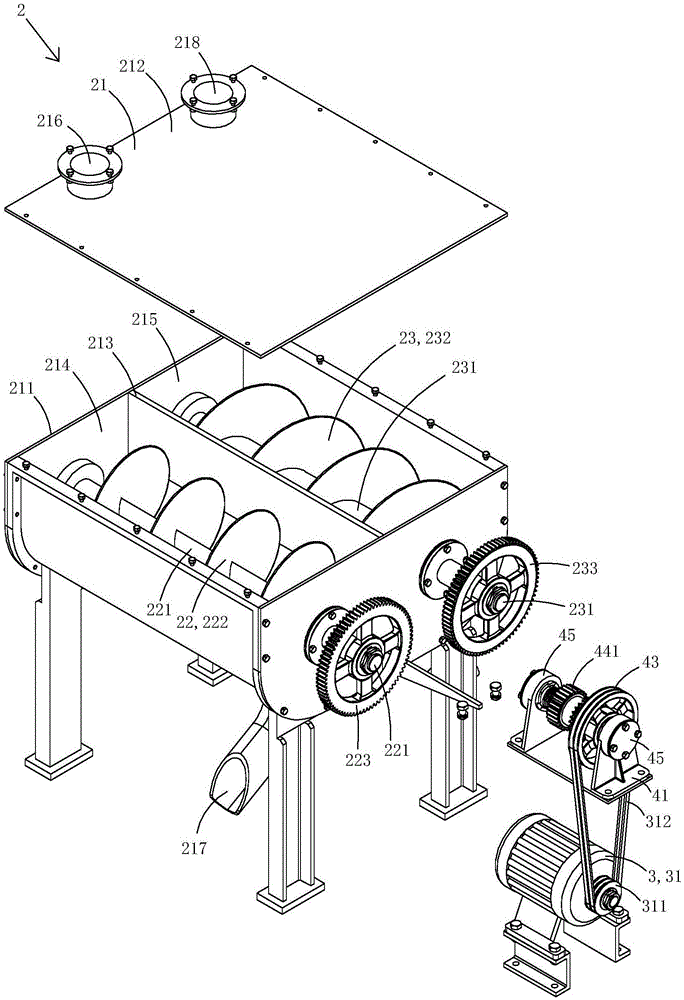

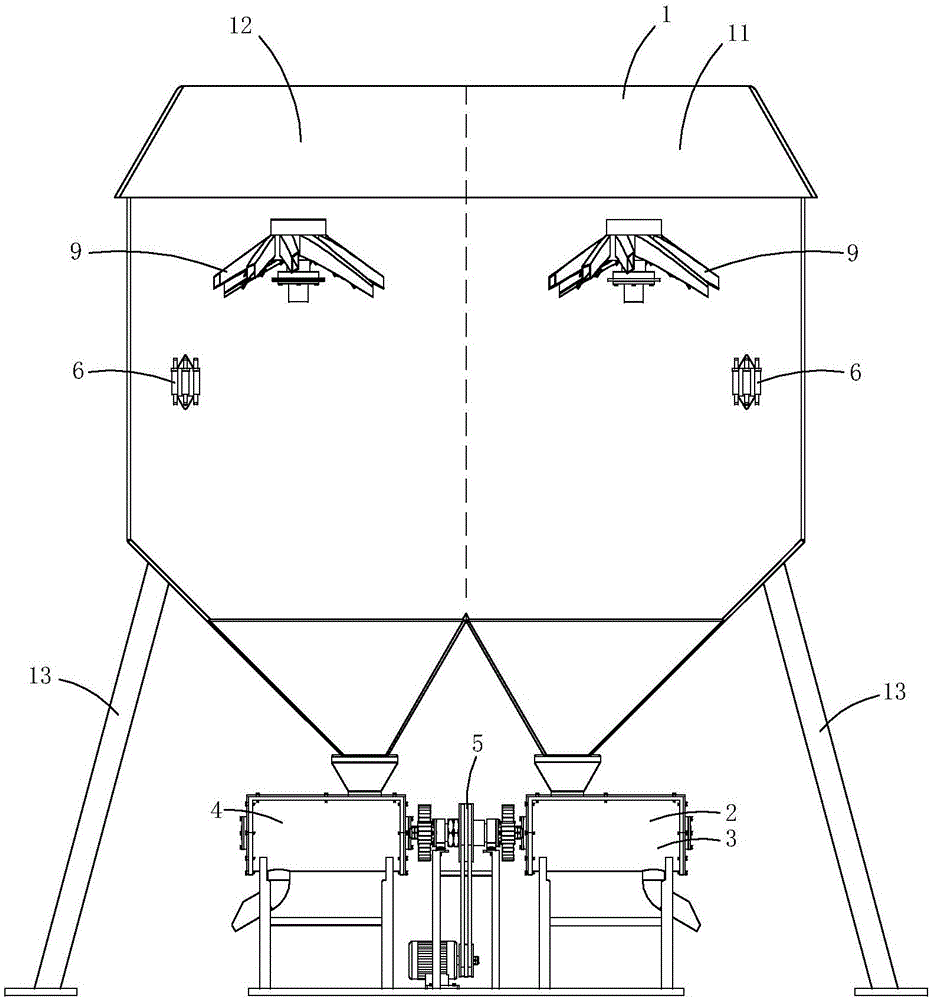

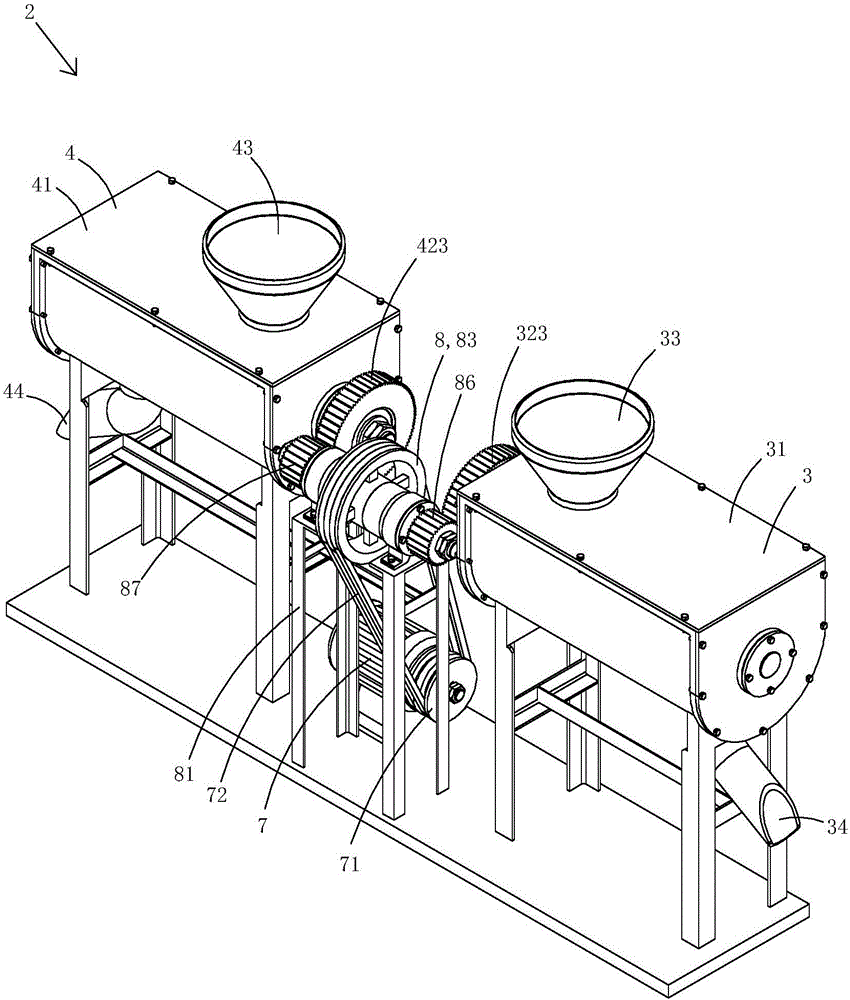

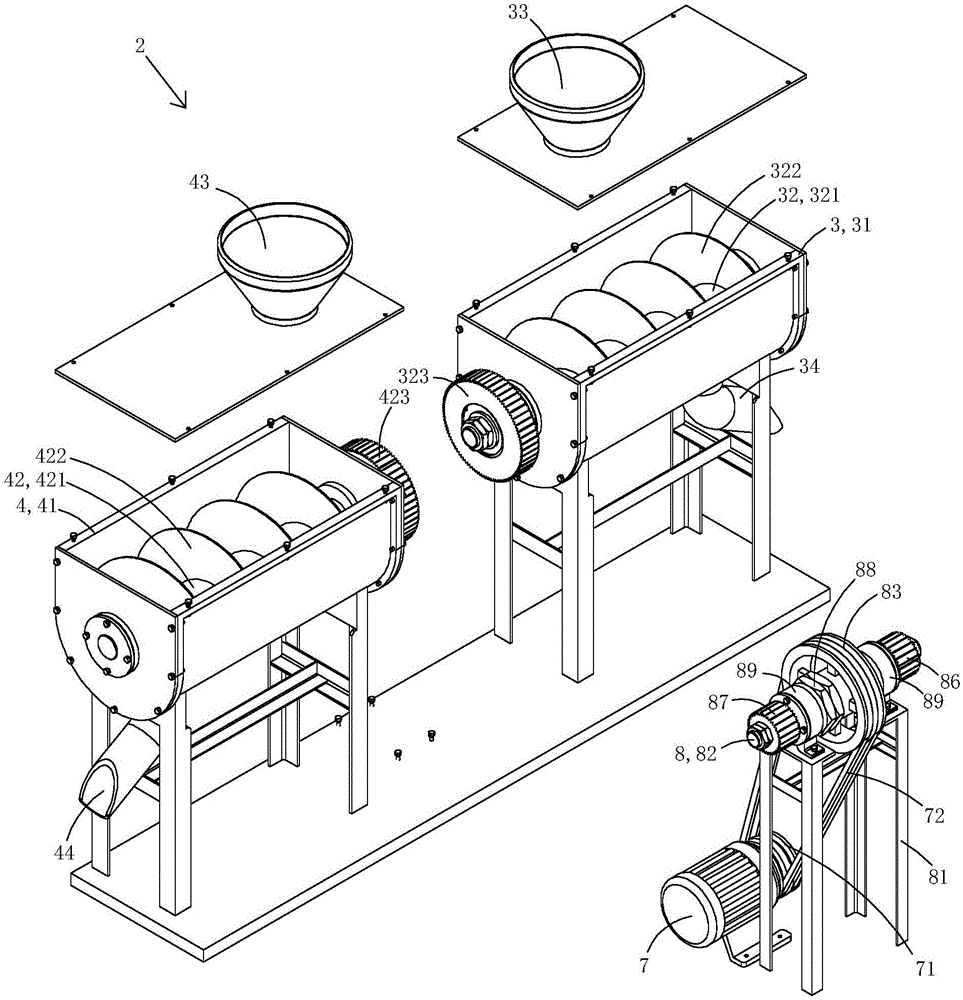

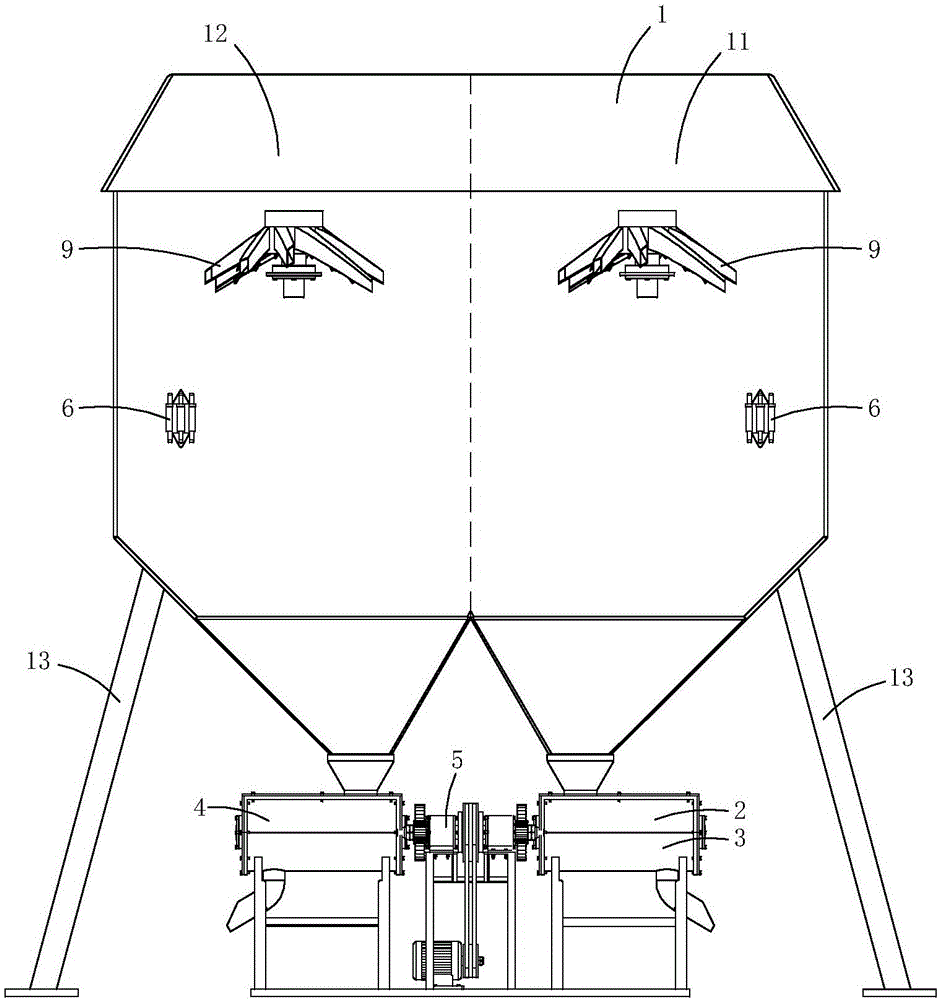

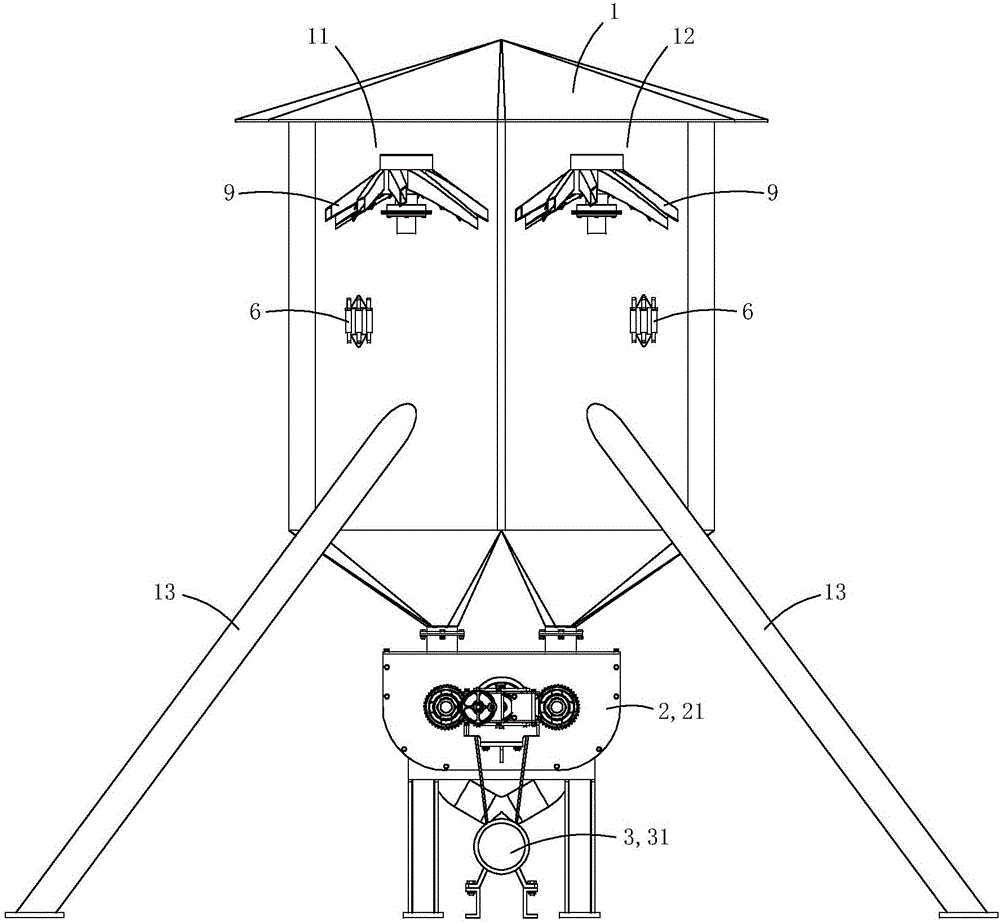

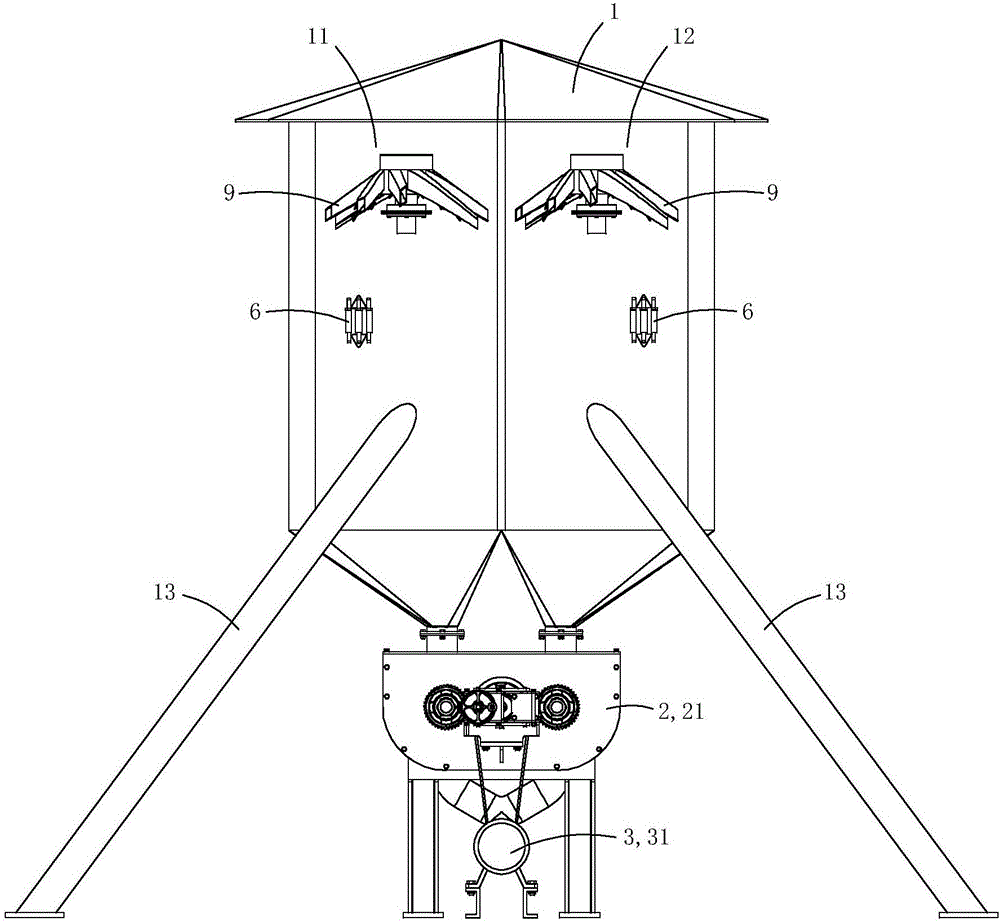

Logistics granary capable of realizing uniform grain distribution

InactiveCN106629121AUniform grain distributionReasonable structureConveyorsLoading/unloadingClutchDrive motor

