Multifunctional automatic skewering machine

An automatic threading and multi-functional technology, which is applied in the direction of putting meat skewers on meat skewers, slaughtering, meat processing equipment, etc., can solve the problems of low production efficiency, inability to realize fast mass production, and slow speed, so as to improve production efficiency , easy to operate, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

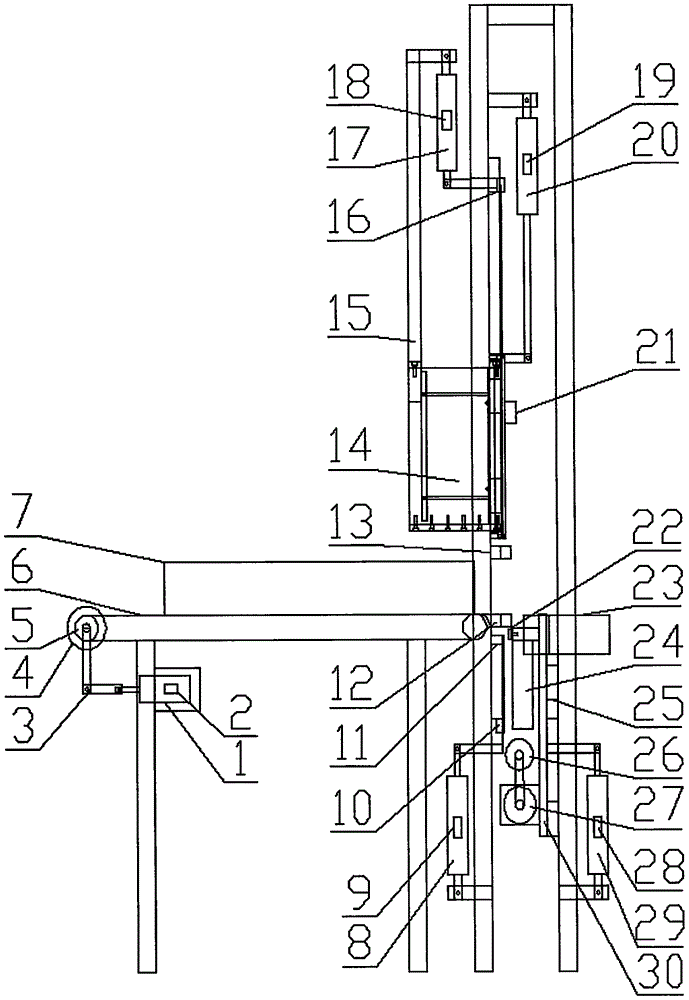

[0008] After the worker arranges the materials on the conveyor belt 6 according to the width of the conveyor belt and the height of the height limit baffle 7, after using the PLC to get the start command, at the same time connect the power supply of the solenoid valve 2 of the walking cylinder and the power supply of the electromagnetic clutch 4, and push the walking cylinder 1 after getting gas. The cylinder connecting rod 3 drives the electromagnetic clutch 4 and the belt idler 5 to rotate, and the conveyor belt 6 produces a specified moving distance. After the set conveying time is reached, the PLC simultaneously disconnects the power supply of the solenoid valve 2 and the electromagnetic clutch 4 of the walking cylinder, and the walking Cylinder 1 retracts automatically, and because electromagnetic clutch 4 is released, conveyer belt 6 does not produce displacement. After the conveying process is completed, the PLC turns on the power supply of the solenoid valve 9 of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com