Loading roller way with buffer device

A buffer device and material roller technology, applied in the field of mechanical equipment, can solve the problem of short life of the bearing seat, and achieve the effect of prolonging the service life and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

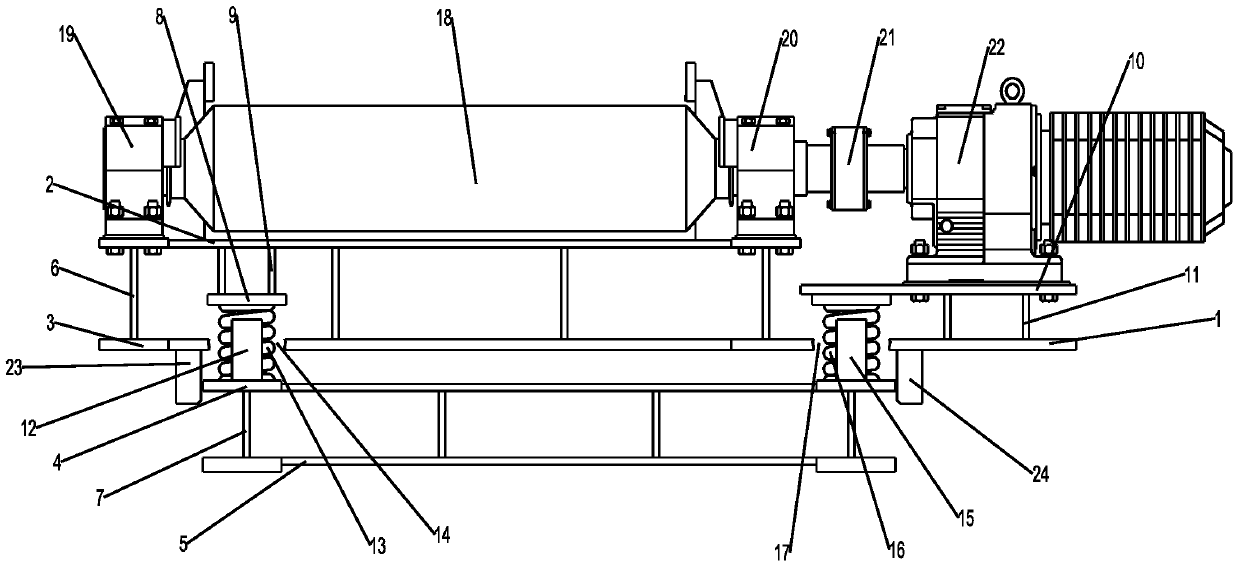

[0016] This embodiment includes a bearing seat 1, and the bearing seat 1 includes a first-layer support plate 2, a second-layer support plate 3, a third-layer support plate 4, and a fourth-layer support plate 5 arranged from top to bottom. Plate 2, the second support plate 3, the third support plate 4, and the fourth support plate 5 are horizontally parallel, the first support plate 2 and the second support plate 3 are connected by connecting plate A6, and the third support plate The support plate 4 and the fourth support plate 5 are connected by a connecting plate B7, an intermediate support plate A8 and an intermediate support plate B10 are arranged between the first support plate 2 and the second support plate 3, and the intermediate support plate A8 and the The support plates 2 of the first layer are connected through the connection plate C9, the middle support plate B10 is connected with the support plate 3 of the second layer through the connection plate D11, and the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com