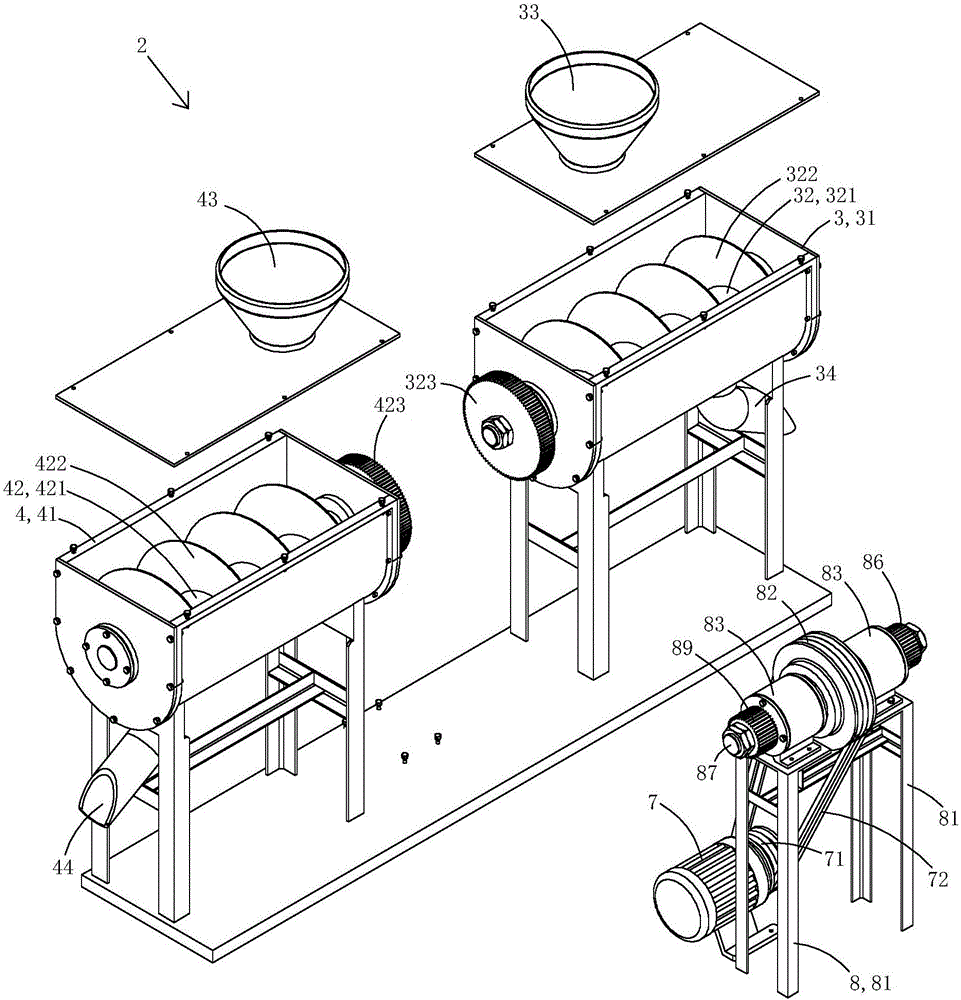

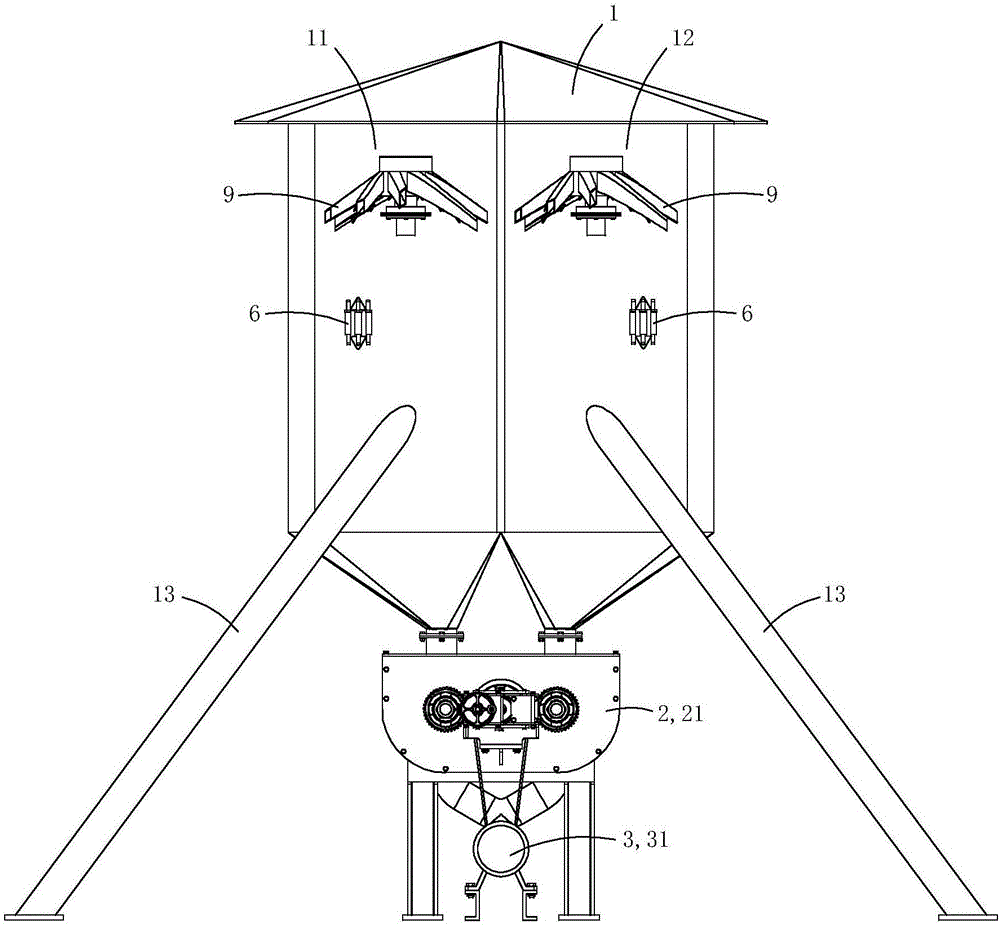

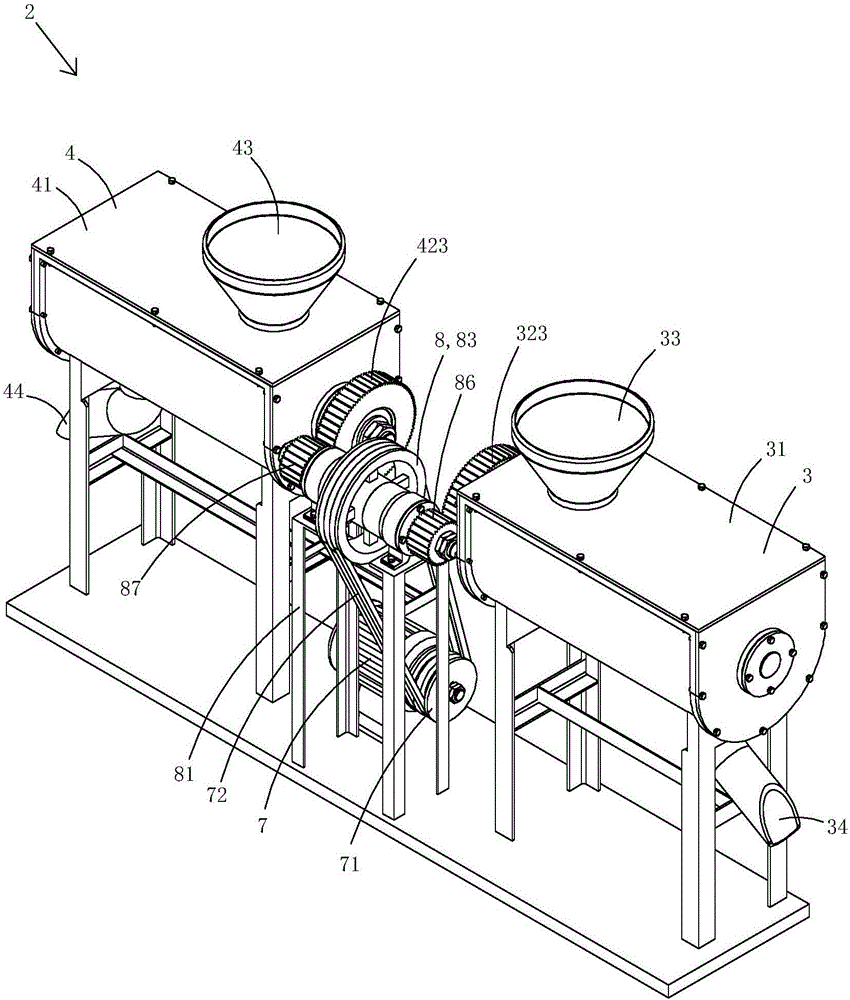

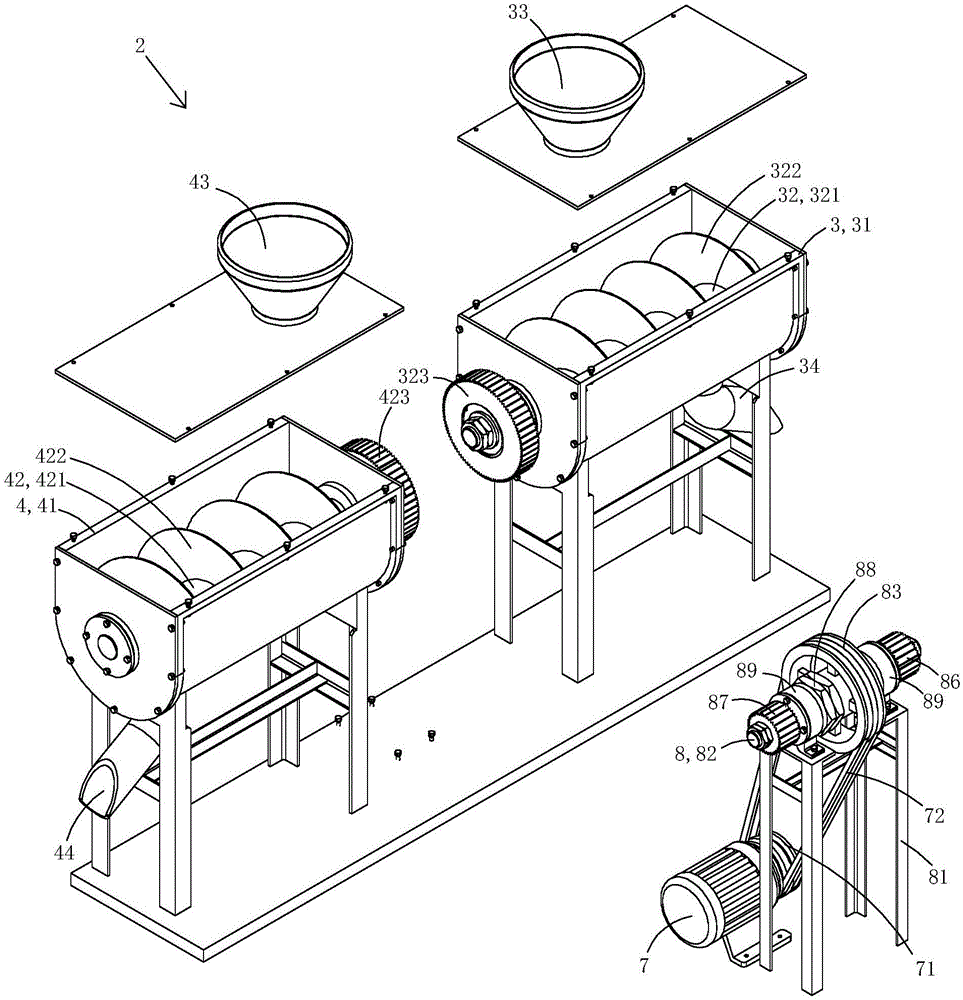

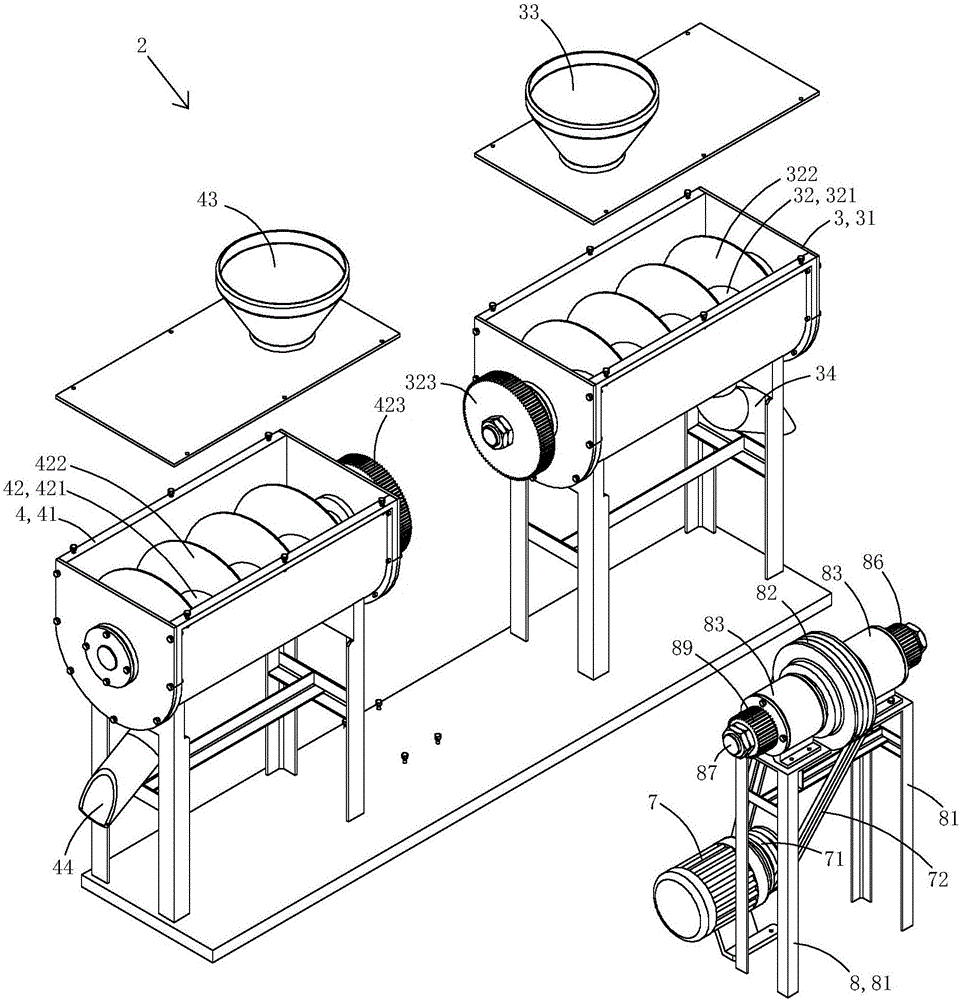

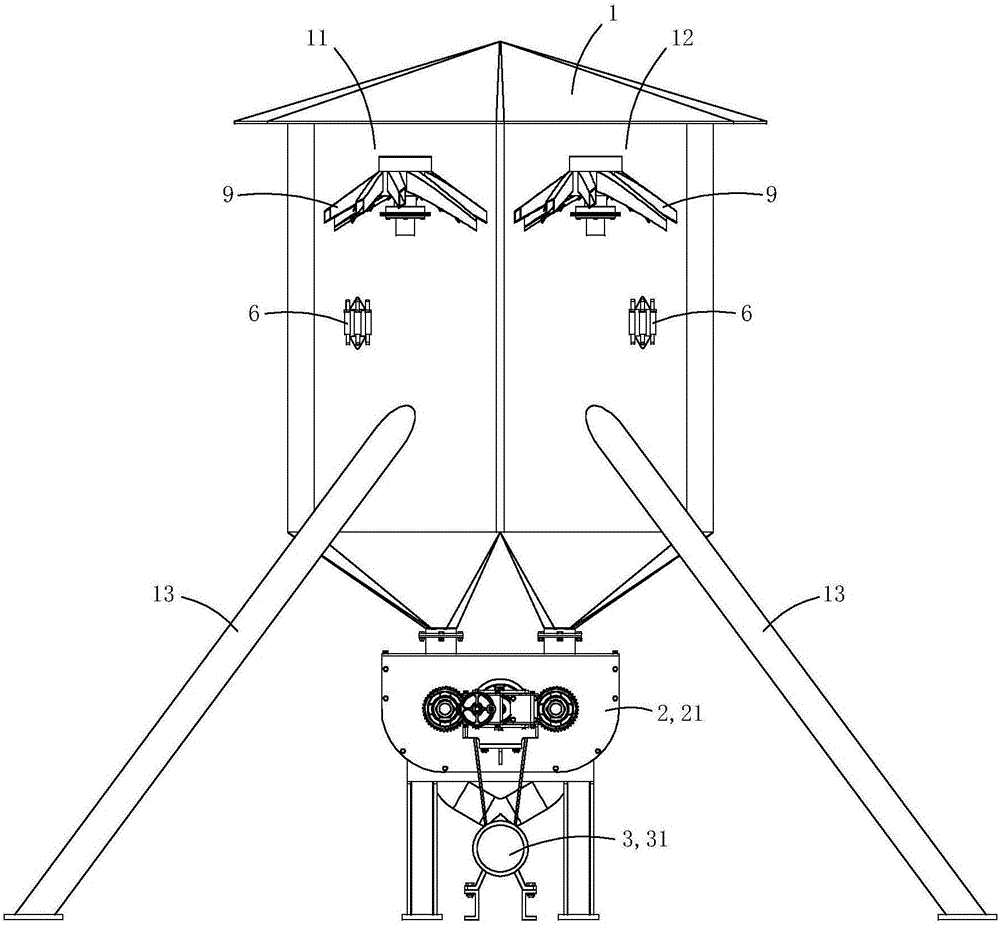

The invention discloses a logistics granary capable of realizing uniform grain distribution. The logistics granary comprises a dual-body warehouse and a grain unloading device, wherein a self-rotating grain distributor is arranged in each of a first warehouse and a second warehouse; the grain unloading device comprises a first grain unloading box, a second grain unloading box and a drive device; the first grain unloading box comprises a first box body and a first auger; the drive device comprises a drive motor and a clutch transmission mechanism; the clutch transmission mechanism comprises a belt wheel, a first transmission shaft, a first one-way overrunning clutch, a second transmission shaft and a second one-way overrunning clutch; the drive motor drives the belt wheel to carry out reciprocating rotation; and the locking direction of the first one-way overrunning clutch and the locking direction of the second one-way overrunning clutch are opposite. The logistics granary disclosed by the invention is capable of realizing uniform grain distribution and storing two types of grains, and low in manufacturing cost.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

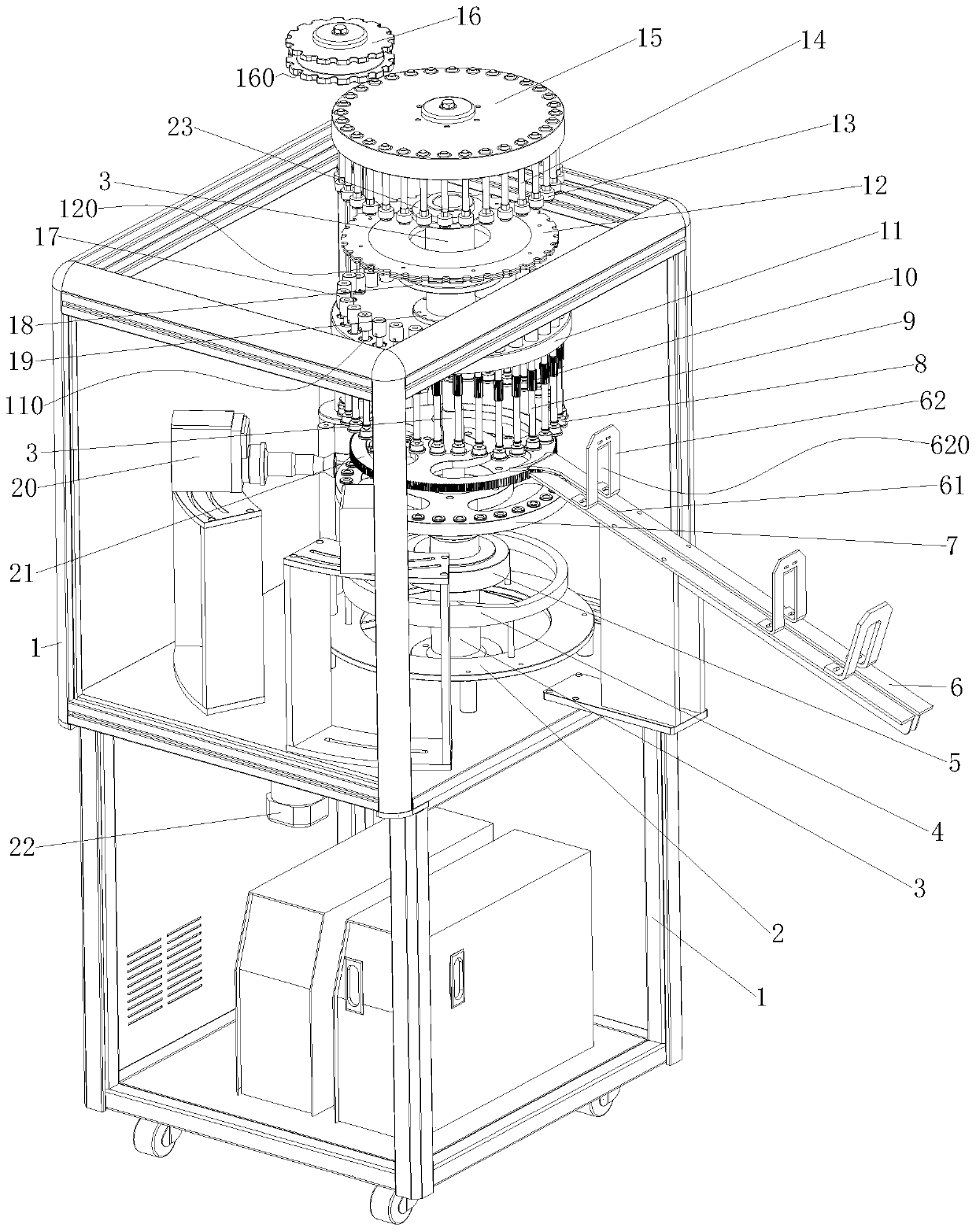

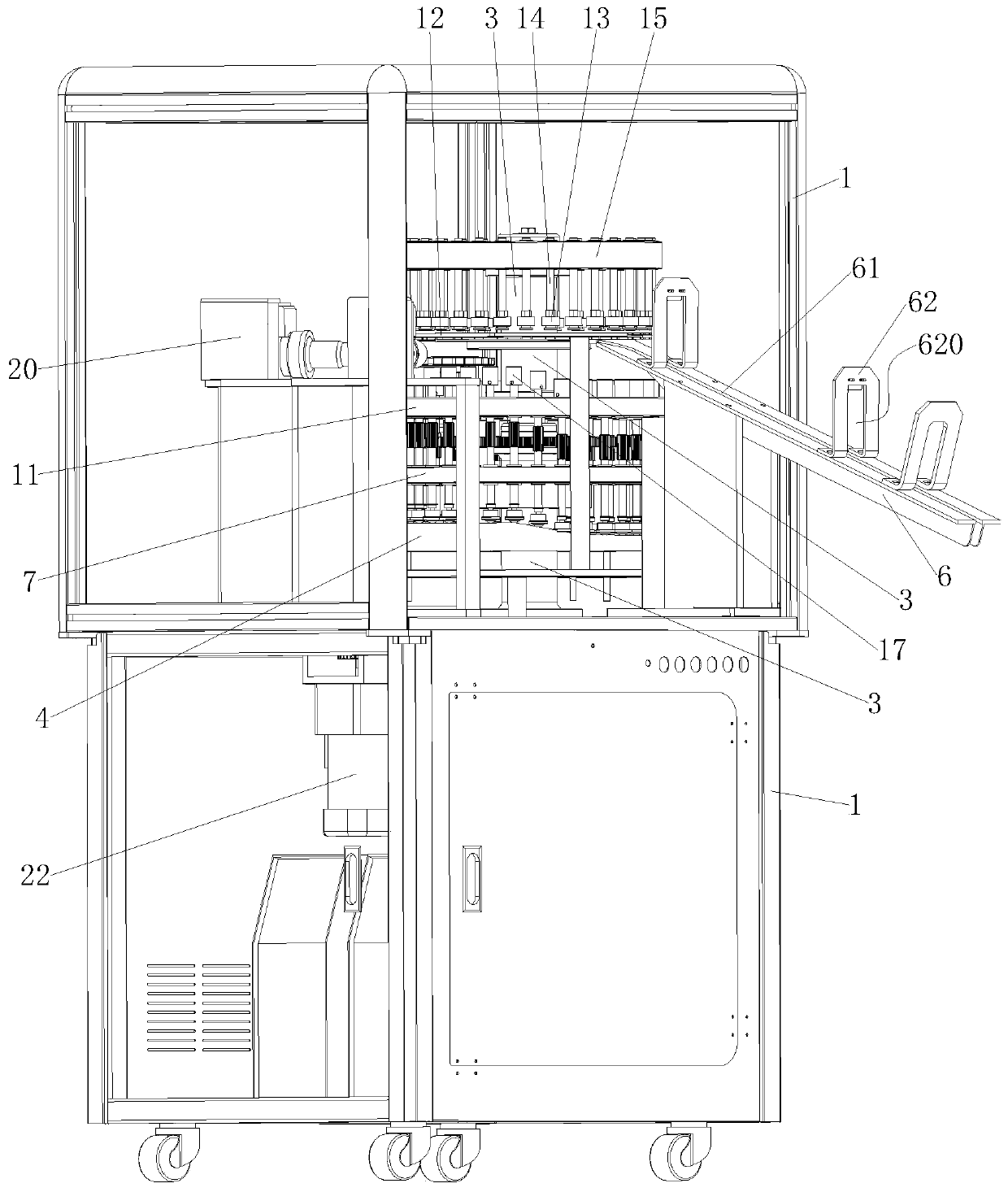

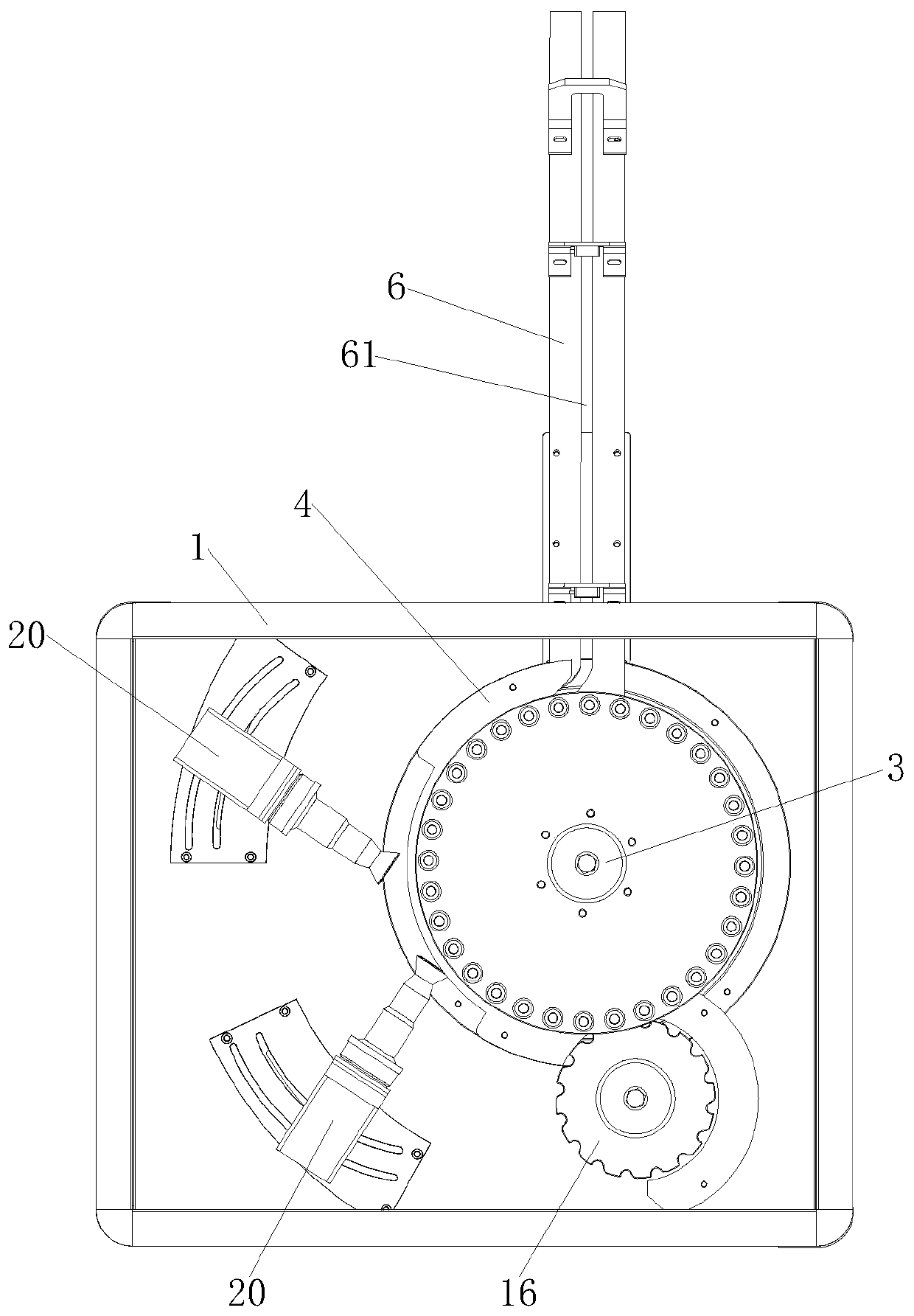

Corona treatment equipment for surface of injector tube body

PendingCN110193962AUniform corona treatmentHigh surface ink adhesionDomestic articlesPrinting press partsProduction lineBiochemical engineering

The invention discloses corona treatment equipment for the surface of an injector tube body. The equipment comprises a rack, a feeding mechanism, an upper pressing mechanism, a guide mechanism, a transmission mechanism, a driving mechanism, a corona treatment machine and a discharging mechanism. According to the corona treatment equipment, the feeding mechanism, the upper pressing mechanism, the guide mechanism, the transmission mechanism, the driving mechanism, the corona treatment machine and the discharging mechanism are adopted to form the integrated production line corona treatment equipment in a linked mode, uniform corona treatment on a whole circle of the outer surface of the injector tube body is realized, so that the injector tube body has high surface ink adhesion capability, printing firmness and definition, stability of the printing process of an injector is greatly improved and becomes high, and the corona treatment effect and efficiency are improved; and the equipment isingenious in structural design, limited installation and arrangement space is fully utilized, high stability, firmness and balance capability are achieved, the working efficiency is high, the energyis saved, the environment is protected, and the equipment is suitable for popularization and application.

