Method of carrying cigarette assisted by slight friction force and apparatus thereof

A technology of assisting device and micro-friction, applied in storage devices, conveyors, transportation and packaging, etc., can solve the problems of damaged cigarettes, inconsistent sliding speed, scattered stacking, etc., to prevent blocking, the method is simple and practical, and the device structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

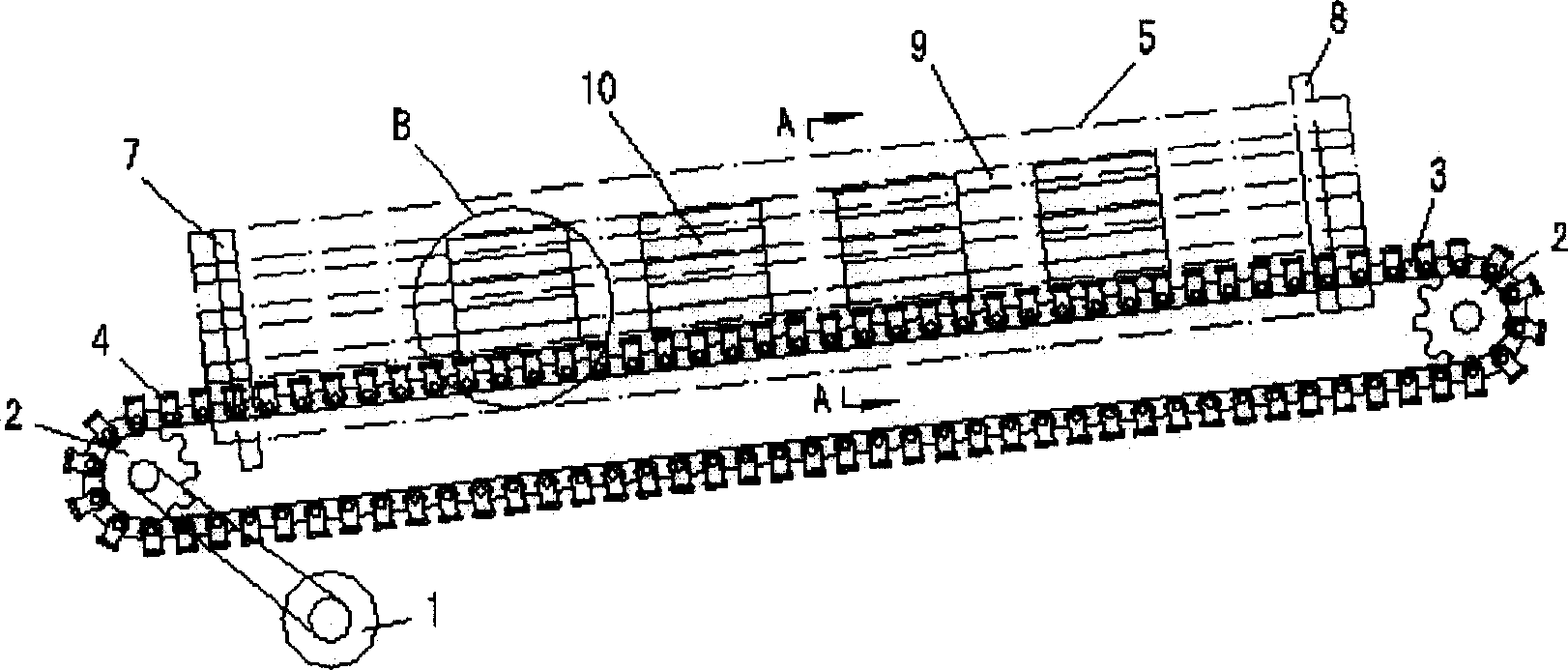

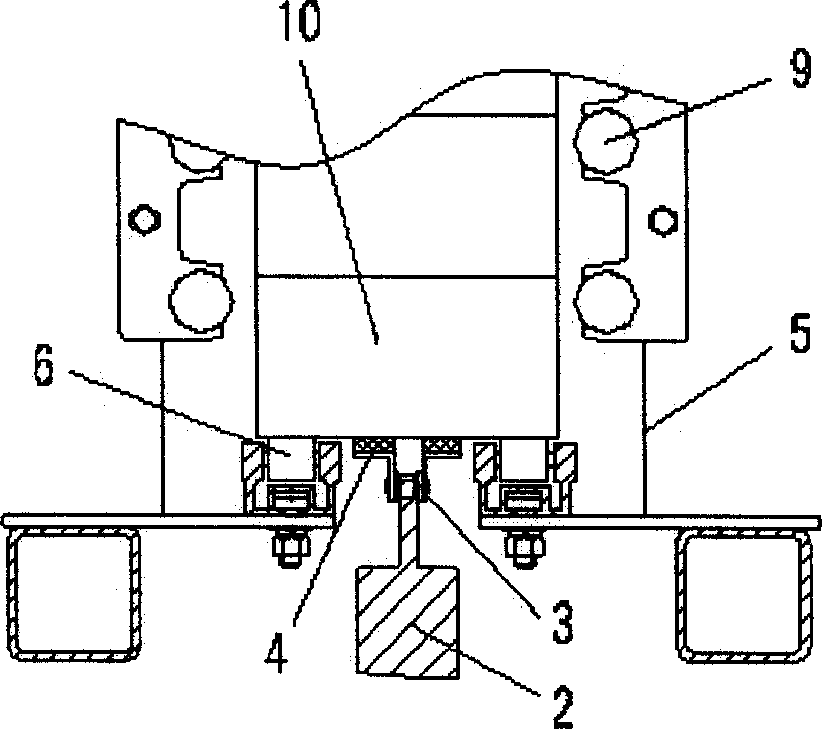

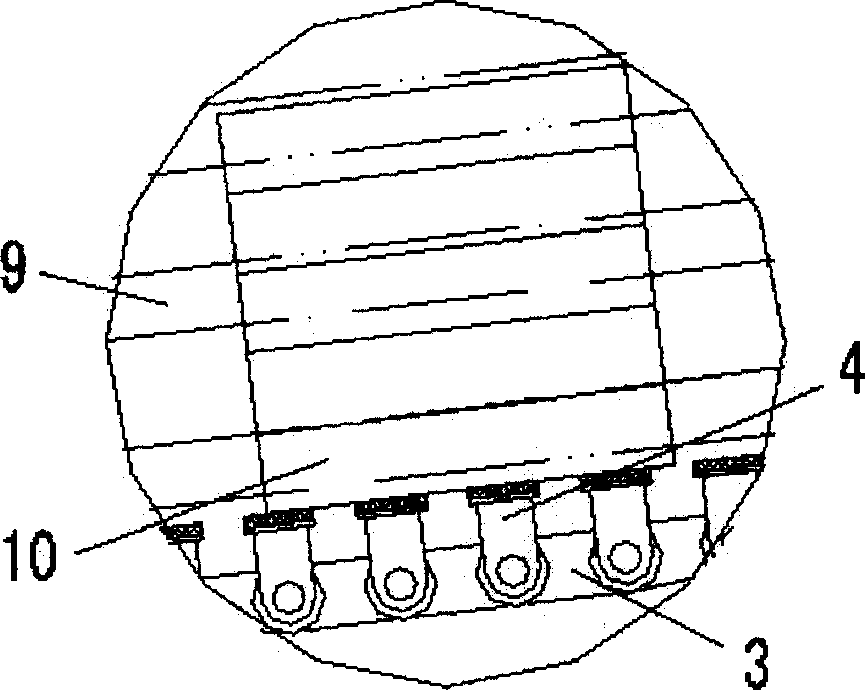

[0011] Embodiment of the present invention: because the transmission process of the current rod cigarettes in the storage bin is like this, the storage bin 5 for storing the rod cigarettes is placed obliquely, the smoke inlet is high, the smoke outlet is low, and the bottom of the storage bin is provided with The fluent bar 6 and the both sides of the storage bin 5 are provided with guardrails 9. When conveying, a cigarette is placed on the fluent bar at the cigarette inlet. The smoke outlet slides. But the sliding speed of the cigarette is difficult to control, if the sliding speed is too fast, the cigarette will damage the outlet valve 7 of the cigarette outlet, or damage the cigarette and cause the damage or loose stack of the cigarette; if the sliding speed is too slow, The cigarette sometimes stops moving in the middle of the storage bin and does not slide down, and it is not easy to restart after the cigarette stops moving. The sliding speed of the cigarette is related ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com