Assembly type building pre-embedded electrical pipeline system

A prefabricated and architectural technology, applied in construction, electrical components, building components, etc., can solve problems such as low installation efficiency of electrical pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

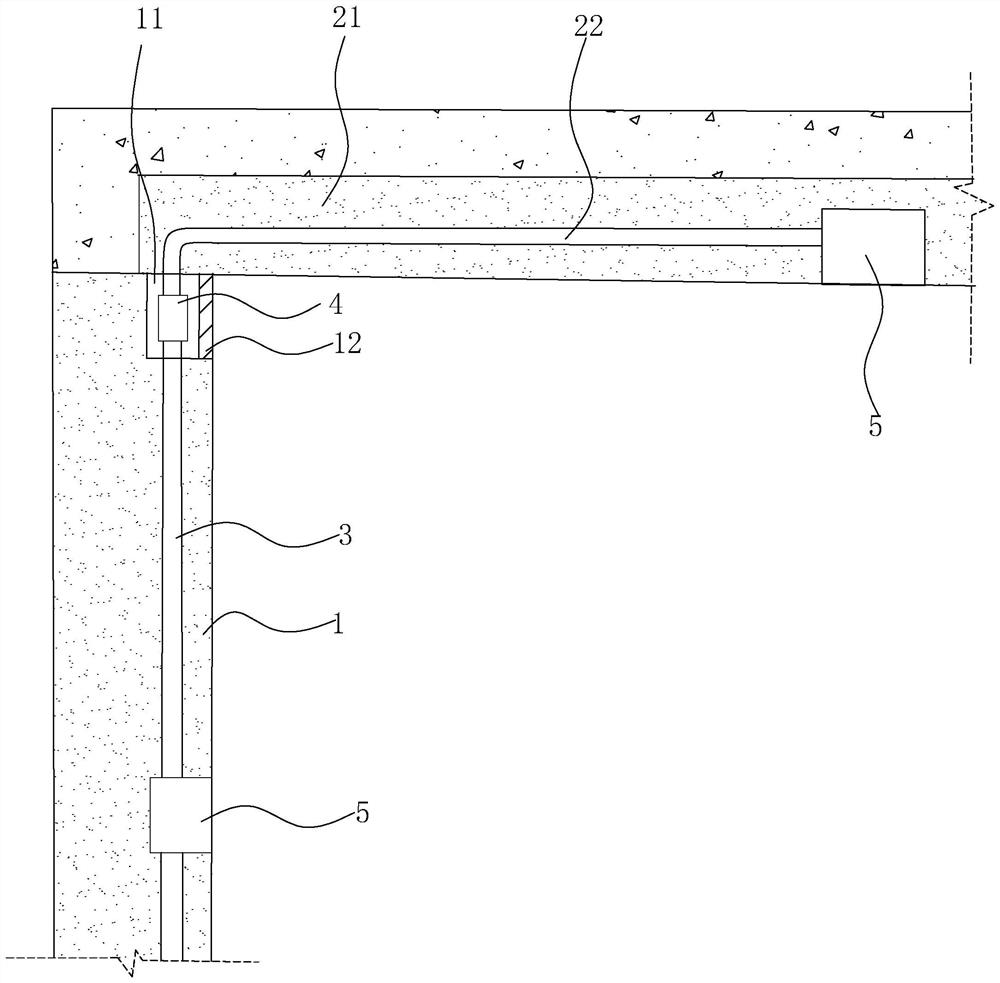

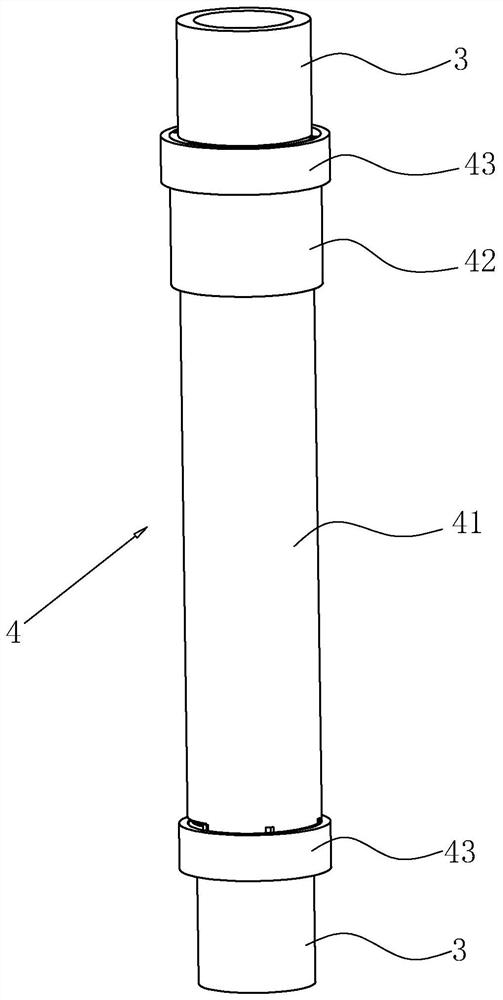

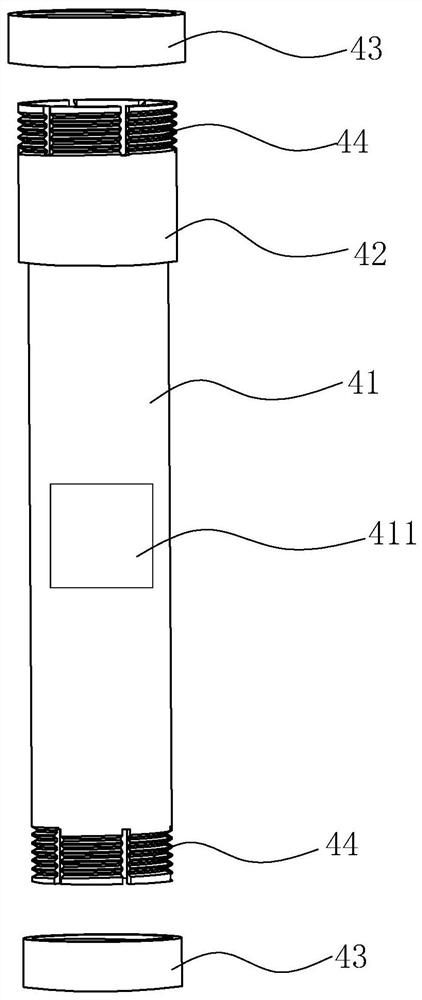

[0038] The embodiment of the present application discloses a pre-embedded electrical pipeline system for a prefabricated building. refer to figure 1 , including prefabricated wall 1 and laminated floor 2, laminated floor 2 includes prefabricated roof 21 and cast-in-place layer 22, prefabricated wall 1 and laminated floor 2 are installed perpendicular to each other, prefabricated wall 1 and prefabricated roof 21 are pre-buried Wire pipes 3 are provided, and junction boxes 5 are preset on the prefabricated wall 1 and the prefabricated roof 21, and a connection groove 11 is preset at the connection between the prefabricated wall 1 and the laminated floor 2, and the prefabricated wall 1 and the laminated floor 2 The wire pipes 3 all extend into the connection groove 11, and the wire pipes 3 located in the prefabricated wall 1 and the laminated floor 2 are connected through the connecting pipe fitting 4 in the connection groove 11, and the opening of the connection groove 11 is clo...

Embodiment 2

[0043] Embodiment two, refer to Figure 5 and Image 6 The difference of the first embodiment is that the operation port 411 of the connecting pipe 41 is detachably connected with the installation box 7, and the installation box 7 is provided with an installation chamber 71 communicating with the operation port 411, and the installation chamber 71 is movably connected with the push rod 8, The end of the push rod 8 close to the operation port 411 is provided with a shifting block 81, and the wall of the installation cavity 71 is opposite to the cavity wall of the operation port 411 to provide a relief port 72 communicating with the outside world. The limit rod 82 is fixed horizontally, and the limit rod 82 is vertically arranged with the push rod 8 . Moreover, the height of the relief opening 72 and the mounting cavity 71 is greater than that of the push rod 8 , thereby facilitating the swing of the push rod 8 . During the continuous threading process of the wires in the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com