Hydraulic test table of electro-hydrostic actuator

An electro-hydrostatic actuation and hydraulic test technology, which is applied in the testing of fluid pressure actuation systems, servo meter circuits, fluid pressure actuation devices, etc., can solve the problems of low test efficiency, low test accuracy, and low degree of automation. Achieve the effect of saving labor cost and time cost, improving test efficiency and reliable test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

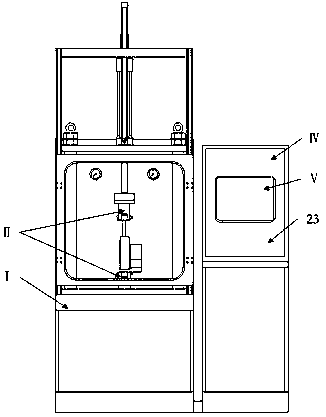

[0018] see Figure 1~Figure 4 , the hydraulic test bench of the electrohydrostatic actuator, including the test base (I), the test tool (II), the hydraulic system (III), the electric control system (IV) and the detection system (V), is characterized in that: The above-mentioned test fixture (II) is installed on the test base (I) and connected to the hydraulic system (III); the electric control system (IV) is connected to the hydraulic system (III) through cables; the components of the detection system (V) are installed in the hydraulic system system (Ⅲ), and connected to the electric control system (Ⅳ) through cables. The tested electrostatic hydraulic actuator is installed and disassembled on the test base (I) through the test tool (II), and the test is carried out through the hydraulic system (III). The electronic control system (IV) controls the hydraulic system (III) components and test The process is controlled, and the detection system (Ⅴ) collects the test data of the ...

Embodiment 2

[0019] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

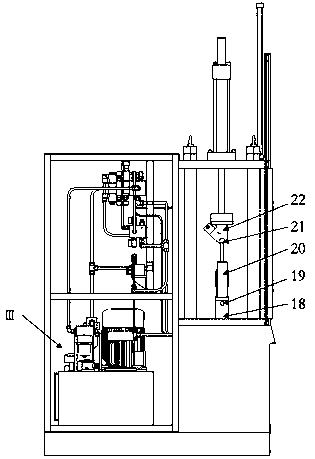

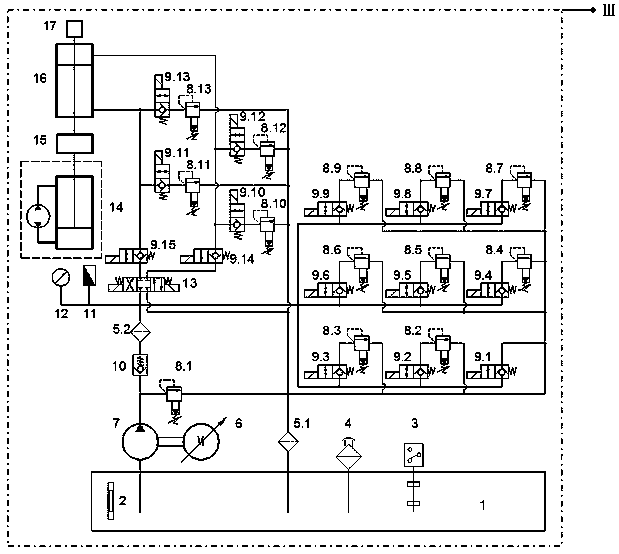

[0020] The test base (I) is a smooth and heavy square iron block, which is used to install the test tool (II) and withstand the loading force generated during the test; the test tool (II) includes a fixing fixture (18), a pin (19), the movable fixture (22) and the second pin (21), the first pin (19) connects the bottom of the electrohydrostatic actuator (20) to be tested with the fixed fixture (18), and the second pin (21) connects the The top of the electrostatic fluid actuator is connected with the movable fixture (22) to realize the installation and disassembly of the electrostatic fluid actuator under test; the hydraulic system (Ⅲ) includes an oil tank (1), two filters (5.1, 5.2 ), frequency conversion motor (6), gear pump (7), thirteen overflow valves (8.1~8.13), thirteen electromagnetic ball valves (9.1~9.13), check valve (10), electromagnetic reversing ...

Embodiment 3

[0022] As shown in the attached figure, the hydraulic test bench of the electrostatic hydraulic actuator includes a test base (I), a test tool (II), a hydraulic system (III), an electric control system (IV) and a detection system (V).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com