Owner:浙江环稠机械设备制造有限公司

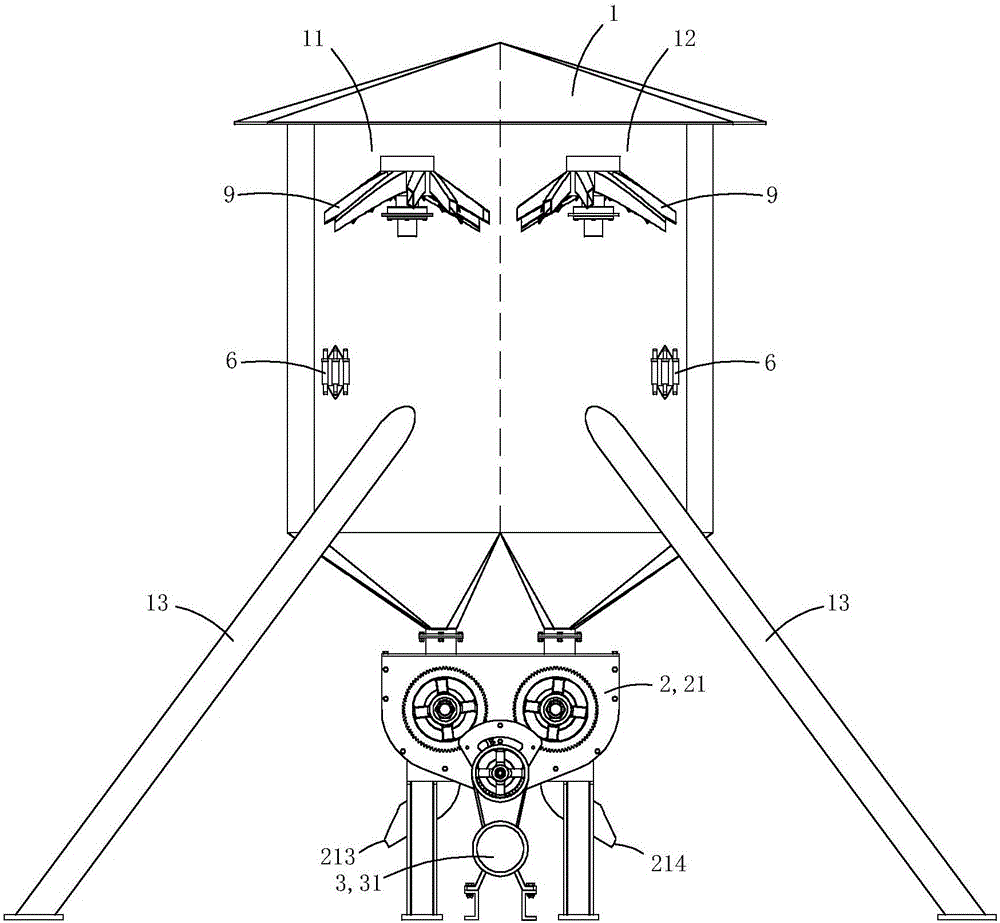

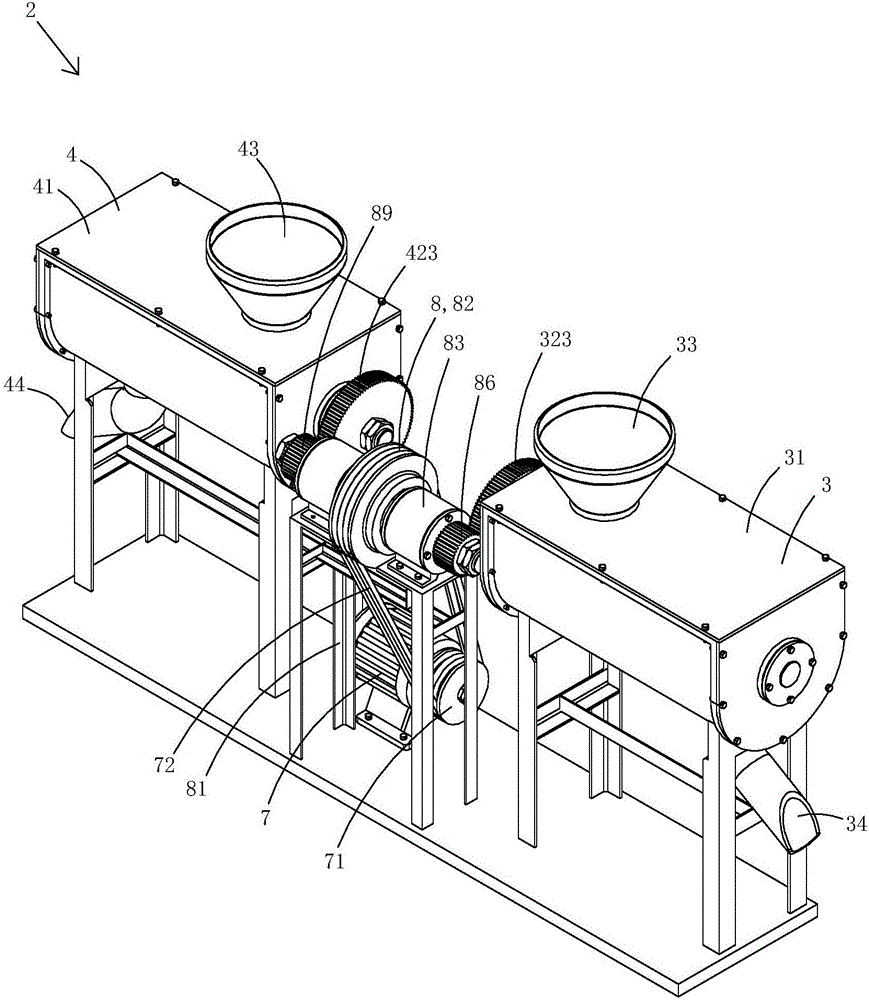

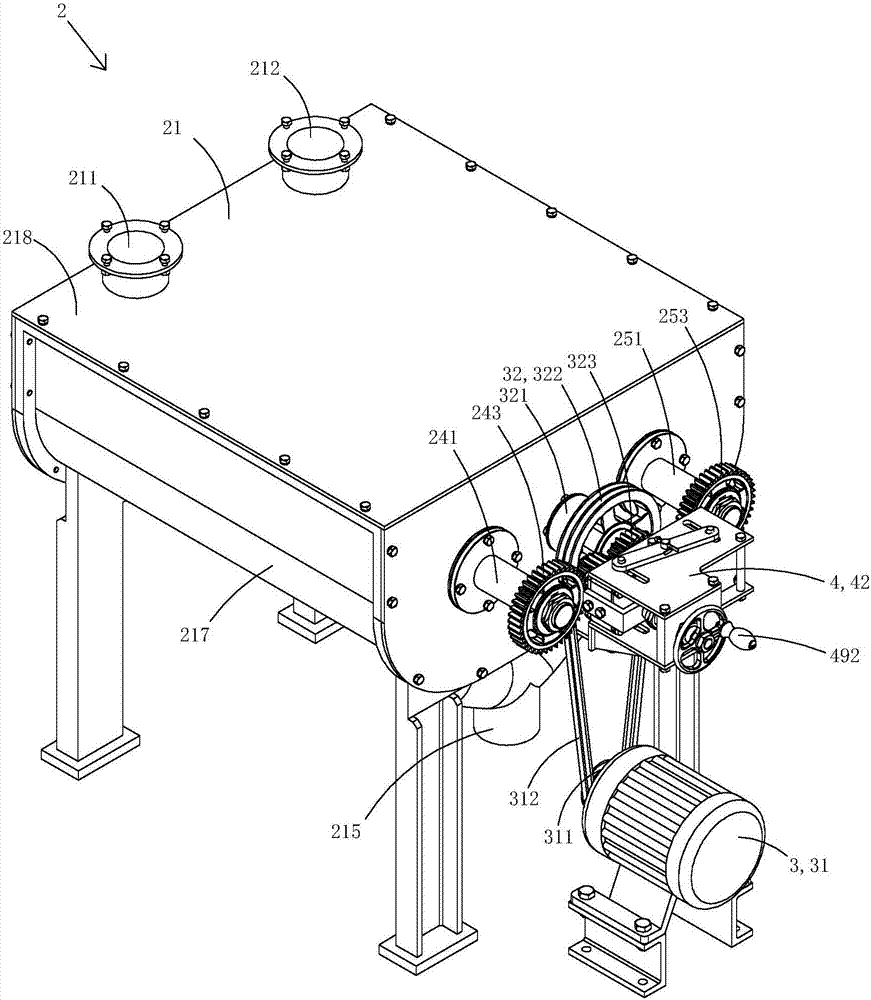

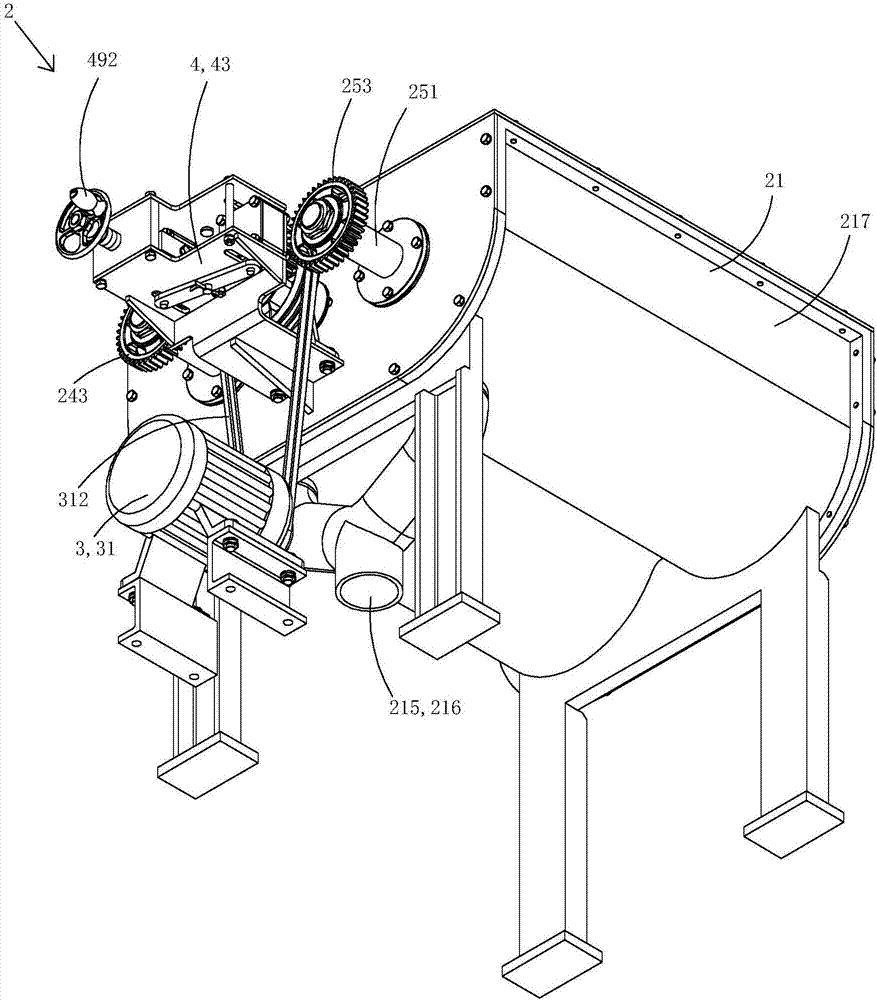

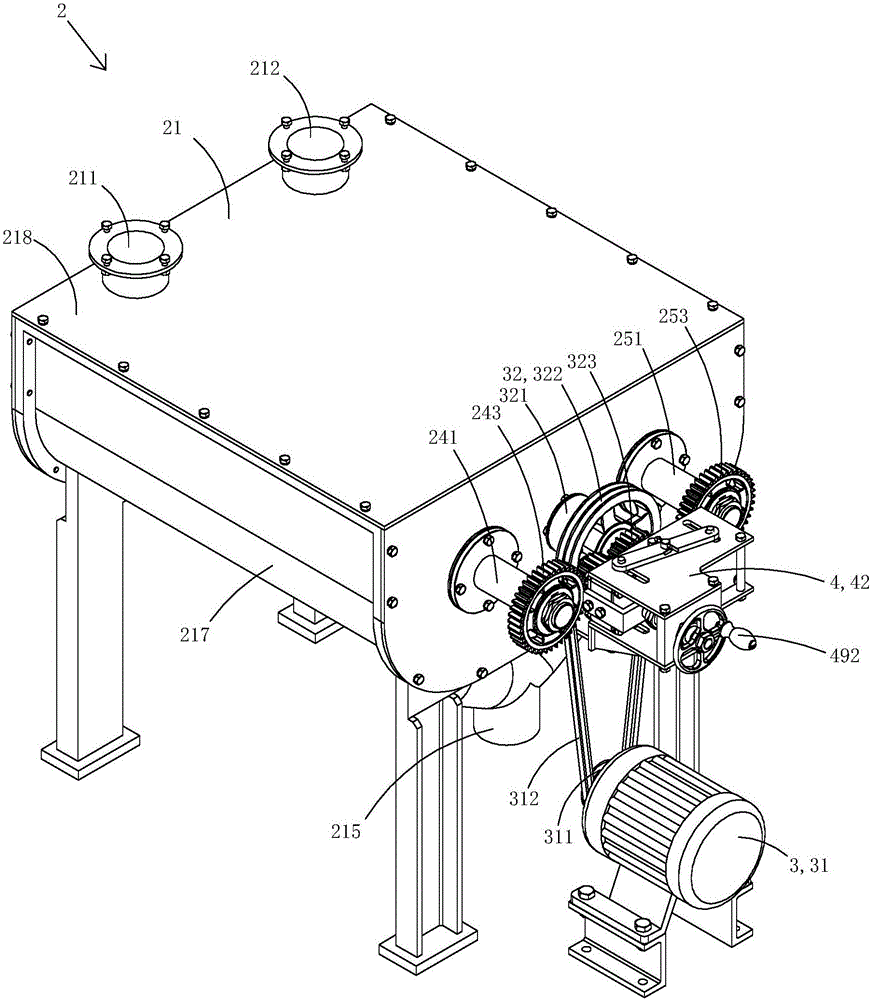

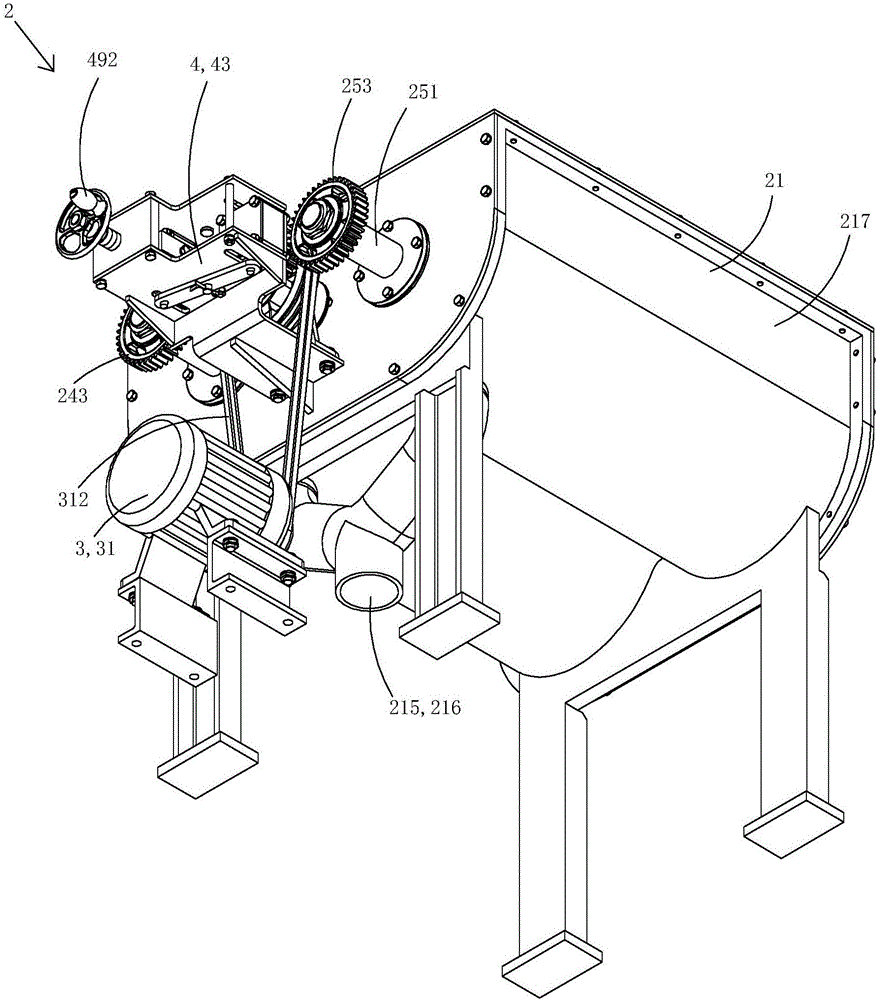

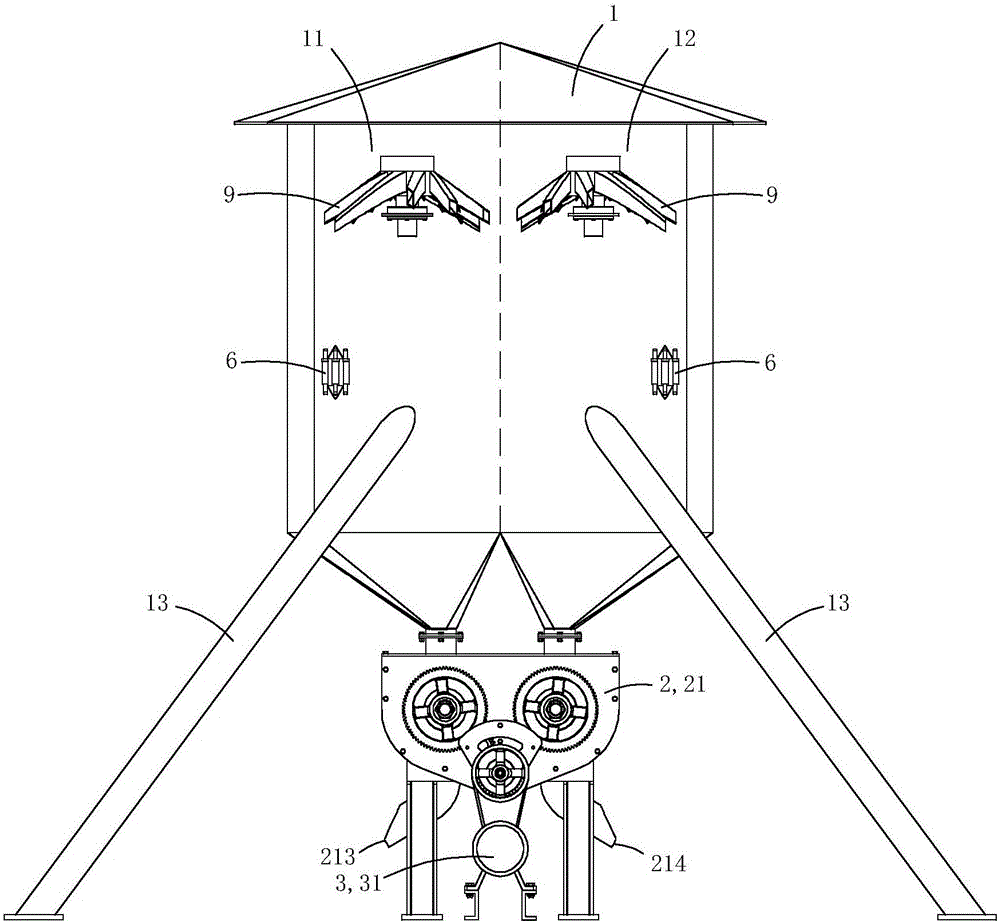

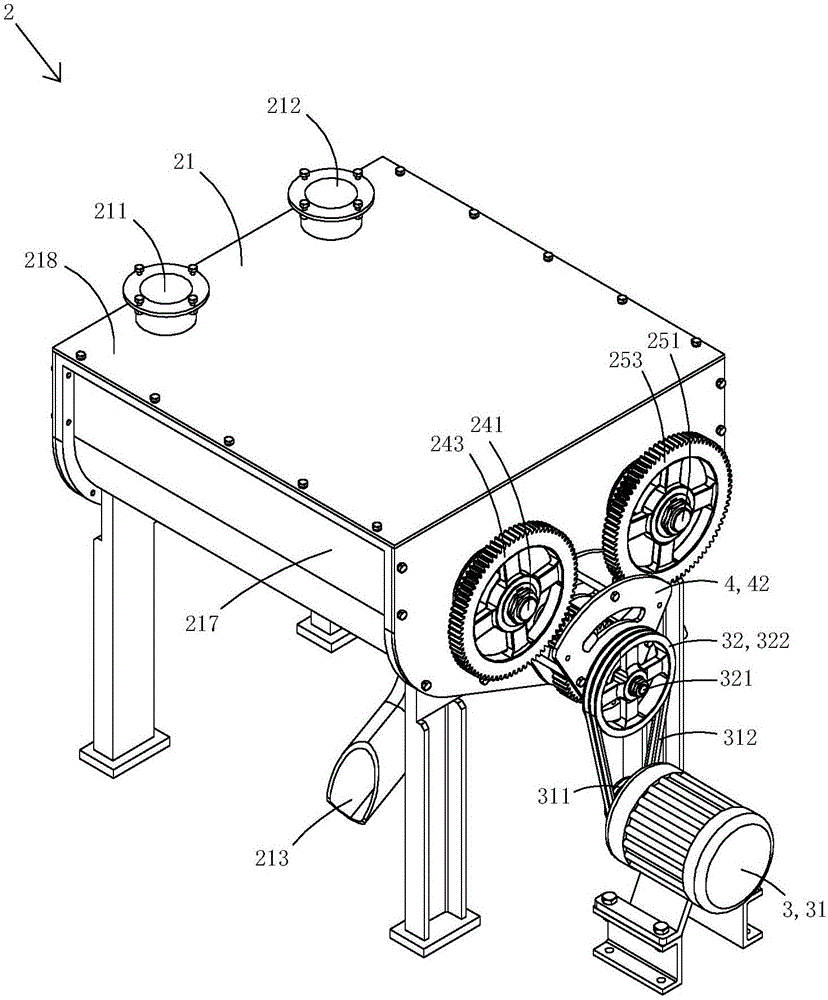

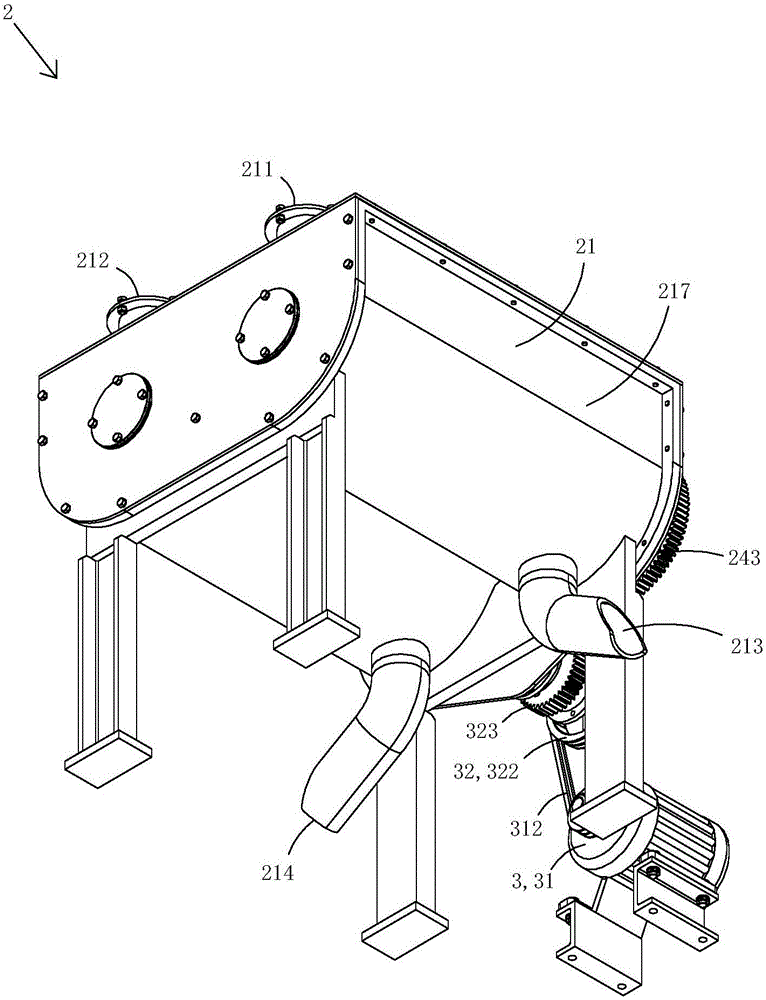

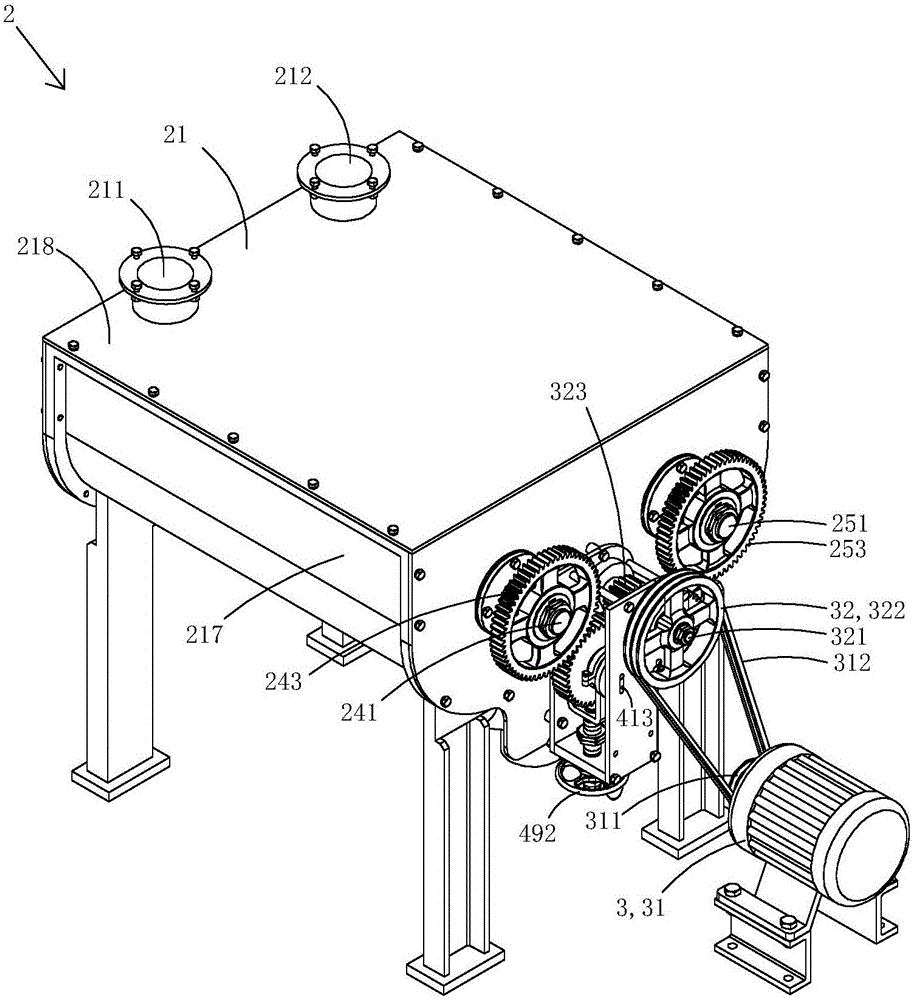

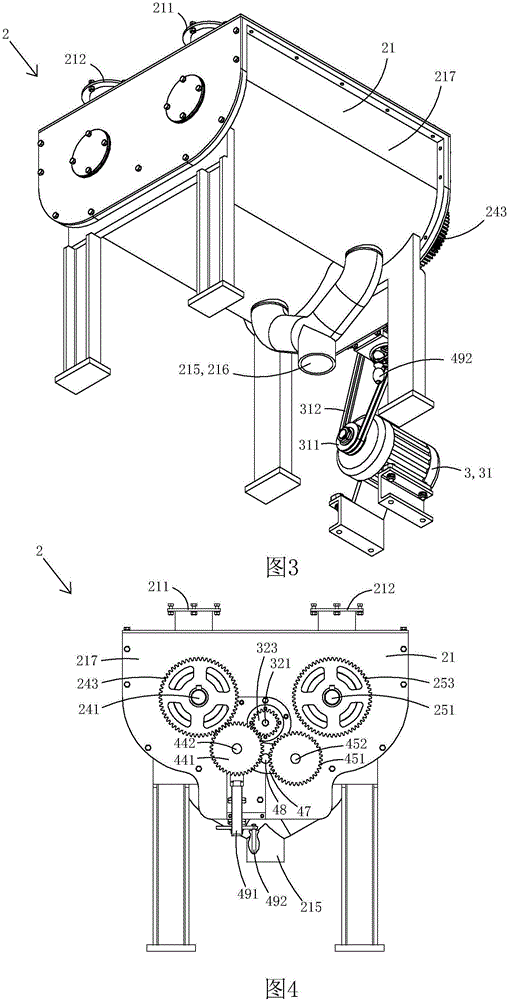

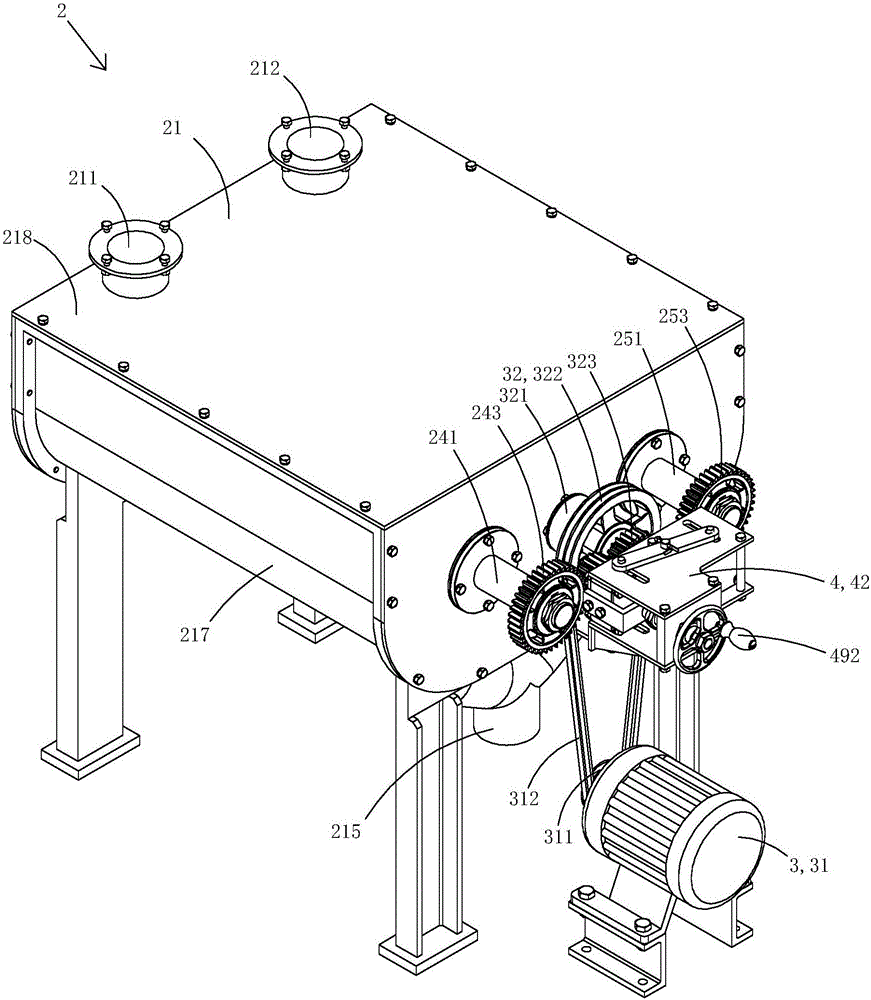

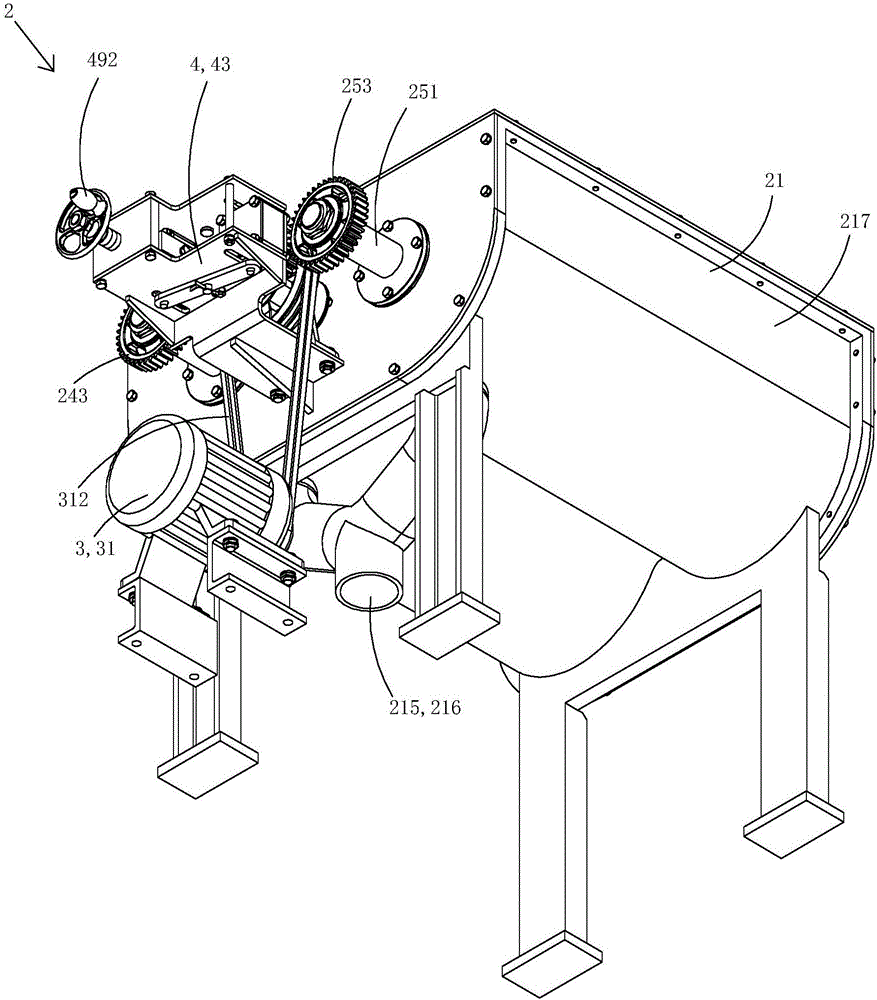

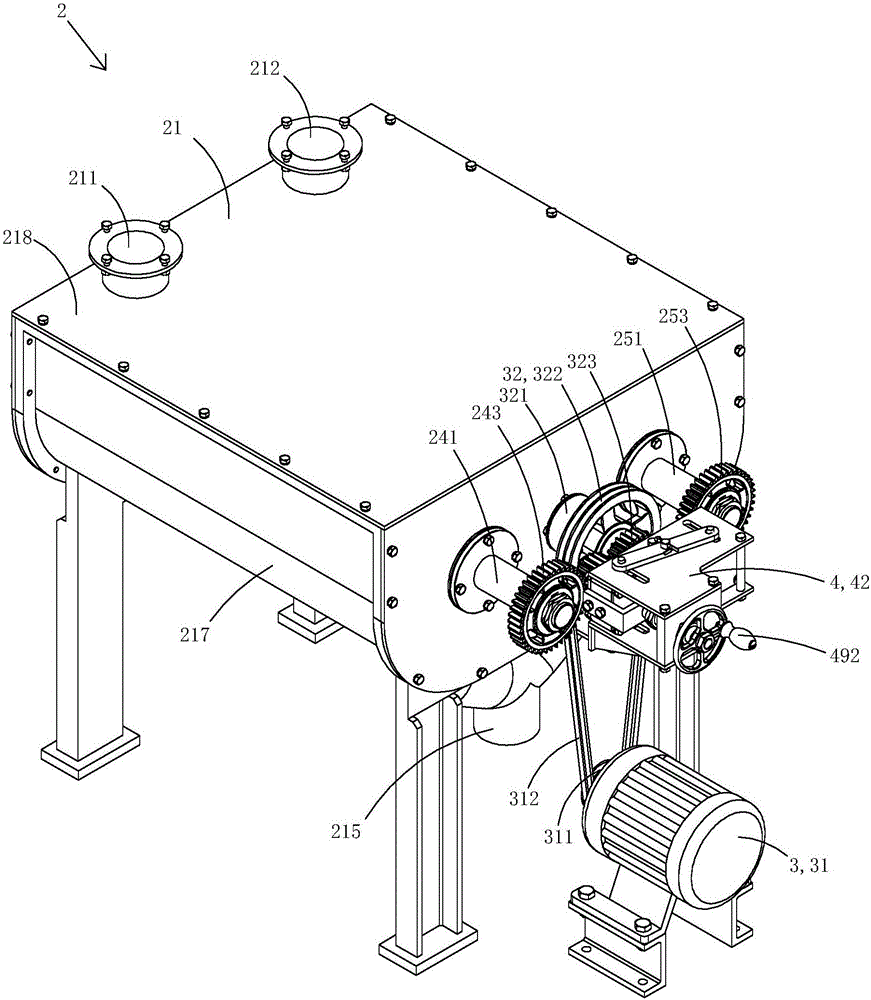

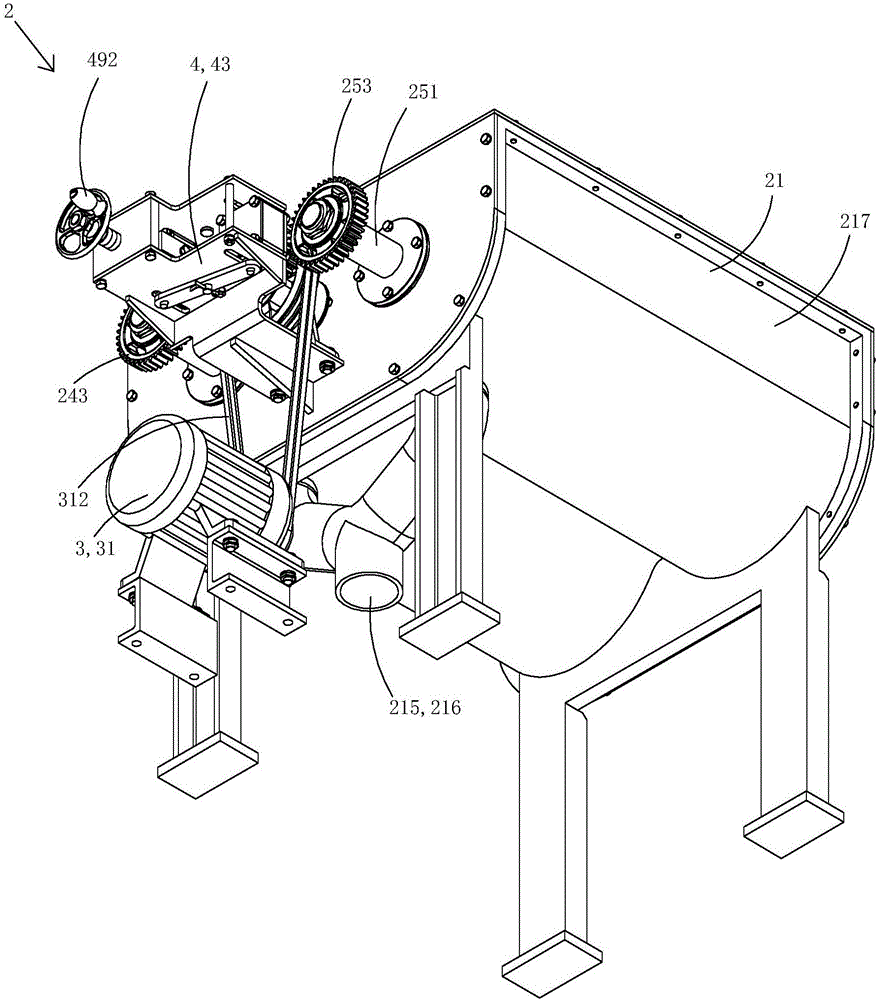

Electronic grain unloading granary with relatively uniform grain distribution

InactiveCN106717642AAvoid gatheringUniform technical effectMowersHarvested fruit hanging devicesDrive wheelDrive shaft

The invention discloses an electronic grain unloading granary with relatively uniform grain distribution. The electronic grain unloading granary comprises double warehouses and a grain unloading device, wherein self-rotated type grain distributors are respectively arranged inside a first warehouse and a second warehouse; the grain unloading device comprises a first packing auger, a second packing auger and a driving device; the driving device comprises a driving motor with a driving wheel and a linked switching device; the linked switching device comprises a rack body, a transmission wheel group, guide plates and a toothed gear component; the transmission wheel group comprises a transmission shaft, a transmission belt pulley and a transmission gear; guide holes are formed in the guide plates; the toothed gear component comprises a toothed gear and a guide part for limiting the toothed gear to slide along the guide holes in a reciprocation manner; the guide part is positioned in the guide holes; when the guide part slides to one