Novel full-electric stringing machine

An all-electric, stringer technology, applied in the field of stringer, can solve the problem of high failure rate, achieve the effect of reducing failure rate, improving efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

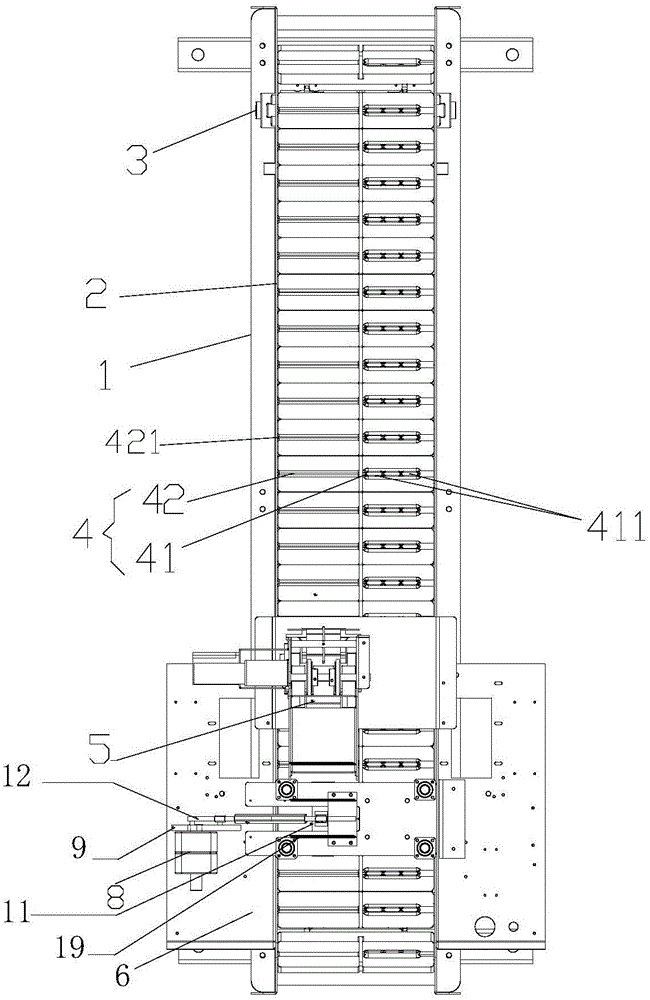

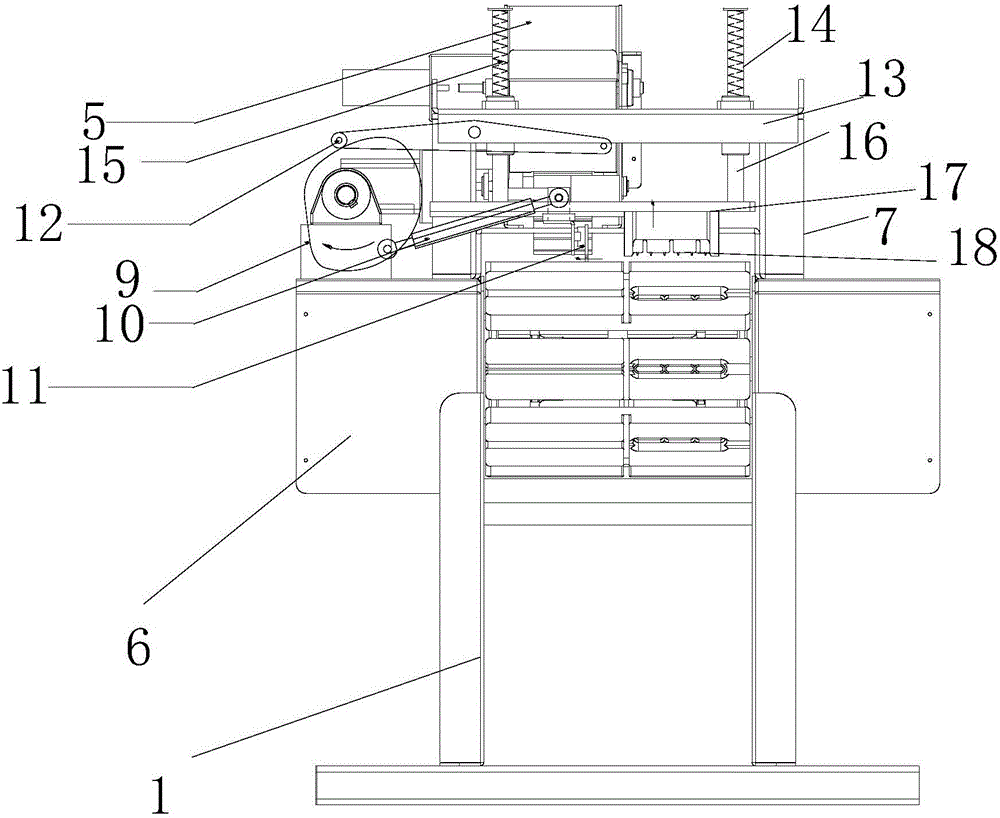

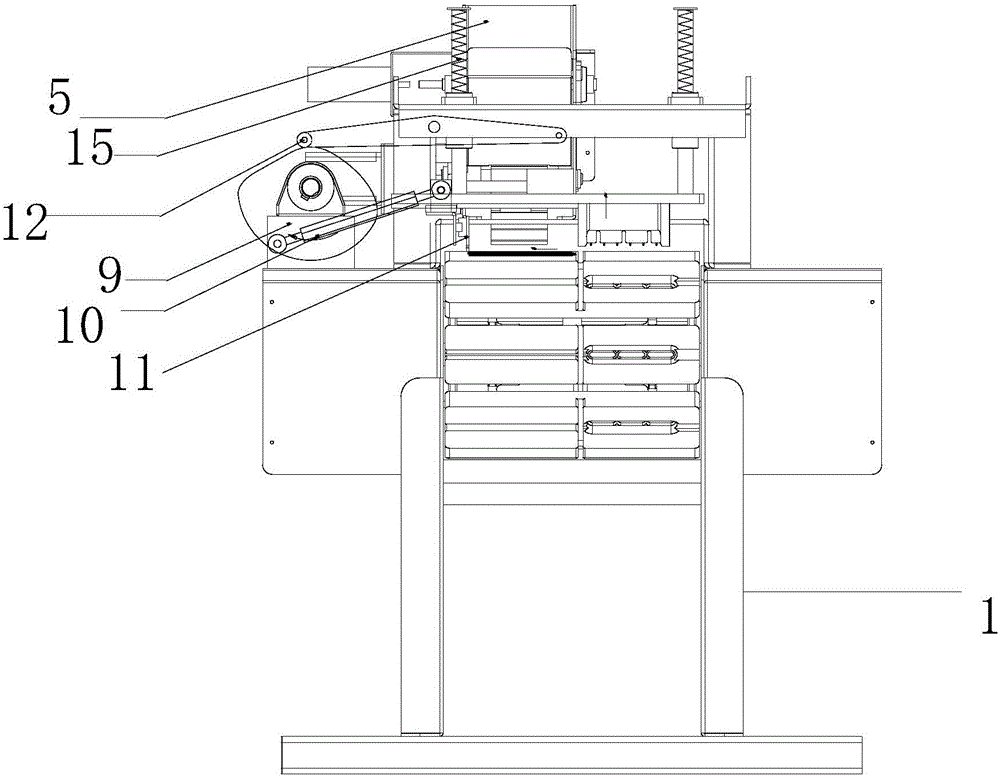

[0026] as attached Figure 1-5 As shown, a new type of all-electric threading machine includes a frame 1, a conveyor belt 2 is arranged on the frame 1, the conveyor belt 2 is driven by a first motor 3, and a lower mold 4 is fixed on the conveyor belt 2 , the lower mold 4 includes several groups of troughs 41, one side of the troughs 41 is provided with the same number of bamboo stick grooves 42, the bamboo stick grooves 42 communicate with the material troughs 42, and the bamboo stick grooves The top of 42 is provided with bamboo stick mechanism 5, and described frame 1 is provided with motor base 6 and upper mold base 7, and described motor base 6 is provided with second motor 8 above, and described second motor 8 is connected with cam 9, One side of the cam 9 is connected with a connecting rod 10, and the connecting rod 10 is connected with a sign-pushing mechanism 11. A pressure bar 12 is arranged above the cam 9, and an upper template 13 is fixed on the upper mold base 7. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com