Threading apparatus for embroidery

A threading and embroidery technology, applied in the field of threading devices for embroidery, can solve the problems of insufficient safety, cumbersome threading, increased workload, etc., and achieve the effect of improving production effect, simple threading process, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

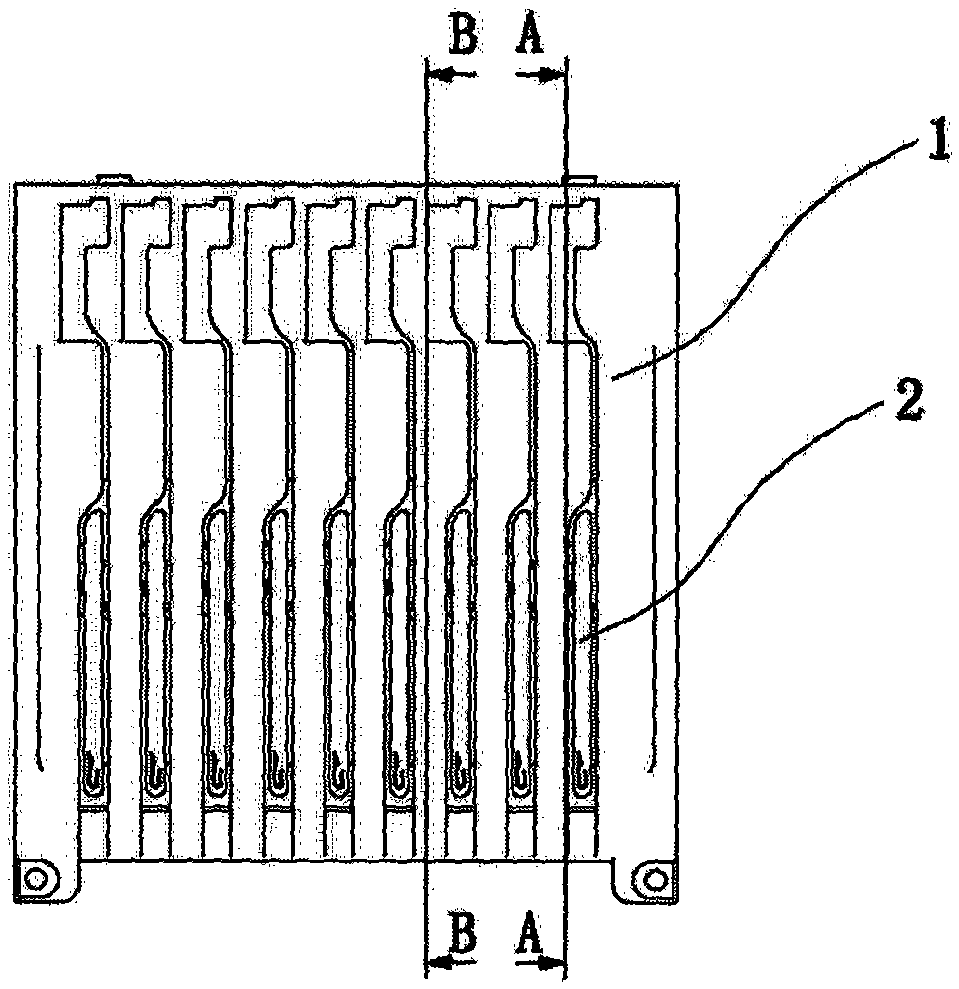

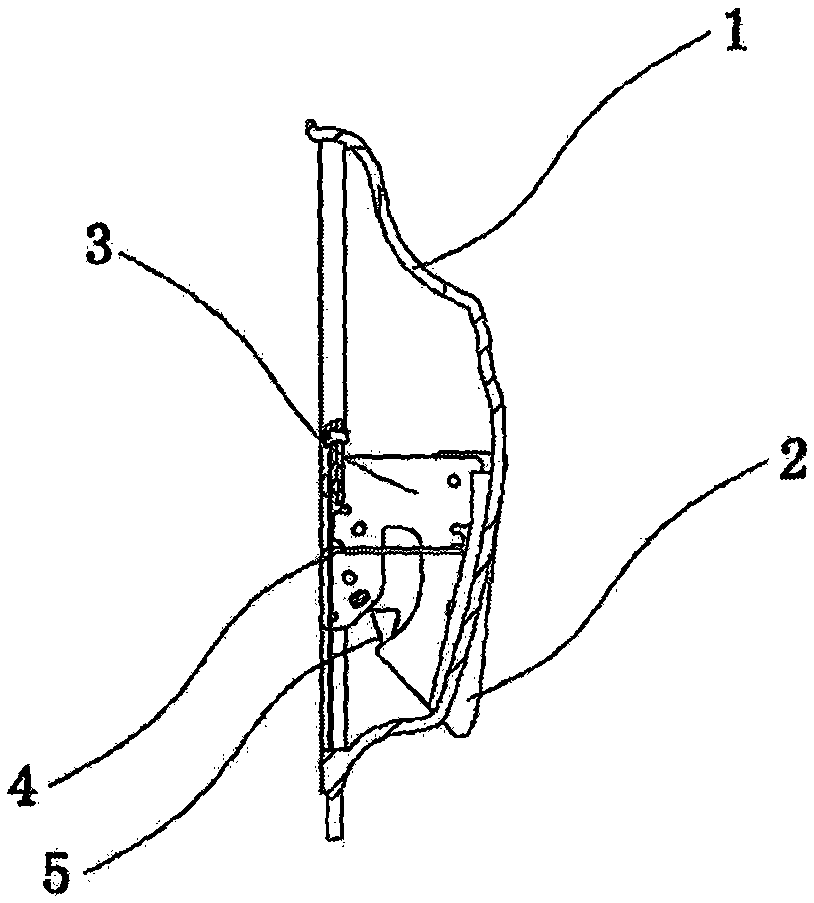

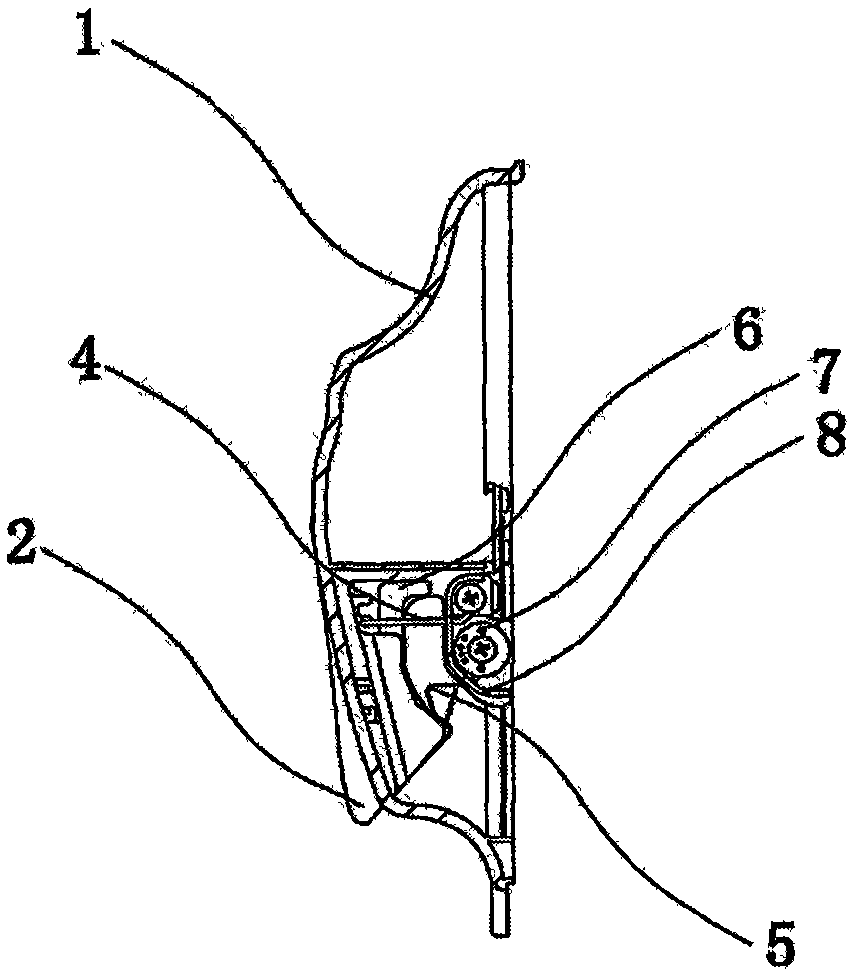

[0024] Embodiment 1: as image 3 , Figure 4 As shown, a thread passing device for embroidery includes a base 1. The base 1 is composed of a bottom plate and a panel. The middle part of the panel bulges outwards and its two ends are fixedly mounted on the bottom plate. A hollow cavity is formed between the two. Multiple sets of wire passing components are contained in the cavity. A fixed plate 9 and a line retaining plate 10 are installed on the inner surface of the base plate, and the line retaining plate 10 is installed between the base plate and the fixed plate 9 .

[0025] Such as Figure 4 and Figure 5 As shown, the wire passing assembly includes a holding plate 3 vertically installed on the fixing plate. The front end of the holding plate 3 is covered with a holding plate cover 2. The holding plate cover 2 extends out of the cavity from the panel and passes through the holding plate cover 2 of the panel. Thread grooves are reserved on both sides, that is, keep a cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com