Cigarette case auxiliary material storage box and automatic feeding system

A technology for storing boxes and accessories, which is applied to unloading devices, packaging, internal accessories, etc., can solve the problems of asynchrony, the relative position deviation of two storage boxes, and the inability of the robot to grasp, so as to improve transportation efficiency and facilitate grasping. take effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

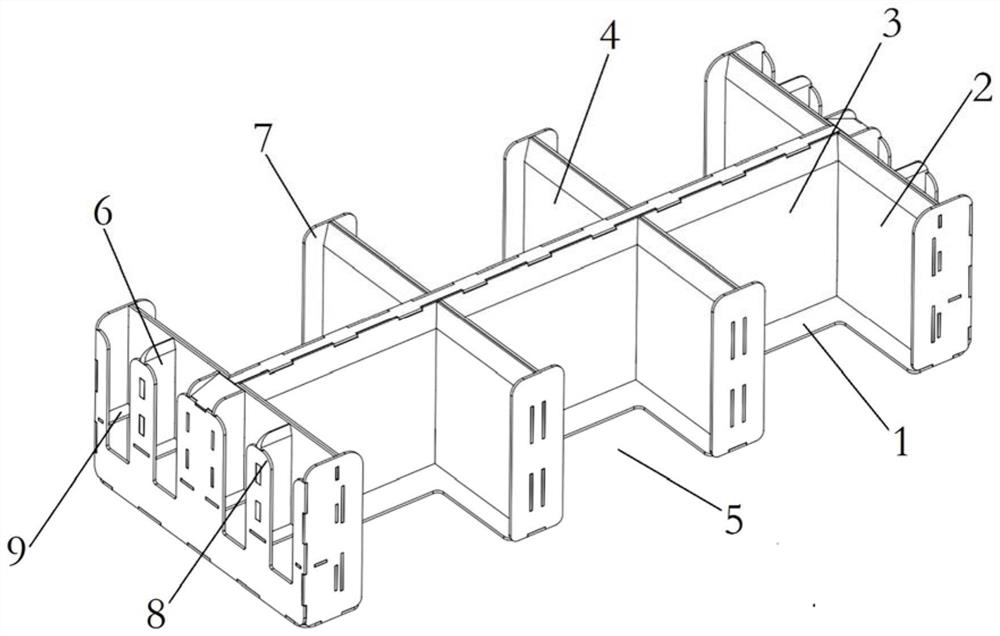

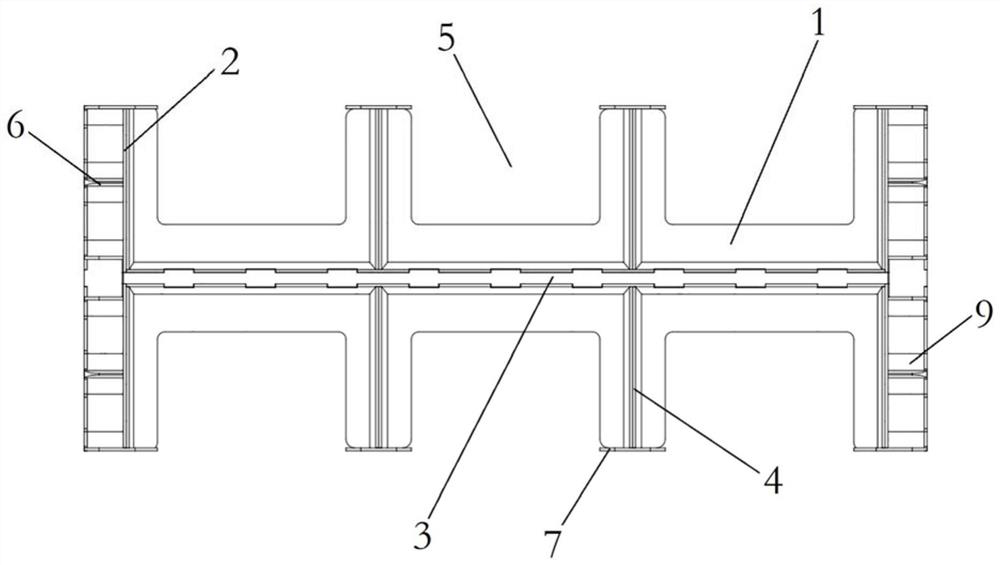

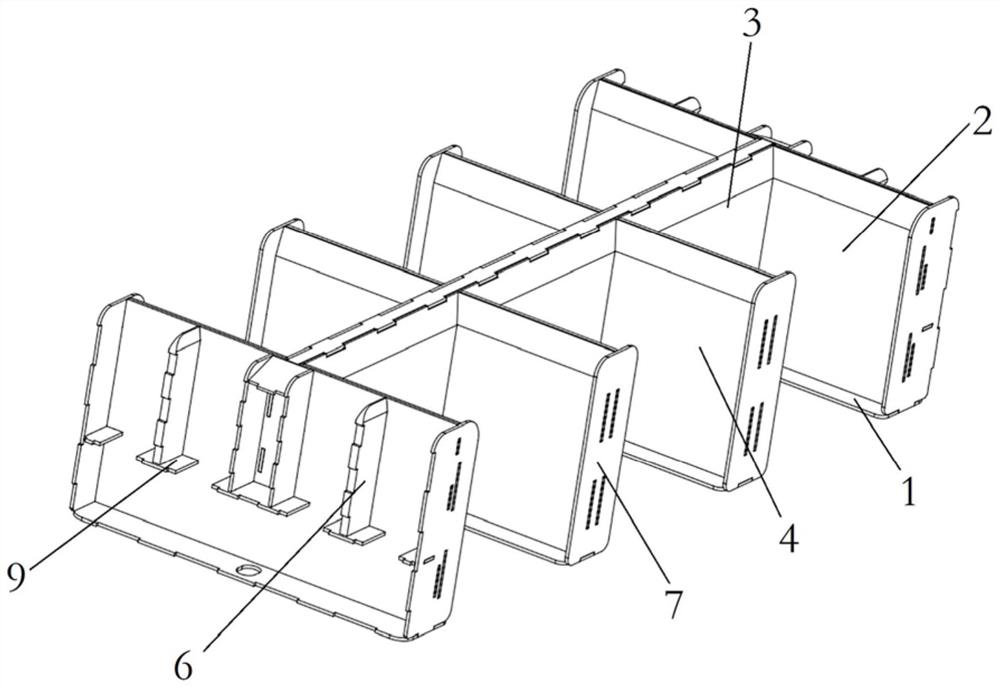

[0041] The storage box for cigarette case accessories provided by this embodiment includes: a carrier plate 1, a first storage position and a second storage position; the first storage position is used to place wrapping paper, and the second storage position is used to place seals; it can realize Simultaneous transportation of wrapping paper and seals; at the same time, the relative placement of wrapping paper and seals will not change, which is convenient for manipulators to grab.

[0042] Such as figure 1 As shown, the middle part of the carrier tray 1 is divided into a plurality of first storage positions by a partition, and the first storage positions are used to place wrapping paper;

[0043] Specifically, the two ends of the carrier plate 1 are respectively vertically provided with end plates 2; the two ends of the first partition plate 3 respectively abut against two end plates 2, and are arranged vertically to the end plates 2 and the carrier plate 1; Both sides of a ...

Embodiment 2

[0052] An automatic feeding system provided in this embodiment includes the storage box for cigarette case auxiliary materials described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com