Self-rotating grain distribution device for granaries

A spin-type, grain distribution device technology, applied in the fields of application, agricultural machinery and tools, gardening, etc., can solve the problems of small voids, agglomeration, mildew and other problems in the grain pile, and achieve the effect of uniform grain distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (Example 1, spin-type grain distributor)

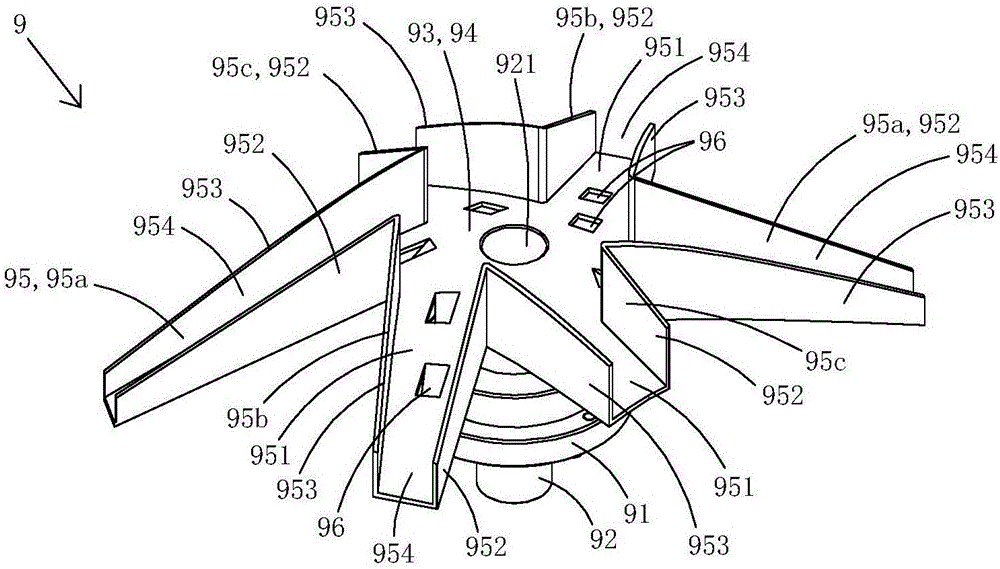

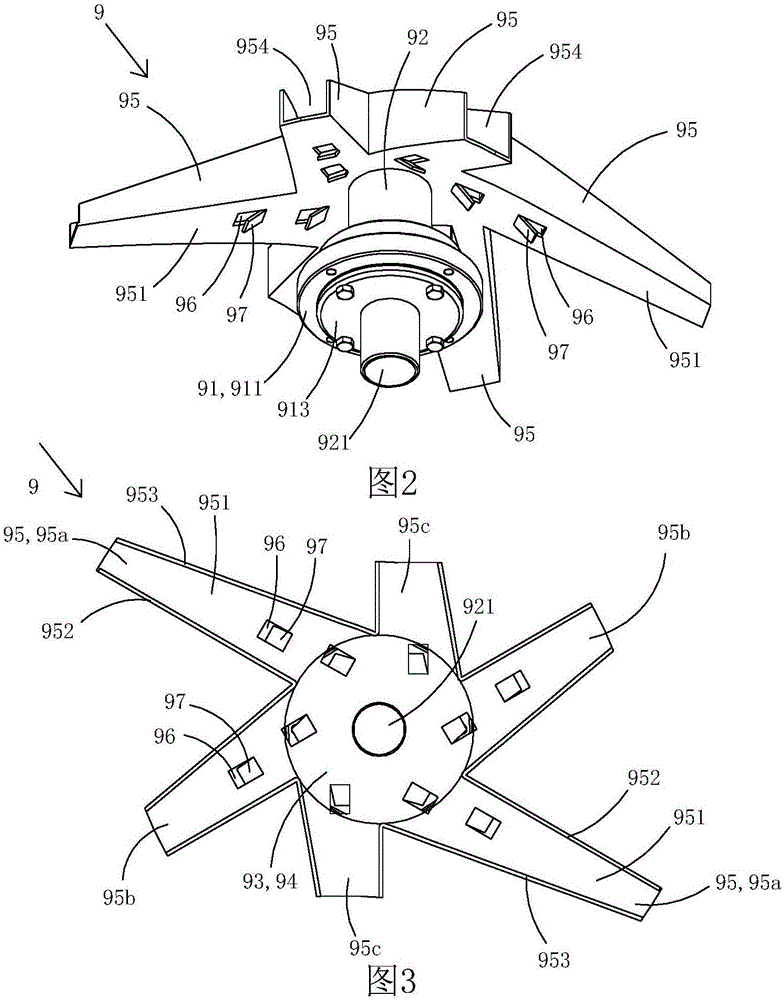

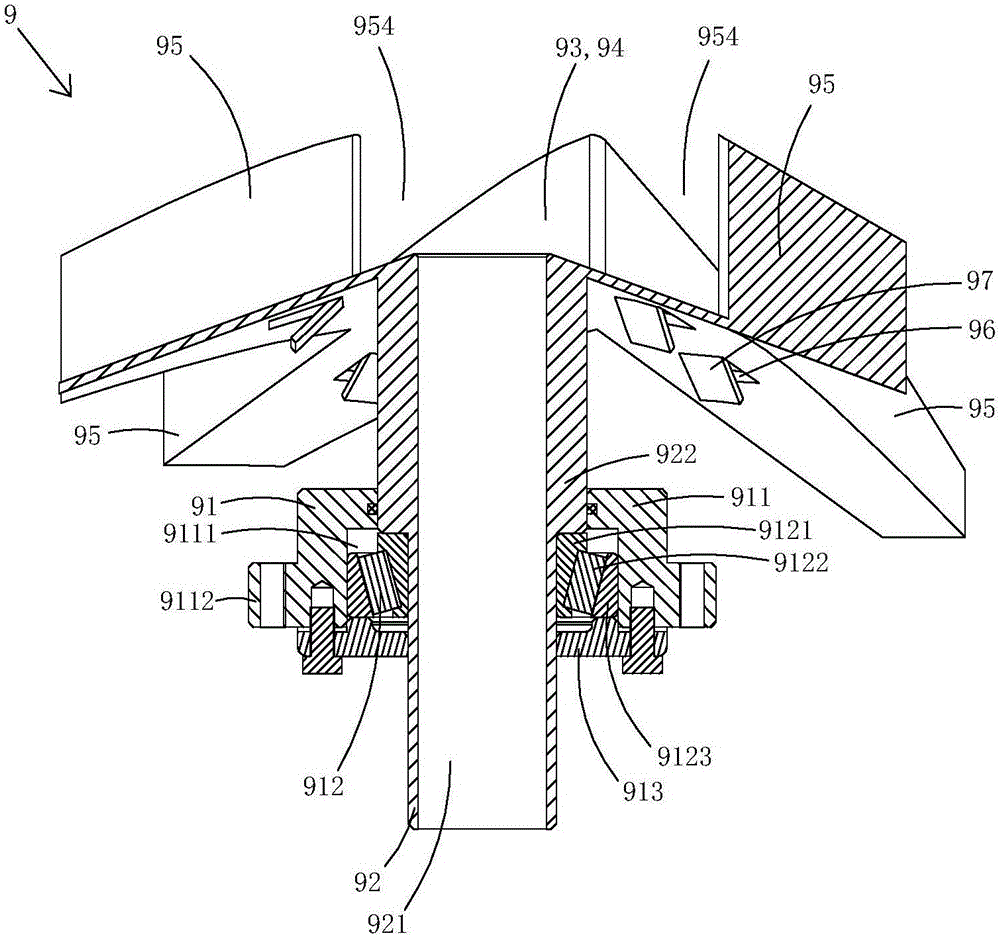

[0033] Figure 1 to Figure 4 One specific embodiment of the invention is shown.

[0034] This embodiment is a kind of spin-type grain distribution device for granary, see Figure 1 to Figure 4 As shown, the spin-type grain distributor 9 includes a bearing seat 91, a rotating shaft 92 rotatably arranged on the bearing seat, and a grain distribution piece 93 fixedly arranged on the rotating shaft; the rotating shaft is arranged along the vertical direction.

[0035] The cloth grain piece comprises the grain collecting area 94 and a plurality of sliding grain arms 95.

[0036] Each grain gliding arm comprises a base plate 951, a first side plate 952 and a second side plate 953, and the base plate, the first side plate and the second side plate of each grain gliding arm encircle and form a grain gliding channel 954; the first side plate and The second side plates are respectively located at both sides of the bottom plate, the fi...

Embodiment 2

[0046] (Example 2, spin-type grain distributor)

[0047] Figure 5 A second specific embodiment of the present invention is shown.

[0048] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 5 As shown, the second side panel in this embodiment is no longer a straight panel, but an arc-shaped panel, and the arc-shaped panel is still arranged along the vertical line.

Embodiment 3

[0049] (Example 3, spin-type grain distributor)

[0050] Figure 6 and Figure 7 A third embodiment of the invention is shown.

[0051] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 6 and Figure 7 As shown, in this embodiment, the rotating shaft is higher than the bottom wall of the grain collecting area, and the first side plate extends toward the interior of the grain collecting area, and is directly fixedly connected with the outer peripheral wall of the rotating shaft, so that the grain sliding passages are no longer connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com