ends of the guide holes, a first driven gear is driven by the transmission gear to rotate through the toothed gear; when the guide part slides to the other ends of the guide holes, a second driven gear is driven by the transmission gear through the toothed gear. The electronic grain unloading granary is relatively uniform in grain distribution, capable of storing two types of grains, and in addition relatively low in manufacturing cost.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

Improved logistics warehouse

The invention discloses an improved logistics warehouse which comprises a double-body warehouse and a discharging device, wherein the double-body warehouse is provided with a first warehouse and a second warehouse; a self-rotating type material distributor is arranged in each of the first warehouse and the second warehouse; the discharging device comprises a first discharging box, a second discharging box and a drive device; the first discharging box comprises a first box body and a first screw conveyor; the first screw conveyor comprises a first one-way overrunning clutch; the second discharging box comprises a second box body and a second screw conveyor; the second screw conveyor comprises a second one-way overrunning clutch; the locking direction of the first one-way overrunning clutch is opposite to that of the second one-way overrunning clutch; the spiral directions of a first spiral plate and a second spiral plate are opposite; the drive device comprises a drive motor and a transmission mechanism; when the drive motor positively rotates, the first screw conveyor is driven to rotate; when the drive motor reversely rotates, the second screw conveyor is driven to rotate. The improved logistics warehouse disclosed by the invention is more uniform in material distribution, can storage two kinds of materials and is lower in manufacturing cost.

