Stringing machine and method for stringing string foods by using machine

A skewering and threading technology, which is applied in application, food science, skewering meat onto skewers, etc., can solve the problems of easily missing skewers, high requirements on bamboo skewers, and low yield of skewers, and achieves manual participation. Small degree, good weight consistency, improved hygiene effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

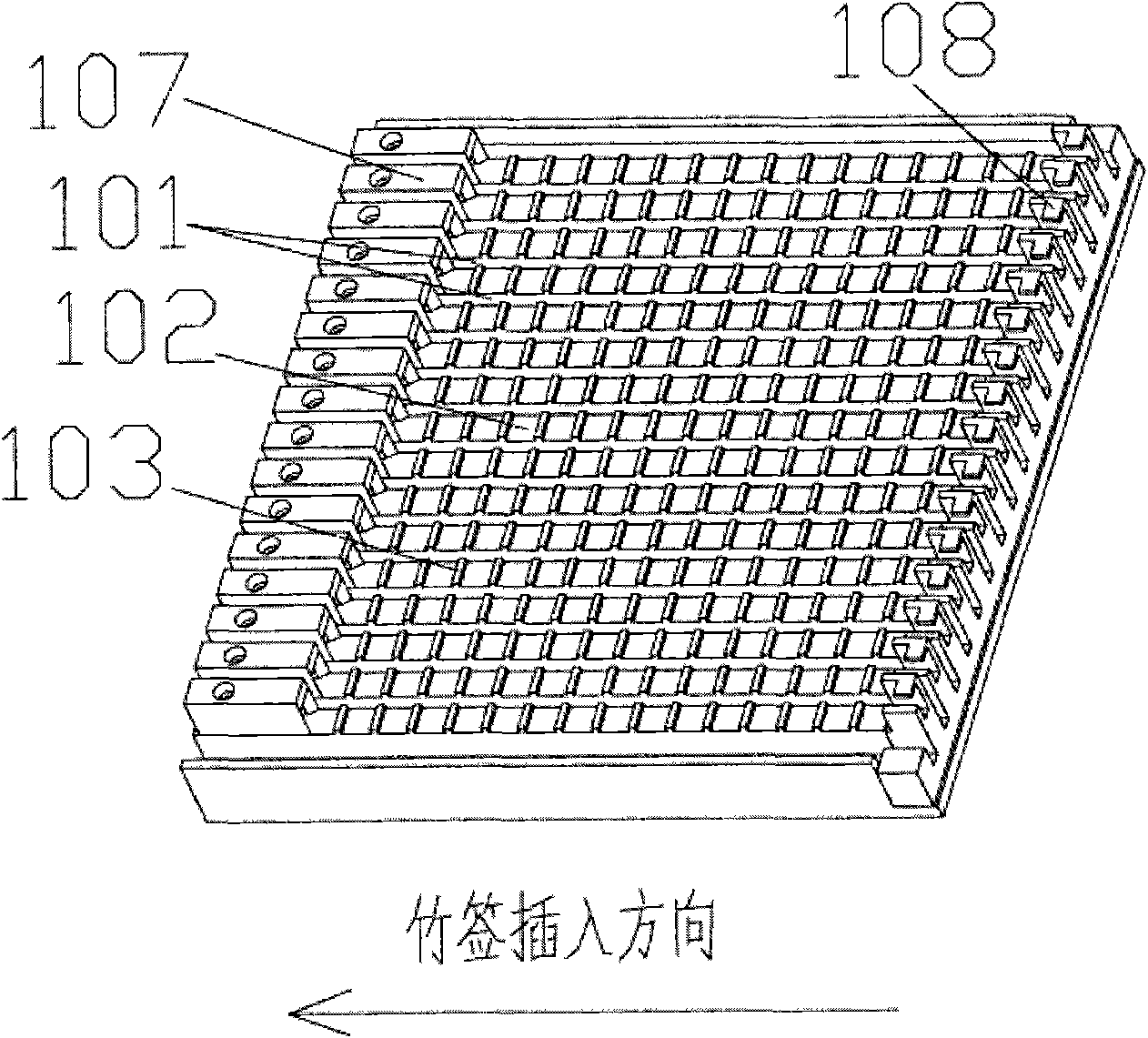

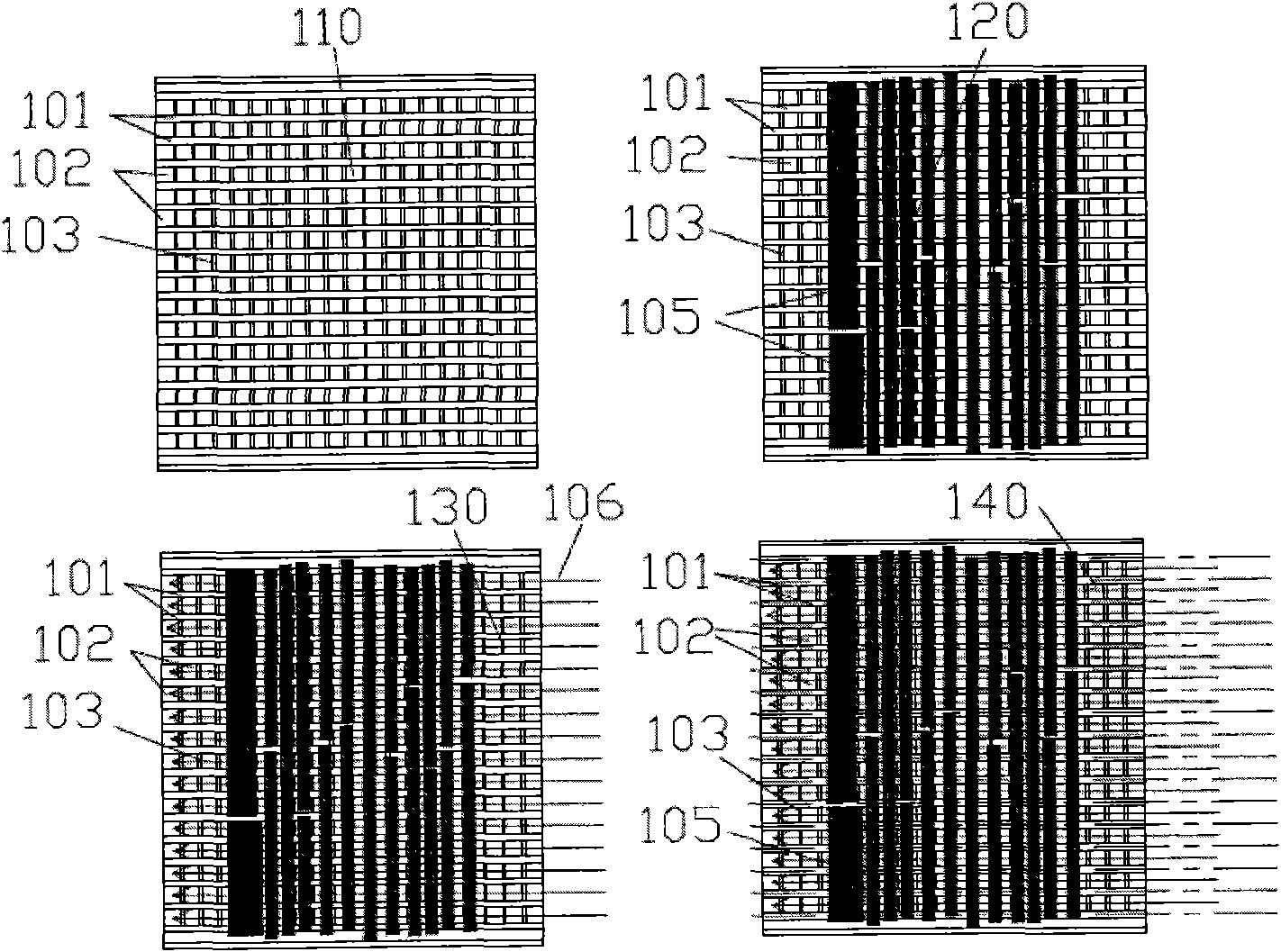

