A solid waste treatment pool

A technology of solid waste and treatment tank, which is applied in the treatment of invertebrates, biological organic parts, agriculture, etc., can solve the problems of long time, high energy consumption, low efficiency, etc., to achieve high efficiency, ensure normal operation, return flow fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

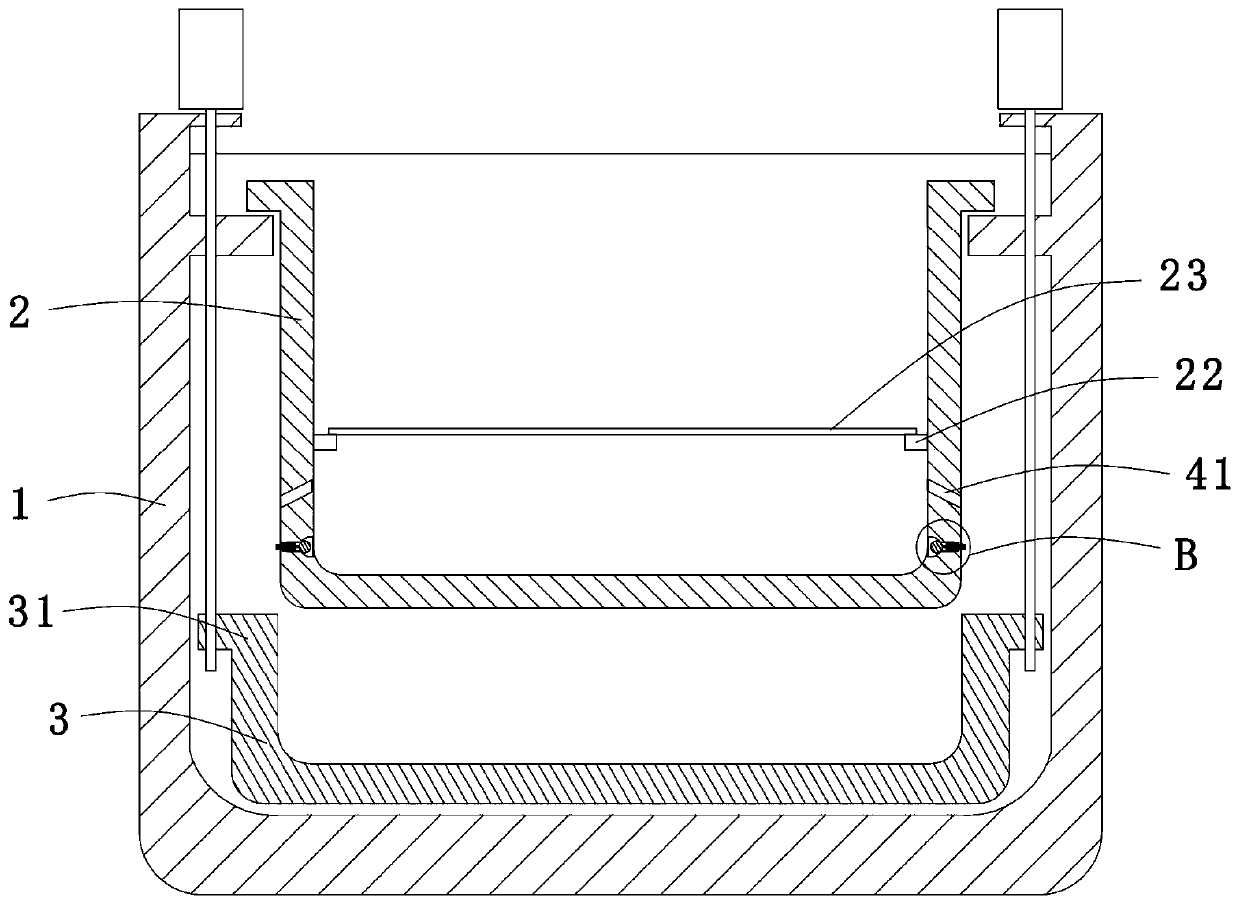

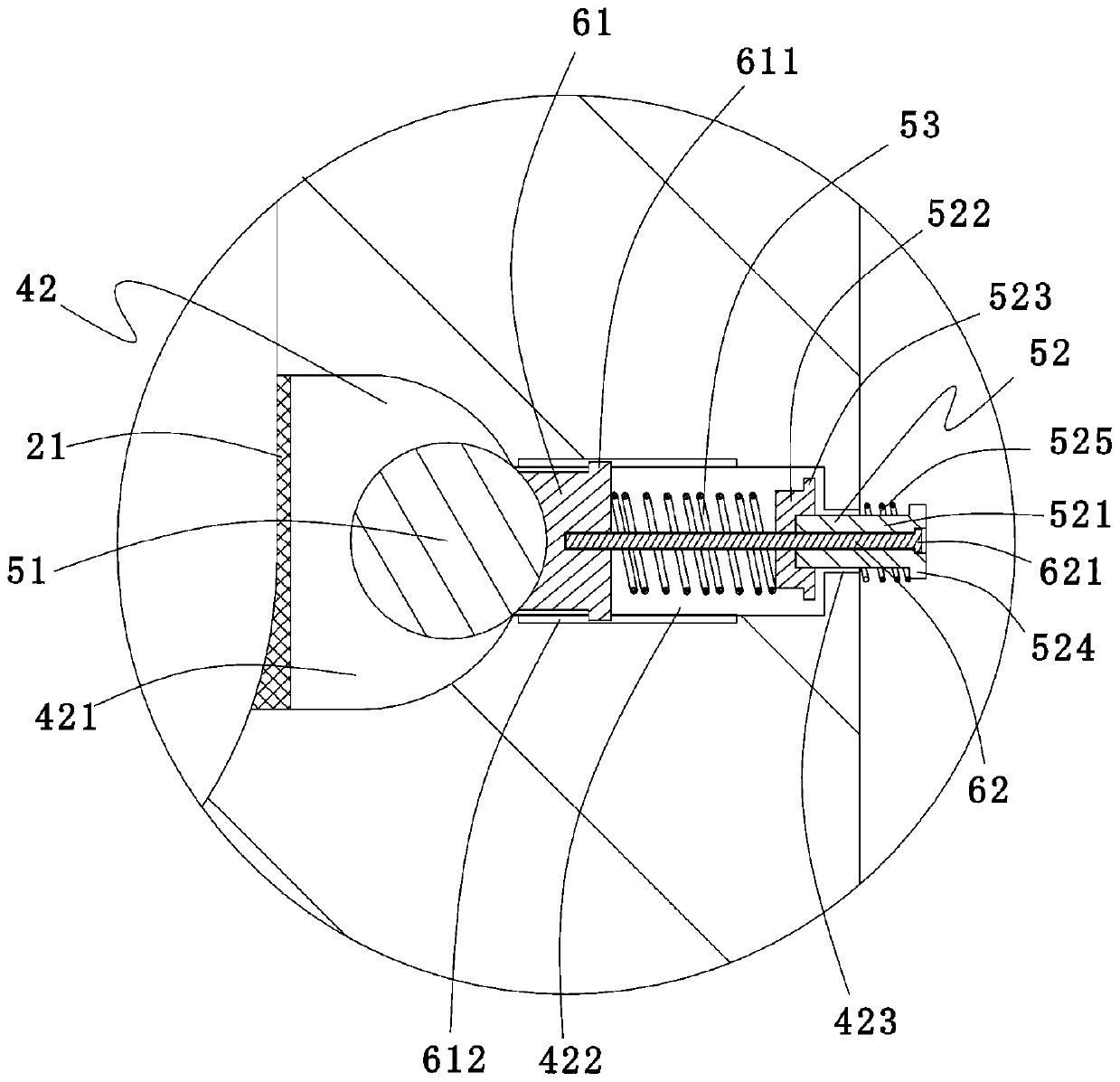

[0026] Such as Figure 1-2 Shown, a solid waste treatment pool, including pool body 1, treatment chamber 2, liquid collection chamber 3, infusion parts and opening and closing device, wherein, treatment chamber 2 and liquid collection chamber 3 are made of stainless steel, the treatment chamber 2 is set in the pool body 1, and the treatment chamber 2 is provided with live earthworms for fermenting biogas residue; the liquid collection chamber 3 is set in the pool body, and is located in the treatment room below, used to collect excess biogas slurry in the treatment chamber 2; preferably, the liquid collection chamber 3 can move up and down relative to the treatment chamber 2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com