Automatic desilting ship

A dredging ship, automatic technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of long cleaning cycle, large manpower and material resources, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the present invention more clearly, the following will briefly introduce the drawings used in the implementation cases or the description of the existing invention.

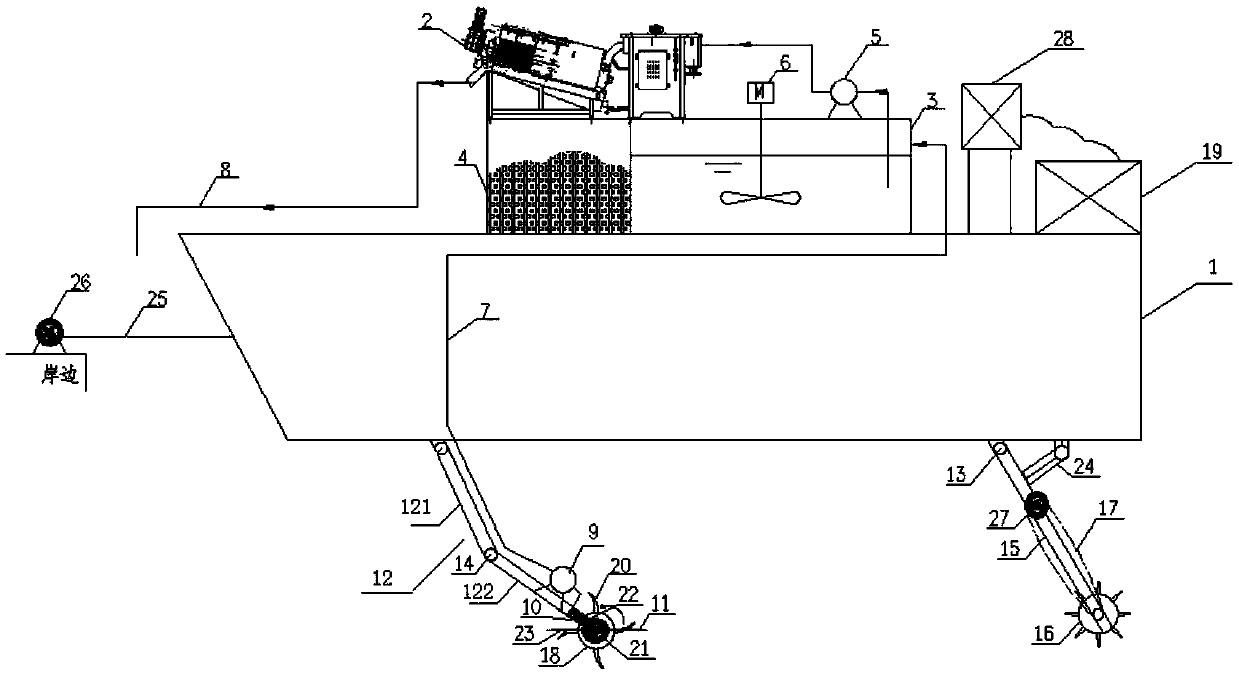

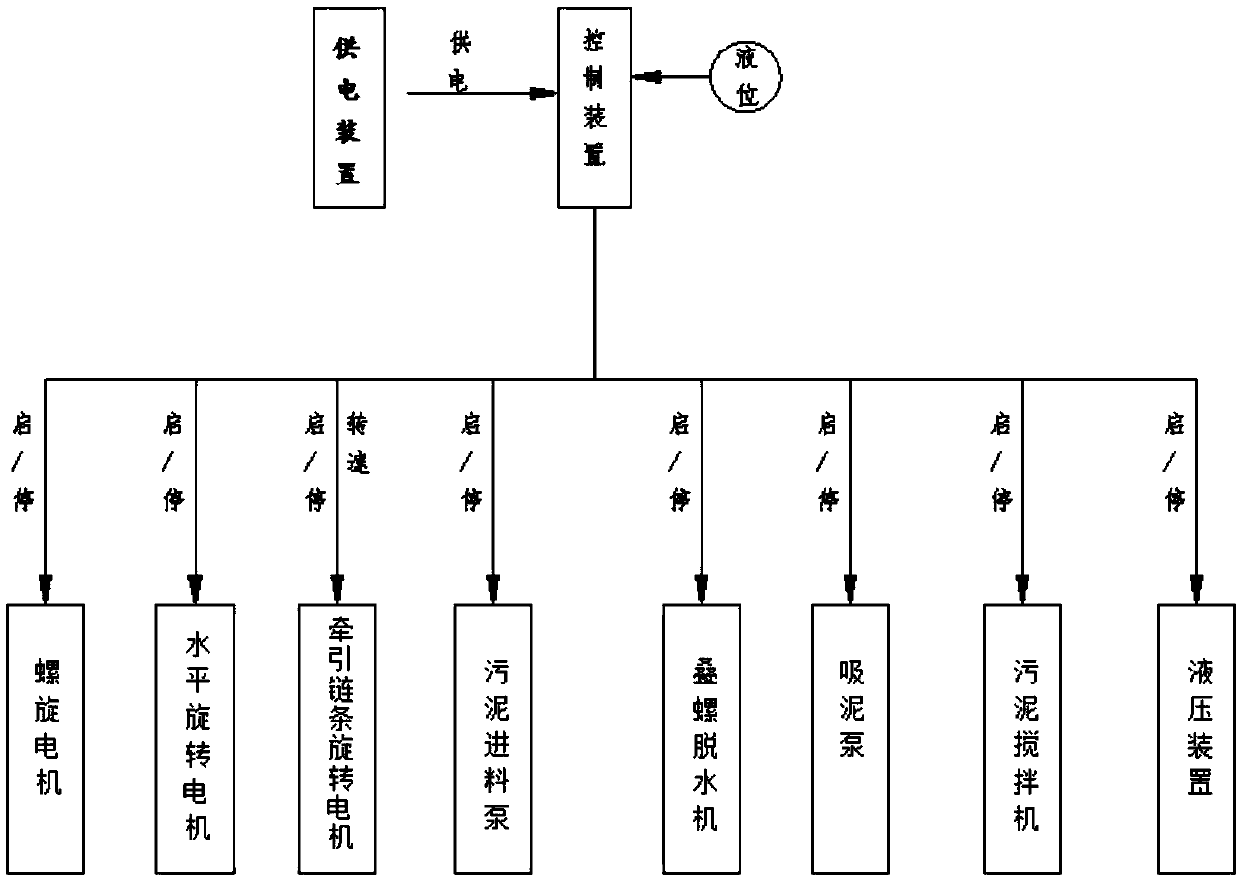

[0026] combine Figure 1 to Figure 3 As shown, a preferred embodiment of an automatic dredging ship is disclosed in the embodiment, which can clean up the silt in rivers and lakes. It mainly includes a hull 