Manufacturing equipment for laying fiber tape

A technology for manufacturing equipment and fiber belts, applied in the field of laying fiber belts, can solve problems such as high process time, and achieve the effect of shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] First of all, it must be ensured that in the different described embodiments the same components are provided with the same reference symbols or the same component designations, wherein the disclosure content contained in the entire description can be transferred to reference symbols with the same reference symbols or the same On the same part of the component name. The positional specifications selected in the description, such as top, bottom, side, etc., also refer to the directly described and shown figures, and these positional specifications are transferred to the new position in the event of a position change.

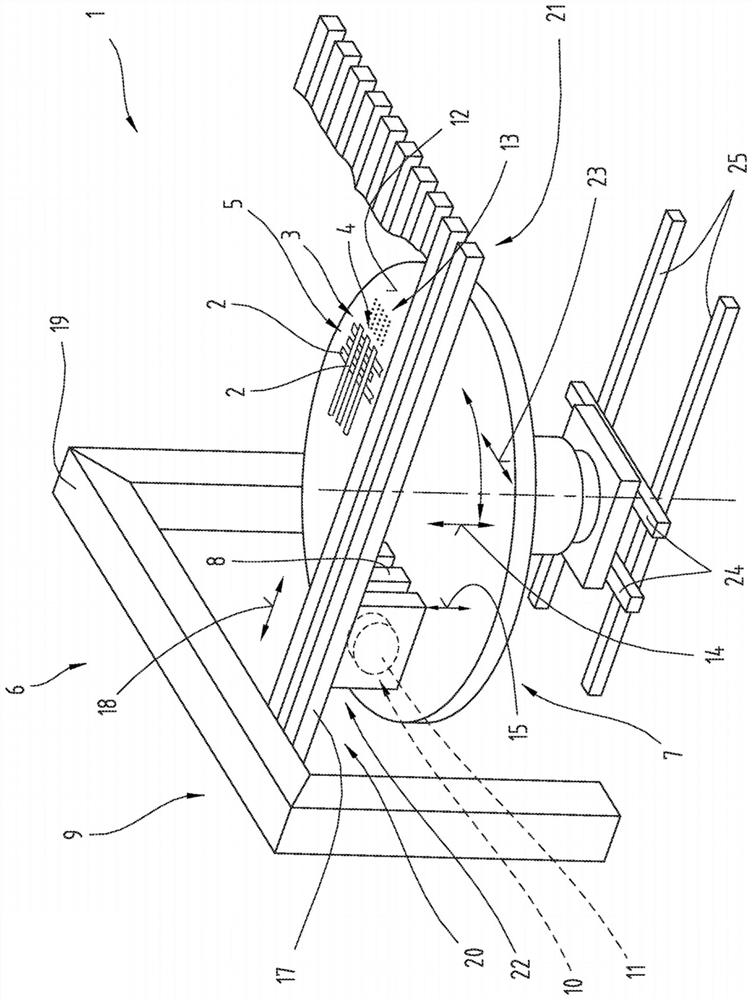

[0052] figure 1 A perspective view of a production device 1 for laying fiber strips 2 is shown. With the aid of the production device 1 , the fiber tape 2 can be laid into a first fiber tape layer 3 . The fiber tape layer 3 can have an outer edge that is contoured and adapted to the respective use by using the individual fiber tapes 2 in the production p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com