Gear tooth structure of gear, gear pump with gear tooth structure and fluid transmission device with gear pump

A gear pump and gear technology, which is used in hoisting devices, components with teeth, portable lifting devices, etc., can solve the problems of easy breaking from the root, unfavorable casing sealing, sliding fit, etc., and achieve the effect of reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

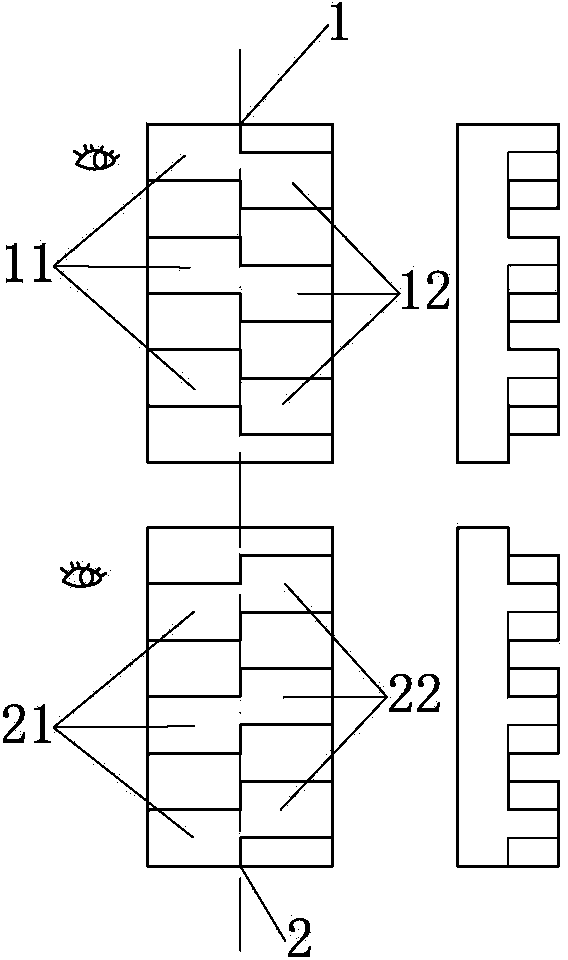

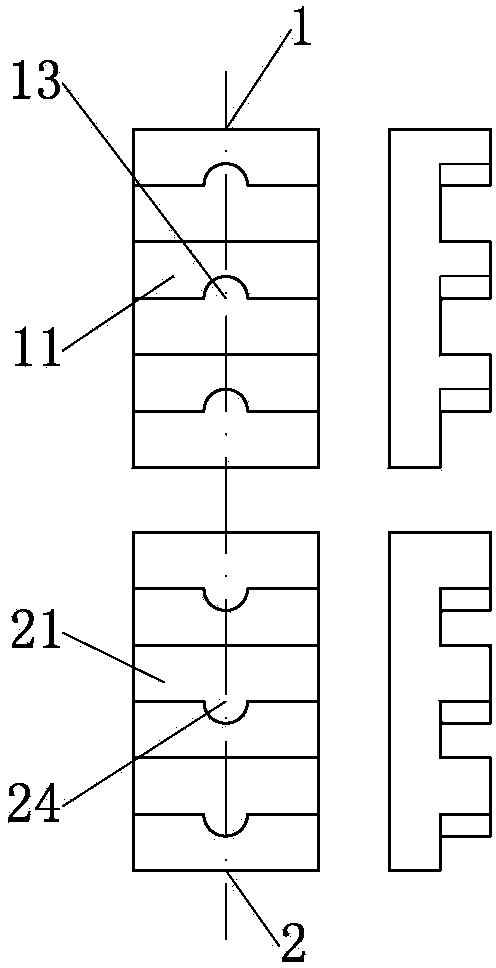

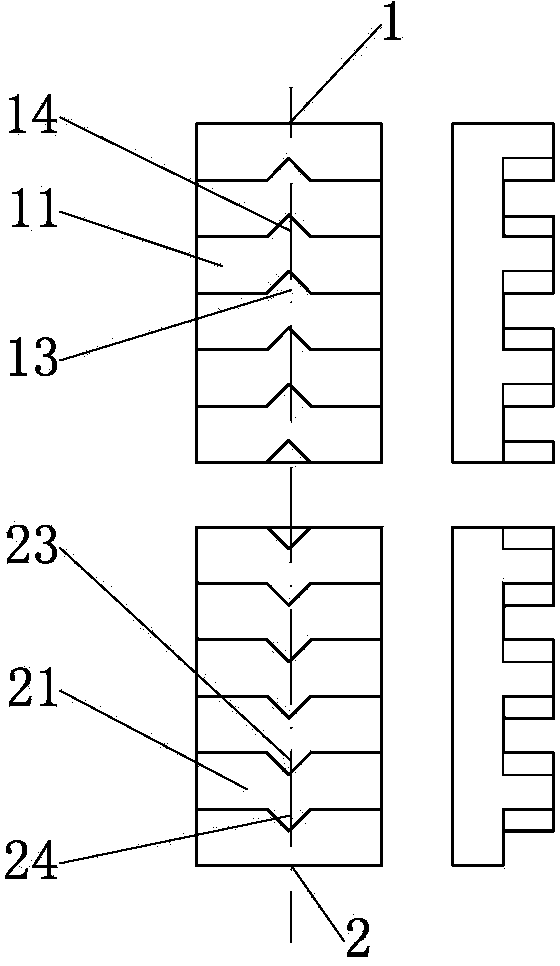

[0044] Such as Figure 1 to Figure 5 As shown, this embodiment provides a tooth structure of a gear, including a gear 1 and a gear 2 that mesh with each other; the gear 1 and the gear 2 are external gears, of course, it can also be one of the gear 1 and the gear 2 for internal gears. The external gear 1 and the external gear 2 (or, the internal gear 1 and the external gear 2) are spur gears, of course, the external gear 1 and the external gear 2 (or, the internal gear 1 and the external gear 2) can also have One-way helical gears with corresponding inclination angles. The tooth side of the spur gear (of course, it may also be the tooth side of the one-way helical gear) is provided with an anti-slip structure that prevents the mutually meshing gears from sliding relative to each other in the axial direction.

[0045] This embodiment adopts the technical means that the tooth side of the spur gear or the tooth side of the one-way helical gear is provided with an anti-slip struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com