Automatic press-polishing machine for gold bracelet

A technology for calenders and bracelets, which is applied in the field of automatic calenders for gold bracelets, which can solve the problems of poor consistency of finished products and large labor costs, and achieve the effect of compact structure, convenient operation and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

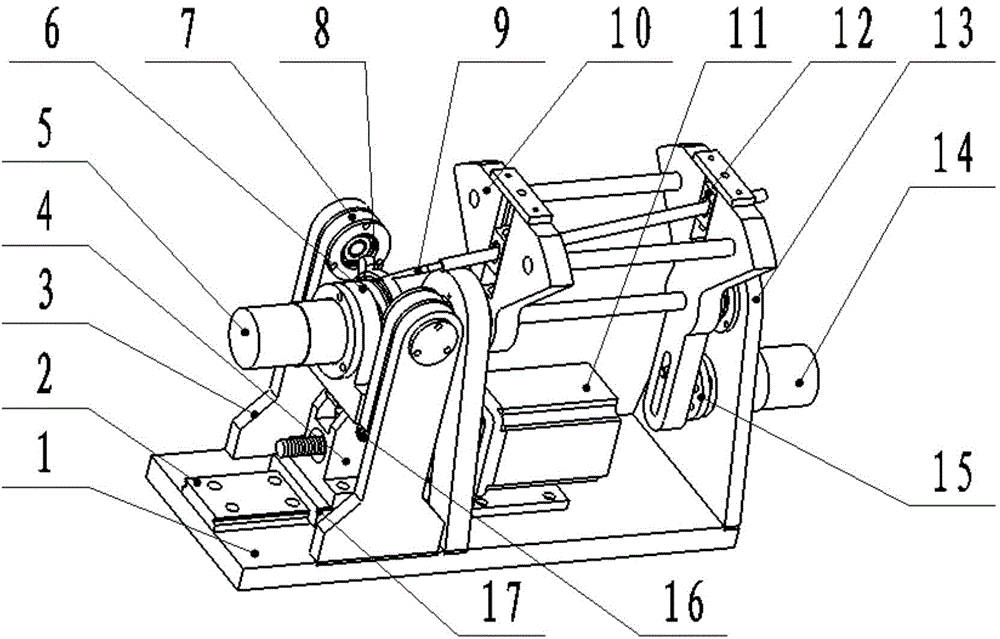

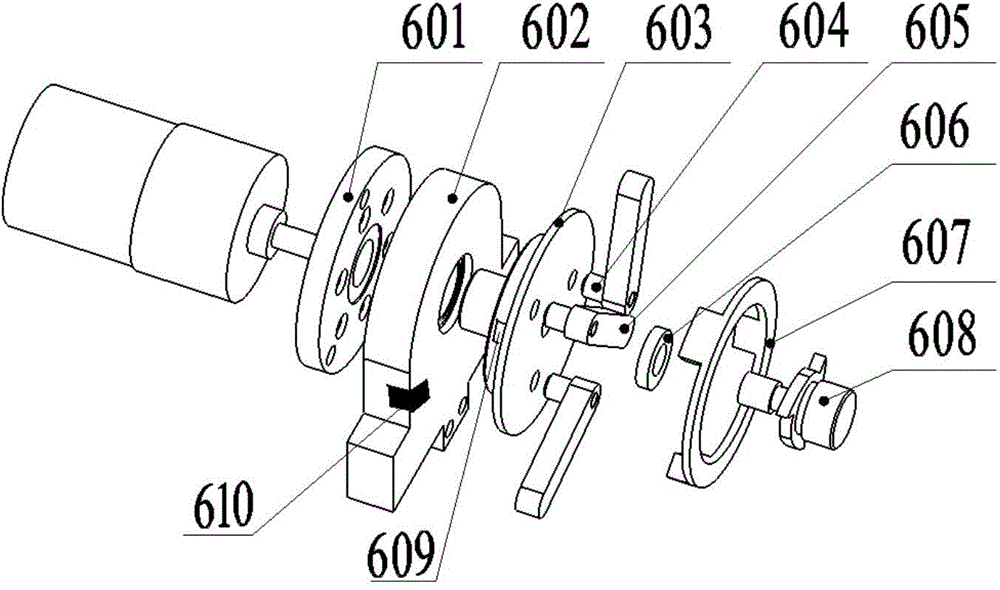

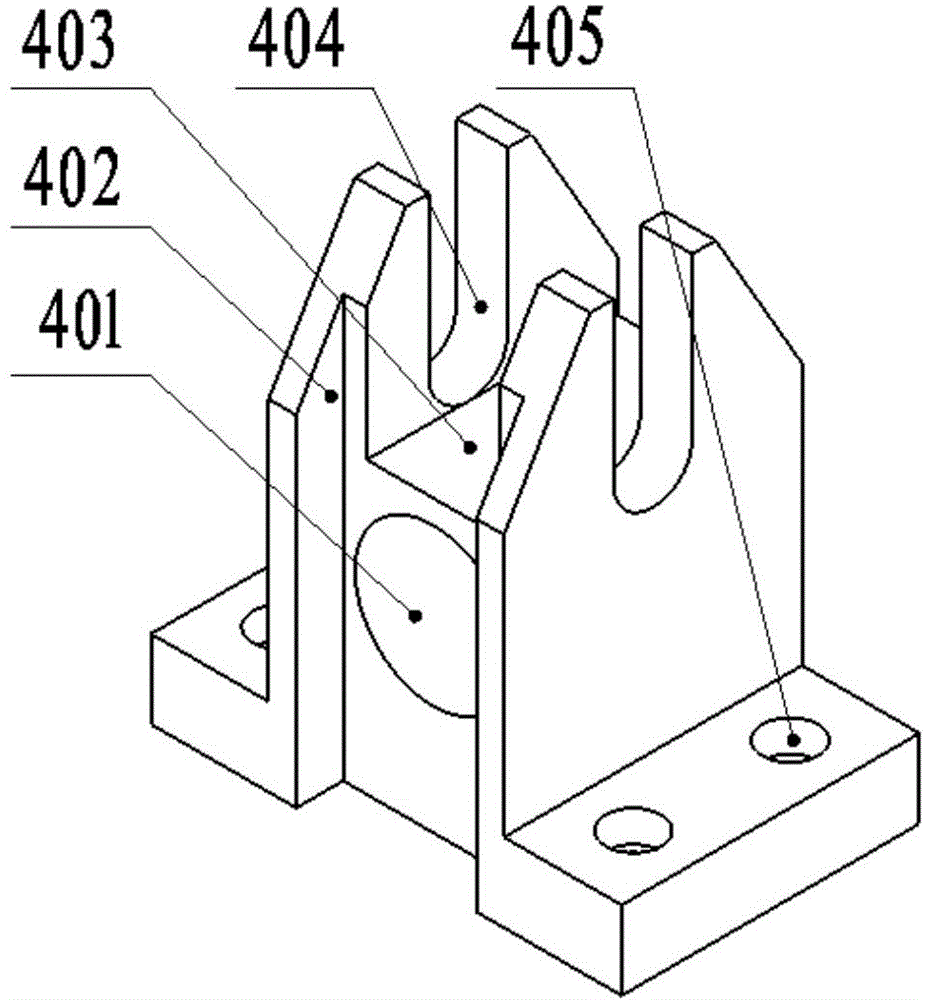

[0026] An automatic calendering machine for gold bracelets is composed of a base 1, a guide rail 2, a side support plate 3, a swing fork 4, a DC motor I5, a bracelet support body 6, a connecting plate 7, a bearing 8, a calendering needle 9, and an ornament 10. , Stepper motor 11, intermediate clip body 12, vertical plate 13, DC motor II 14, flywheel 15, transmission dial shaft 16, slider 17, on the upper part of the base 1, there are installed guide rail 2, side support plate 3, DC motor I5 , the stepping motor 11, the vertical plate 13, the slider 17 is installed on the guide rail 2, the swing fork 4 is installed on the slider 17, the upper part of the swing fork 4 is connected with the bracelet support body 6 through the transmission axis 16, and the bracelet is fixed On the bracelet support body 6, the side support plate 3 is connected to the bracelet support body 6 through the connecting plate 7, the bearing 8 is installed in the connecting plate 7, the calendering needle 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com