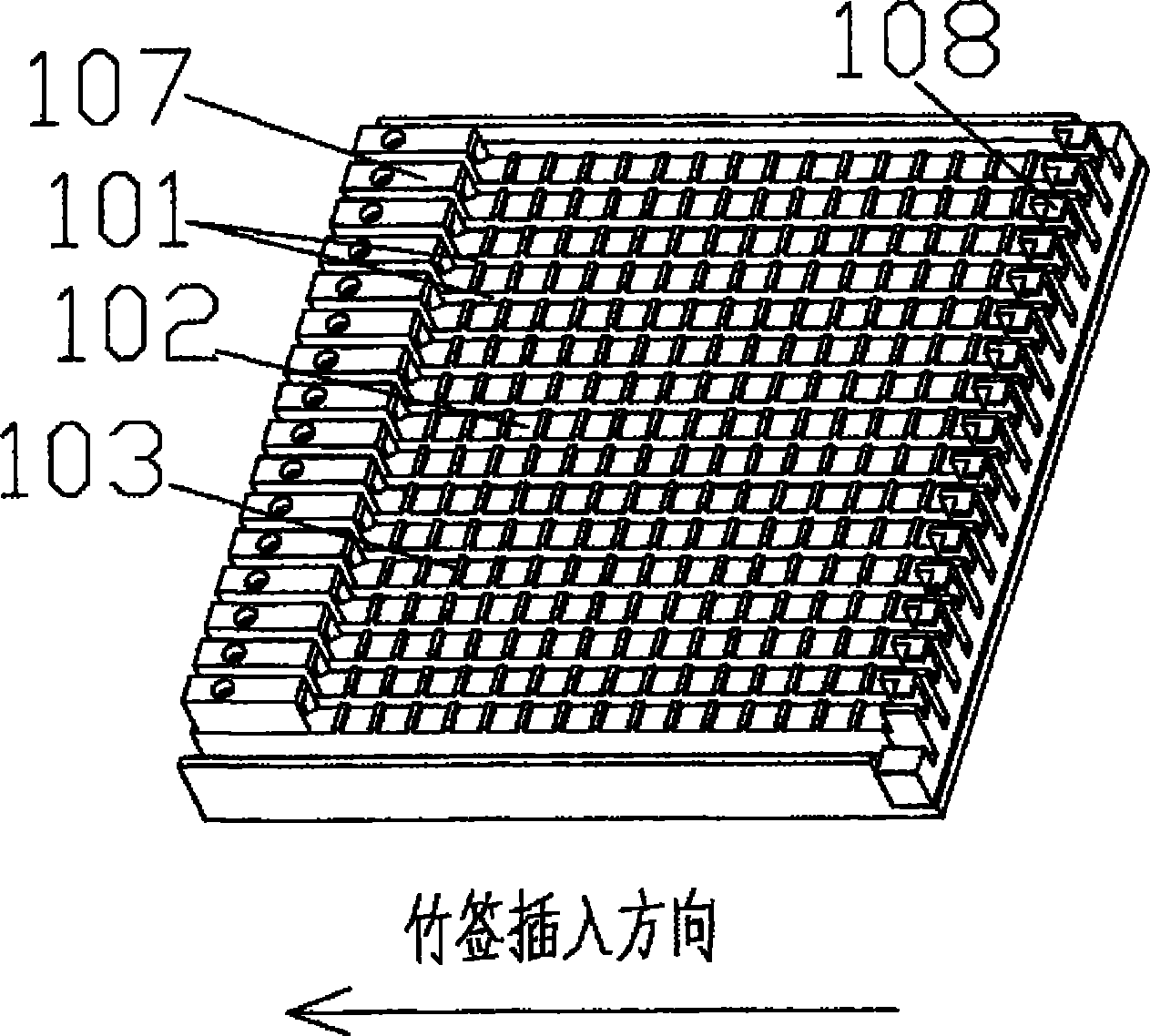

[0018] In this method, a meat-setting template (100) is required, and the meat-putting template (100) mainly includes the following parts: a cutter channel (101), an anti-slip protrusion (103), a meat skewer carrying strip (102), A sign head limit block (107) and a sign tail limit block (108). A sketch of the template is attached figure 1 , the cutter channel (101) is used for the passage of the cutter when cutting meat, and the meat skewer carrying strip (102) is spaced apart from the cutter channel (101), and is used to carry the meat strips (blocks) to be threaded before being skewered. ), after the meat skewers are put on, the meat skewers carrying bar (102) is used to carry the meat skewers. The anti-skid protrusions (103) are some small protrusions arranged neatly on the meat skewer carrying bar (102), and the stick head limit block (107) is located at the tail of the meat skewer carrying bar (102), and is used to prevent the stick head from Move up and down left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com