Automatic meat cutting and bunching machine

A threading machine and automatic threading technology, which is applied in the direction of processed meat, meat processing equipment, slaughtering, etc., can solve the problems of low efficiency and unsafety of manual threading, and achieve small footprint, high safety and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

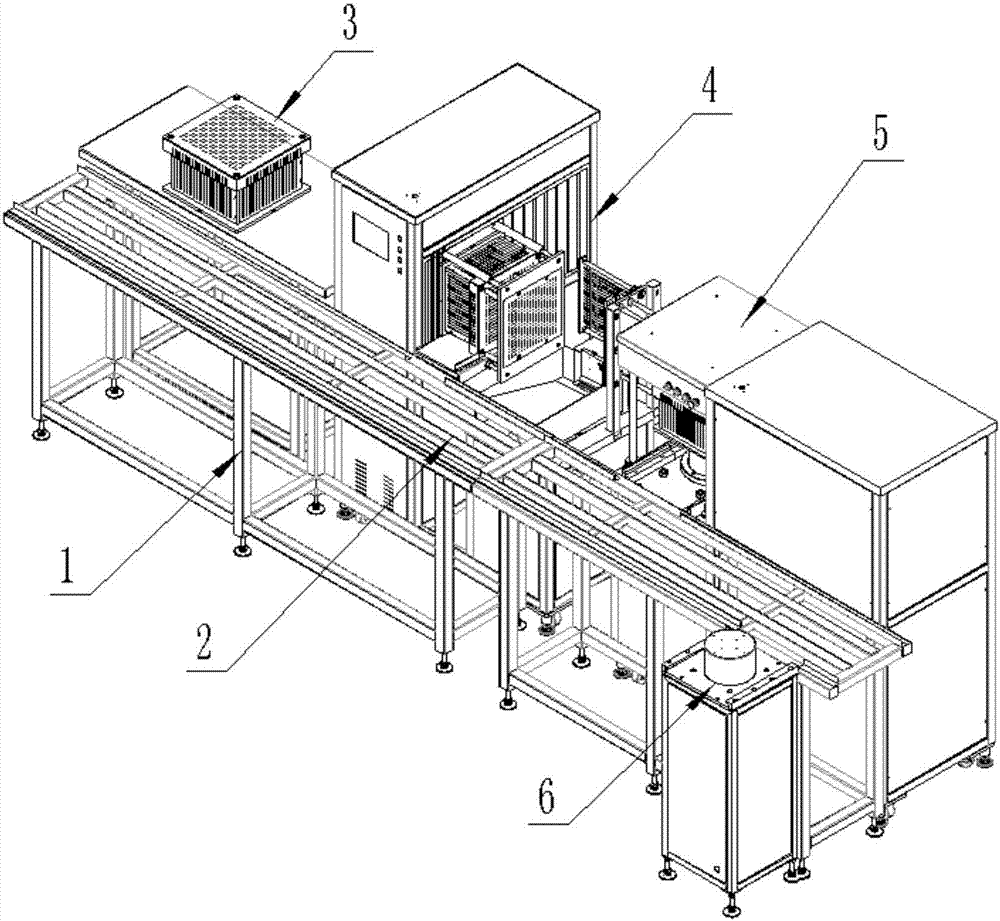

[0038] Such as figure 1 As shown: the automatic meat cutting and skewering machine is composed of a slideway 2, a meat code device 3, which are arranged on the frame 1, an automatic skewering device 4, an automatic skewer cutting device 5, and a meat skewer ejection device which are arranged next to the slideway 2 in turn. 6 components, of which:

