Self-rotation grain distribution device

A grain distributing device and spin-type technology, applied in fruit hanging devices, botany equipment and methods, horticulture, etc., can solve the problems of small voids in grain piles, heat generation, and inability to effectively eliminate the accumulation of impurities, etc., to achieve uniform grain distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (Example 1, spin-type grain distributor)

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

Embodiment 1)

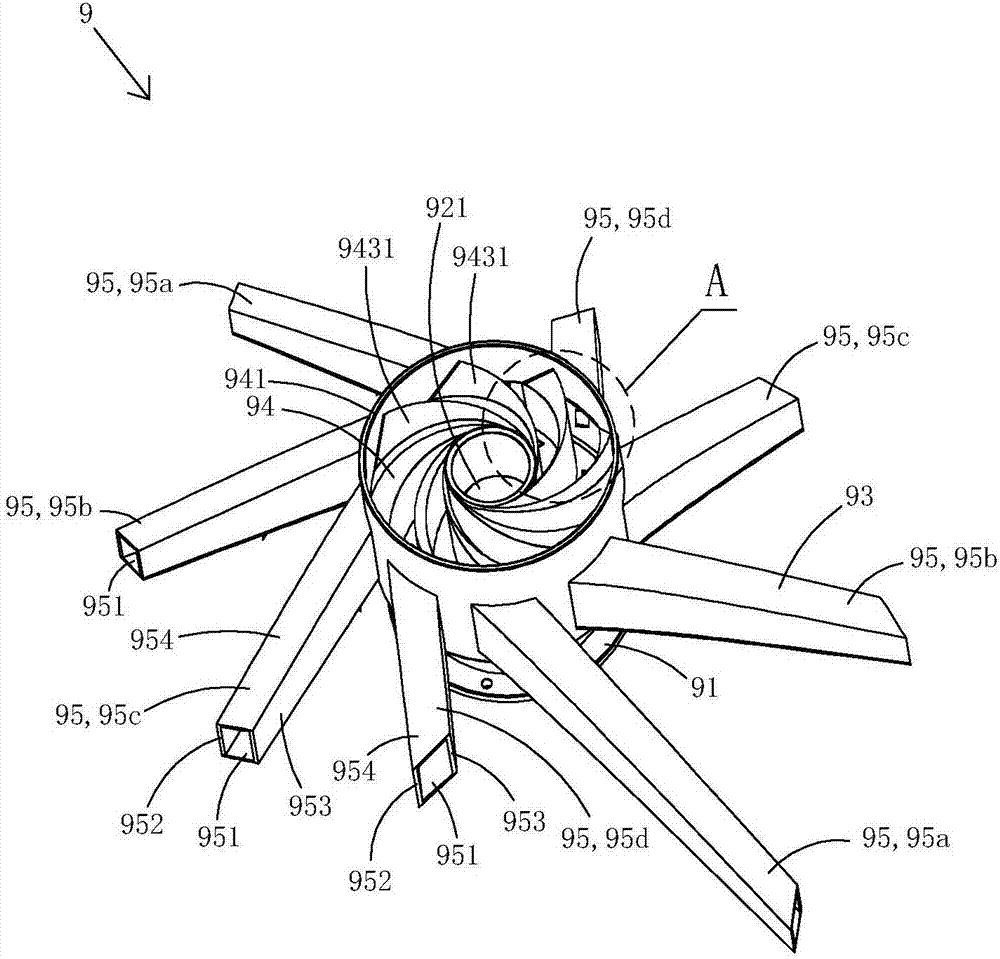

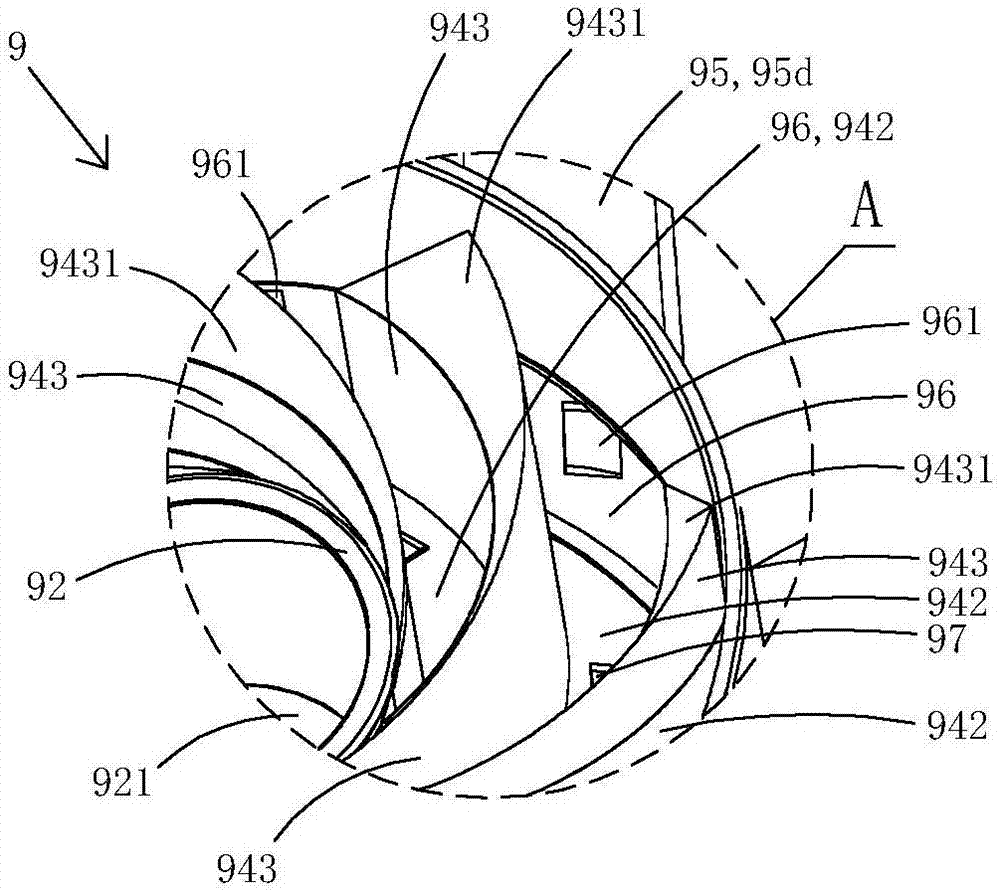

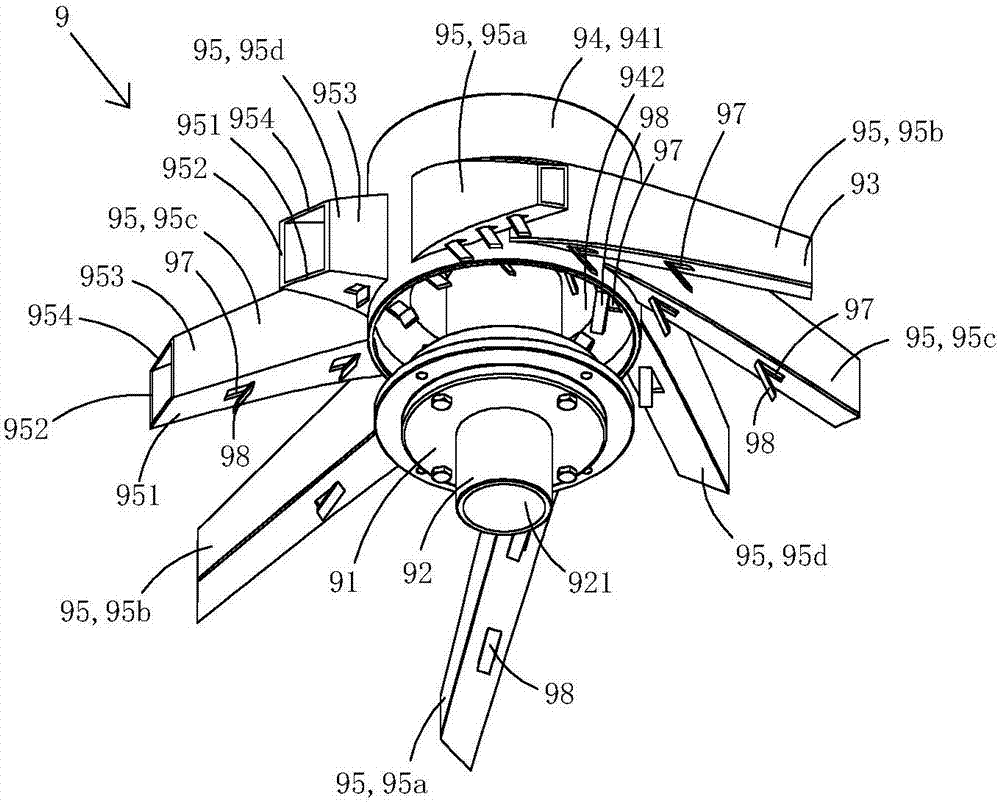

[0033] Figure 1 to Figure 6 One specific embodiment of the invention is shown. The invention provides a spin-type grain distributor, such as Figure 1 to Figure 6 As shown, the spin-type grain distributor 9 includes a bearing seat 91, a rotating shaft 92 rotatably arranged on the bearing seat, and a grain distribution piece 93 fixedly arranged on the rotating shaft; the rotating shaft is arranged along the vertical direction.

[0034] The cloth grain piece comprises a grain collection area 94 and eight grain slippers 95.

[0035] The grain collection area comprises an annular plate 941, a circular bottom wall 942 and eight involute plates 943, the rotating shaft is positioned at the center of the circular bottom wall, and the top of the rotating shaft is higher than the circular bottom wall. In this embodiment, the top of the rotating shaft level with the top of the ring plate.

[0036] The inner end of each involute plate is fixedly connected with the outer wall of the ro...

Embodiment 2

[0050] (Example 2, spin-type grain distributor)

[0051] This embodiment is basically the same as Embodiment 1, the difference is that: viewed from top to bottom, the second side plate in this embodiment is no longer a straight line, but an arc-shaped plate, and the arc-shaped plate is still vertically Line direction setting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com