Long-casing-pipe automatic line threading device

A technology of automatic threading and casing, which is applied to the field of tools for the flexible wire to pass through the casing, can solve the problems of time-consuming and laborious operation, inconvenient use, etc., and achieve the effect of convenient use, high threading efficiency, and time-saving and labor-saving threading operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

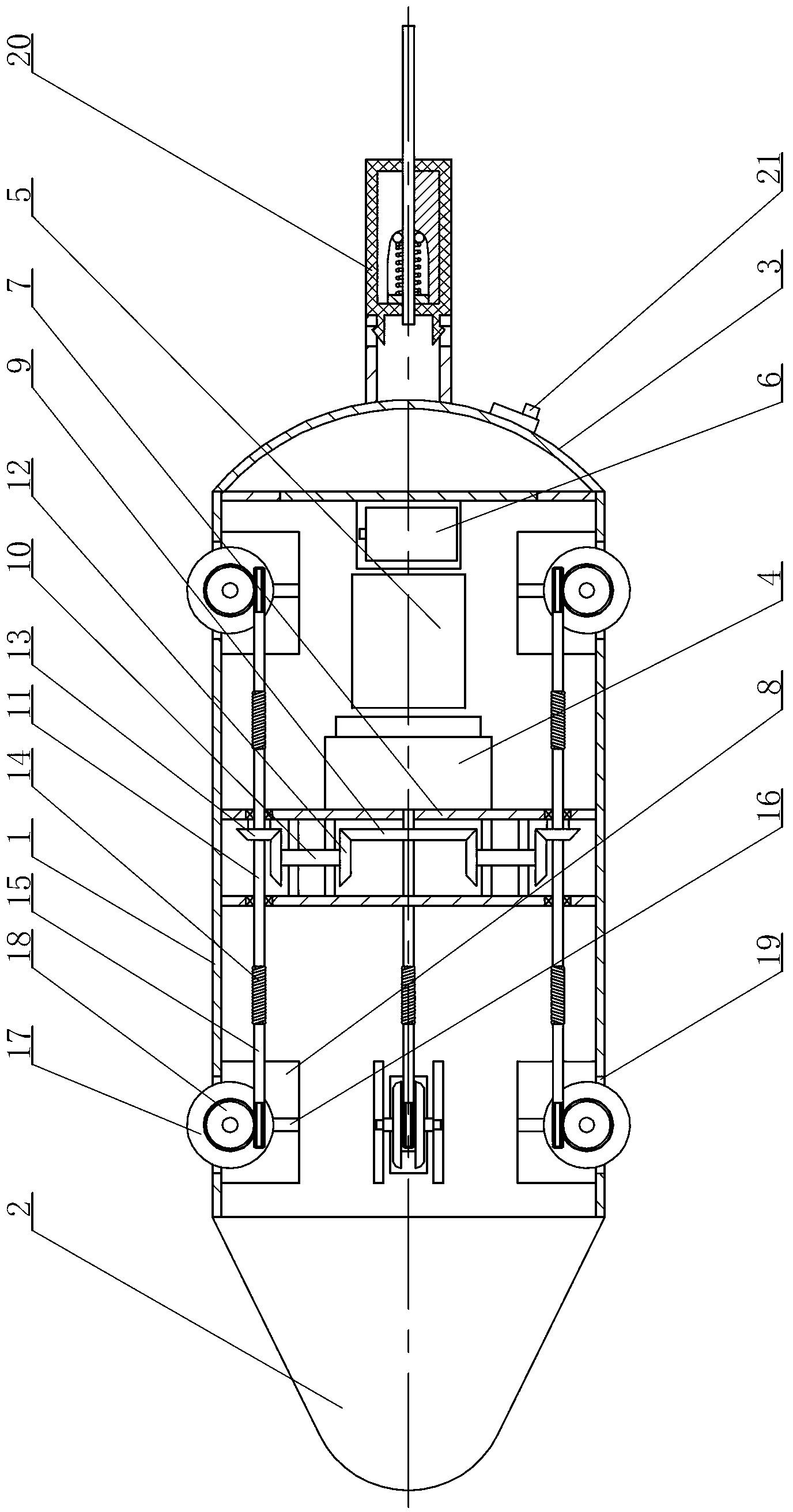

[0012] Depend on figure 1 As shown, a long casing automatic threader includes a cylindrical main body 1, a guide head 2 and a wire connection part 3, the guide head 2 is bullet-shaped and fixed at one end of the main body 1, and the main body 1 is fixed with a DC Motor 4, circuit board 5 and battery 6, and main body 1 is provided with gear chamber 7 and roller mounting bracket 8, and gear chamber 7 is provided with large tooth plate 9, reversing shaft 10 and drive shaft 11 that passes through gear chamber. The two ends of the shaft 10 are respectively connected with an intermediate bevel gear 12, the drive shaft 11 is provided with an output bevel gear 13, the output bevel gear 13 is meshed with the intermediate bevel gear 12, and the two ends of the drive shaft 11 are respectively connected to the worm 15 through a spring 14. , the output shaft of the DC motor 4 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com