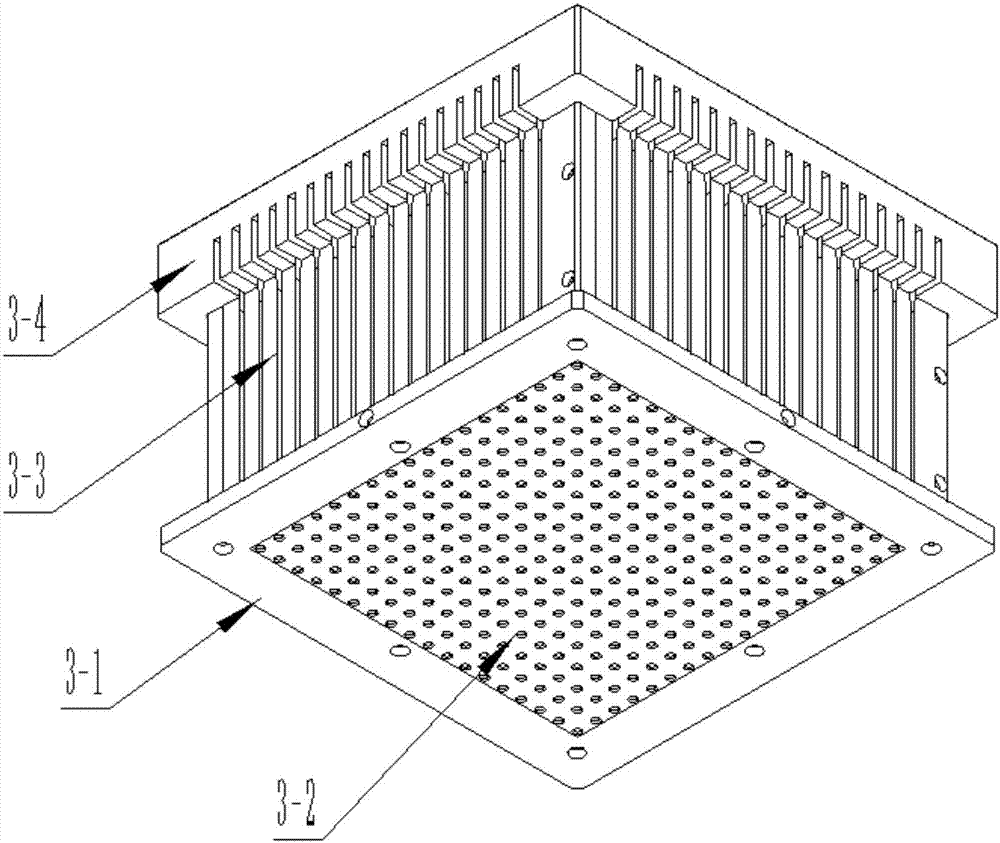

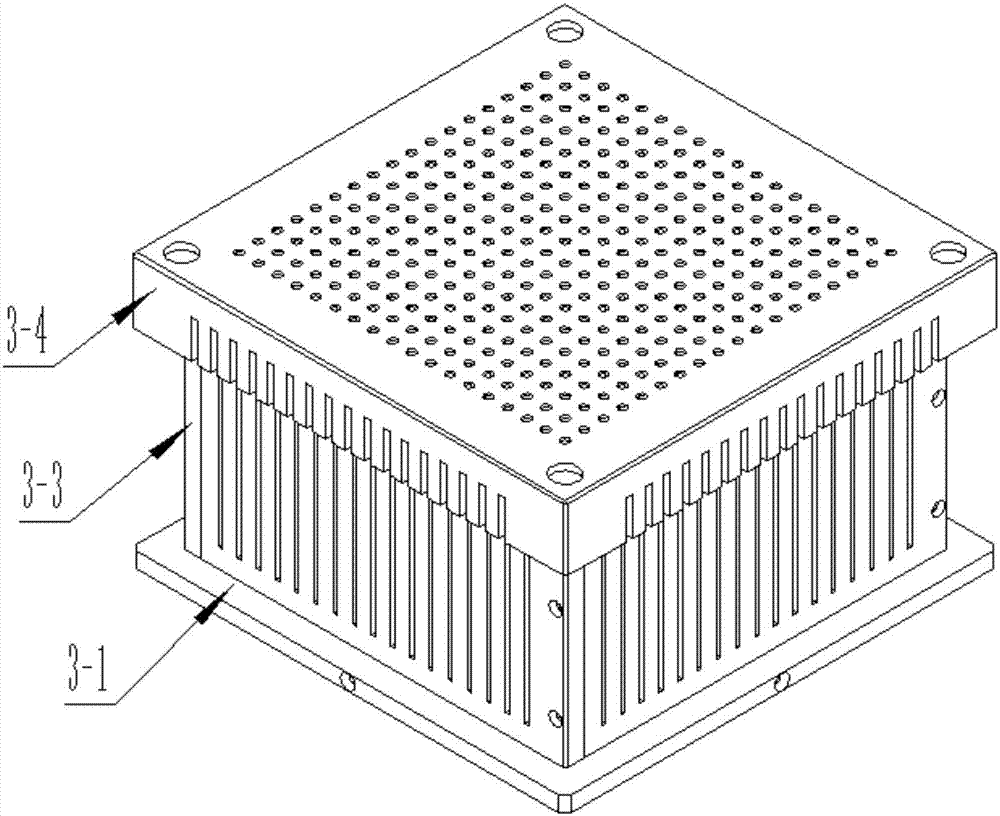

[0039] Such as Figure 2-5 As shown, the meat coding device 3 is composed of a box bottom 3-1, a bottom support 3-2 movably arranged in the box bottom, a frame body 3-3 arranged on the box bottom, and a cover upside down on the top of the frame body. body 3-4; the bottom bracket 3-2 is composed of a bottom plate 3-6, an array arranged on the bottom plate 3-6 and a number of bosses 3-7 with through holes in the middle; a number of through holes are arranged on the cover 3-4 Holes, the through holes on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com