Owner:乐清市华尊电气有限公司

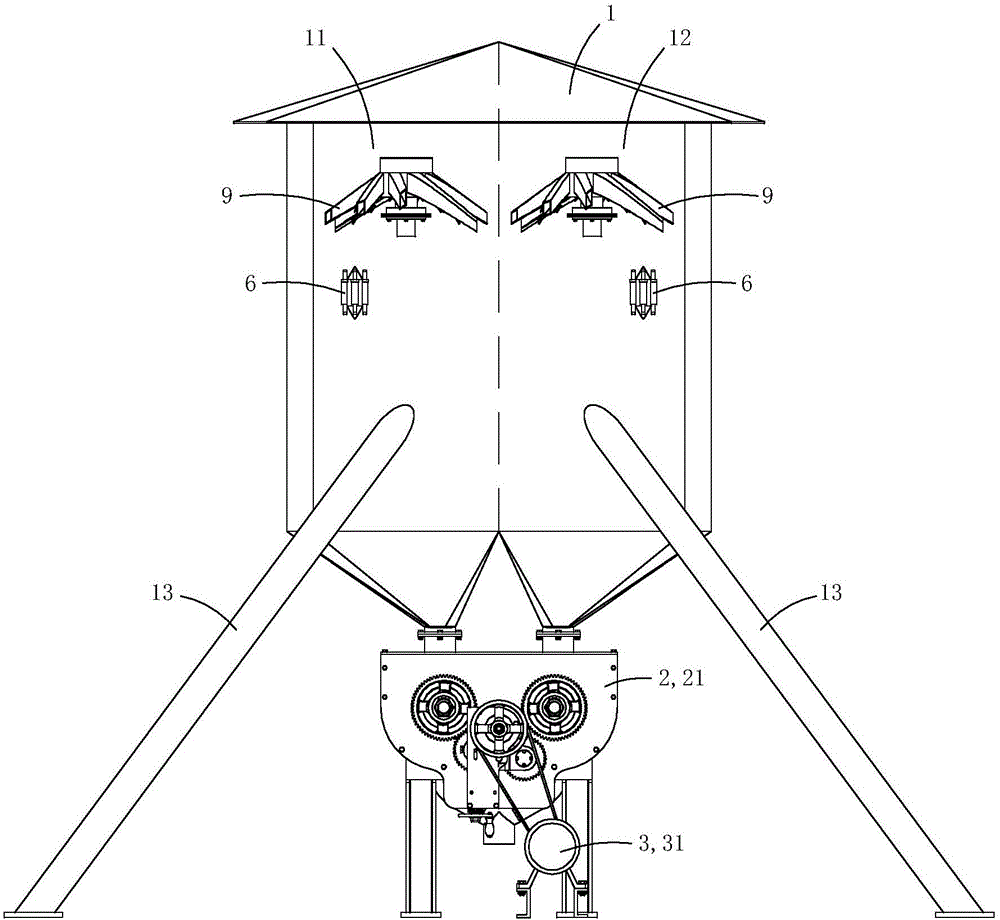

Self-unloading twin granary with more uniform grain distribution

PendingCN106429515AUniform grain distributionReasonable structureAgriculture tools and machinesConveyorsClutchDrive motor

The invention discloses a self-unloading twin granary with more uniform grain distribution. The self-unloading twin granary comprises a twin warehouse body and a grain unloading device; the twin warehouse body is provided with a first warehouse and a second warehouse; self-rotating grain distributors are respectively arranged in the first warehouse and the second warehouse; the grain unloading device includes a tank with a first grain unloading cavity and a second grain unloading cavity, a first auger for unloading grains stored in the first grain unloading cavity, a second auger for unloading grains stored in the second grain unloading cavity, and a driving device for driving the first auger and the second auger to rotate; the first auger includes a first rotating shaft, a first spiral plate and a first driven gear; the second auger includes a second rotating shaft, a second spiral plate and a second driven gear; the driving device includes a driving motor and a clutch linkage device; the clutch linkage device includes a frame body, a transmission shaft, a clutch transmission gear, a belt wheel and a translation limiting piece; and the clutch transmission gear is screwed on an external thread part of the transmission shaft. The self-unloading twin granary is more uniform in grain distribution, can store two types of grains, and is lower in manufacturing cost.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

