Elevator self-help system

An elevator system and elevator technology, applied in elevators, transportation and packaging, etc., can solve the problems that users cannot effectively save themselves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

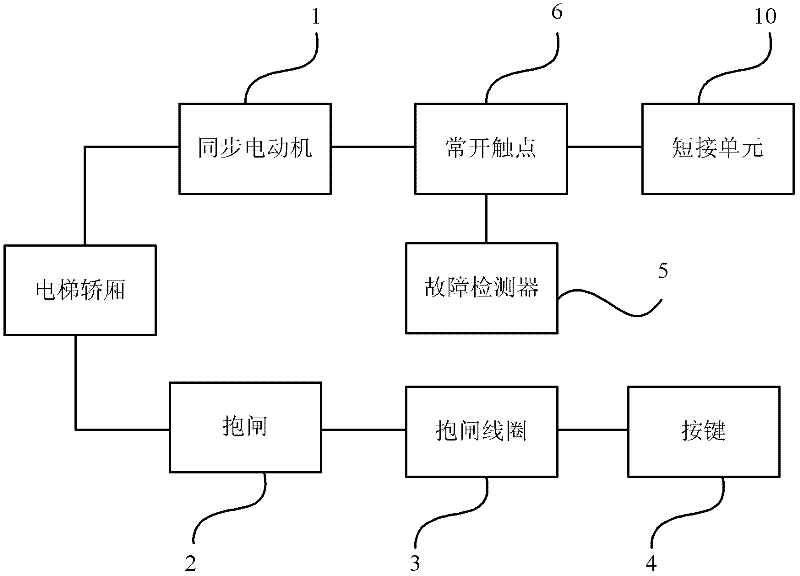

[0024] like figure 1 As shown, the elevator self-rescue system of this embodiment includes a synchronous motor 1 , a brake 2 , a brake coil 3 , a button 4 , a fault detector 5 , a normally open contact 6 and a shorting unit 10 .

[0025] The synchronous motor 1 is electrically connected to the short-circuit unit 10 through the normally open contact 6, and the short-circuit unit 10 is used to short-circuit the motor, and the brake coil 3 is connected to the brake 2 is connected and when the brake coil 3 is turned on, the brake 2 is opened, and the elevator car starts to move at this time, otherwise the brake 2 brakes the elevator car, and the elevator is in a static state. In this embodiment, the release action of the brake 2 is realized by controlling the brake coil in the brake 2 .

[0026] The brake coil 3 is also connected to the button 4. When the user presses the button 4, the button 4 is connected to the brake coil 3, and the loop formed makes the brake coil 3 also cond...

no. 2 example

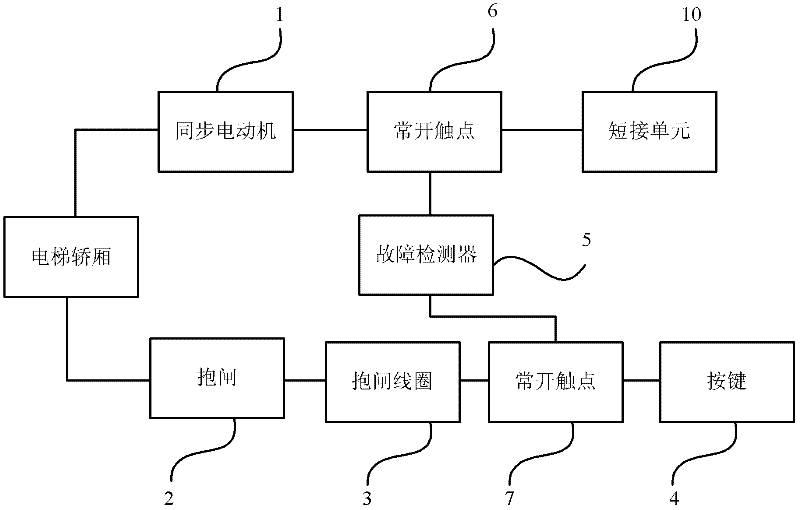

[0038] like figure 2 As shown, the difference between this embodiment and the first embodiment is that the elevator self-rescue system in this embodiment further includes a normally open contact 7, and the normally open contact 7 is connected in series with the brake coil 3 and the button between 4.

[0039] When the elevator fails, the fault detector 5 also closes the normally open contact 7 , so that a path is formed between the brake coil 3 and the button 4 . At this time, the user can make the connection between the button 4 and the brake coil 3 to release the brake 2, so that the elevator car enters the leveling area, which is convenient for the user's self-rescue.

[0040] In this embodiment, the brake coil 3 and the button 4 are isolated by the normally open contact 7, so as to prevent the user from misoperation when the elevator is running normally, that is, when the elevator is running normally, the user cannot control the button 4 The brake coil 3 is used to relea...

no. 3 example

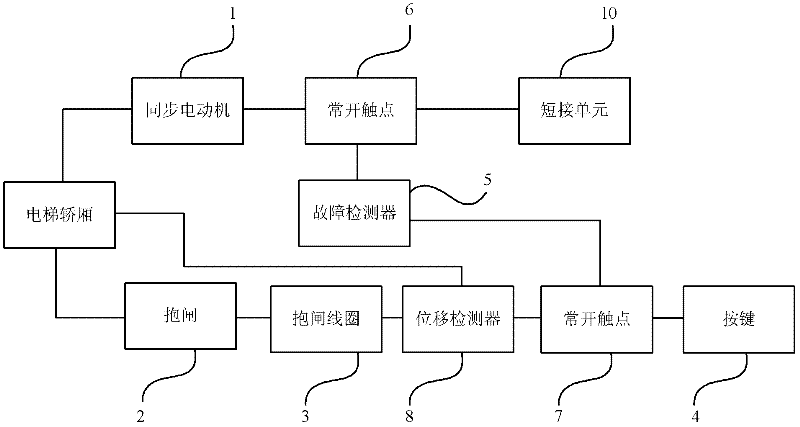

[0042] like image 3 As shown, the difference between this embodiment and the second embodiment is that the elevator self-rescue system in this embodiment further includes a displacement detector 8, which is used to detect whether the car of the elevator reaches the bottom of the elevator shaft or top.

[0043] In this embodiment, the displacement detector 8 is arranged between the normally open contact 7 and the brake coil 3. In addition, the user can also connect the displacement detector 8 with other components according to the design and structure of the elevator system. For example, the displacement detector 8 is arranged between the normally open contact 7 and the button 4 and the like.

[0044] When the elevator fails, when the displacement detector 8 does not detect that the car of the elevator reaches the bottom or top of the elevator shaft, the brake coil 3 and the displacement detector 8 are conductive, so the brake coil 3 Release the brake 2, so the user can rele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com