Continuous plasticizing production device and method

A production device and twisted cage technology, which is applied in the field of energy-saving and environmentally friendly continuous plasticizing production devices, can solve the problems of difficulty in fully recovering the performance of rubber powder, uneven electric heating temperature control, affecting the stability of the production process, etc. Small, improve plasticizing effect, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

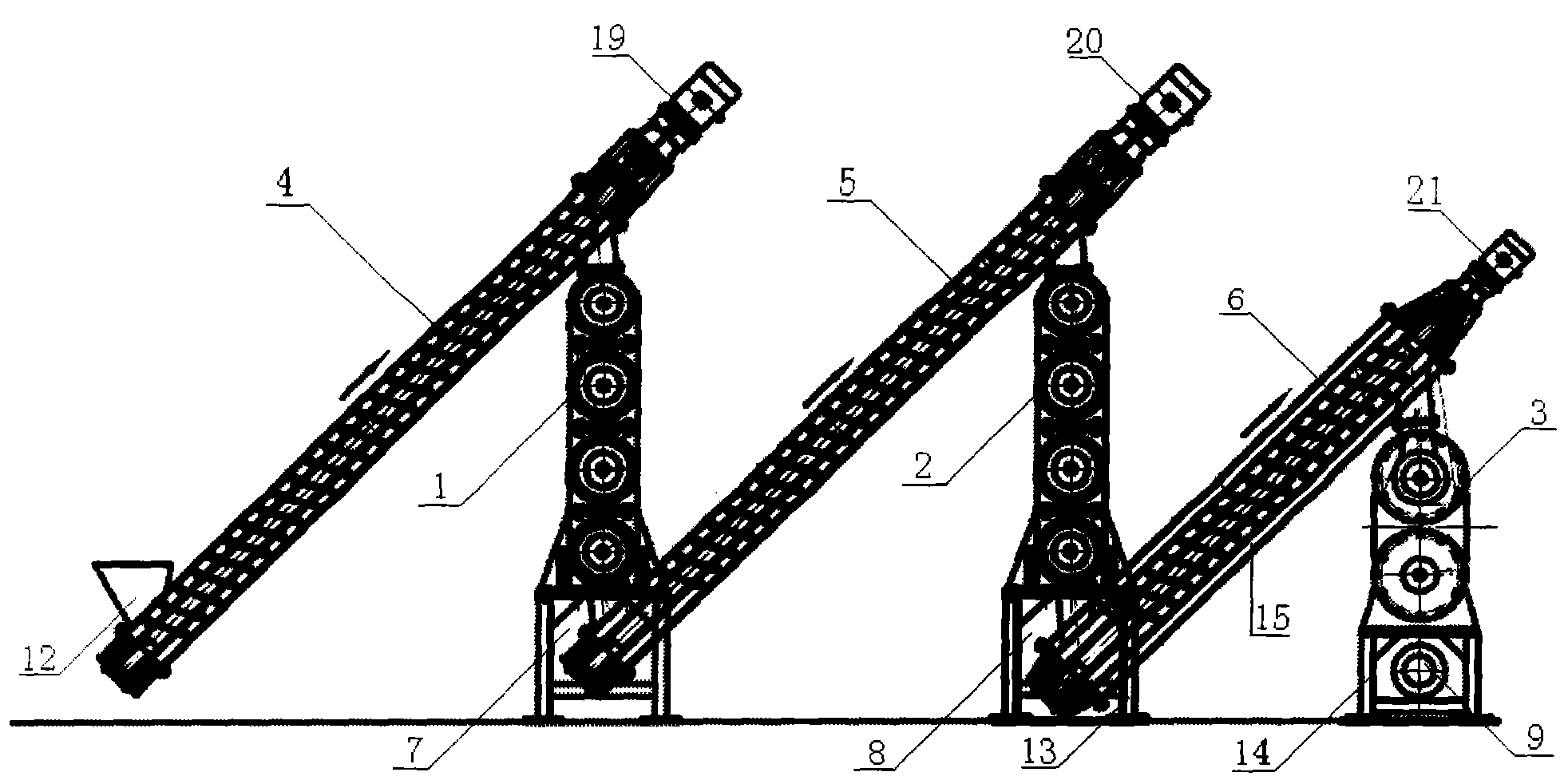

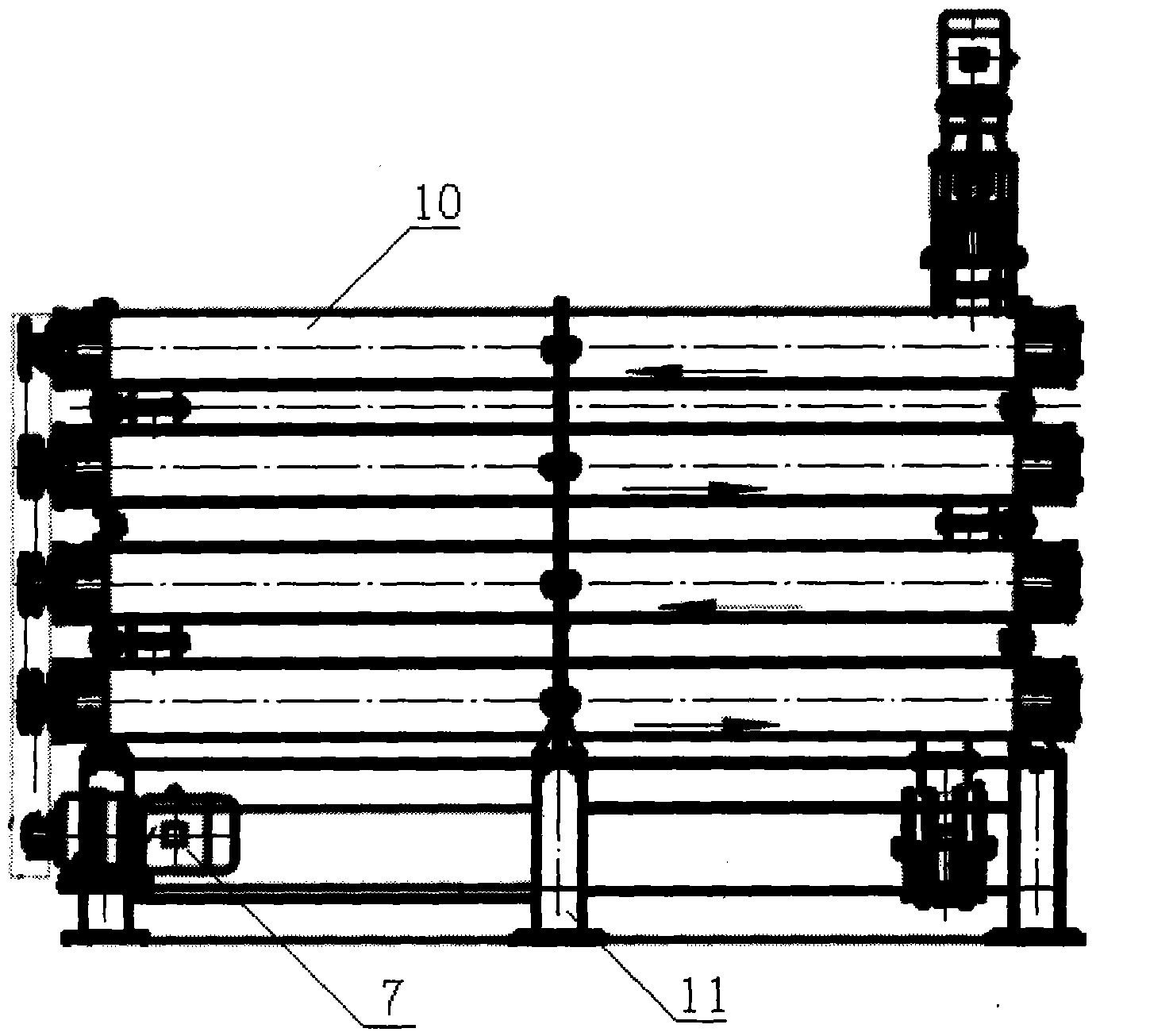

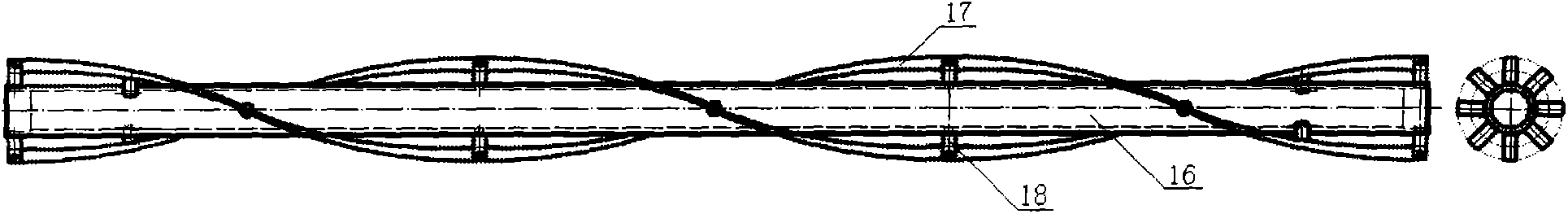

[0017] Such as figure 1 , 2 As shown, the continuous plasticizing production device is mainly composed of intermediate conveying cylinders 4, 5, 6, a set of heating and plasticizing twisted cages 1, a set of heat preservation twisted cages 2, a set of cooling twisted cages 3, electromagnetic induction heating 10 and the transmission mechanism 7, 8, 9, a set of heating and plasticizing twisted cages 1 provided in this embodiment is four heated and plasticized twisted cages A and B arranged in a row on the support 11 and connected to each other. . The inlet end of the heating and plasticizing cage A is connected to the outlet end of the intermediate conveying cylinder 4 arranged obliquely, and the inlet end of the intermediate conveying cylinder is connected to the feed hopper 12 . The outlet end of the heating and plasticizing twisted cage D is connected to the intermediate conveying cylinder 5 arranged obliquely, and the outlet end of the intermediate conveying cylinder 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com