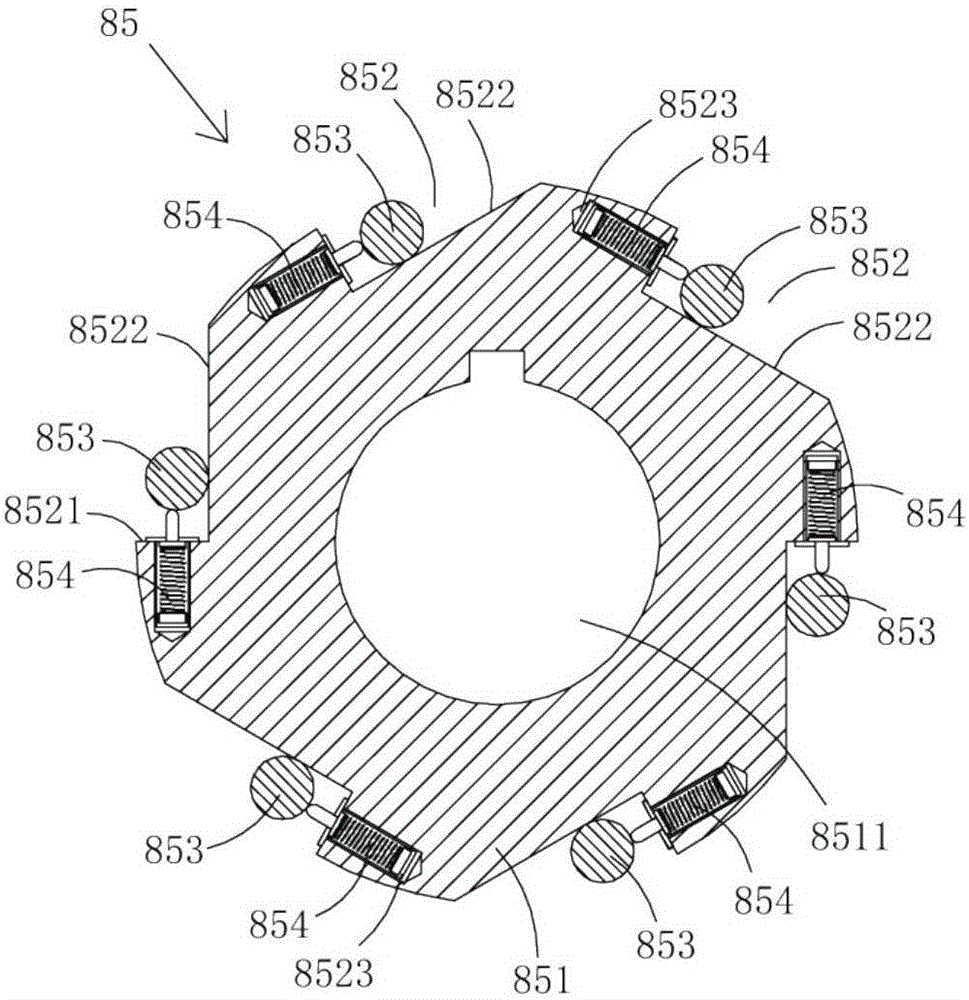

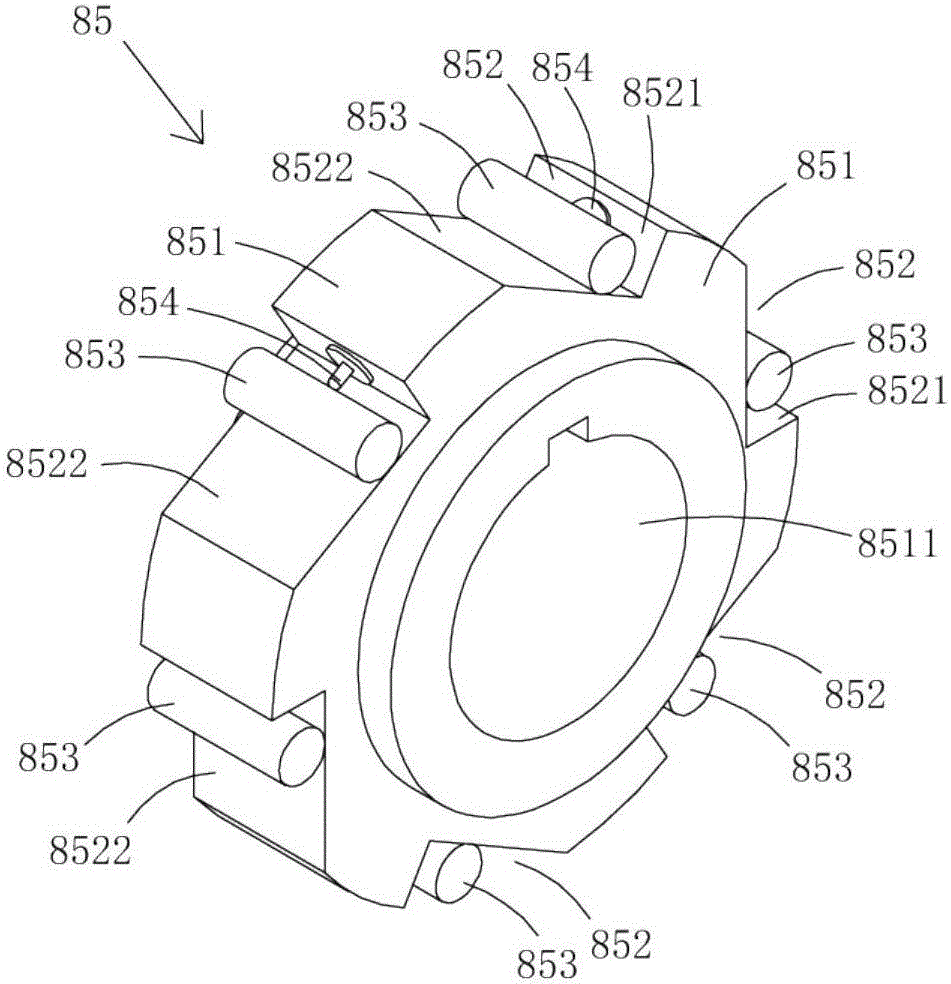

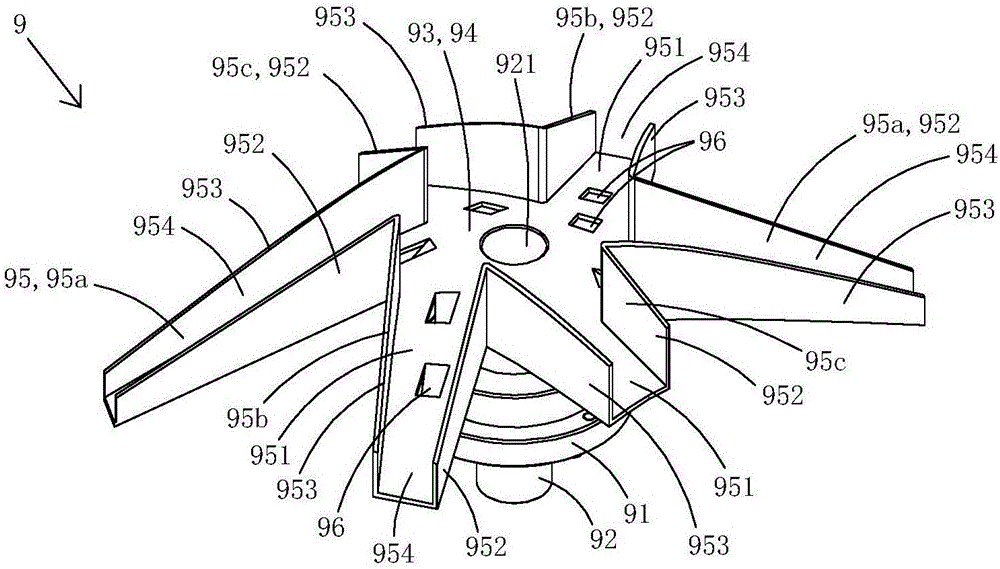

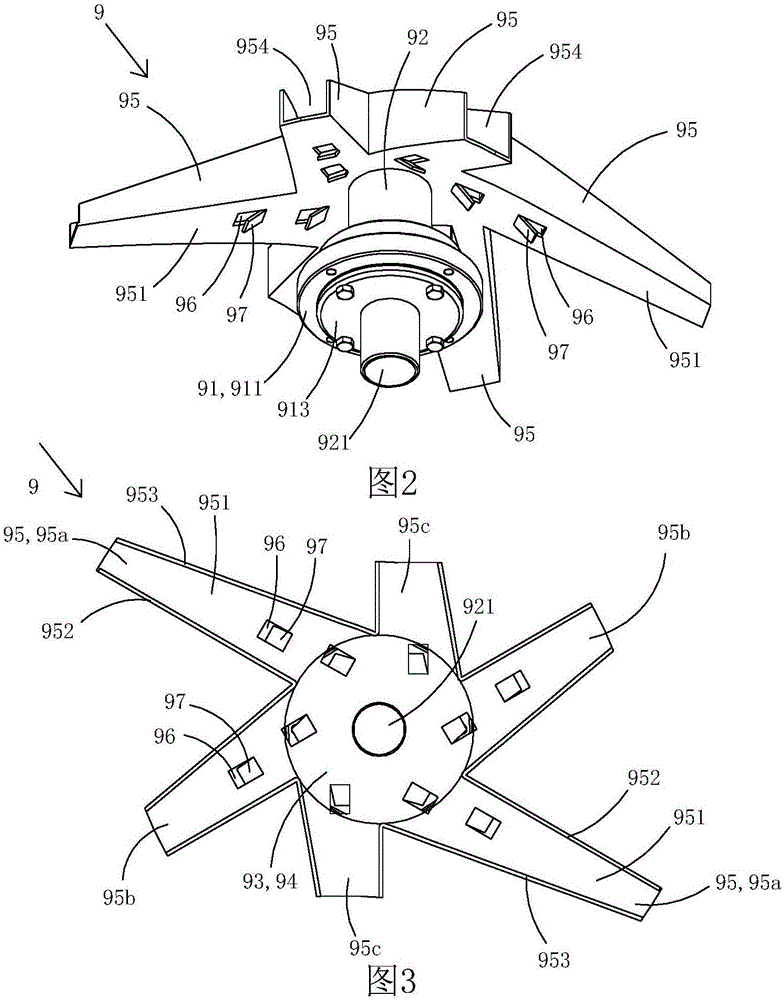

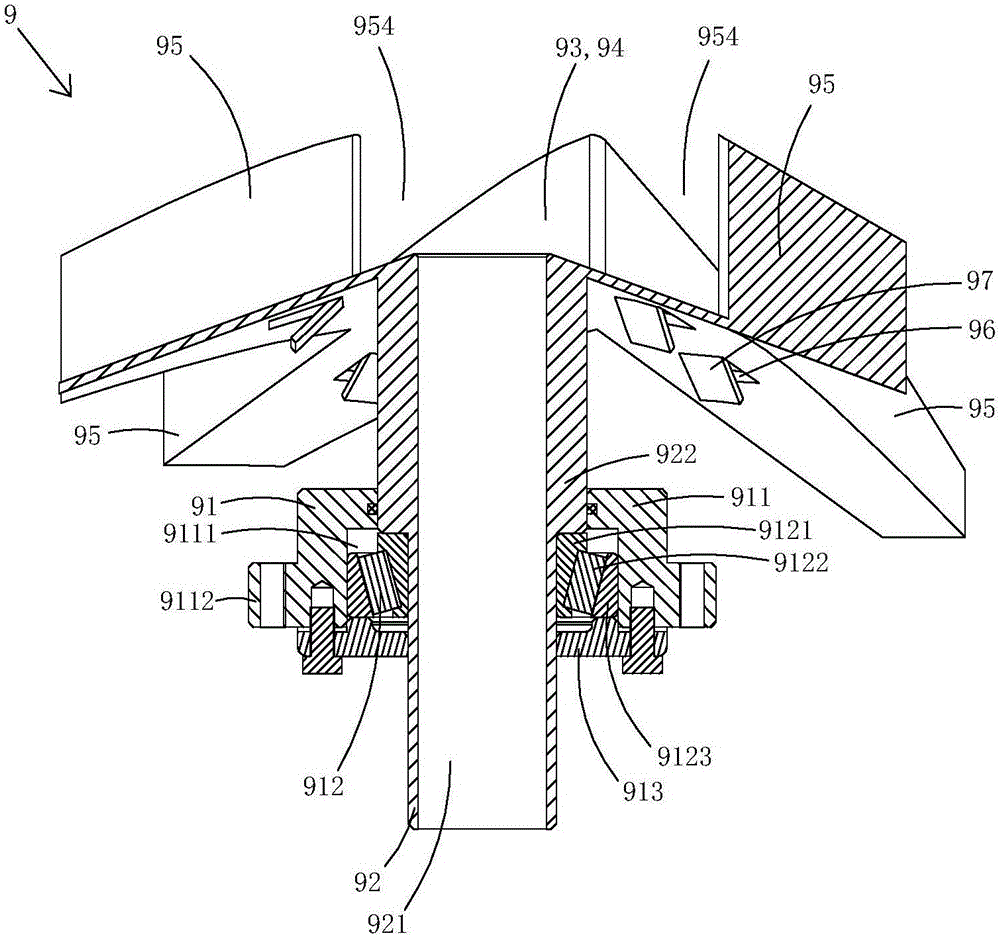

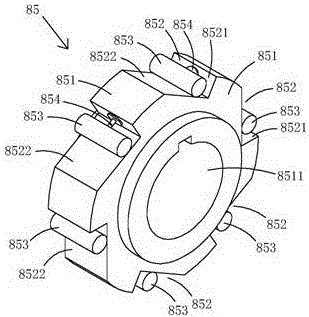

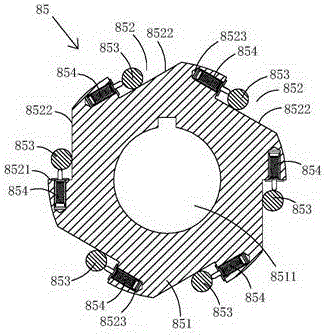

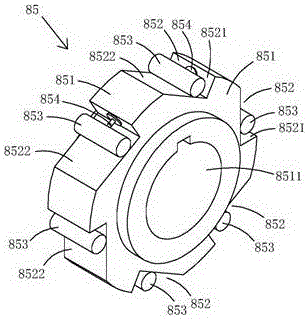

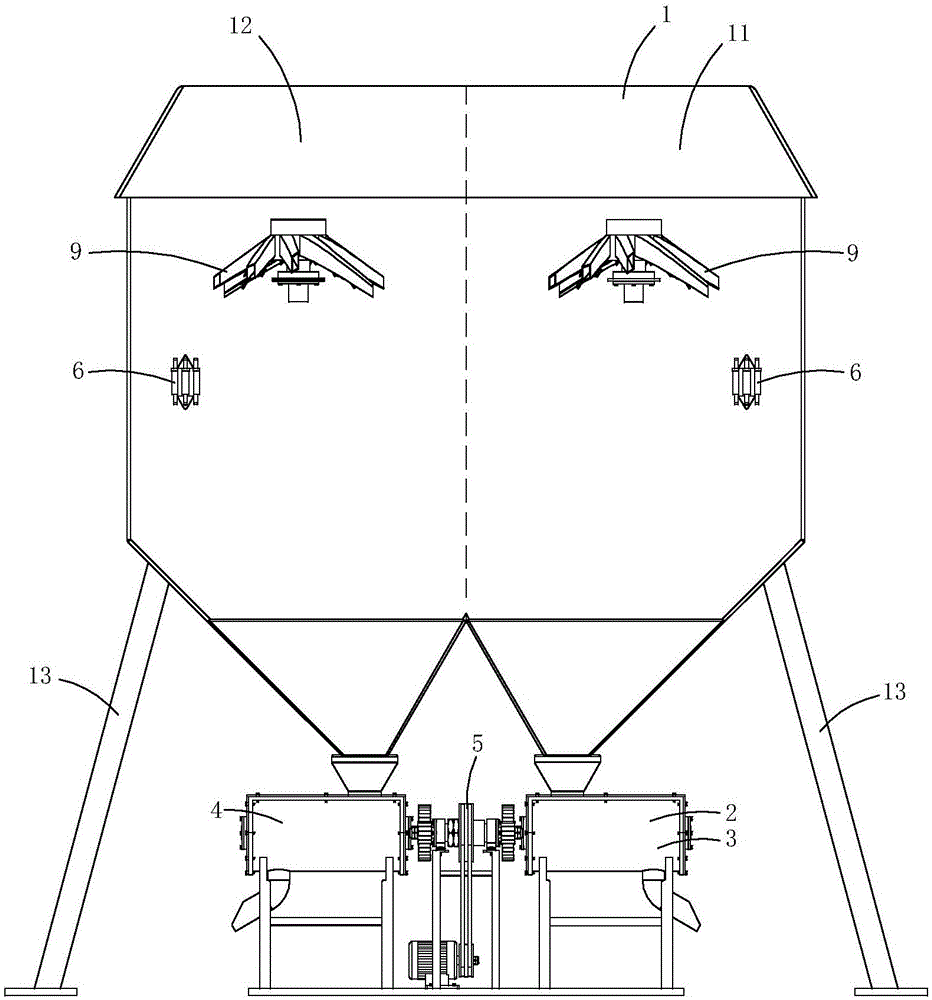

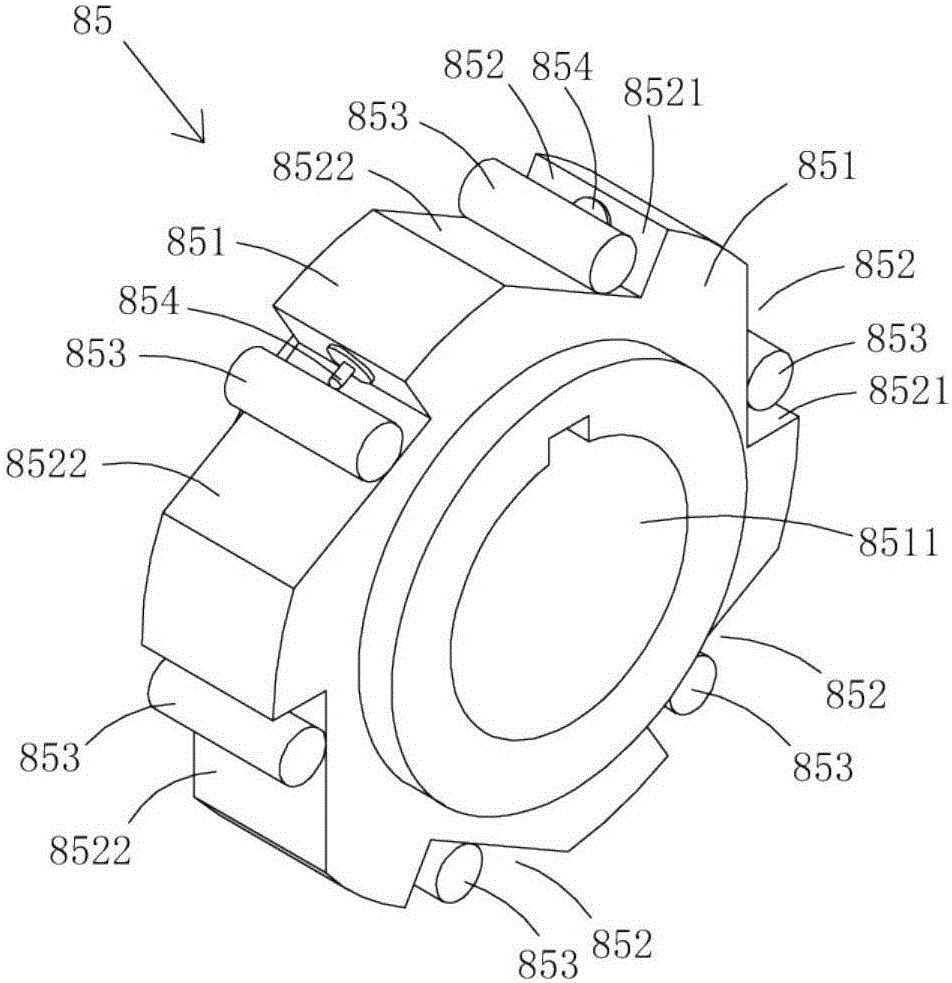

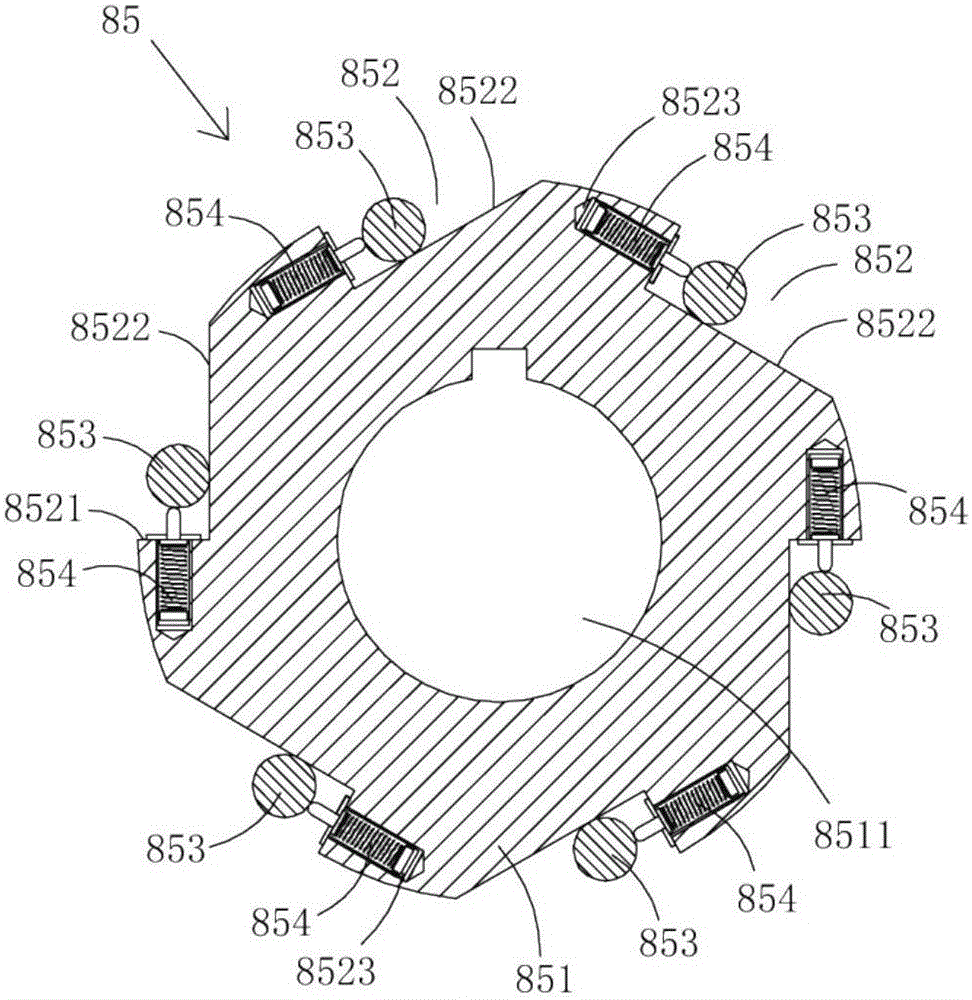

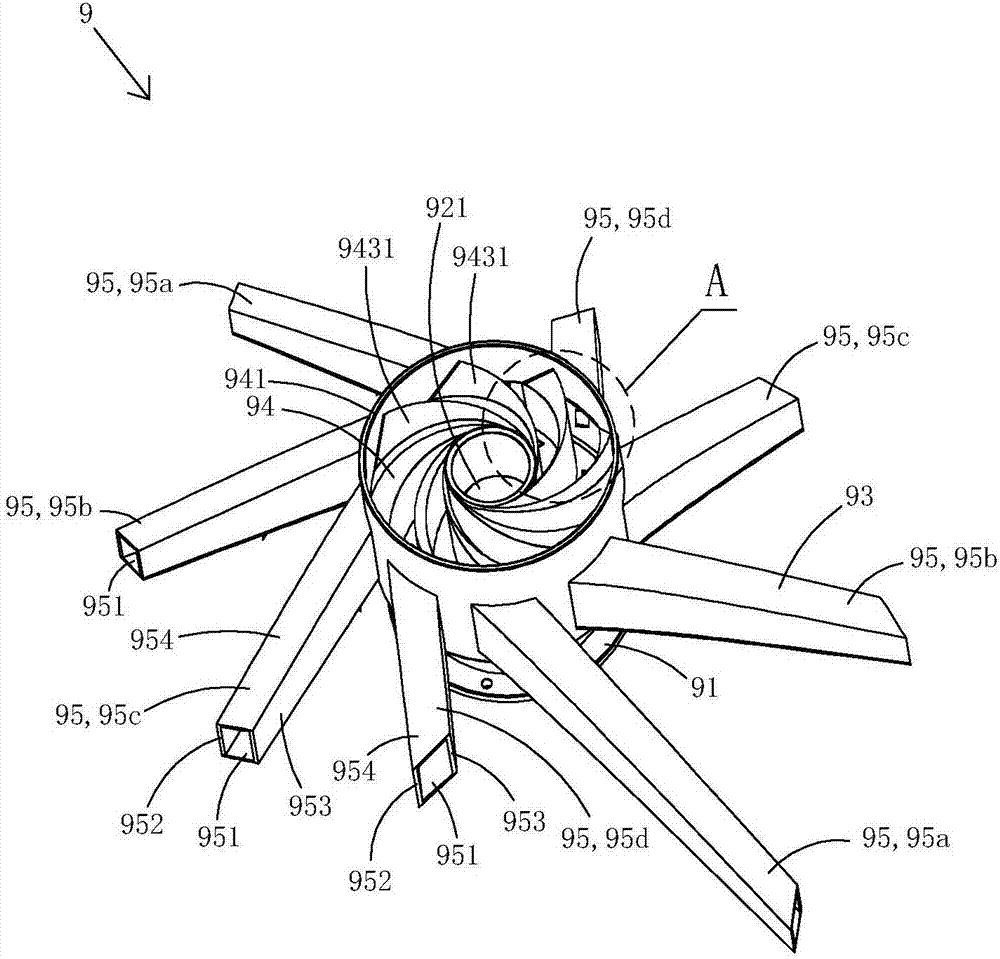

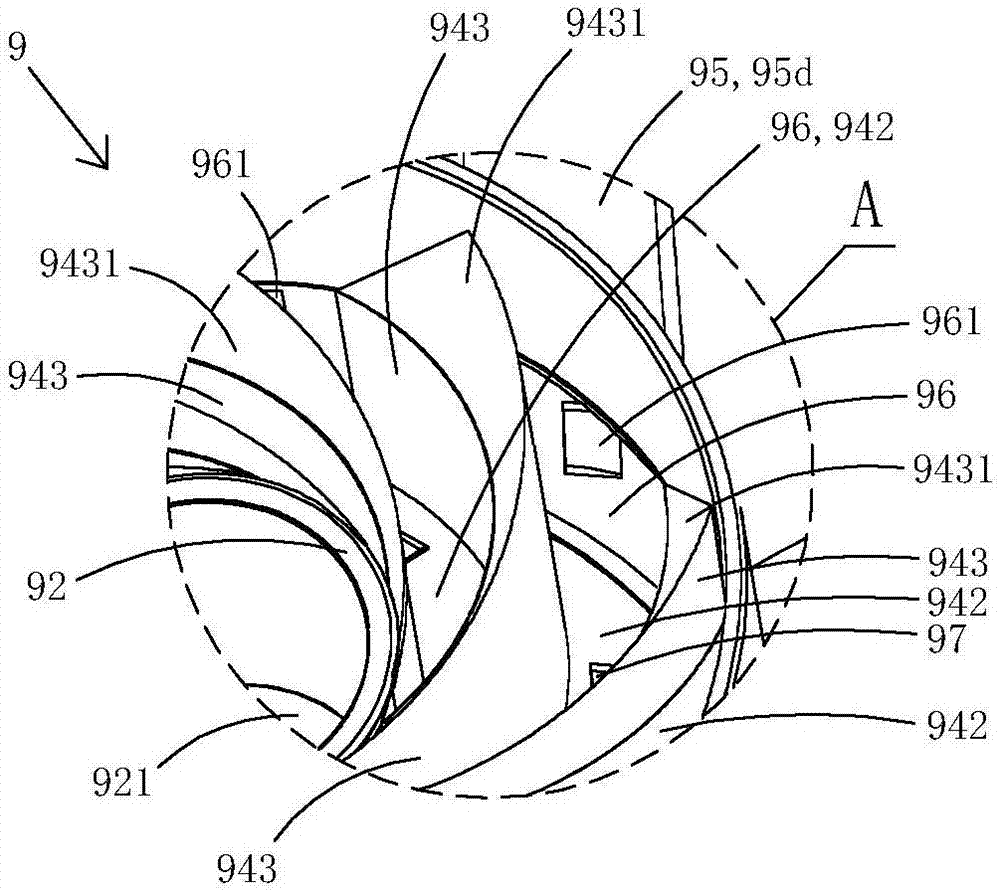

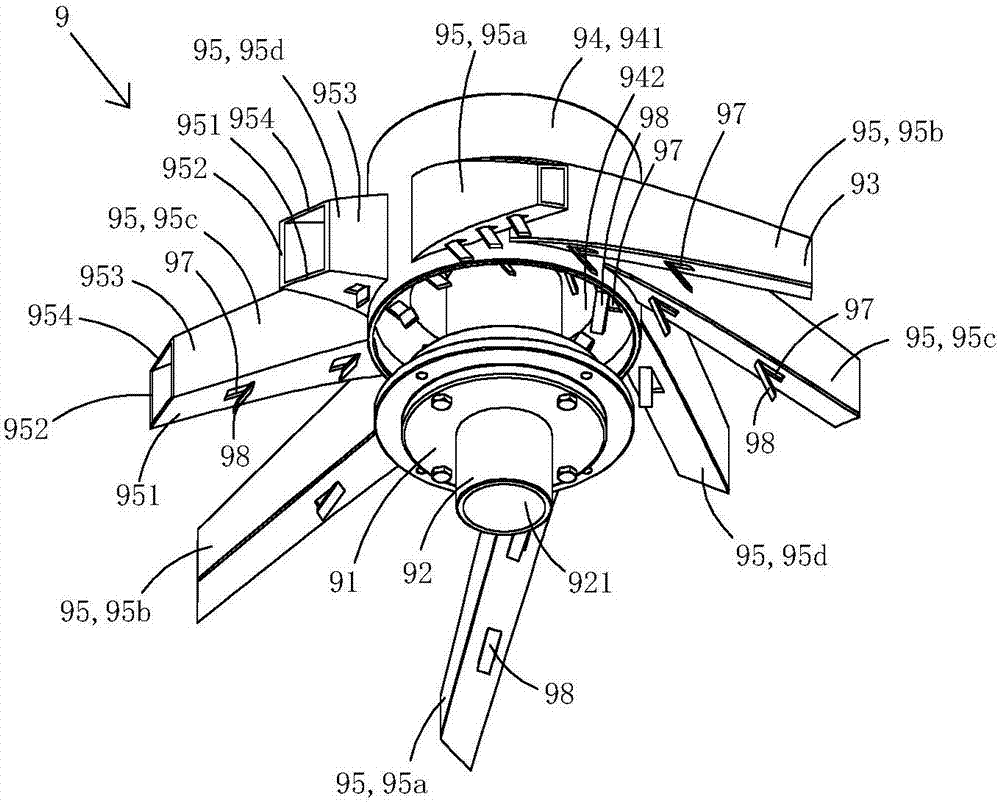

Self-rotating grain distribution device for granaries

InactiveCN106688460AUniform technical effectAchieve self-rotationAgriculture tools and machinesHarvested fruit hanging devicesAgricultural engineeringGrain distribution

The invention discloses a self-rotating grain distribution device for granaries. The self-rotating grain distribution device comprises a bearing block, a rotating shaft and a grain distribution part, the rotating shaft is rotatably arranged on the bearing block, the grain distribution part is fixedly arranged on the rotating shaft, the rotating shaft is arranged along the plumb line direction, the grain distribution part comprises a grain collection area, a plurality of grain sliding arms and a plurality of guide plates, each grain sliding arm comprises a bottom plate, a first side plate and a second side plate, the bottom plate, the first side plate and the second side plate of each grain sliding arm enclose into a grain sliding channel, each first side plate and each second side plate are positioned on two side ends of the corresponding bottom plate, the first side plates and the second side plates are linear plates and arranged along the plumb line direction, each bottom plate is obliquely arranged downwards along the direction from the corresponding second side plate to the corresponding first side plate, six grain discharging ports are formed in the bottom wall of the grain collection area, one end of each guide plate is fixedly arranged on the bottom wall of the grain collection area or the bottom plate of the corresponding grain sliding arm, and the other end of the guide plate obliquely extends downwards below the corresponding grain discharging port. The self-rotating grain distribution device can automatically rotate, and grains are uniformly distributed.

Owner:胡妍

Self-unloading physical distribution storehouse with relatively low cost

InactiveCN106688467AAvoid gatheringUniform technical effectAgriculture tools and machinesHarvested fruit hanging devicesDrive shaftElectric machinery

The invention discloses a self-unloading physical distribution storehouse with a relatively low cost. The self-unloading physical distribution storehouse comprises a twin-hull storehouse and an unloading device, wherein the twin-hull storehouse has a first storehouse and a second storehouse; each of the first and second storehouses is provided with a spinning distributor; the unloading device comprises a box body, a first screw conveyer, a second screw conveyer and a driving device; the first screw conveyer comprises a first driven gear; the second screw conveyer comprises a second driven gear; the driving device comprises a driving motor and a clutch linkage; the clutch linkage comprises a rack body, a transmission shaft, a belt pulley and a clutch transmission gear which can reciprocate on the transmission shaft; the clutch transmission gear is in a first transmission station when the clutch transmission gear moves to one end of an external threaded part; and the clutch transmission gear is in a second transmission station when the clutch transmission gear moves to the other end of the external threaded part. According to the self-unloading physical distribution storehouse, the material distribution is relatively uniform, two kinds of materials can be stored, and the manufacturing cost is relatively low.

Owner:申清章

Logistics warehouse

The invention discloses a logistics warehouse. The logistics warehouse comprises a binary warehouse body and a discharging device. The binary warehouse body is provided with a first warehouse body and a second warehouse body. The first warehouse body and the second warehouse body are each internally provided with a spinning type material distributing device. The discharging device comprises a first discharging box, a second discharging box and a driving device. The first discharging box comprises a first box body and a first auger. The first auger comprises a first one-way overrunning clutch. The second discharging box comprises a second box body and a second auger. The second auger comprises a second one-way overrunning clutch. The locking direction of the first one-way overrunning clutch is opposite to the locking device of the second one-way overrunning clutch. The spiral direction of a first spiral plate and the spiral direction of a second spiral plate are opposite. The driving device comprises a driving motor and a transmission mechanism. When the driving motor rotates positively, the first auger is driven to rotate; and when the driving motor rotates reversely, the second auger is driven to rotate. The logistics warehouse achieves uniform material distribution, can store two kinds of materials and is low in manufacturing cost.

Owner:乐清市华尊电气有限公司

Double-body granary with self-rotating grain distributors

InactiveCN106697996AUniform grain distributionReasonable structureLoading/unloadingClutchDrive motor

The invention discloses a double-body granary with self-rotating grain distributors. The double-body granary comprises a double-body warehouse and a grain unloading device; the double-body warehouse has a first warehouse and a second warehouse; the self-rotating grain distributors are respectively arranged in the first warehouse and the second warehouse; the grain unloading device includes a box body with a first grain unloading cavity and a second grain unloading cavity, a first auger for unloading grains stored in the first grain unloading cavity, a second auger for unloading the grains stored in the second grain unloading cavity, and a driving device for driving the first auger and the second auger to rotate; the first auger includes a first rotating shaft, a first spiral plate and a first driven gear; the second auger includes a second rotating shaft, a second spiral plate and a second driven gear; the driving device includes a driving motor and a clutch linkage device; the clutch linkage device includes a frame body, a transmission shaft, a clutch transmission gear and a belt wheel; the transmission shaft is provided with an external thread part; and the clutch transmission gear is screwed on the external thread part of the transmission shaft. The double-body granary is more uniform in grain distribution, can store two types of grains, and is lower in manufacturing cost.

Owner:申清章

Low-cost self-discharging type logistics warehouse

InactiveCN106698000AAvoid gatheringUniform technical effectLoading/unloadingLogistics managementDrive shaft

The invention discloses a low-cost self-discharging type logistics warehouse. The low-cost self-discharging type logistics warehouse comprises double warehouse bodies and a discharging device. The double warehouse bodies comprise the first warehouse body and the second warehouse body. The first warehouse body and the second warehouse body are each internally provided with a self-rotating type distributor. The discharging device comprises a box body, a first auger, a second auger and a driving device. The first auger comprises a first driven gear. The second auger comprises a second driven gear. The driving device comprises a driving motor and a clutch linkage device. The clutch linkage device comprises a frame body, a transmission shaft, a belt wheel and a clutch transmission gear which can move back and forth on the transmission shaft. The clutch transmission gear is in a first transmission station when moving to one end of an external thread part, and the clutch transmission gear is in a second transmission station when moving to the other end of the external thread part. According to the low-cost self-discharging type logistics warehouse, distributing is uniform, two kinds of materials can be stored, and the manufacturing cost is low.