1, a silt turning mechanism arranged at the bottom front end of the hull 1 and obstacle removal Mechanisms, the rear end of the bottom of the hull 1 is a walking mechanism, the dehydration device, control device and power supply device on the hull 1, and the sludge conveying mechanism. The details are as follows:

[0027] The hull 1 serves as a carrier for various mechanisms and devices on board, providing support and connections for various mechanisms and devices.

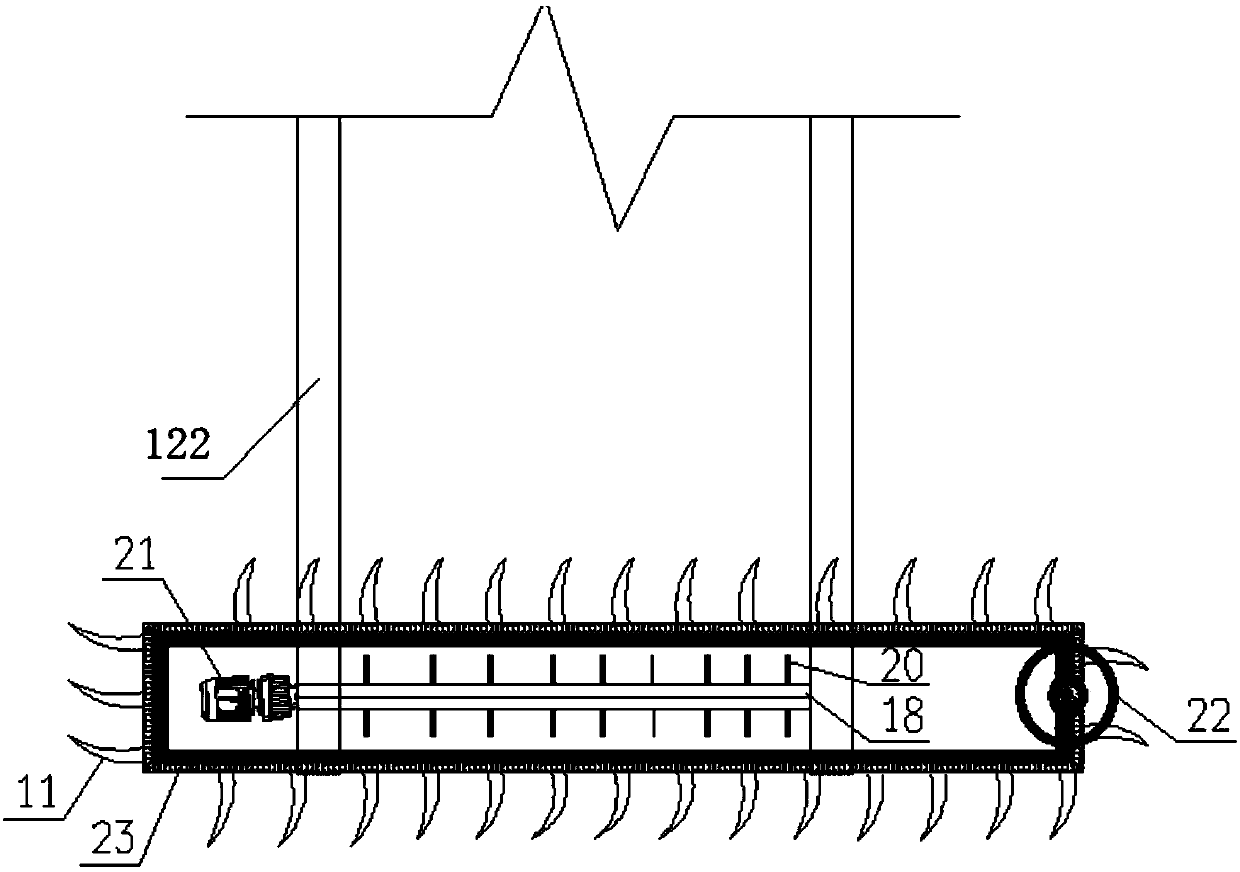

[0028] The mud turning mechanism mainly includes a front end connecting rod 12, a hinge 14, a tooth rake 20, a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com