Self-adaptive control incremental forming method

An adaptive control, incremental forming technology, applied in the field of machining, can solve problems such as increased processing time and cost, reduced surface quality of parts, and flexibility and operability that do not conform to incremental forming of sheet materials, to improve forming accuracy and The effect of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

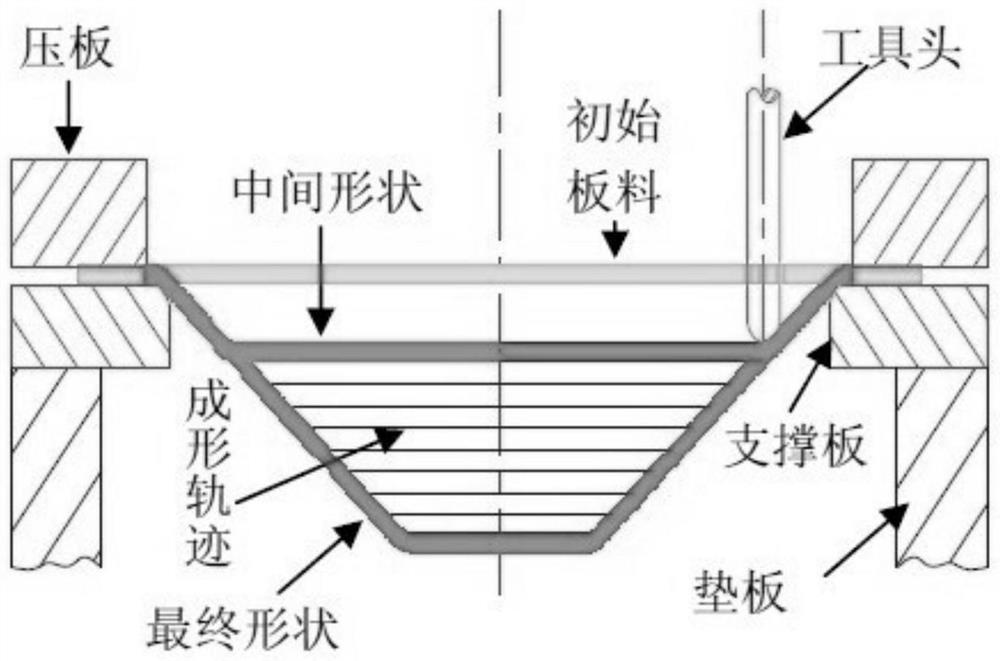

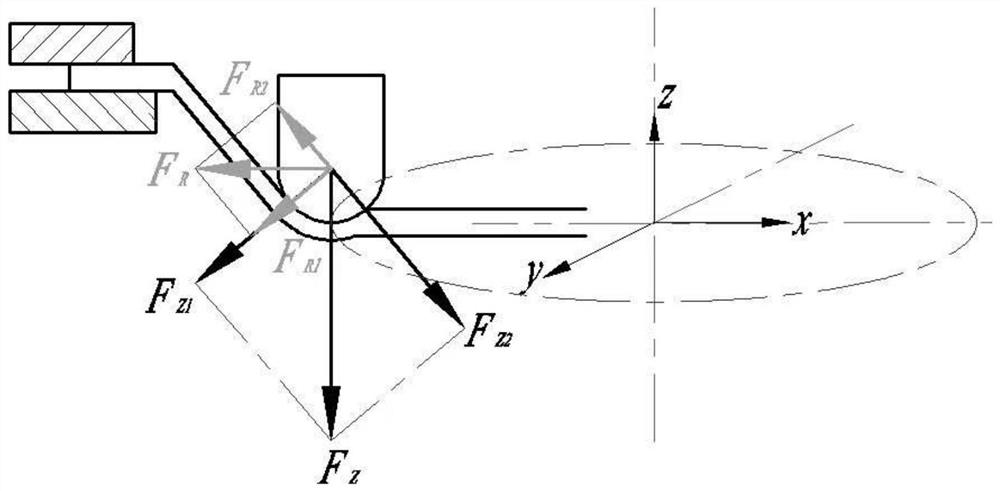

[0033] Step 1: Put the forming tool with a spherical working surface into the tool holder on the CNC machine tool, and the spherical end of the forming tool is against the metal sheet to be processed, and installed at the end of the forming tool for real-time detection of the processing process Piezoelectric sensors for axial force and radial force changes of the middle forming tool head;

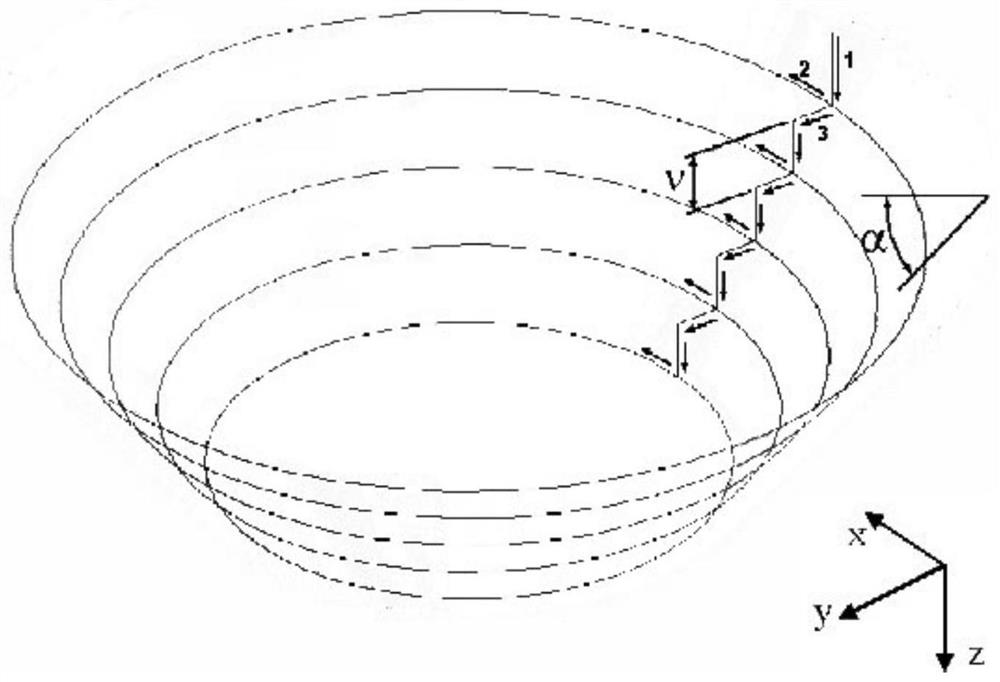

[0034] Step 2: When the forming tool is working, the spherical working surface is pressed into the direction of the metal sheet, and the depth is the axial feed amount ν;

[0035] Step 3: Follow the contour line along the conical section of the metal sheet. After completing the entire section path, the forming tool is pressed again to the depth of the axial feed ν to carry out the next contour line processing, such as figure 1 , figure 2 As shown, the spherical surface at the end of the forming tool is pressed into the metal sheet to a certain depth, which is equal to the designed axial f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com