Prod falling and penetrating mechanism of novel and full-automatic stringing machine

A technology of wearing and dropping signs, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as low efficiency, and achieve the effects of improving processing efficiency, convenient control, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

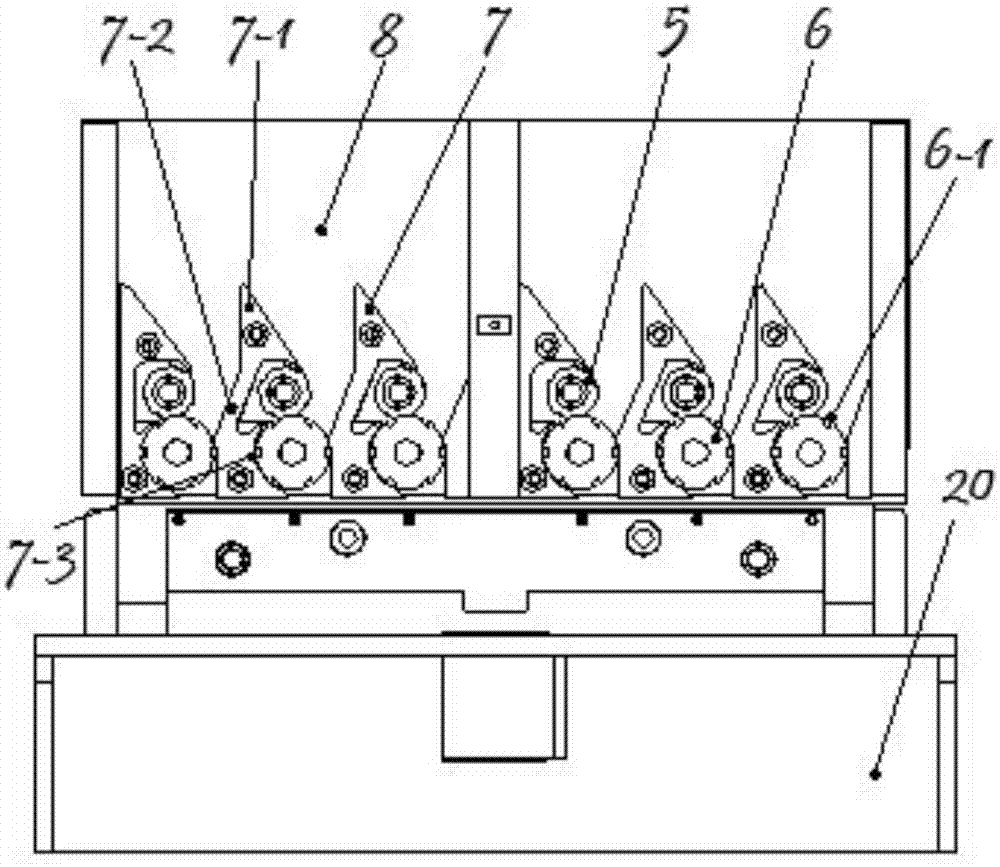

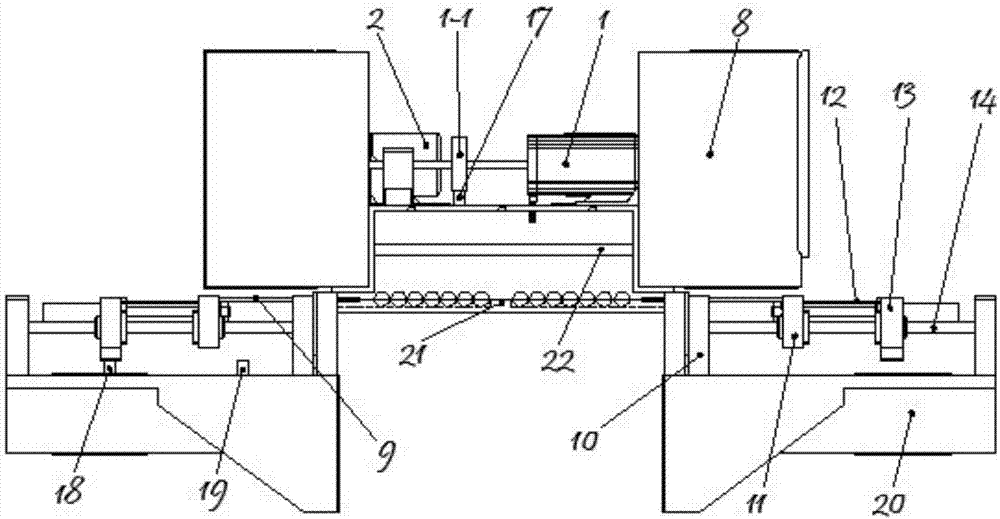

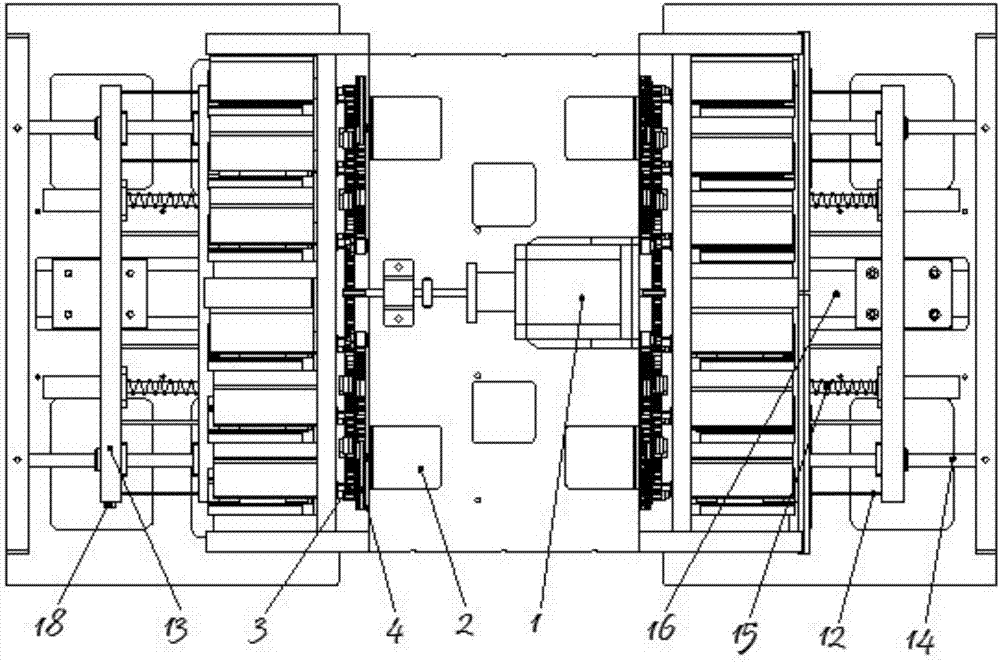

[0021] refer to Figure 1 ~ Figure 3 , shows a specific embodiment of the present invention: the structure of a new type of fully automatic threading machine's label-dropping and label-threading mechanism.

[0022] A new type of fully automatic threading machine with a label-dropping and label-threading mechanism, including:

[0023] The label-passing mechanism arranged on the main mounting plate 20, its structure is mainly referred to figure 2 , image 3 , including setting a sign-through mechanism on two oppositely arranged main mounting plates 20, the sign-through mechanism includes a head sign block 10, a tail end sign block 11, a thimble 12, a sign push block 13, a linear guide rail 14, a reset Spring 15, rodless cylinder 16 etc., there is a signing opening on the said head signing block 10, and a signing opening is arranged on the tail end signing block 11, and twelve described signing openings and signing openings are arranged altogether on the left and right sides, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com