Owner:申清章

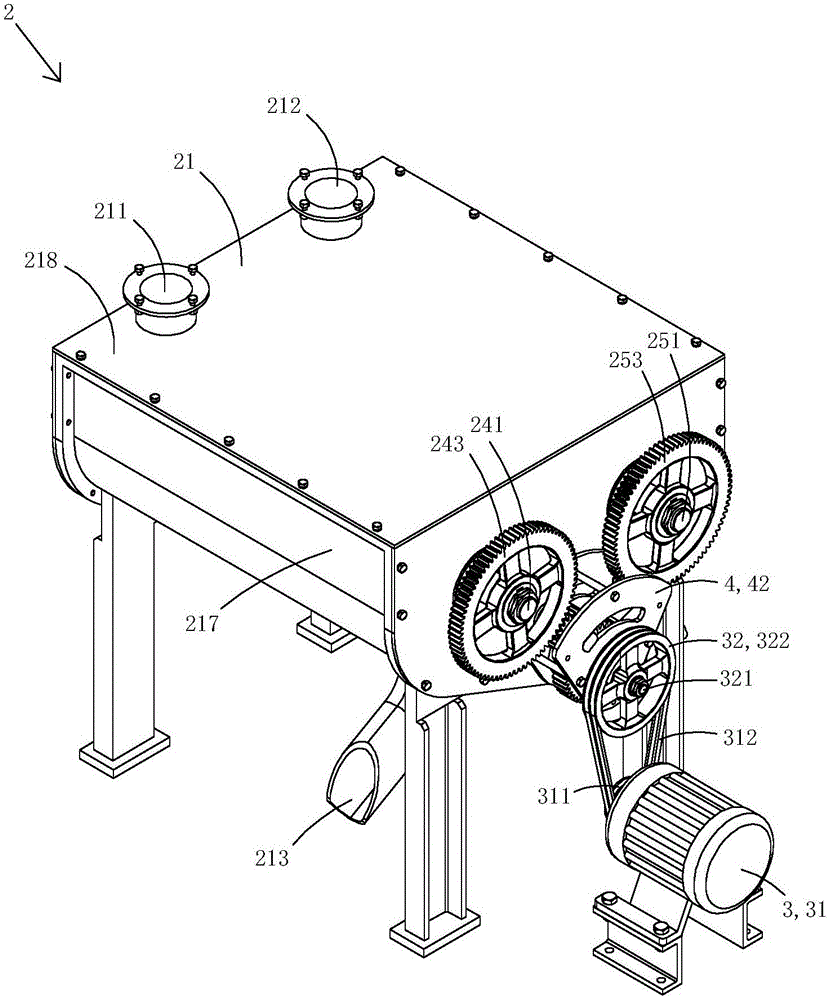

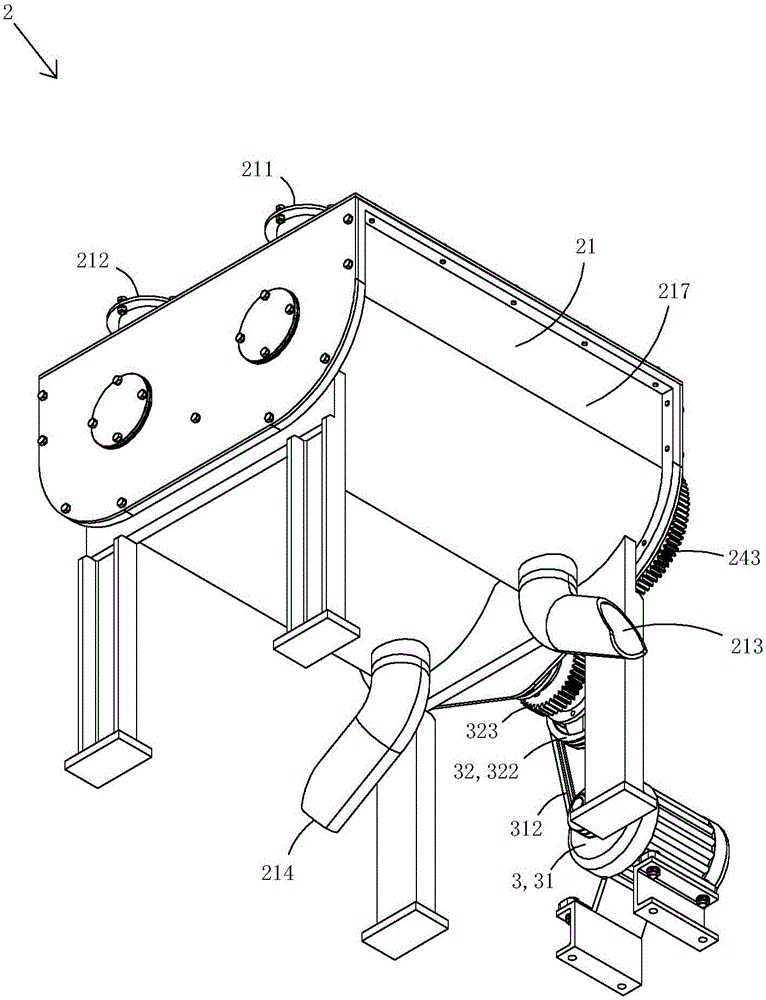

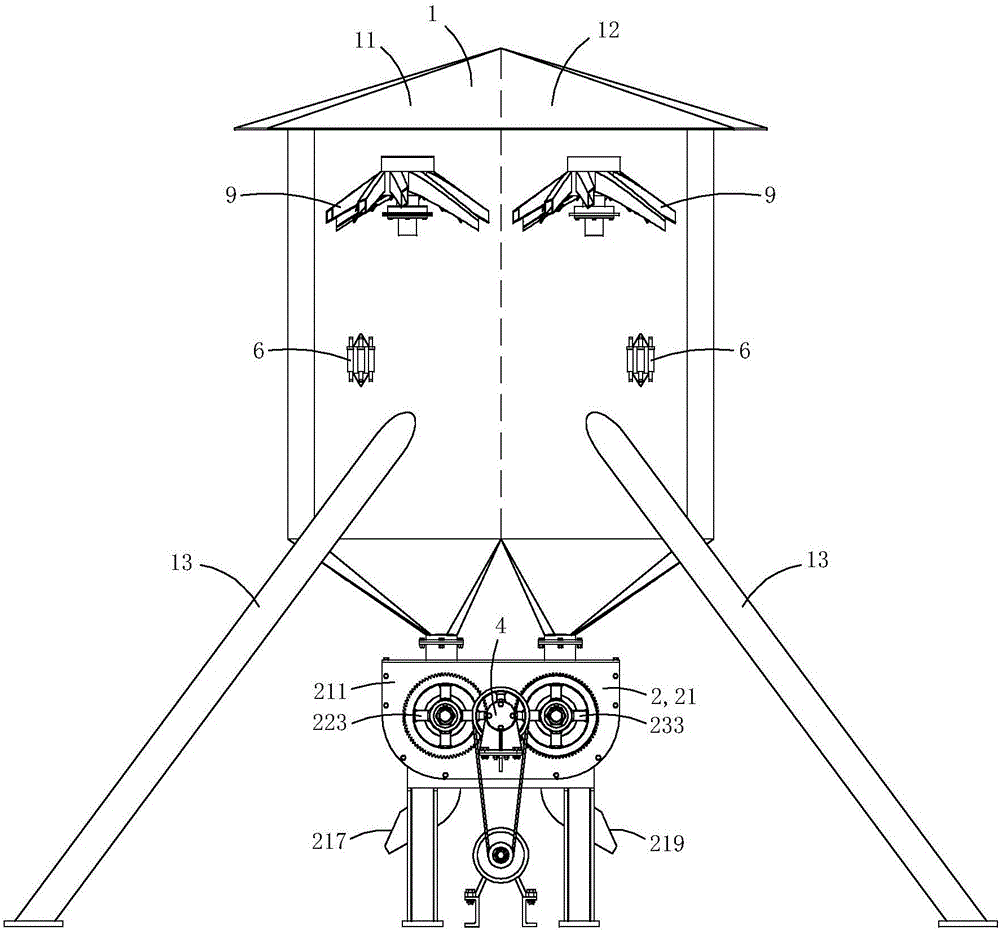

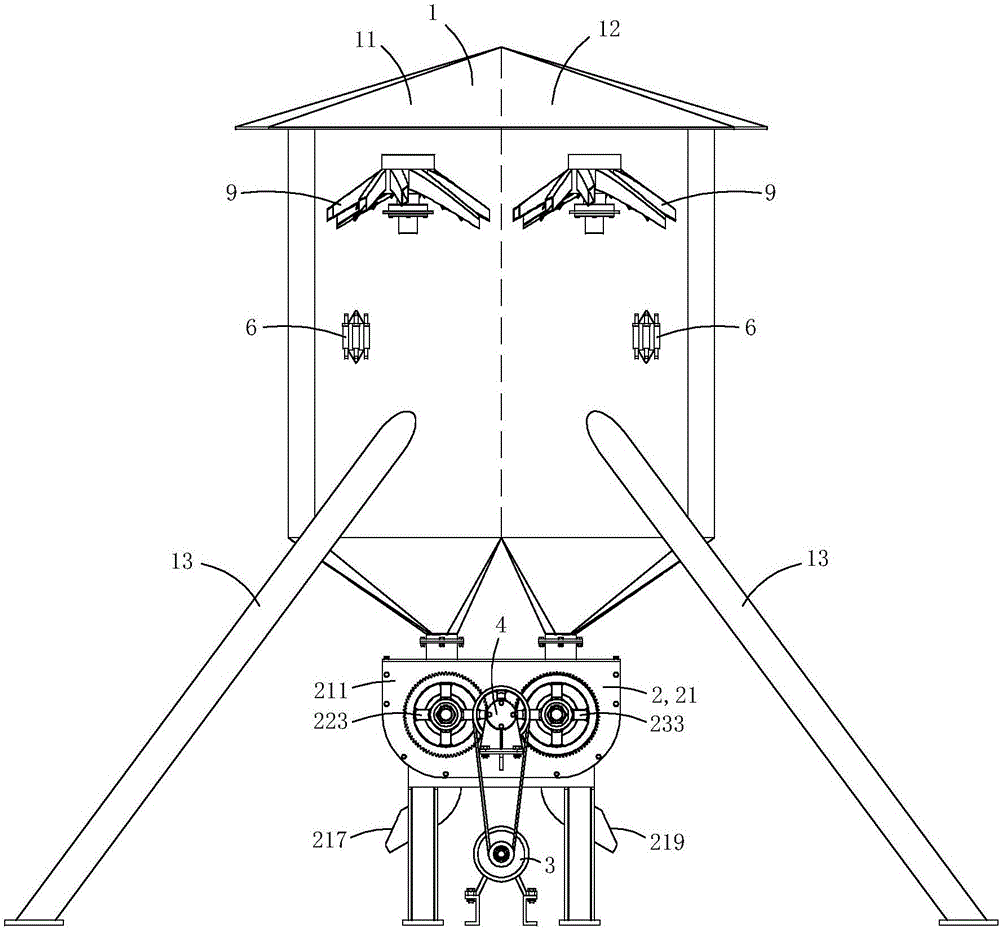

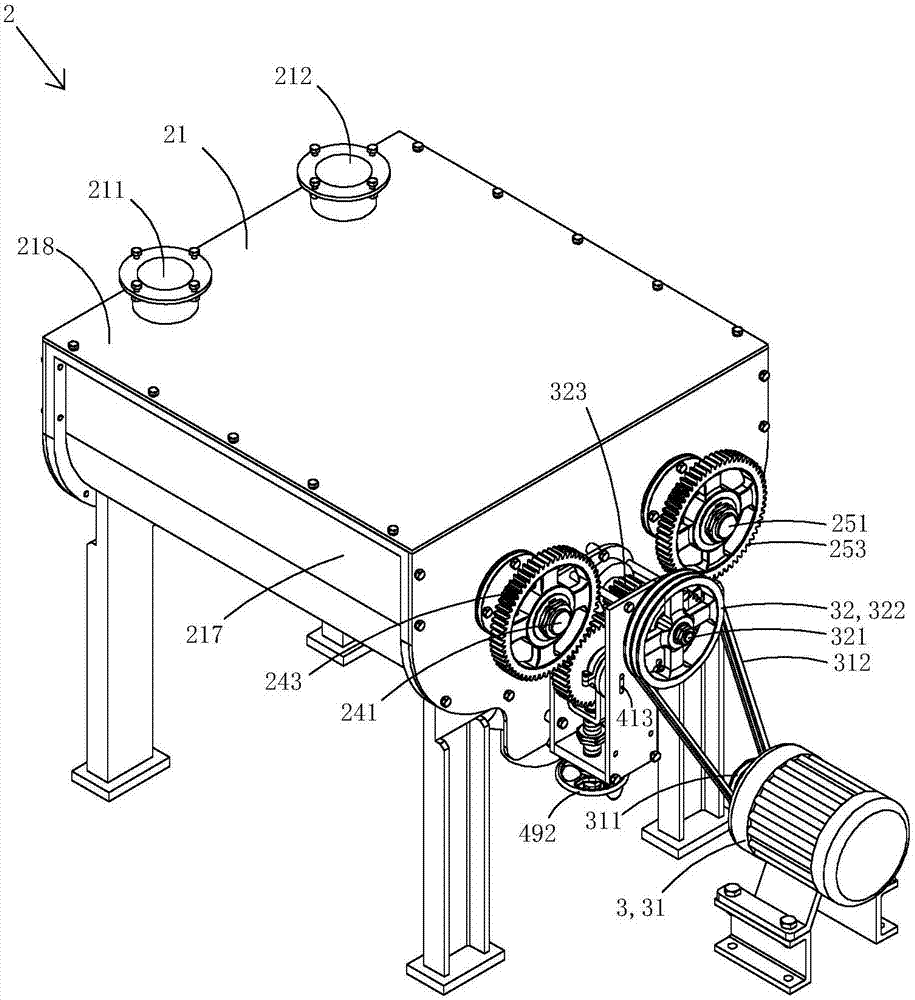

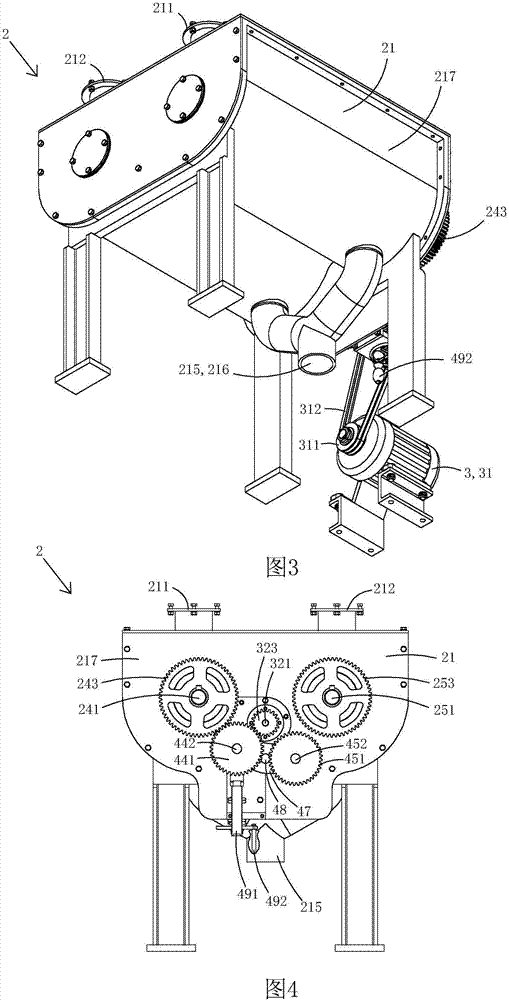

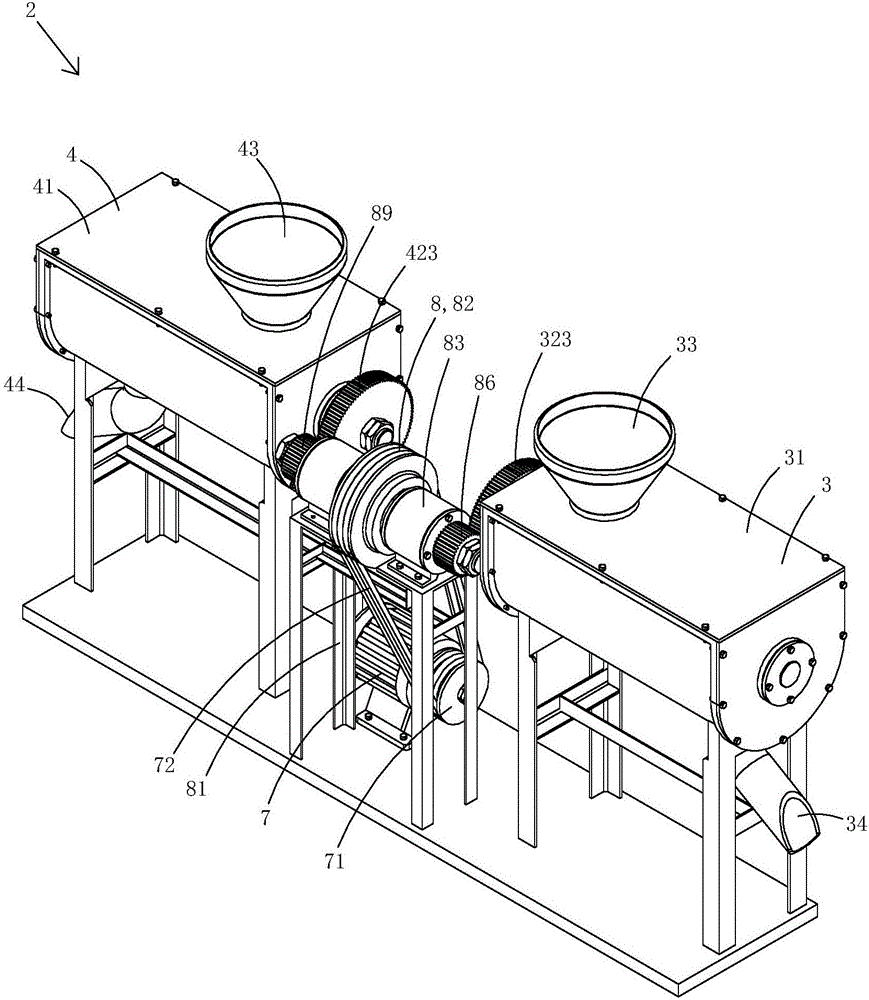

Electric unloading type two-body barn

InactiveCN106856893AAvoid gatheringUniform technical effectAgriculture tools and machinesHarvested fruit hanging devicesElectric machineryDrive motor

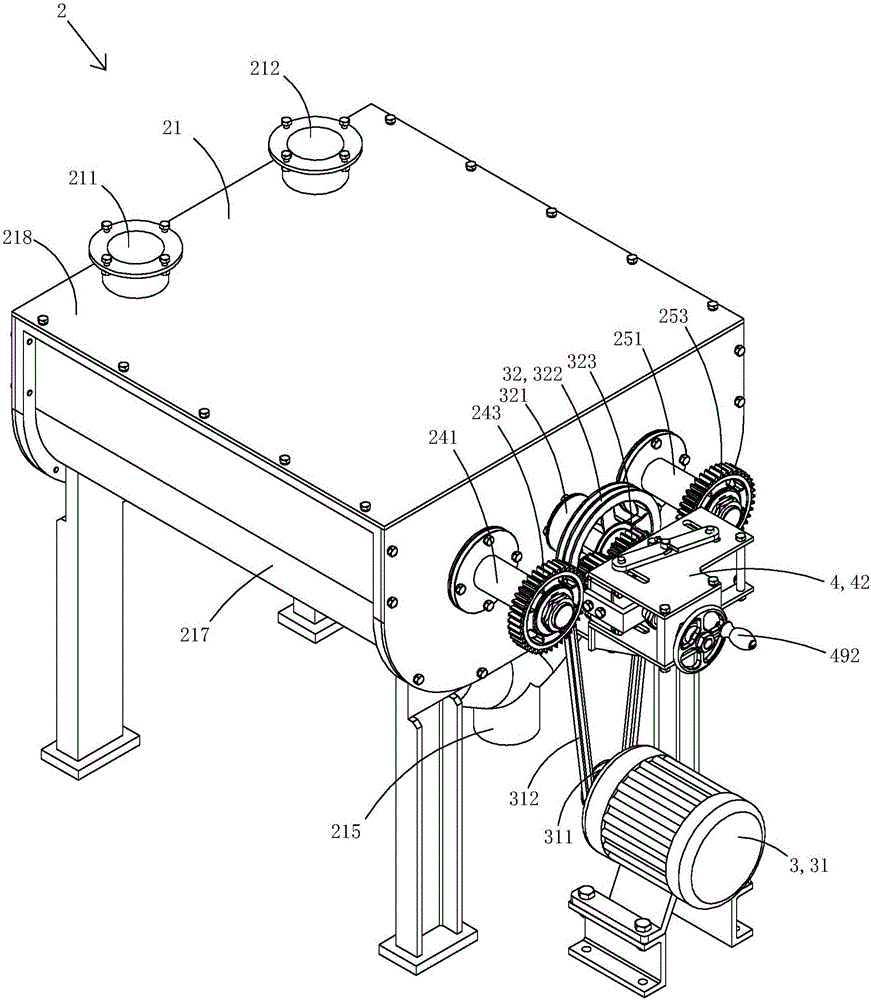

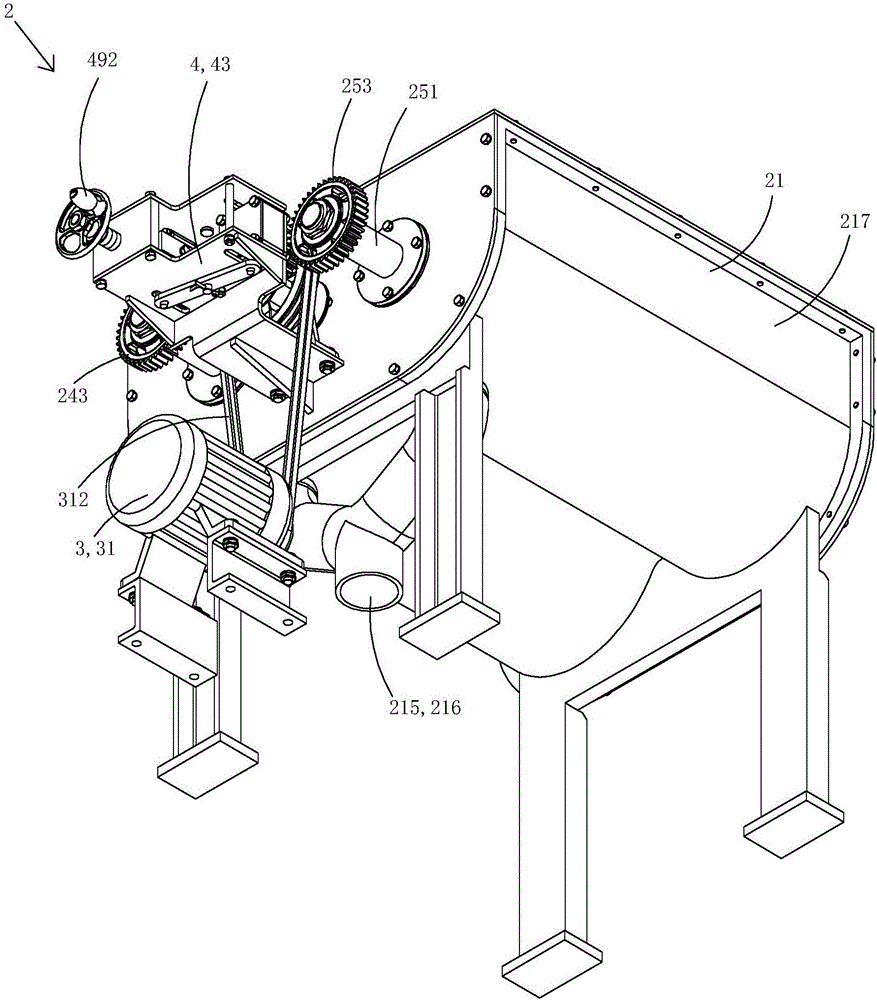

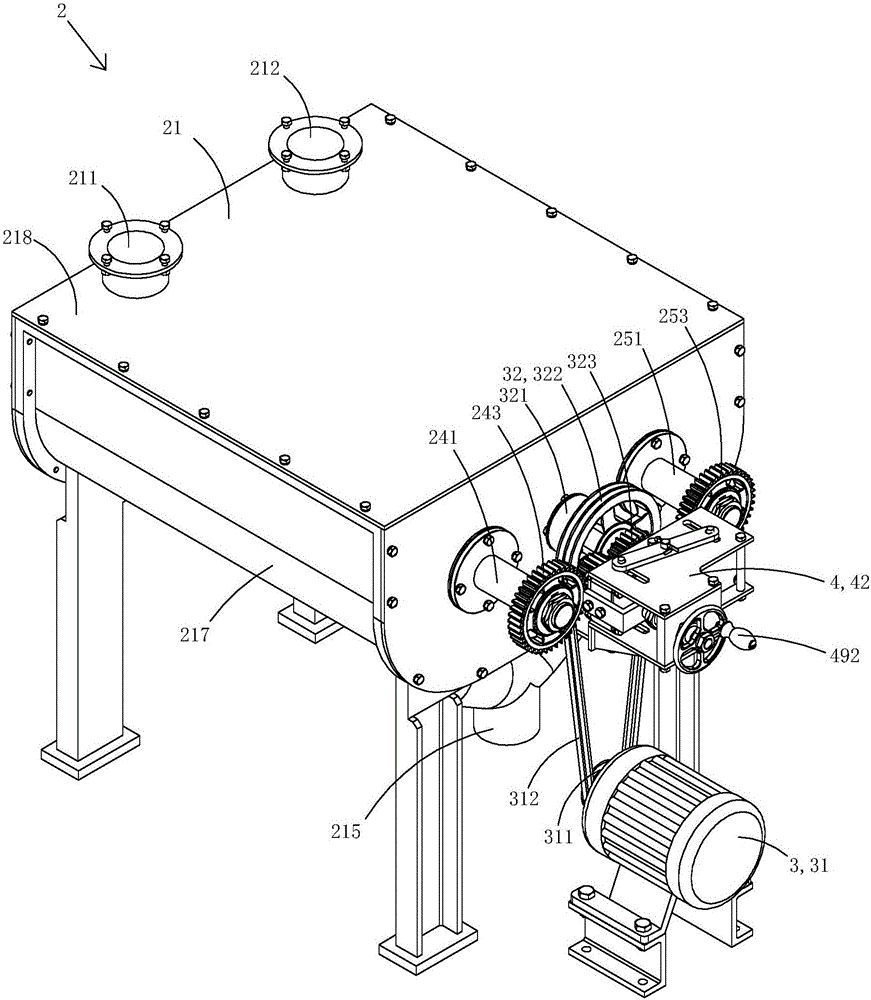

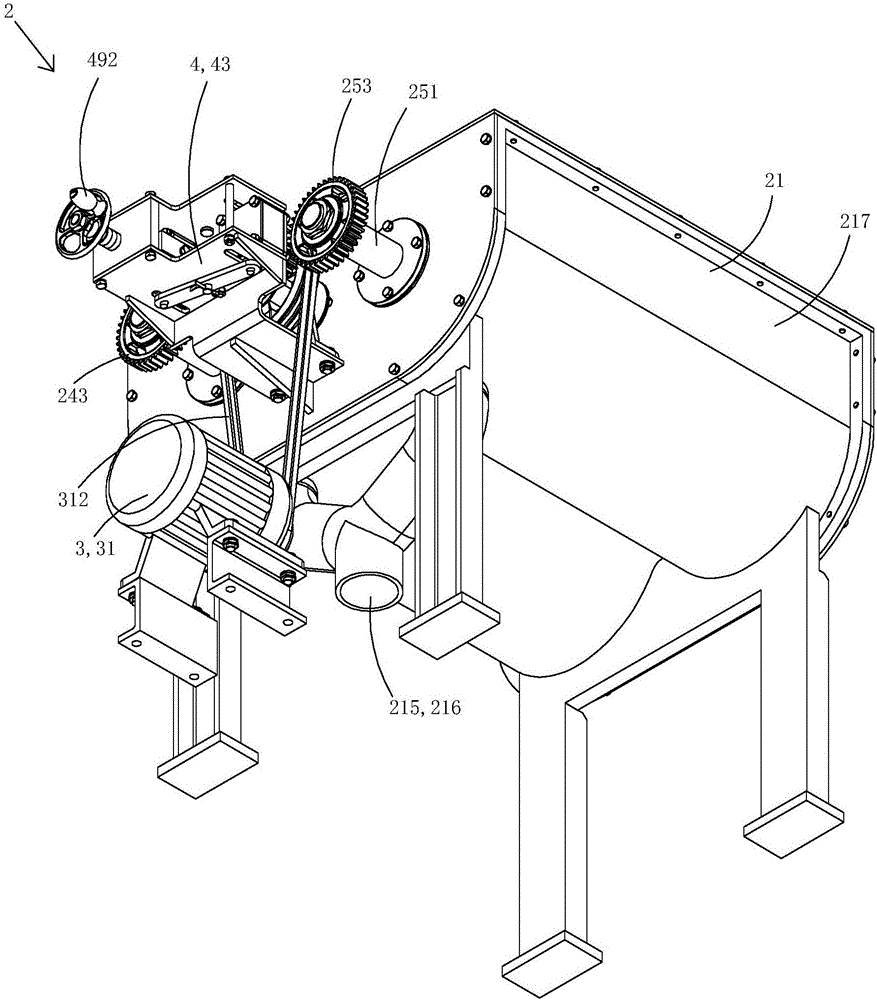

The invention discloses an electric unloading type two-body barn. The electric unloading type two-body barn comprises a two-body warehouse and an unloading device arranged below the two-body warehouse; a self-rotating grain distributing device is arranged in each of a first warehouse and a second warehouse; the two-body warehouse is provided with the first warehouse and the second warehouse arranged side by side; the unloading device comprises a first packing auger, a second packing auger and a driving device; the first packing auger comprises a first driven gear, and the second packing auger comprises a second driven gear; the driving device comprises a driving motor provided with a driving wheel, a transmission wheel set and a linkage switching device; the transmission set comprises a transmission shaft, and a transmission belt wheel and a transmission gear which are fixedly arranged on the transmission shaft; and the linkage switching device comprises a rack body, a first linkage gear assembly, a second linkage gear assembly, a reverse linkage assembly and a switching driving mechanism. The electric unloading type two-body barn is relatively uniform in grain distribution and relatively low in manufacturing cost, and two kinds of grain can be stored.

Owner:申清章

Logistics warehouse

The invention discloses a logistics warehouse, which comprises a double-body warehouse and a material unloading device; the double-body warehouse has a first warehouse and a second warehouse; each of the first warehouse and the second warehouse is provided with a spin-type material distributor; The device includes a first unloading box, a second unloading box and a driving device; the first unloading box includes a first box body and a first auger; the first auger includes a first one-way overrunning clutch; the second unloading box It includes a second box and a second auger; the second auger includes a second one-way overrunning clutch; the locking direction of the first one-way overrunning clutch is opposite to that of the second one-way overrunning clutch, and the first spiral plate It is opposite to the spiral direction of the second spiral plate; the driving device includes a driving motor and a transmission mechanism; when the driving motor rotates in the forward direction, it drives the first auger to rotate; when the driving motor rotates in the reverse direction, it drives the second auger to rotate. The invention has relatively uniform cloth, can store two kinds of materials, and has low manufacturing cost.

Owner:乐清市华尊电气有限公司

Double-body grain bin capable of distributing grains uniformly

InactiveCN106586596AAvoid gatheringUniform technical effectLoading/unloadingAgricultural engineeringEngineering

The invention discloses a double-body grain bin capable of distributing grains uniformly. The bin comprises a double-body warehouse and a grain discharge device. The double-body warehouse is provided with a first warehouse and a second warehouse. One self-rotating type grain distributor is arranged in each of the first warehouse and the second warehouse. The grain discharging box comprises a grain discharge box and a driving device. The grain discharge box comprises a box body, a first auger, a second auger, a first material inlet, a second material inlet, a discharge port and a belt pulley. The first auger comprises a first rotary shaft, a first spiral plate and a first one-way overrunning clutch. The second auger comprises a second rotary shaft, a second spiral plate and a second one-way overrunning clutch. The first spiral plate and the second spiral plate are opposite in spiral directions. The first one-way overrunning clutch and the second one-way overrunning clutch are arranged in shaft holes of the belt pulley. The lock-up directions of the first one-way overrunning clutch and the second one-way overrunning clutch are opposite. The double-body grain bin capable of distributing grains uniformly has the following beneficial effects: grains can be uniformly distributed; and two kinds of grains are stored; and manufacture cost is low.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

Logistics granary capable of achieving relatively uniform grain distribution

InactiveCN106364938AAvoid gatheringUniform technical effectLoading/unloadingLogistics managementDrive shaft

The invention discloses a logistics granary capable of achieving relatively uniform grain distribution. The logistics granary comprises a double-body warehouse and a grain unloading device, wherein a self-rotating grain distributor is arranged inside each of a first warehouse and a second warehouse; the grain unloading device comprises a first grain unloading box, a second grain unloading box and a driving device; the first grain unloading box comprises a first box body and a first screw conveyer; the driving device comprises a driving motor and a clutch transmission mechanism; the clutch transmission mechanism comprises a belt pulley, a first transmission shaft, a first one-way overrunning clutch, a second transmission shaft and a second one-way overrunning clutch; the driving motor drives the belt pulley to rotate in a reciprocating manner; and the locking direction of the first one-way overrunning clutch is opposite to the locking direction of the second one-way overrunning clutch. According to the logistics granary, the grain distribution is relatively uniform, two kinds of grains can be stored, and the manufacturing cost is relatively low.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

Double-body granary with uniform grain distributing and electric grain unloading functions

InactiveCN106672656AAvoid gatheringUniform technical effectConveyorsLoading/unloadingDrive wheelElectric machinery

The invention discloses a double-body granary with uniform grain distributing and electric grain unloading functions. The double-body granary comprises a double-body warehouse and a grain unloading device. The double-body warehouse is provided with a first warehouse body and a second warehouse body. The first warehouse body and the second warehouse body are each provided with a spinning grain distributing device. The grain unloading device comprises a tank internally provided with a first grain unloading channel and a second grain unloading channel, a first auger used for unloading grain stored in the first grain unloading channel, a second auger used for unloading grain stored in the second grain unloading channel, and a drive device used for driving the first auger and the second auger to rotate. The first warehouse body communicates with the first grain unloading channel. The second warehouse body communicates with the second grain unloading channel. The drive device comprises a drive motor provide with a drive wheel, a transmission wheel set and a linkage switching device. The drive motor drives the transmission wheel set to rotate through the drive wheel. The transmission wheel set drives the first auger or the second auger to rotate through the linkage switching device. By adoption of the double-body granary with the uniform grain distributing and electric grain unloading functions, grain is distributed uniformly, two types of grain can be stored, and the manufacturing cost is low.

Owner:申清章

Binary electric unloading grain bin

InactiveCN106856894AAvoid gatheringUniform technical effectAgriculture tools and machinesHarvested fruit hanging devicesDrive motorGrain distribution

The invention discloses a binary electric unloading grain bin which comprises a binary warehouse and a grain unloading device, wherein the binary warehouse is provided with a first warehouse and a second warehouse; a self-rotating grain distributor is arranged in each of the first warehouse and the second warehouse; the grain unloading device comprises a box body internally provided with a first grain unloading channel and a second grain unloading channel, a first auger used for unloading stored grain in the first grain unloading channel, a second auger used for unloading stored grain in the second grain unloading channel, and a driving device used for driving the first auger and the second auger to rotate; the first warehouse communicates with the first grain unloading channel; the second warehouse communicates with the second grain unloading channel; the driving device comprises a driving motor provided with a driving wheel, a transmission wheel set and an interlocking switching device; the driving motor drives the transmission wheel set to rotate by the driving wheel; and the transmission wheel set drives the first auger or the second auger to rotate by the interlocking switching device. The grain bin is relatively uniform in grain distribution and lower in manufacturing cost, and can store two kinds of grain.

Owner:申清章

Electric grain discharging type dual-body granary with self-rotating type grain distributors

The invention discloses an electric grain discharging type dual-body granary with self-rotating type grain distributors. The electric grain discharging type dual-body granary with the self-rotating type grain distributors comprises a dual-body warehouse and a grain discharging device arranged below the dual-body warehouse; a first warehouse and a second warehouse are each internally provided with the corresponding self-rotating type grain distributor; the dual-body warehouse is provided with the first warehouse and the second warehouse which are arranged side by side; the grain discharging device comprises a first auger, a second auger and a driving device; the first auger comprises a first driven gear; the second auger comprises a second driven gear; the driving device comprises a driving motor provided with a driving wheel, a transmission wheel set and a linkage switching device; the transmission wheel set comprises a transmission shaft, a transmission belt pulley and a transmission gear, and the transmission belt pulley and the transmission gear are fixedly arranged on the transmission shaft; and the linkage switching device comprises a frame body, a first linkage gear assembly, a second linkage gear assembly, a reverse linkage assembly and a switching driving mechanism. The electric grain discharging type dual-body granary with the self-rotating type grain distributors is uniform in grain distribution, can store two kinds of grain and is low in manufacturing cost.

Owner:申清章

Two-body electric grain-unloading barn

InactiveCN106688466AAvoid gatheringUniform technical effectAgriculture tools and machinesHarvested fruit hanging devicesDrive wheelEngineering

The invention discloses a two-body electric grain-unloading barn, which comprises a two-body barn and grain-unloading device. The two-body barn has a first barn and a second barn with a Self-screwing grain spreader. The unloading device comprises a box with a first grain-unloading channel and a second grain-unloading channel set inside, a first auger used to unload stored grain in the first grain-unloading channel, a second auger used to unload stored grain in the second grain-unloading channel, and a driving device used to drive and rotate the first auger and the second auger. The first barn is communicated with the first grain-unloading channel, and the second barn is communicated with the second grain-unloading channel. The driving device comprises a drive motor with driving wheels, a transmission wheel group and a linked switch device. The drive motor drives and rotates the transmission wheel group by the driving wheel, and the transmission wheel group drives and rotates the first auger and the second auger by the linked switch device. The two-body electric grain-unloading barn can spread grain evenly and store two kinds of grain and has a lower manufacturing cost.

Owner:申清章

Electric grain-unloading granary capable of distributing grains uniformly

InactiveCN106717624AAvoid gatheringUniform technical effectMowersHarvested fruit hanging devicesDrive wheelGear drive

The invention discloses an electric grain-unloading granary capable of distributing grains uniformly. The electric grain-unloading granary comprises a double-body warehouse and a grain unloading device, wherein self-rotating grain distributors are respectively arranged in a first warehouse and a second warehouse; the grain unloading device comprises a first auger, a second auger and a drive device; the drive device comprises a drive motor provided with a drive wheel, and a linkage switching device; the linkage switching device comprises a rack body, a transmission wheel group, a guiding plate and a linkage gear assembly; the transmission wheel group comprises a transmission shaft, a transmission belt wheel and a transmission gear; a guiding hole is formed in the guiding plate; the linkage gear assembly comprises a linkage gear and a guiding element for limiting the linkage gear to slide along the guiding hole in a reciprocating way; the guiding element is located in the guiding hole; when the guiding element slides to one end of the guiding hole, the transmission gear drives a first driven gear to rotate through the linkage gear; when the guiding element slides to the other end of the guiding hole, the transmission gear drives a second driven gear to rotate through the linkage gear. The electric grain-unloading granary capable of distributing the grains uniformly provided by the invention can be used for distributing the grains uniformly and storing two species of grains, and has lower manufacturing cost.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

Improved logistics warehouse

InactiveCN106542350AAvoid gatheringUniform technical effectConveyorsLoading/unloadingLogistics managementEngineering

The invention discloses an improved logistics warehouse. The improved logistics warehouse comprises a double-body warehouse and an unloading device, wherein the double-body warehouse comprises a first warehouse and a second warehouse; the first warehouse and the second warehouse are separately provided with a self-rotating-type material distributer; the unloading device comprises a first material unloading box, a second material unloading box and a driving device; the first material unloading box comprises a first box body and a first packing auger; the first packing auger comprises a first one-way overrunning clutch; a second unloading box comprises a second box body and a second packing auger; the second packing auger comprises a second one-way overrunning clutch; the locking direction of the first one-way overrunning clutch is opposite to that of the second one-way overrunning clutch; the spiral direction of a first spiral plate is opposite to that of a second spiral plate; the driving device comprises a driving motor and transmission mechanism; when the driving motor rotates forwardly, the first packing auger is driven to rotate; and when the driving motor rotates reversely, the second packing auger is driven to rotate. The improved logistics warehouse has the advantages that material distribution is uniform; two materials can be stored; and manufacture cost is low.

Owner:乐清市华尊电气有限公司

Double-logistics-granary capable of distributing grain evenly

InactiveCN106429523AUniform grain distributionReasonable structureLoading/unloadingClutchDrive motor

The invention discloses a double-logistics-granary capable of distributing grain evenly. The double-logistics-granary comprises a double-warehouse and a grain unloading device; the double-granary is provided with a first warehouse and a second warehouse; the first warehouse and the second warehouse are both provided with a self-rotating grain distributing device correspondingly; the grain unloading device comprises a first grain unloading case, a second grain unloading case and a driving device; the first grain unloading case comprises a first case body and a first screw conveyor; the first screw conveyor comprises a first rotating shaft, a first spiral plate, a first one-way overrun clutch and a first driven gear; the second grain unloading case comprises a second case body and a second screw conveyor; the second screw conveyor comprises a second rotating shaft, a second spiral plate, a second one-way overrun clutch and a second driven gear; the driving device comprises a driving motor and a transmission mechanism; the transmission mechanism comprises a transmission shaft, a transmission gear and a belt pulley; and a driving wheel drives the belt pulley. According to the double-logistics-granary capable of distributing the grain evenly, the grain can be distributed evenly, two kinds of grain can be stored, and manufacturing cost is low.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

Electric grain unloading type double-body barn

InactiveCN106672655AUniform grain distributionReasonable structureConveyorsLoading/unloadingDrive motorEngineering

The invention discloses an electric grain unloading type double-body barn. The electric grain unloading type double-body barn comprises a double-body warehouse and a grain unloading device arranged below the double-body warehouse. Each of a first warehouse and a second warehouse is internally provided with a spinning type grain distributor. The double-body warehouse is provided with the first warehouse and the second warehouse which are arranged side by side. The grain unloading device comprises a first packing auger, a second packing auger and a drive device. The first packing auger comprises a first driven gear. The second packing auger comprises a second driven gear. The drive device comprises a drive motor with a drive wheel, a transmission wheel set and a linkage switching device. The transmission wheel set comprises a transmission shaft, a transmission belt wheel and a transmission gear, wherein the transmission belt wheel and the transmission gear are fixedly arranged on the transmission shaft. The linkage switching device comprises a frame, a first linkage gear assembly, a second linkage gear assembly, a reverse linkage assembly and a switching drive mechanism. The electric grain unloading type double-body barn is uniform in grain distribution, capable of storing two kinds of grain and low in manufacturing cost.

Owner:申清章

Self-discharging type logistics warehouse

InactiveCN106697999AAvoid gatheringUniform technical effectConveyorsLarge containersGear wheelEngineering

The invention discloses a self-discharging type logistics warehouse. The self-discharging type logistics warehouse comprises a dual-body warehouse and a discharging device. The dual-body warehouse is provided with a first warehouse body and a second warehouse body. A self-rotation material distributing device is arranged in each of the first warehouse body and the second warehouse body. The discharging device comprises a box body, a first packing auger, a second packing auger and a drive device. The first packing auger comprises a first driven gear. The second packing auger comprises a second driven gear. The drive device comprises a drive motor and a clutch linkage device. The clutch linkage device comprises a frame, a transmission shaft, a belt wheel and a clutch transmission gear capable of doing reciprocating motion on the transmission shaft. When moving to one end of an external thread, the clutch transmission gear is located at a first transmission station. When moving to the other end of the external thread, the clutch transmission gear is located at a second transmission station. The self-discharging type logistics warehouse is uniform in material distribution, can store two kinds of materials and is low in manufacturing cost.

Owner:申清章

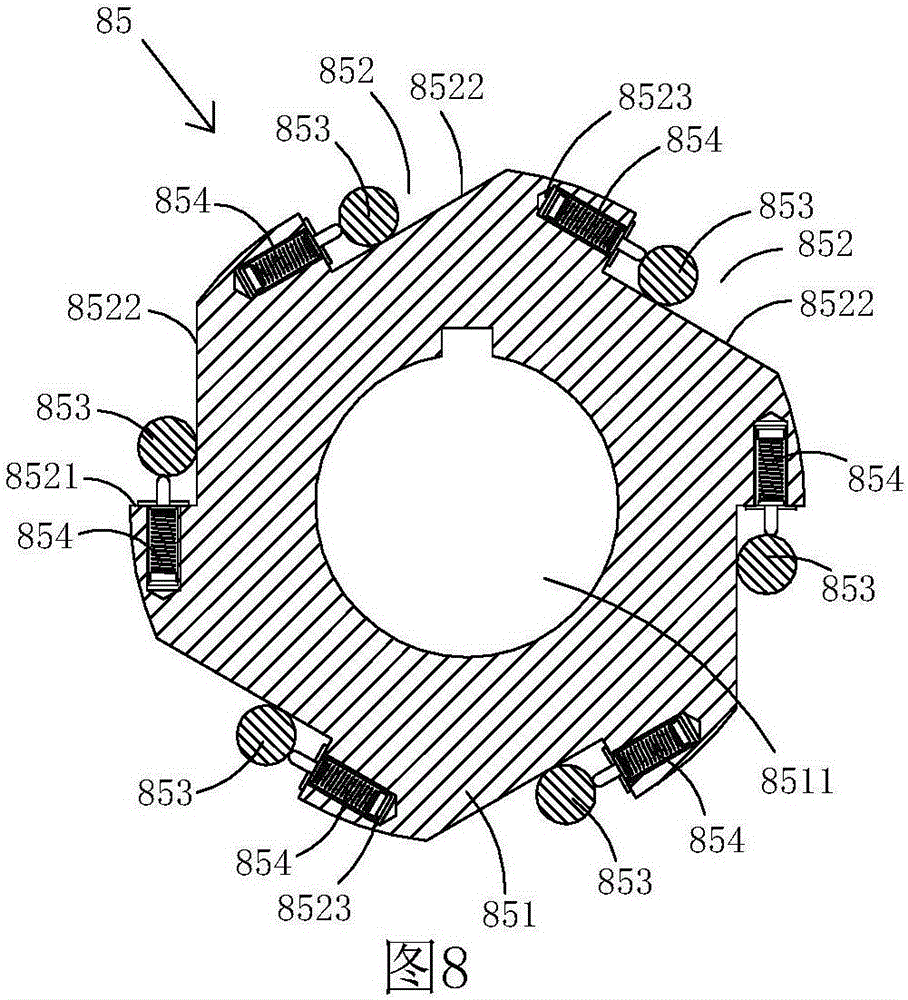

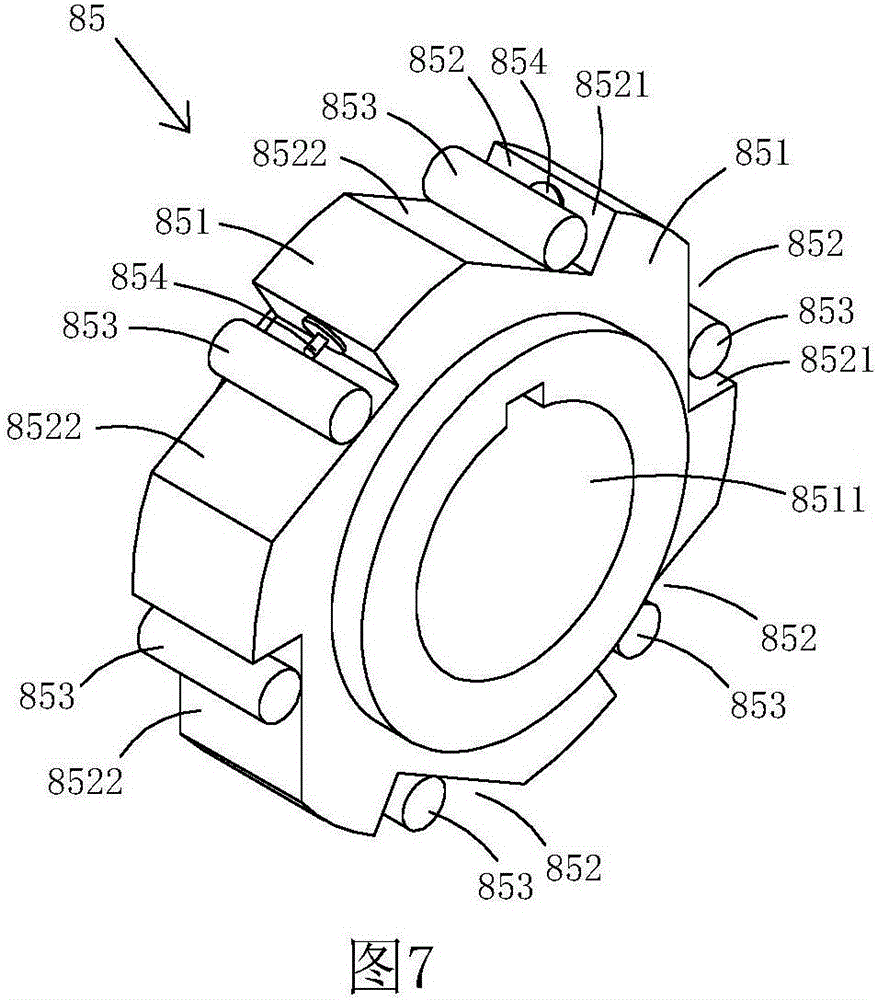

Self-rotation grain distribution device

InactiveCN106856895AUniform technical effectAchieve self-rotationAgriculture tools and machinesHarvested fruit hanging devicesEngineeringGrain distribution

The invention discloses a self-rotation grain distribution device comprising a bearing pedestal, a rotating shaft and a grain distribution piece, wherein the rotating shaft is arranged in the direction of a plumb line; the grain distribution piece comprises a grain collection area and a plurality of grain sliding barrels; the grain collection area comprises an annular plate, a round bottom wall, and a plurality of evolvent plates; the rotating shaft is positioned at the center of the round bottom wall; the two adjacent evolvent plates are combined in a clamping manner to form a flowing guiding channel; a plurality of grain outlets are formed in the annular plate; each grain outlet just faces a corresponding flowing guiding channel; each grain sliding barrel is fixedly arranged at the peripheral wall of the annular plate; each grain sliding barrel is communicated with one grain guiding channel by a corresponding grain outlet; each grain sliding barrel is arranged in an inclined manner in a direction from top to bottom; a self-rotation stress surface is arranged at the top end of each evolvent plate and is an inclined surface inclined downwards or an arc-shaped surface; and a grain falling opening is formed in the bottom wall of each flowing guiding channel. In the invention, the self-rotation performance can be realized, and the grain distribution is relatively uniform.

Owner:胡妍

Logistics warehouse

InactiveCN106395414AAvoid gatheringUniform technical effectLoading/unloadingLogistics managementDrive motor

The invention discloses a logistics warehouse. The logistics warehouse comprises a double-body warehouse and an unloading device. The double-body warehouse comprises a first warehouse body and a second warehouse body, and the first warehouse body and the second warehouse body are each internally provided with a self-rotating type material distributor. The unloading device comprises a first unloading box, a second unloading box and a driving device. The first unloading box comprises a first box body and a first auger. The first auger comprises a first one-way overrunning clutch. The second unloading box comprises a second box body and a second auger. The second auger comprises a second one-way overrunning clutch. The locking direction of the first one-way overrunning clutch is opposite to that of the second one-way overrunning clutch. The spiral direction of a first spiral plate is opposite to that of a second spiral plate. The driving device comprises a driving motor and a transmission mechanism. When the driving motor rotates in the forward direction, the first auger is driven to rotate; and when the driving motor rotates in the reverse direction, the second auger is driven to rotate. By means of the logistics warehouse, materials are distributed uniformly; two types of materials can be stored; and manufacturing cost is low.

Owner:乐清市华尊电气有限公司

Logistic granary with spinning grain distributors

The invention discloses a logistic granary with spinning grain distributors. The logistic granary comprises a two-body warehouse and a grain discharger. The first warehouse and the second warehouse are each internally provided with one spinning grain distributor. The grain discharger comprises a first grain discharging box, a second grain discharging box and a driving device. The first grain discharging box comprises a first box body and a first auger. The driving device comprises a driving motor and a clutch transmission mechanism. The clutch transmission mechanism comprises a belt wheel, a first transmission shaft, a first one-way overrunning clutch, a second transmission shaft and a second one-way overrunning clutch. The driving motor drives the belt wheel to rotate in a reciprocating mode. The locking direction of the first one-way overrunning clutch is opposite to the locking direction of the second one-way overrunning clutch. The logistic granary is even in grain distribution, capable of storing two kinds of grains and low in manufacturing cost.

Owner:SUZHOU JUNFENGCHEN ELECTRONICS TECH

Dual-body electric grain discharging granary

InactiveCN106818078AUniform grain distributionReasonable structureAgriculture tools and machinesHarvested fruit hanging devicesDrive motorScrew conveyor

The invention discloses a double-body electric grain unloading granary, which comprises a double-body warehouse and a grain unloading device; the double-body warehouse has a first warehouse and a second warehouse; Grain device; the grain unloading device includes a box body with a first grain unloading channel and a second grain unloading channel, the first auger used to unload the grain stored in the first unloading channel, and the first auger used to unload the grain in the second unloading channel The second auger for storing grain, and the driving device for driving the first auger and the second auger to rotate; the first warehouse is connected with the first unloading channel, and the second warehouse is connected with the second unloading channel; the driving device It includes a driving motor with a driving wheel, a transmission wheel set and a linkage switching device; the driving motor drives the transmission wheel set to rotate through the driving wheel, and the transmission wheel set drives the first auger or the second auger to rotate through the linkage switching device. The invention has relatively uniform grain distribution, can store two kinds of grains, and has low manufacturing cost.

Owner:申清章

Double-body electric grain unloading granary with more uniform grain distribution

InactiveCN106697987AAvoid gatheringUniform technical effectConveyorsLoading/unloadingDrive wheelDrive motor

The invention discloses a double-body electric grain unloading granary with more uniform grain distribution. The double-body electric grain unloading granary comprises a double-body warehouse and a grain unloading device; the double-body warehouse has a first warehouse and a second warehouse; self-rotating grain distributors are respectively arranged in the first warehouse and the second warehouse; the grain unloading device includes a box body with a first grain unloading channel and a second grain unloading channel, a first auger for unloading grains stored in the first grain unloading channel, a second auger for unloading the grains stored in the second grain unloading channel, and a driving device for driving the first auger and the second auger to rotate; the first warehouse is communicated with the first grain unloading channel; the second warehouse is communicated with the second grain unloading channel; the driving device includes a driving motor provided with a driving wheel, a transmission wheel set and a linkage switching device; the driving motor drives the transmission wheel set to rotate through the driving wheel; and the transmission wheel set drives the first auger or the second auger to rotate through the linkage switching device. The double-body electric grain unloading granary is more uniform in grain distribution, can store two types of grains, and is lower in manufacturing cost.

Owner:申清章

Double-body electric grain unloading granary

InactiveCN106829543AAvoid gatheringUniform technical effectConveyorsLoading/unloadingDrive wheelElectric machinery

The invention discloses a double-body electric grain unloading granary, which comprises a double-body warehouse and a grain unloading device; the double-body warehouse has a first warehouse and a second warehouse; Grain device; the grain unloading device includes a box body with a first grain unloading channel and a second grain unloading channel inside, the first auger used to unload the grain stored in the first unloading channel, and the first auger used to unload the grain in the second unloading channel The second auger for storing grain, and the driving device for driving the rotation of the first auger and the second auger; the first warehouse is connected with the first unloading channel, and the second warehouse is connected with the second unloading channel; the driving device It includes a driving motor with a driving wheel, a transmission wheel set and a linkage switching device; the driving motor drives the transmission wheel set to rotate through the driving wheel, and the transmission wheel set drives the first auger or the second auger to rotate through the linkage switching device. The invention has relatively uniform grain distribution, can store two kinds of grains, and has low manufacturing cost.

Owner:申清章

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com